2003-2005 Rincon 650 TRX650 Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

A Few Wo rds Abo ut Safe ty

Service Info rm ation

The service and repair in/OIlTIation contained in th~ manual is intended for use by qualilied, professional tecllnicians,

Anempling service 0< repairs withol.llthe prQger training, tools, and equipmenl could C$use injury to 1'00 or others, II could also

damage tile vellide or Cleate an unsafe condition,

This manual describes tile proper methods and procedures for perfooning service, maintenance, and repairs, Some ptocedures

require t!)e use of specialty designed toots and (!edicatoo eo;r..oipmeol. AllY person WilD inlends to use a replacemeot pan, service

procedure or a looIlIlal is not recommended by Honda, must determine Ihe risks to t!)eir personal safety and the sale operation 01

the v~lcle,

If you need to replace a pari, l>Se genuine Honda pans w~h tM correct pan Ilumber or all equ;val,mt part, We strongty recommend

that you do 001 usc replaoemont P<'rtl> 01 inferiOr quality,

For Your Customer's Safety

Proper seNice and maintenance are essential to the customer's saJety and

the reliabitity 01 the vehicle. AffoJ error or oversight while servicing a vehicle

can fe5uH in faulty operation, damage to the vehicle. or injury to others.

For Your Safety

Because this maoual is iolended lor the professional service tecllnician, m

do not provide wami ngs about many basiC shO!) sal oty practices (e.9., Hot

parts-wear gloll1)s) . II you have not received shO!) salety treining or do nol

leet confidant about your knowledge of safe sCIVicing practice, we

recommended that you do not at1empt to perform the procedures described

irlthis manual.

Some of the O1"IO$t important general service safety precautions are giWln

below. However, we cannot warn you of eVlilry conceivable hazard thaI can

arise in porforming service and repllir prooedur6S. Only you can decide

whether or not you shoUld perform a givlm task. can cause you to be

seriously hurt or k ;I!&d.

Important Safety Pre cautions

AWARNING

Improper service or repairs can create an

unsafe condition Ihat can cause your customer

or others to be seriously lIurt or killed.

Follow the procedures and pr&C3ubons in t!1is

manual and otller service materials carefully.

AWARNING

Failure to property lollow instructions and

precautions can cause you 10 be seriousty hurt

or killed.

Follow the procedures and preeautions In t!1;s

manual carefulty.

Make sure you have a clear understanding 01 all basic shop safely practices aod that you are wearing appropriate clothing and

using safety equipment. When performing any service taSk. be especially careful 01 the following:

• Read all 01 the instl1lClions belo(8 you begin, and make sure you have the 100ls, IhO replacemCl'11 or repair parts, and the skills

required to perform the tasks safely and oompletely.

• Proted your eyes by using preper salety glasses, goggles or face Shields any time you hammer. drill, grind, pry or work around

pressurized air 01 liquids, and springs or otllel stored-energy components. II there is affoJ doubt, put on eye protection.

• Use othel pfotecli~e wear when necessary, lor example gloves or safety shoes. Handling flo{ or sllarp parts carl cause severe

burns or cuts. Before you grab something that 1000 like it can hurl you. stop and put on gloves.

• Protect yourself and Olhers whenevor you have the vehiCle up in the eir. Ally lime you lilt the vehicle, either with a hoiSt or a jack.

make sure that rt is always securety support&d. Use Jad<: stands.

Make sure the engine Is off before you begin any servicing procedures, unless the instruc1ion tells you to do otherwise.

This will help eliminate severat potential hazardS: '

• Carbon monoxide poisoning from engine exhaust. Sa sure there is adequate ventilation whenever you run Ihe eng,ne.

• Bums from hoi part<; or coolan1. Let the engine and exhaust system cool before working if) Ihose areas

• Injury lrom moving parts. If tile instl\lCliontells you to filii the engine, be sure your hands, fingers and cklthing are out of the way .

Ga&Oline vapors and lIydrogen gases trom batteries are explosive. To reduce tile posSibility of a fire or expfosion, be carelul wilen

working around gasdine or batteries.

• US& onty a non1Tsmmabie $Owent, f)()t gaser,nc. to clean parts.

• Never drain or slor o gasoline in an open conlainef.

• Keep all cigarettes, sparks and llames away from Ihe battery and a ll fuel·related pans.

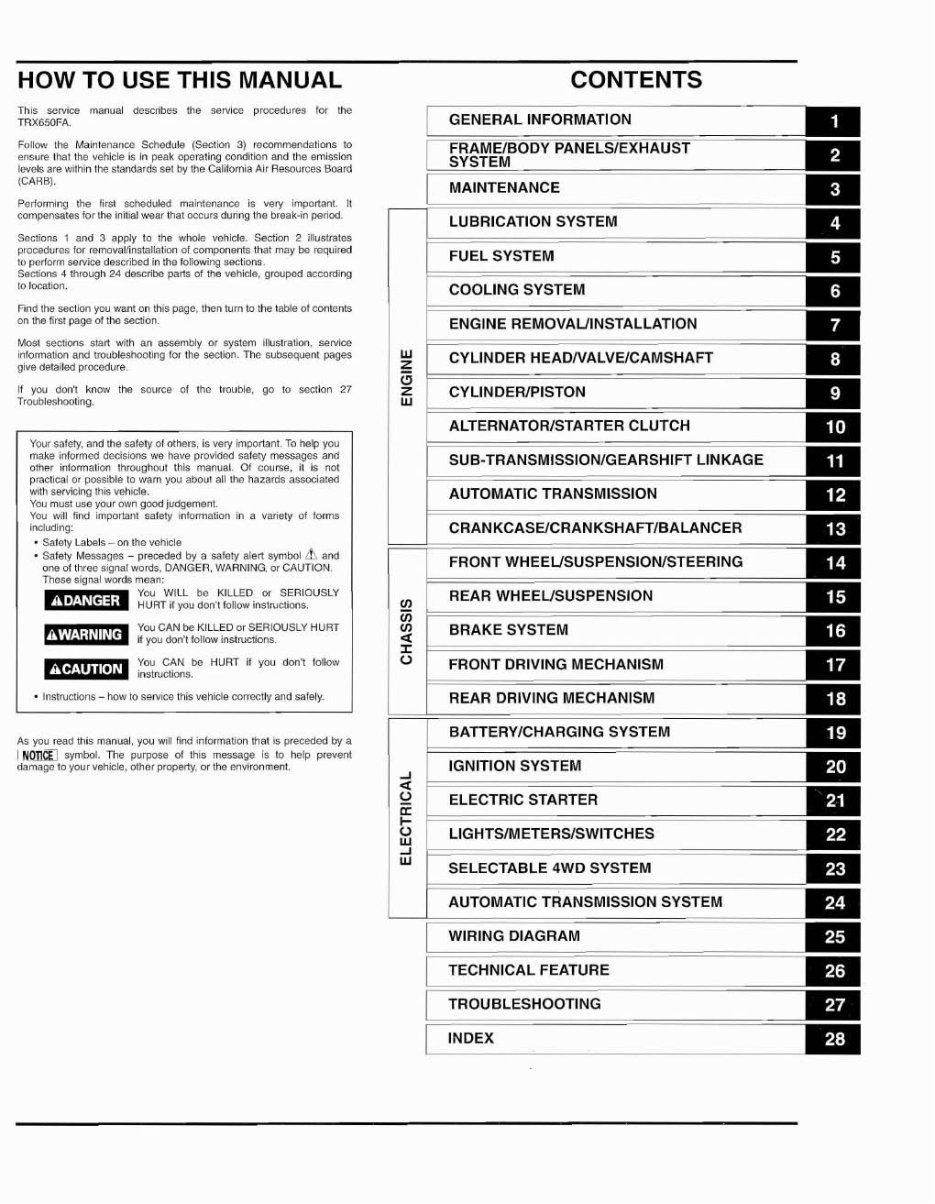

HOW TO USE THIS MANUAL

This """""" "'"""'" 00""-. "'" "''''"''' p"""","",. lor IJIe

Tll X650FA

1'<0_ t'" Ma." .... """ -... (Sac!"" 3) _do tlon< to

""".." , .. , tOo .... _ 10 In pota k """f31o.g oon<IItlon Md ",. ~

_ are WdrIin me _landa,,,,, .. I tI'r tile Coik>mia .&.Ir I1MOu1oes Board

(CAHB)

Perro.rr;"Il the r..- _oM<! ma",~ ~ ""'I' 1tnpo<IaroI. II

~I" lot ..... Itl illal-.r 'hat occurs o;klnng t .. br ... ..... .-;ad_

5oc1io.. 1 IUld 3 apply to ,he __ dO. s..ction 2 iIIu.trlllOs

Pf~'" !of """""allin' ta la t.", o! ~ tt>at may bo rnqo..ored

ttl pe<lo<m .. ~ <Io$crlbed In "'" Iolloooing ~iono

-.. ~ """'-'9h 24 """""'" parIS o! tho ""_. groupod occarn;ng

to Ioca'"",_

Fond !he...ctIOO roo \OTdlI on 11'0. pag". then rum 10 the , oDI& ot """'crib

on !he fi"" page 01 tOO ""'-on.

",..,.. W<'\IOnO ot M _ an ...-y 0< oyotom "' .. lra_. "'Moo

0010""",.,.., and _""""mg to. !t>e _. The ~ 1'0\)0'$

gMo OOIa i lO<l JX~r&,

If roo ""'" know 11>0 """"0 01 "'" "auble, goo '" _ 27

T~log,

y"", •• fety, and!he .. My oIOfl>Mo, if .. 'Y importan t. To help roo

ma)ce inIoo'm<>d __ .... llaw por_ H ie\)' moSSoagO$ and

0 .... ' o-.tom> •• 1on II'IIOIJghooA !hie mao ...... Of OOO'fSO, ~ Ii; I'lOl

prao1l~ Ot pooosil)le '0 "'am roo al>OuI "'I "'" ...... <do assotia'od

...;m -*Jng IM _.

Yoo " .... , .... )'OUr """ IJOOd ~

You .,.. fir>:,! importan1 oaloty .. _ in a ... iel)l of Iorm.

W>ckldi"ll

• Sal...,. Lobols _ 00 tOO .... hiel •

• S418~ ~ - P<~ b)' a ulery 016<1 .ymt>ol Lh aM

<>nO 01 tI ... e.ogn.1 "",ro.. DANGEn, WMlNIIfG. or C"'UTIO~,

ThtIU .ig .. I_,," me"":

V "" WIU bo Kl l LEO Of SER I OU~Y

G"" m-W

'

HU~T ~ roo CIO(I ', loIIow ... ,,,,,,,,,",,,

You CAN.,., Kl lLEIl or SER IOUSLY HURT

mj" · 'W"I'tJ ~ you don~ toIkYwin .. tuC1ions.

y"" C"N bo H URT ~ yoo don' ~

C' ·""'t'tl in.m.:tion •.

kl)'Ou ,.,...ttois "'.......ai.)'O<l .... fn;j ;m",mation 11 .. it p.eoedO<I by .

I N QIIC[] oymboI. The pu!pOU 01 lhio me>Mgf> i. 10 tlclp """,,,,,,

da~ 10 YOU' • ...,ielo . ""'&f p<opMy. or me """""""""".

w

z

a

z

w

CONTENTS

GENERAL INFORMATI ON

MAINTENAN CE

LUBRIC ATI ON SYSTEM

FUEL SYSTEM

COOLING SYSTEM

ENGINE REMOVAUINSTALLATION

CYLINDER HEADNALVEfCAMSHAFT

CYLINDERIPISTON

ALTERNATOR/STARTER CLUTCH

SUB·TRANSMISSIONJGEARSHIFT LINKAGE

AUTOMATIC TRAN SM ISSION

CRANKCASE/CRANKSHAFT/BALANCER

FRONT WHEELJSUSPENSIONISTEERING

REAR WHEE USUS PEN SION

BRAKE SYSTEM

FRONT DRIVING MECHANISM

REAR DRIVING MECHANISM

BATTERY/CHARGING SYSTEM

IGNITION SYSTEM

ELECTRIC STARTER

lI GHTSfMETERSlSWITC HES

SE LECTABLE 4WD SYSTEM

SYSTEM

WIRING DIAGRAM

TEC HNI CAL FEATURE

TROUBLESHOOTING

INDEX

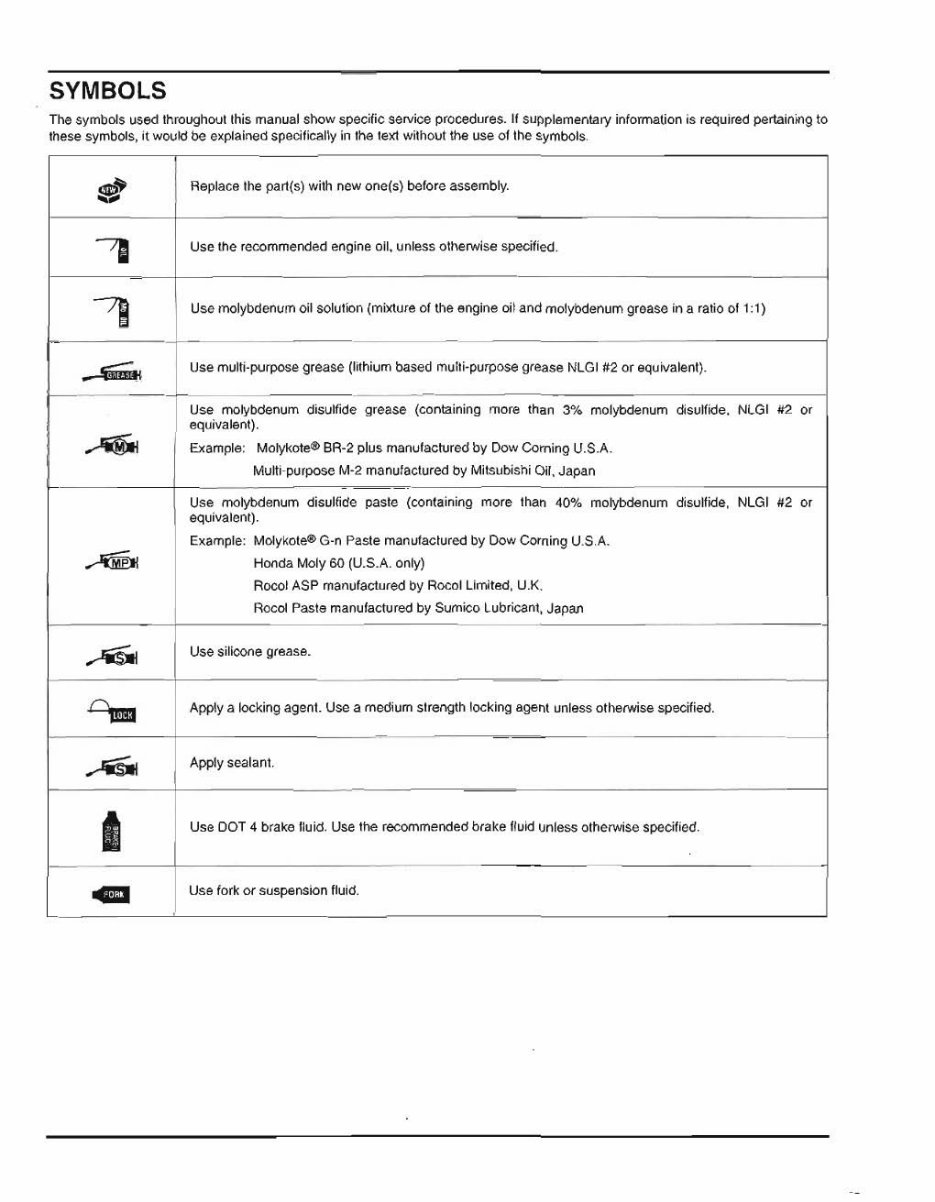

SYMBOLS

The symbols \.ISed throughout this manual show specijic service procedures. If supplementary information is required pertain~9 to

these symbols, it would be expllli"llo spedlie311y in !he le)(l without the use of the symbols.

~

Replace t he partes) with fleW one( s) before assembly.

'I

Use the recommended engine oil, unless otherwise spWfied

/Q

Usc rnolybdef'lum oil $OluHon (mixlu1(~ of the engine oil and molybdenum grease in II ra~o of 1:1)

.... am.

Use mul!i-pu,po$e grease (lithium based mul1;·purpOSEl grease NLGI #2 or equivalent).

Use molybdenum disulfide grease (containi ng more Itlan 3"4 molybderlum oisullide. NLGI <r2 or

equivalent) .

.....

E><ample: Motykole$ SA-2 plus manufacturw by Dow Coming U.S.A,

Multi-pur pose M·2 maJ'\l .. ~aclured by Mitsubishi Oil. Japan

Use molybdenum disulfide paste (containing more ttlan 40% molybdenum disullide, NLGI 112 or

equivalent).

Example' MoIykoteC' G-o Paste manl,llacture(l by Oow Corning U.S.A-

~

Honda Moly 60 (U.S.A. only)

Aocol ASP manufactured by Rocol Limited, UK

Rocol Pasta manufactured by Sumico Lubficanl, Japan

AiSio

Use silioone gr9ase.

"'11!1!1

Apptya locking agent Use a mooum slre;,gltllocking agel11 unless ottlerwise specified.

AiSio

Apply sealant

I

Use DDT 4 b ra k;e fiui<!_ Use the recommended brake Iluicluniess olherwi se speCified.

GI

Usa fork or suspension Hui tl.

1. GENERAL INFORMATION

SERVICE RULES ................................... ........ ' -2

MODEL IDENTIFiCATION····················· ........ 1-2

GENERAL SPECiFiCATIONS················ ..... ... 1-5

LUBRICATION SYSTEM SPECIFICATIONS · ' -7

FUEL SYSTEM SPECIFICATIONS ················ ' -7

COOLING SYSTEM SPECIFICATIONS ······· ·· ' -7

CYLINDER HEADIVALVE/CAMSHAFT

SPECIFICATIONS .......................................... ' -8

CYLINDER/PISTON SPECIFICATIONS 1-8

AL TERNATORI ST ARTER CLUTCH

SPECIFICATIONS ········································· 1-8

SUB·TRANSMISSION/GEARSHIFT

LINKAGE SPECiFiCATIONS····· .................... 1-9

AUTOMATIC TRANSMISSION SPECIFICA·

liON S ····················································· .. ·· .. ·· 1-9

CRANKCASE/CRANKSHAFT/BALANCER

SPECiFiCATIONS····················· .. ···· ·.... ··········· 1-9

FRONT WHEELI SUSPENSION /STEERING

SPECiFiCATIONS········· ····················· 1-9

REAR WHEEl/SUSPEN SION

SPECiFiCATIONS··································· ........ 1-9

BRAKE SYSTEM SPECIFICATIONS ············ '-10

FRONT DRIVING MECHANISM

SPECiFiCATIONS····· .. ·· ······················ ·········· 1· 10

REAR DRIVING MECHANISM

SPECiFiCATIONS········································,,'-10

BATI ERY /C HARGING SYSTEM

SPECIFICATIONS ........ ... ·····························' -10

IGNITION SYSTEM SPECIFICATIONS ·······' - 11

ELECTRIC STARTER SPECIFICATIONS .... ·· 1- 11

LIGHTS/M ETERS /SWITCHES

SPECiFiCATIONS····· ....................... ············ '· 11

STANDARD TORQUE VALUES····· ··············1· 12

ENGINE & FRAME TORQUE VALUES ...... ·· 1-1 2

TOOLS ·· .......... ·········· .... ······················ .. ········· 1-16

LUBRICATION & SEAL POINTS ............ ·· .... 1-18

CAB LE & HARNESS ROUTING ··········· .. · .. ··· 1·21

EMISSION CONTROL SYSTEMS ···············1·35

EMISSION CONTROL INFORMATION

LABEL (U.S.A. only) .... .. ........... .......... .. ······· 1-36

1·1

GENERAL INFORMATION

SERVICE RULES

1. Use genuine Honda or Honda-recommended parts and lubricants or their eQu ivalents. Parts that do not meet Honda's

dosign specifications may cause damage to the motorcycle.

2. Use the special tools designed for this product to avoid damage and incorrect assembly.

3. Use only metric tools when servicing the motorcycle. Metr ic bo lts. nuts and screws are not interchangeable w ith

English fastelle,s.

4. Illsta!! new gaskets, O-rings, cotler pins. and lock plates whell reassembling.

5. When tightening boits or nuts . begin wi th tho la. ger diameter or ir lil er bolt first. Then tig hten to the specified torque

diagonally in incremental steps unless a part icu lar seque rl ce is specified

6 Clean parts in cleaning solvent upon disassembly. lu bricate any aliding surfaces before reassembly.

7. After reassembly, check all parts for proper installation and operation.

8. Route all electrical wires as show in the Cable arid Hamess Routi 'l g lpage 1·21).

MODEL IDENTIFICA nON

1-2

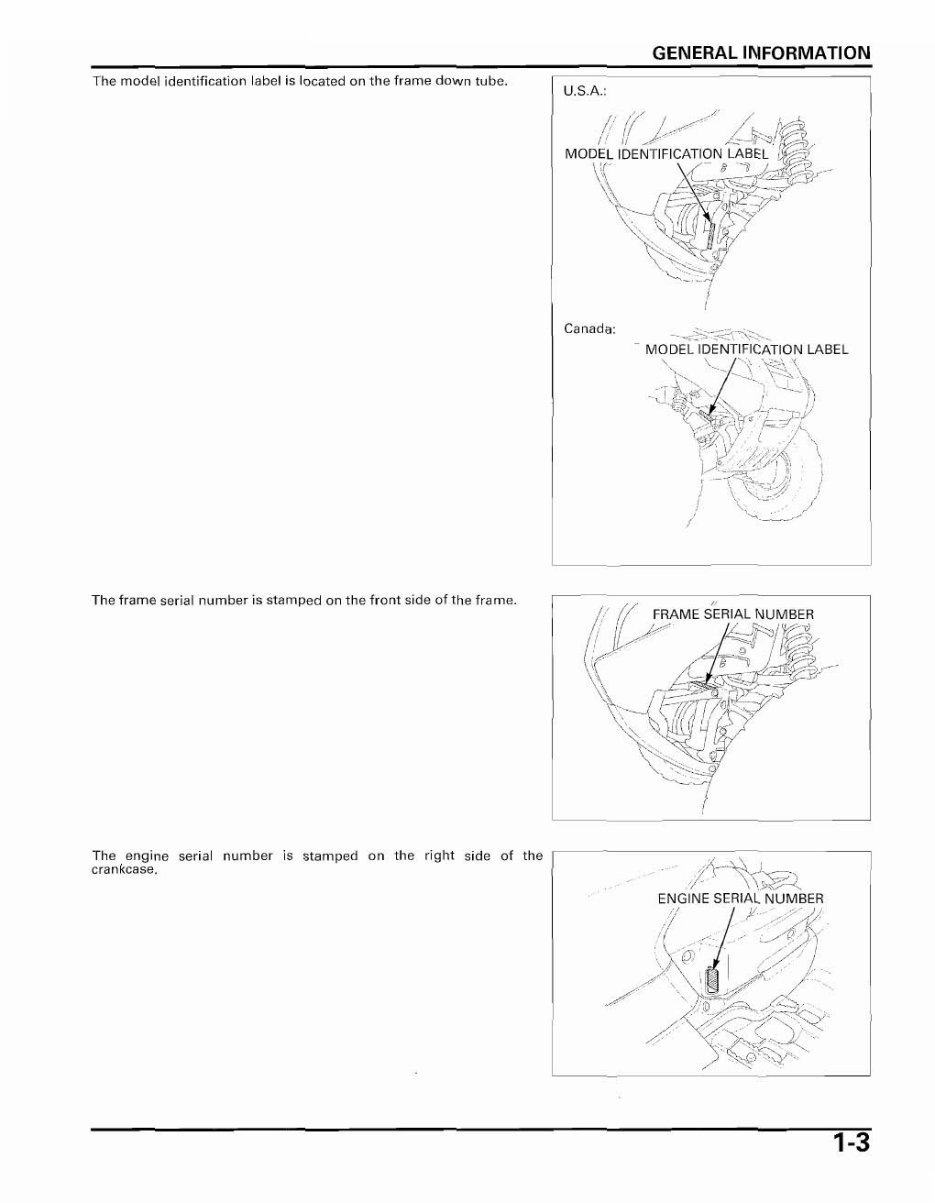

GENERAL INFORMATION

The model identification label is located on the frame down tube.

U.S.A.:

Carlada:

The frame serial number is stamped on the fro" t side of the frame.

The angine serial number is Stamped on the right side of the ,-- -------c- C----- -- ,

cranKcase. /"l~2'--<'

ENGINE SERIAL NUMBER

!~t~

/, "",,4.

/'- ;rc; '<

/.>._,J".

~v

1-3

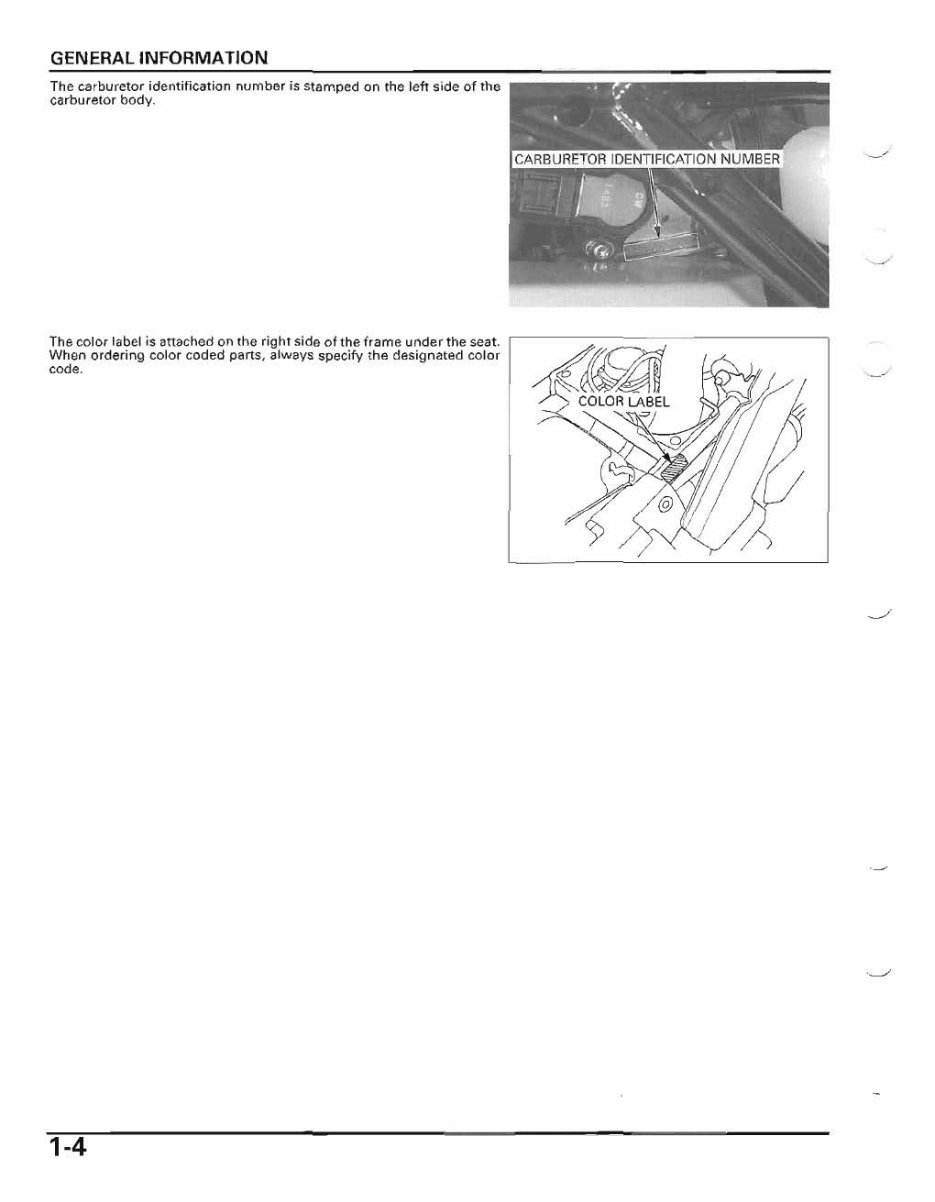

GENERAL INFORMATION

The clIrburetor identifiC"tion numb(' '' ;$ stamped on Ihe lett side of tho

earburet or body.

The color label; $ altachod 011 1 1'10 ri ght sido 01 the frame under the scat. ,----~--c=-__:---------_,

Whon ord ering color coded pans, always specify the designated col or ;Y,f'~

code . ~~M~

1-4

GENERAllNFORMATIQN

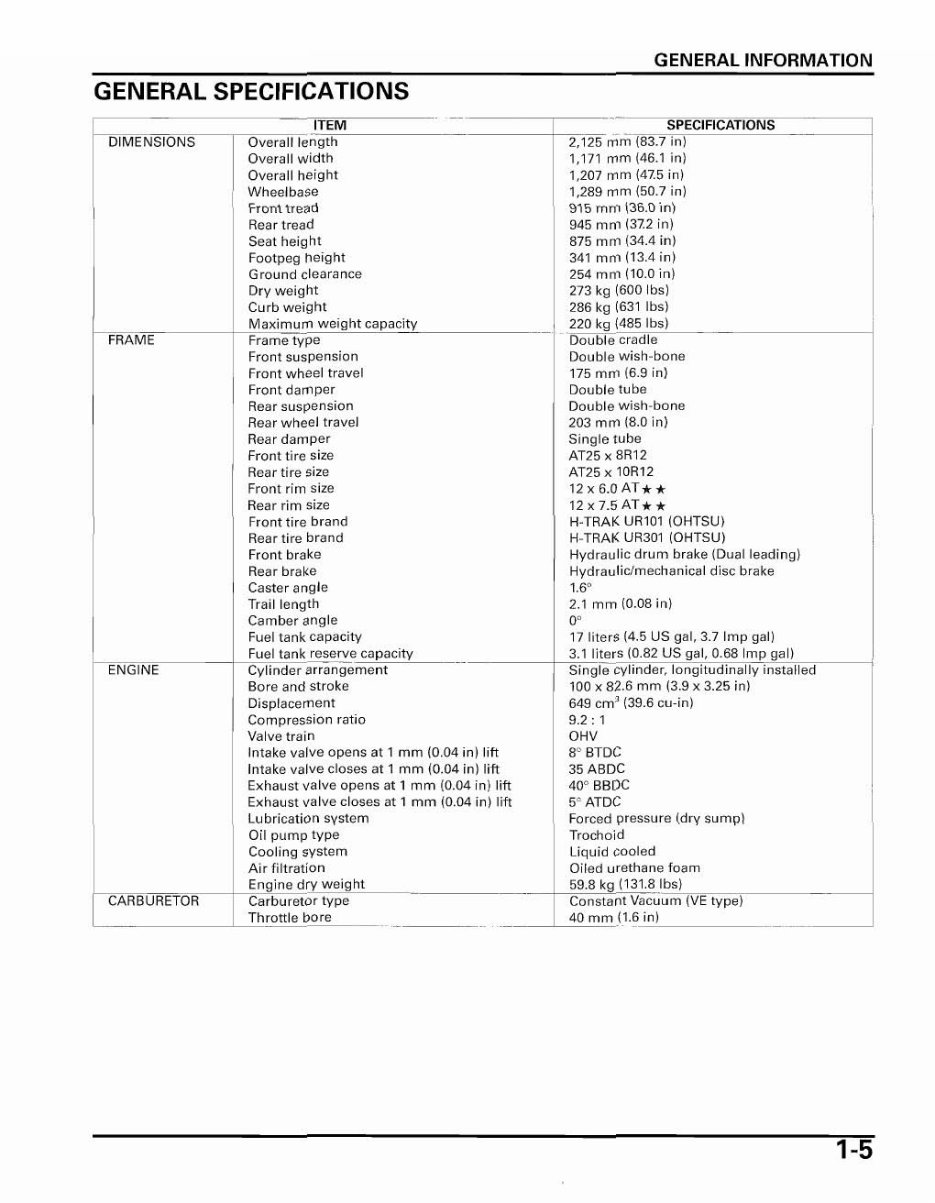

GENERAL SPECIFICATIONS

ITEM

-

SPECI FI CA TIONS

DIMENSIONS

Overalllen~~n

2, 125 riim (83.7 in)

Overall widlh 1.171 mm (46.1 in)

Overall height 1, 207 m m (47.!> in )

Wheelbase 1.289 mm (50.7 in)

Front IJea el 915 mm 1 3&.0 in)

Rear tread 945 mm (37.2 in)

Seat height 875 mm (34.4 in )

Footpeg height 34 1 mm (13. 4 in)

Ground clearance 254 m m (10.0 in )

Dr y weight 273 kg (600 Ibs)

Curb weig ht 286 kg (63 1 Ibs)

Maximum weight I:apaci ty 220 kg (485 Ibs)

FRAM E Frame type Double Grad e

Front suspension Double wish-bone

Front wheel travel 175 mm (6.9 in)

Front damper Double tu be

Rear suspension Double wish-bo ne

Rear wheel travel 203 mm (8.0 in)

Rear damper Single tube

Fr ont lire size AT25 x SR 12

Rca r tire size AT25 x 10R12

Front rim size

12 x 6.0AT **

Rea r rim size 12 x 7.5 AT * *

Front tire brand H-TRAK UR10l IOHTSU)

Rear tire brand H-TRAK UR301 IOH TS U)

Front brake Hydraulic drum brake (Dual leading)

Rear brake Hydrauli cl mechanil:sl disl: brake

Caster angle 1.6 "

Tr ail length 2.1 mmIO.08i n)

Camber angle (p

Fuel lank capacity 17 liters (4.5 US g81, 3.7 Imp gal)

Fuallank reserve capacity 3.1 liters (0.82 US gal, 0.68 I mp ga l)

ENG INE Cylinder arrangeme nt Single cylinder, longi tudinal ly installed

Bore and stroke 100 )( 82.6 mm (3.9 x 3.25 in)

Oisplal:ement 649 cm'139.6 cu-in)

Compression ra t io 9.2 : 1

Va lve train OHV

Intake valve opens at 1 mm (0.04 in l lift 8" BTDC

Intake valve closes at 1 mm (0.04 in) lift 35 ABDC

E)( haust valve ope ros at 1 mm (0.04 in) lift 40" BB DC

E)(hauS I valve doses at 1 mm (0.04 in ) li ft 5° ATDe

Lubrication system Forced pressure (dry sump)

Oil pump type Trochoid

Cooling system Liquid cooled

Ai r filtration Oiled urethane foam

Engine dry w eig hl 59 .8 k

(131 .8Ibs)

CARBURETOR Carburetor type Constant Vacu lJ m (V E type)

Throttle bore 40 mm (1. 6 in)

~

-

1~5

GENERAL INFORMATION

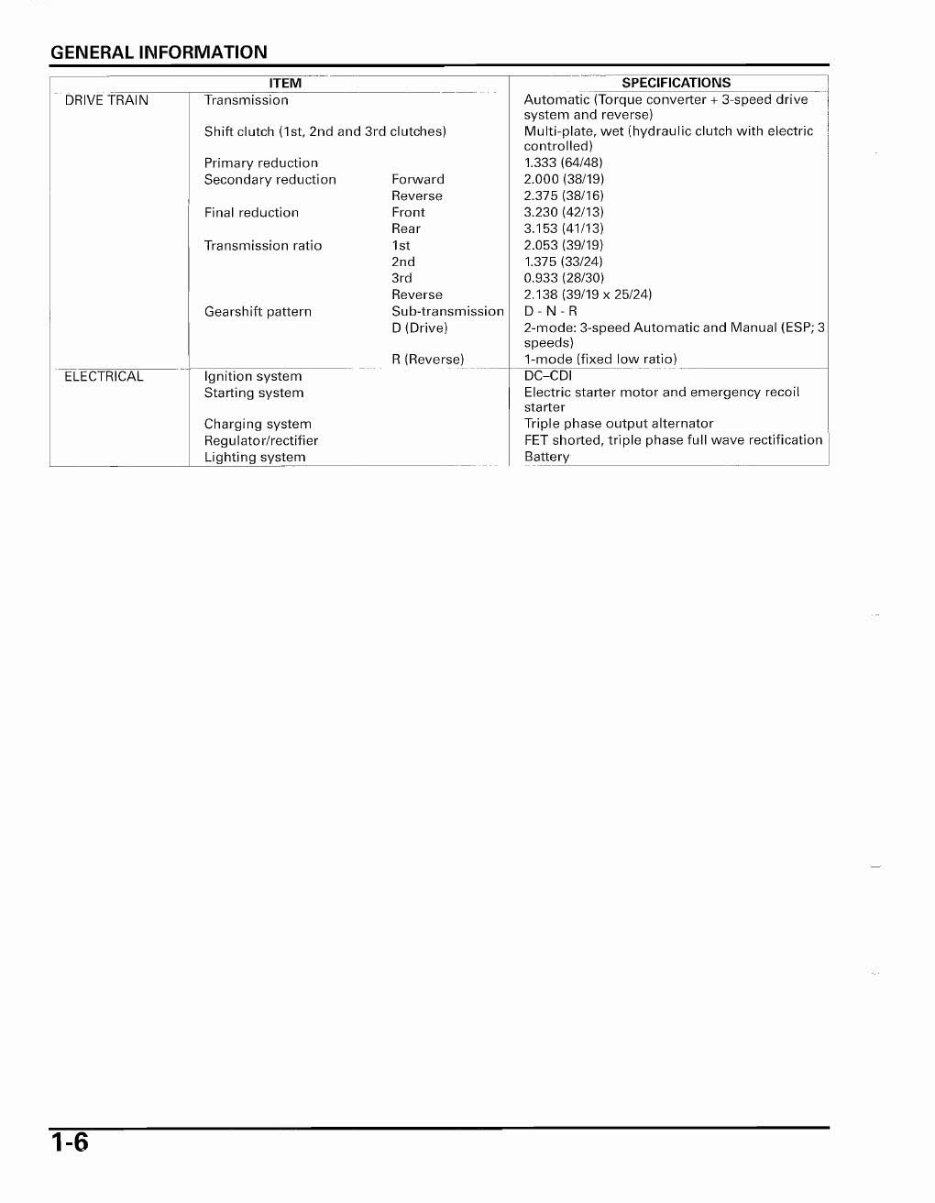

DR I VE TRA IN

ITEM

Transmission

Shift clutch (1st, 2nd and 3rd clutchesl

Primary reduct io "

Socondary reduction

Final reduction

Transmission ratio

Gearshift pattern

- EL- ECCT"RmIC~AITL---I-====~--

F Ignition system

1-6

Starting system

Charging system

Regula t or/ rectifier

Lighting system

Forward

Reverse

Front

Rear

'" ,",

3"

Reverse

Sub-transmission

o (Driv.,)

R (Reverse)

~ SPECIFICATIONS I

AutomatIC (Torque converter + 3 speed drrve

system and reverse) I

Multi plate, wet (hydraulIc clutch wIth eleetnc

controlled)

1.333 (64/48)

2.000 (38119)

2.375138116)

3.230142/13)

3. 153141/13)

2.053 (39119)

1. 375 (33/24)

0.933(28130)

2.1 38 (39/19 x 25124)

0 - N - R

2-modfl; 3-spfled Automatic and Manual (ESP; 3

speeds)

1-mode Ifixed l ow ratio) ________ ---j

DC-CDI

Electric staller motor and emergency recoil

staller

Triple phase output alternator

FET shorted, tr ip le phase full wave rect ifi cation

Batlery

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

$41.99

Viewed 89 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

$41.99

This repair manual is for the 2003-2005 Honda Rincon 650 ATV. It covers a complete tear down and rebuild, including pictures and part diagrams, torque specs, maintenance, troubleshooting, and more. With 529 pages, it provides comprehensive information for both professional mechanics and DIY enthusiasts.

The manual features clickable chapters and is searchable, allowing for easy navigation to find the necessary information. There are no restrictions on printing or saving/burning to disc.

- Complete tear down and rebuild

- Pictures and part diagrams

- Torque specs

- Maintenance procedures

- Troubleshooting guidance

- 529 pages

- Clickable chapters

- Searchable content

- No restrictions on printing or saving/burning to disc