2009-2012 Honda MUV700 Big Red 700 Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

A Few Words About Safety

Service Information

The Service and repair Information contained In this manual IS intended for use by qualified. professional technicians.

Attempting servICe or repairs without the proper training. 1000s, and equipment couk! cause injury 10 you or others. It could also

damage the vehICle or create an unsafe oondltlon.

This manual describes the proper methods and procedures for per10rmlng service, maintenance, and repairs. Some procedures

reqUIre the use of specialty designed too ls and dedicated equipmenl. Any persoo who inleocis 10 use a replacement part, service

procedure or a 1001 that is not recommended by Honda, must determine the risks 10 their persooaJ salery and the safe operatJon of

the vehicle.

II you need to re~ce a part, use genuine Honda parts with the correct pari number or an equivalent part. We strongly recommend

that you do nol use replacement parts 01 I nferIOr qua lity.

For Your Customer's Safety

Proper service and maintenance are essential to the customer's salety and

the reliability of the vehicle. Any error or oversight while servicing a vehicle

can result in faulty operation, damage to the vehicle, or injury to others .

For Your Salety

Because Ihis manual is intended lor the professional service techmcian, we

do nol provide warnings about many baSIC shop safety practices (e.g., Hot

parts-wear gloves) . II you have not received shop safety training or do not

feel oonfident about your knowfedge 01 safe servicing practice. we

recommended that you do !lOt attempt to pertorm the procedures described

In thiS manual.

Some 01 the most Important general service safety precautioos are given

below. However, we cannot warn you of every conceivable hazard that can

arise in pertormtng seMCe and repair procedures. Only you can decide

whether or not you should perform a given task.

Important Salety Precautions

AWARNING

Improper service or repairs can create an

unsafe condition that can cause your customer

or others to be seriously hurl or killed.

Follow the procedures and precautions in thiS

manual and other service materials carefully.

AWARNING

Failure to property Iollow Instructions and

precautIOns can cause you to be seriously hurt

or killed.

Follow the procedures and precaulJons In thts

manual carefully.

Make sure you have a clear understanding 01 all basIC Shop safety practices and that you ate wearing appropriate clothing and

uSlOg safety equipment When pertorming any Service task, be especially careful of the follOWing:

• Read all of the Instructions before you begin, and make sure you have the tools, the replacement or repair parts, and the skIlls

required to perform the tasks safely and completely.

• Protect your eyes by using proper safety glasses, goggles or face shields any time you hammer , drill, grind, pry or work around

pressurized alT or liqUids, and SPrings or other stored-energy components. If there is any doubt, put on eye protection.

• Use olher protectIve wear when necessary, for exampJe gloves or safety shoes. Handling hot or sharp parts can cause severe

burns or cuts. Belore you grab something lhat looks like it can hurt you. stop and put on gloves.

• Protect yourself and others whene\ler you have the vehicle up in the air. Any time you liftlhe vehicle, either with a hOist or a jack,

make sure thai it is always securely supported. Use Jack stands.

Make sure the engine is off before you begIn any serVICing procedures, unless the instruction tells you 10 do otherwise.

This WIll help eliminate several potentlaJ hazards:

• Carbon monoXide poisoning from engine exhaust. Be sure there IS adequate ventilation whenever you run the engine.

• Burns from hoc parts or coolant. let lhe engine and exhaust system cool betare working In those areas.

• Injury from mOVIng pans. If the Instruction lells you to run the engine. be sure your hands, fingers and clothing are out of the way.

Gasoline vapors and ~drogen gases from banenes are explosive. To reduce Ihe possibility of a fire or explosion, be careful when

working around gasolme or banenes.

• Use only a nonflammable solvent, not gasoline. to clean paris .

• NeYer drain or store gasoline In an open container.

4 Keep all cigarenes. sparks and flames away from the banery and alilueJ.related parts.

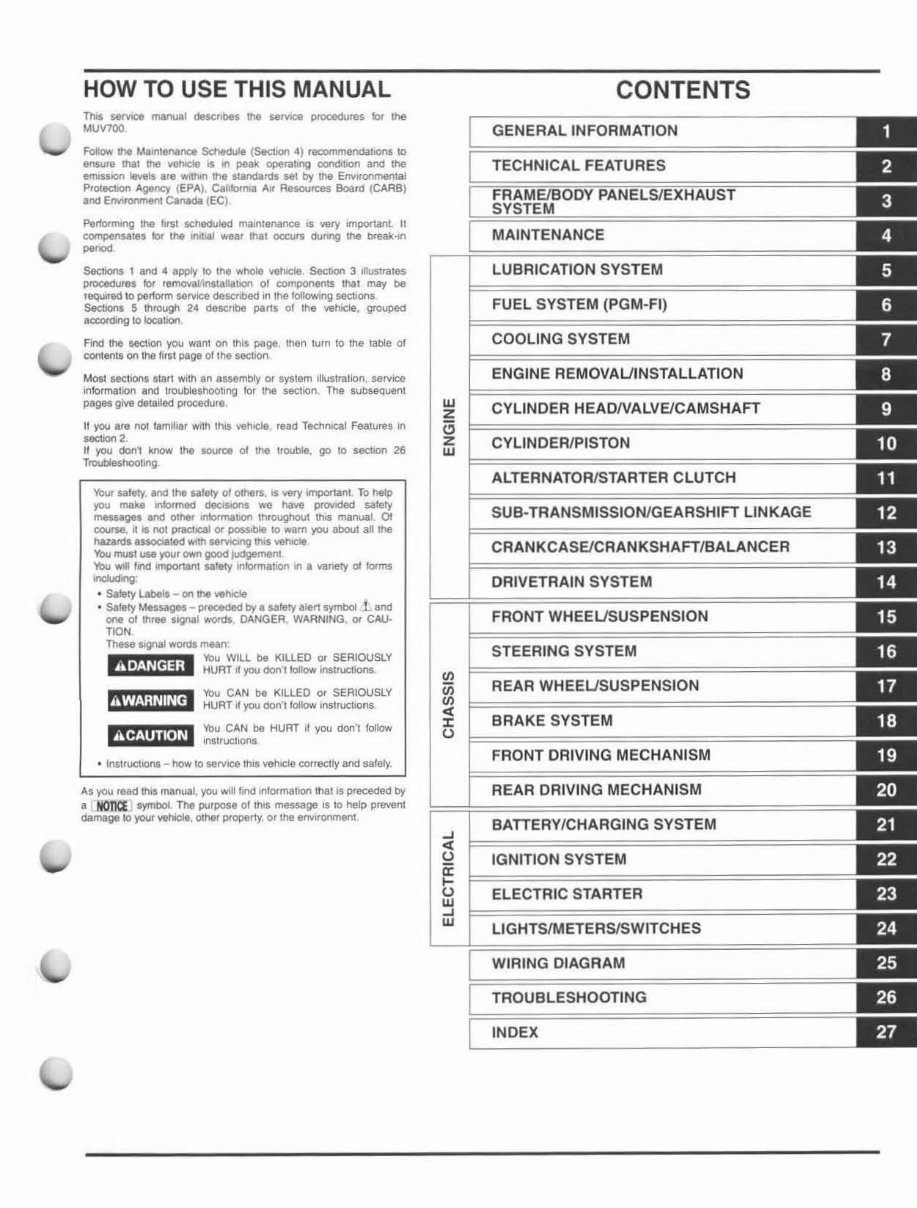

HOW TO USE THIS MANUAL

Thrs 58MCe tnllflUl,l delCtlbes the WrY1C8 prooodu<es lor Ule

MUV700,

FoIow !he Ma.lOt_nee ~ tSeebon 4) recommendabOnS to

_UI. that the \IehicI4I • In peak operating coodibon and the

lIfI'IIS5on IlYels .,. WIIhIn tne standard. set tIy the EnYnonmenlal

PtoIectJOn Agency (EPA). CaliIc:lN'4 AIr Resources Boord (CARB)

Ind EfMroomenI ~ tEe)

PertOlnung II\ei ',rsl SCheduled malOll1011nce IS WIry mportant. II

compensates 10< the Wltbll w&ar lhat OCC\.Irs dunng me break ......

p.,,"

SeeIions 1 1M .. apply to tn. whole vehocIe Sec::tion 3 lIusrrates

proc:«Iure, lor remO'alfinltalla1lofl ot cornpoo&nl$ thaI may De

'Bqllll\ld 10 pertorm MMce descnbed in tnelollowing sectionS

s.ctioM 5 through 24 describe parts 01 II'Ie vehlde, grouped

ac:cordklg to IocatlOl'l

Find the &eet.an you want on thiS page, then lurn 10 the table 01

content. 00'\ the Hit' page oIllle secllOO

Most sectiol'll star' With In 8$Sf1mb/y 04' system Illustration, sel\lice

ifllormatlon Ind lroubles.hootlrlg lor the section. The SI.Ibseqll6nl

pages give deta1led pl'oeedure

,t you .r. not lamMiar WIlli thiS vehICle read Tac/mlca' Features III

seetiorI2.

II you don' know 1h4t source 01 the llOUbie. go 10 sectlOI'I 26

Troubleshoolong

'!'ou CAN be KILLED 0< SERIOUSLY

mXWjI h! !h let! HURT II you cion', klIlow InsuUCllona.

AS you read thlt manual, you woll r,nd ~ma\Jon ItIat Is preceded by

• 1tOI1iCE symbOl. The purpose of In,. message IS to help pnMHlI

damage to your Y&/lIeIe, 0I1lef property, or the 8f>Vlronmenl

OJ

Z

'"

Z

OJ

II>

iii

II>

<

:I:

U

-'

<

u

ir

....

frl

-'

OJ

CONTENTS

GENERAL INFORMATION

TECHNICAL FEATURES

MAINTENANCE

LUBRICATION SYSTEM

FUEL SYSTEM (PGM-FI)

COOLING SYSTEM

ENGINE REMOVALJINSTALLATION

CYLINDER HEADNALVE/CAMSHAFT

CYLINDER/PISTON

ALTERNATOR/STARTER CLUTCH

SUB-TRANSMISSION/GEARSHIFT LINKAGE

CRANKCASE/CRANKSHAFT/BALANCER

DRIVETRAIN SYSTEM

FRONT WHEELJSUSPENSION

STEERING SYSTEM

REAR WHEELJSUSPENSION

BRAKE SYSTEM

FRONT DRIVING MECHANISM

REAR DRIVING MECHANISM

BATIERY/CHARGING SYSTEM

IGNITION SYSTEM

ELECTRIC STARTER

LIGHTS/METERS/SWITCHES

WIRING DIAGRAM

TROUBLESHOOTING

INDEX

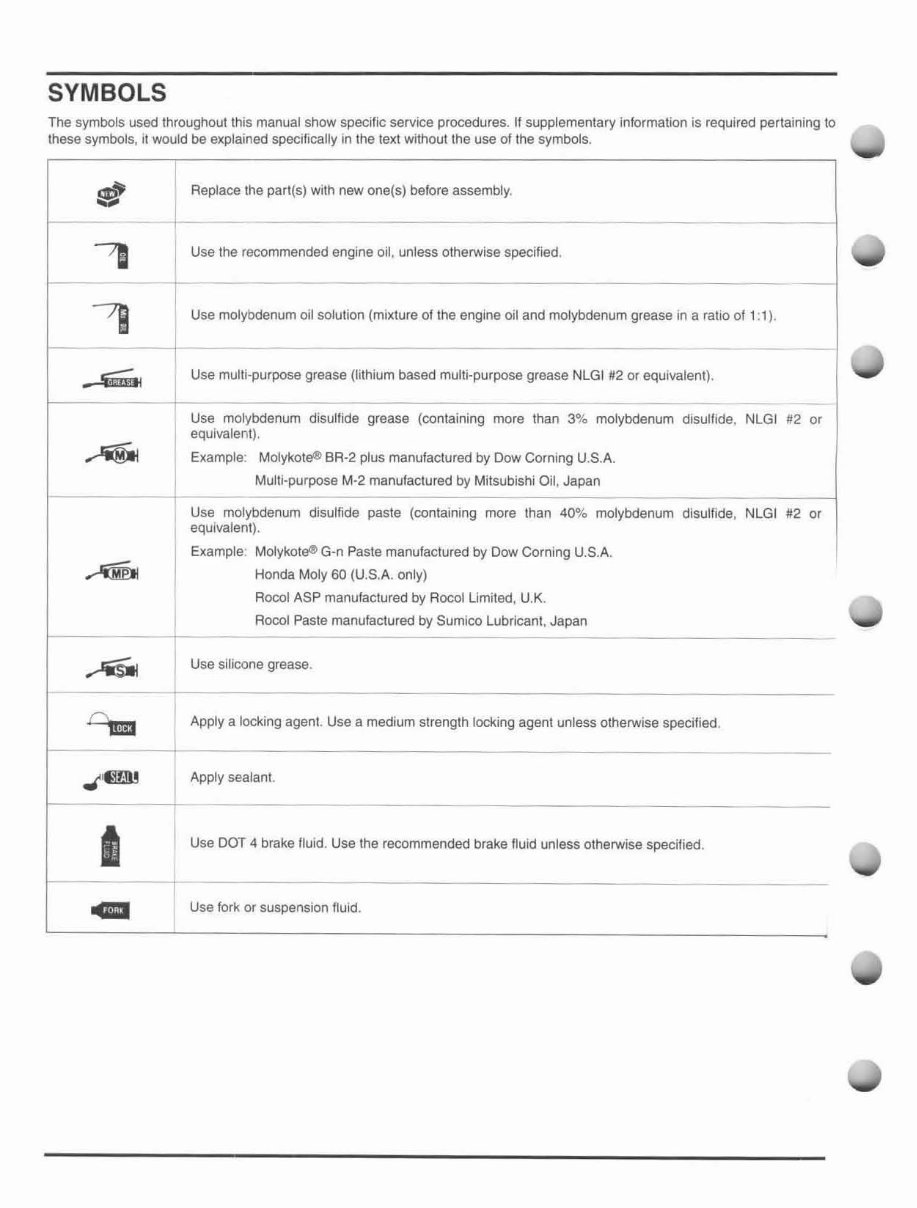

SYMBOLS

The symbols used Ihroughoullhis manual show specific service procedures. If supplementary information is required pertaining to

Ihese symbols, it would be explained specifically in the texl without the use of the symbols.

!f;!~

....

I

Replace the parl(s) with new one(5) before assembly.

'D

Use the recommended engine oil , unless otherwise specified.

-

i

7J

Use molybdenum oil solution (mixture of the engine oil and mOlybdenum grease in a ratio of 1: 1).

----

~

u;;..

I

Use multi-purpose grease (lithium based multi-purpose grease NlGI #2 or equivalent).

--

,

Use molybdenum disulfide grease (containing more than 3% molybdenum disulfide, NLGI #2 or

equivalent).

~ Example: Molykole® BR·2 plus manufactured by Dow Corning U.S.A.

Mutti-purpose M-2 manulactured by Mitsubishi Oil, Japan

Use molybdenum disulfide paste (containing more than 40% molybdenum disulfide, NLGI 112 or

equivalent).

Example: Molykot~ G-n Paste manufactured by Dow Corning U.S.A.

~ Honda Moty 60 (U.S.A. only)

Rocol ASP manufactured by Aocol Umited, U.K.

Aocol Paste manufactured by Sumico Lubricant, Japan

---

Use silicone grease.

t1m:J

Apply a locking agent. Use a medium strength locking agent unless otherwise specified,

.,( ' 61ll

Apply sealant.

•

Use DOT 4 brake fluid. Use the recommended brake fluid unless otherwise specitied.

GIl

I Use fork or suspension ftuid.

1. GENERAL INFORMATION

SERVICE RULES ......................................... '·2

MODEL IDENTIFICATION .................... · ...... '·3

GENERAL SPECIFICATIONS ...................... '·5

LUBRICATION SYSTEM

SPECIFICATIONS .. ·.... · .... · .. · .. · .... · .. ··· .. · .. · .. ···'·7

FUEL SYSTEM SPECIFICATIONS .............. '·7

COOLING SYSTEM SPECIFICATIONS ...... ' -7

CYLINDER HEADIVALVE/ CAMSHAFT

SPECIFICATIONS ·.... ·· .. ·· .. · .. ·.... · .. · .. ··· .. · .. · .... ' -8

CYLINDER/PISTON SPECIFICATIONS ...... ' -8

ALTERNATOR/STARTER CLUTCH

SPECIFICATIONS· .. ·· .. ·· .. · ...... · .. · .. · .. · .... ·· ...... '-8

SUB-TRANSMISSION/GEARSHIFT

LINKAGE SPECIFICATIONS ....................... '-9

CRANKCASE/ CRANKSHAFT/BALANCER

SPECIFICATIONS ·· .. · .. ·· .. · .. · .. ·· .. ·· .... · .... ·· .... ·· ' -9

DRIVETRAIN SYSTEM

SPECIFICATIONS ·· .. · .. ···.... · .. ·· .. ·· .... · .... ·· ...... ' -9

FRONT WHEEL/SUSPENSION

SPECIFICATIONS · .. ·· .. ··· .... · .. ··· .. ·...... · .. ·· ...... ' -9

STEERING SYSTEM SPECIFICATIONS .... · ' -9

REAR WHEEL/SUSPENSION

SPECIFICATIONS .. ..................................... '-9

BRAKE SYSTEM SPECIFICATIONS ........ ,., 0

FRONT DRIVING MECHANISM

SPECIFICATIONS ..................................... ,., 0

REAR DRIVING MECHANISM

SPECIFICATIONS ..................................... '·'0

BATIERY / CHARGING SYSTEM

SPECIFICATIONS ..................................... '·'0

IGNITION SYSTEM SPECiFiCATIONS .... '·',

ELECTRIC STARTER SPECIFICATIONS .. ,."

LIGHTS / METERS/ SWITCHES

SPECIFICATIONS ..................................... ,-"

STANDARD TORQUE VALUES .............. · 1-12

ENGINE & FRAME TORQUE VALUES .... '·'2

LUBRICATION & SEAL POINTS .............. 1-18

CABLE & HARNESS ROUTING ............... '·2'

EMISSION CONTROL SYSTEMS ............ '-46

LIFT AND SUPPORT POINTS .................. 1-48

1-1

GENERAL INFORMATION

SERVICE RULES

1. Use genuine Honda or Honda-recommended parts and lubricants or their equivalents. Parts that do not meet Honda's

design specifications may cause damage to the motorcycle.

2. Use the special tools designed for this product to avoid damage and incorrect assembly.

3. Use only metric tools when servicing the motorcycle. Metric bolts, nuts and screws are not interchangeable with

Engl i sh fasteners.

4. Install new gaskets, O-rings, cotter pins, and lock plates when reassembling.

5. When li ghtening bolts or nut s, begin with the larger diameter or inner bolt first. Then tighten to the specified torque

diagonally in incremental steps unless a particular sequence is specified.

6. Clean parts in cleaning solvent upon disassembly. Lubricate any sliding surfaces before reassembly.

7. After reassembly, check all parts for proper installation and operation .

8. Route all electrical wires as show in the Cable and Harness Routing (page 1·21 ).

ABBREVIATION

Throughout this manual, the following abbreviations are used to identify the respective parts or systems.

Abbrev. telTTl Full telTTl

Af[ Automatic Transmission

CKP sensor Crankshaft Position sensor

Clutch PC solenoid Clutch Pressure Control solenoid

I

DLC Data Link Connector

-

DTC Diagnostic Trouble Code

ECT sensor Engine Coolant Temperature sensor

EEPROM , Electrically Erasable Programmable Read Only Memory _

ELR Emergency Locking Retractor

EOT sensor Engine Oil Temperature sensor

HDS Honda Diagnostic System

. IACV Idle Air Control Valve

~;sensor

Intake Air Temperature sensor

MAP sensor Manifold Absolute Pressure sensor

_ ~IL

Malfunction Indicator Lamp

DPS Occupant Protective Structure

PCM Powertrain Control Module

(ECMfTCM ) (Engine Control ModulefTransmission Control Module)

PGM-Fl Programmed Fuel Injection

SCS connector Service Check Short connector

TP sensor Throttle Position sensor

VS sensor Vehicle Speed sensor

2WD,4WD 2 Wheel Drive, 4 Wheel Drive

1-2

MODEL IDENTIFICATION

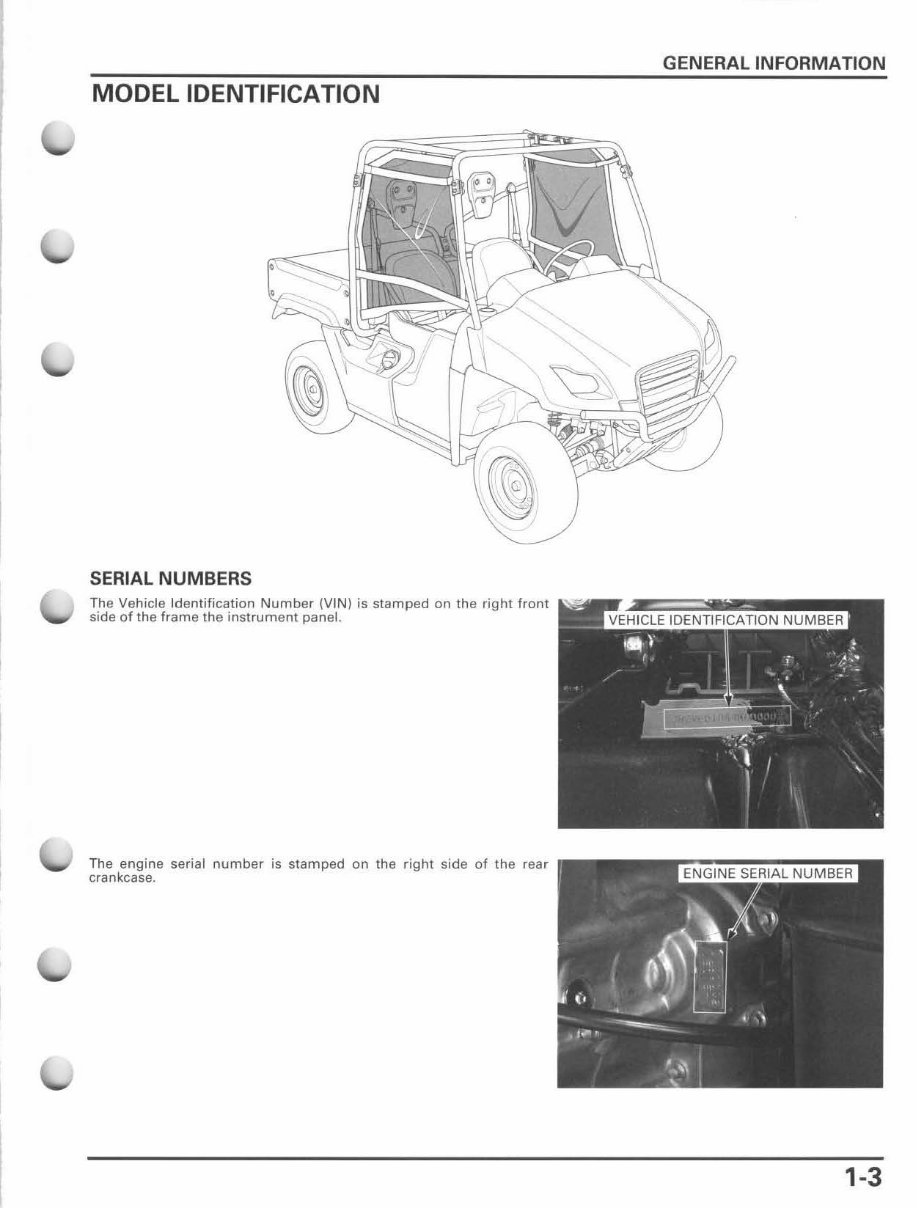

SERIAL NUMBERS

The Vehicle Identification Number (VIN) is stamped on the right front

side of the frame the instrument panel.

The engine serial number is stamped on the right side of the rear

crankcase.

GENERAL INFORMATION

1-3

GENERAL INFORMATION

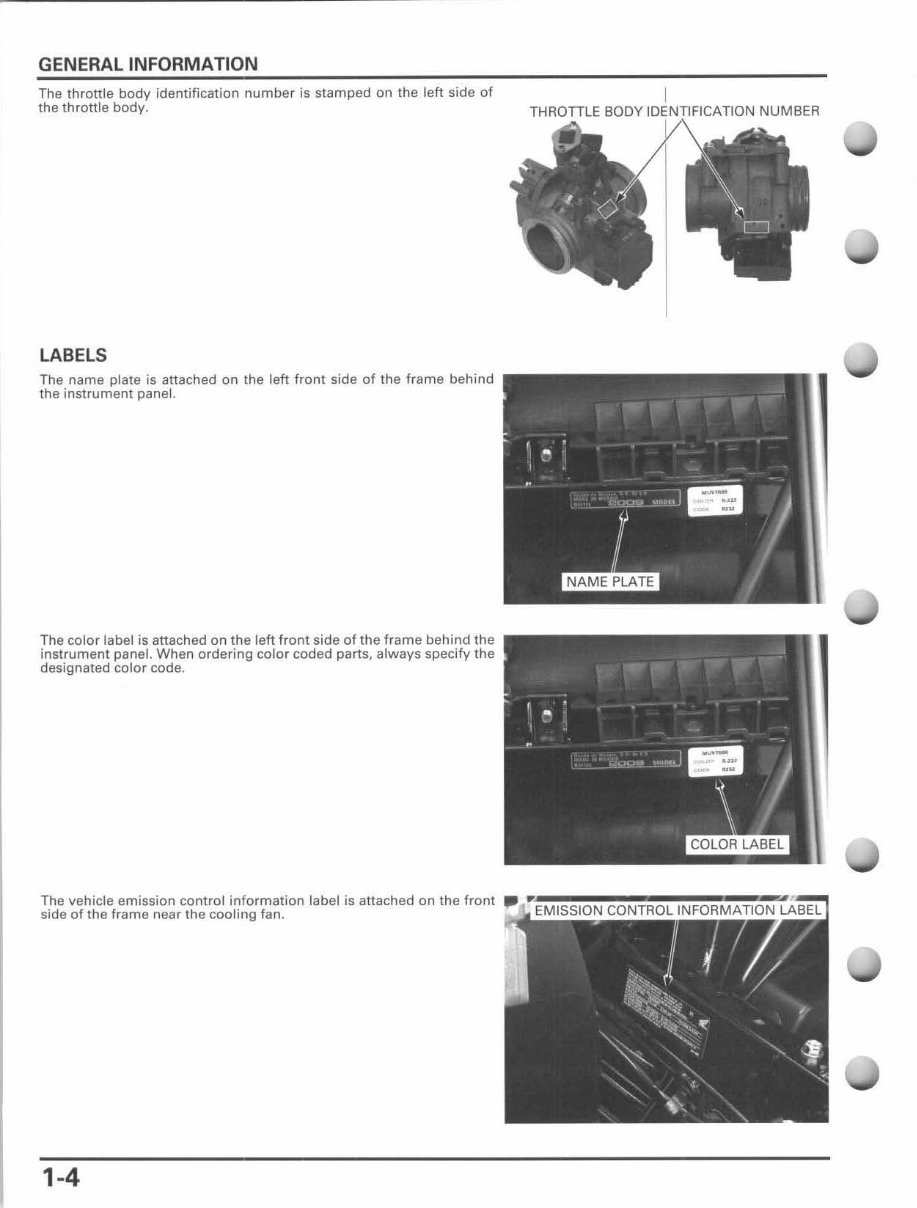

The throttle body identification number is stamped on the left side of

the throttle body.

LABelS

The name plate is attached on the left front side of the frame behind

the instrument panel.

The color label is attached on the left front side of the frame behind the

instrument panel. When ordering color coded parts, always specify the

designated color code.

The vehicle emission control information label is attached on the front

side of the frame near the cooling fan.

1-4

IDENTIFICIHlClN NUMBER

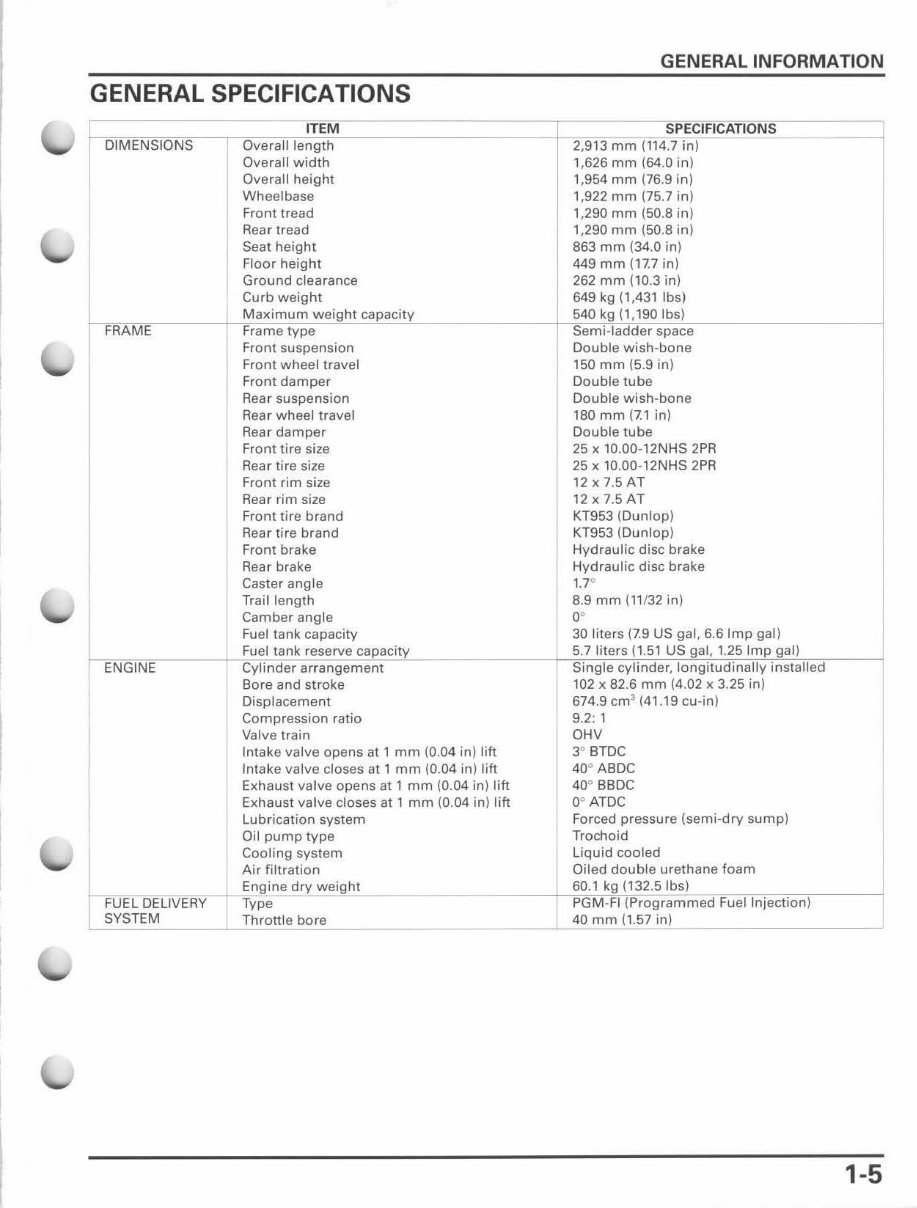

GENERAL SPECIFICATIONS

Overall j

Overall height

Wheelbase

Front tread

Rea r tread

Sea t height

Floor height

Ground clearance

Curb weight

Maximum

Front suspension

Front wheel travel

Front damper

Rear suspension

Rea r wheel travel

Rear damper

Front tire size

Rear tire size

Front rim size

Rea r rim size

Front tire brand

Rear lire brand

Front brake

Rear brake

Caster angle

Trail length

Camber angle

Fuel tank capacity

Fuel tank reserve

Displacement

Compression ratio

Valve train

Intake valve opens at 1 mm (0.04 in) lift

Intake valve closes at 1 mm (0.04 in) lift

Exhaust valve opens at 1 mm (0.04 in) lift

Exhaust valve closes at 1 mm (0.04 in) lift

Lubr ication system

Oil pump type

Cooling system

Air filtration

'i'"iicv-+~ E~ ngine dry weight

FUEL DELIVERY Type

GENERAL INFORMATION

-+"- 0" mm (114.7 in)

1,626 mm (64.0 in)

1,954 mm (76 .9 in)

1,922 mm (75.7 in)

, ,290 mm (50.8 in)

1,290 mm (50.8 in)

863 mm (34.0 in)

449 mm (17.7 in)

262 mm (10.3 in)

649 kg (1,431 Ibs)

540

space

Double wish-bone

150 mm (5.9 in)

Double tube

Double wish-bone

180 mm (7.1 in)

Double tube

25 x 10.00-12NHS 2PR

25 x 10.00-12NHS 2PR

12x7.5AT

12x7.5AT

KT953 (Dunlop)

KT953 (Dunlop)

Hydraulic disc brake

Hydraulic disc brake

1.7

0

8.9 mm (11132 in)

0'

30 liters (7.9 US gal, 6.61mp gal)

PGM-FI (Programmed Fuel Injection)

SYSTEM Throttle bore _____ -"--=4 .. 0"m=m " I"' ,, .5 e.- 7 in"I __________ ---.J

1-5

GENERAL INFORMATION

ELECTRICAL

1-6

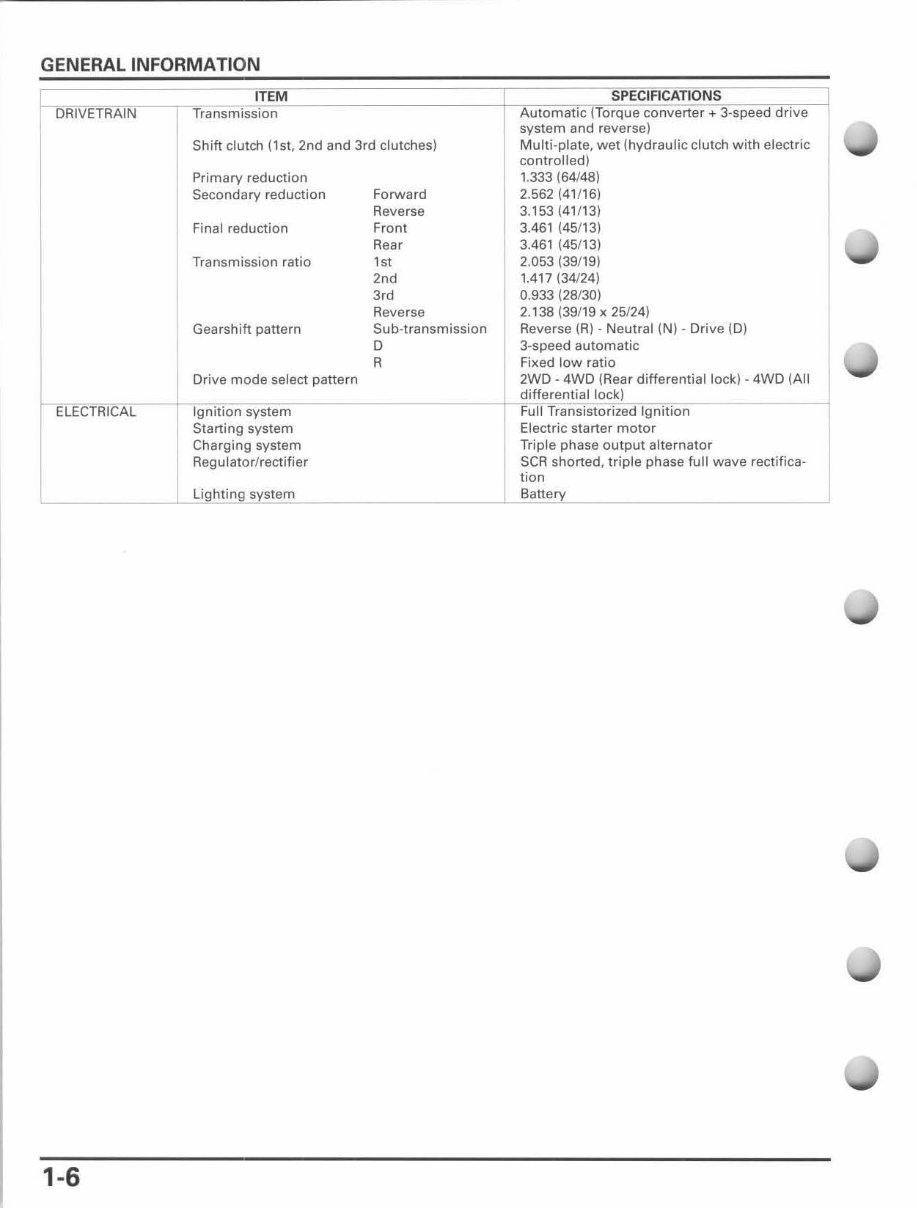

Shift clutch (lS1, 2nd and 3rd clutches)

Primary reduction

Secondary reduction

Final reduction

Forward

Reverse

Front

Rear

Transmission ratio 1st

Gearshift pattern

Drive mode select pattern

Ignition system

Starting system

Charging system

Reg ulator/recti' ie r

Lightin g system

"d

3,d

Reverse

Sub-transmission

o

R

system and ,e',e,,,:

Multi-plate, wet (hydraulic clutch with electric

controlled)

1.333 (64148)

2.562 (41f16)

3.153 (41/13)

3.461 (45/13)

3.461 (45/13)

2,053 (39/19)

1.417 (34124)

0.933 (28/30)

2. 138 (39/19 x 25124)

Reverse (A) - Neutral (N) - Drive (0)

3-speed automatic

Fixed low ratio

2WD - 4WD (Rear differential lock) - 4WD (All

differential lock)

Full Transistorized Ignition

Electric starter motor

Triple phase output alternator

SeR shorted, triple phase full wave rectifica-

tion

Battery

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

$41.99

Viewed 62 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

$41.99

- Complete Factory Service Repair Workshop Manual

- No Extra fees, No Expiry dates

Get the Service Repair Workshop Manual instantly on your computer, tablet, or smartphone. This Professional Manual covers all repairs, servicing, and troubleshooting procedures with detailed photos & diagrams. It is the same type of manual used by professional Mechanics and Technicians, containing step-by-step instructions, highly detailed exploded diagrams, and pictures to guide you through every job.

FAQs:

- Q. Can I print out a page?

A. Yes, you can print out a single page or the entire manual, it's your choice. - Q. Can I use this Manual on more than one computer?

A. Yes, this Manual can be used on as many computers as required. - Q. Is this a trial or a limited version?

A. No, this is the FULL Manual without any limitations or trial periods and can be used for life. - Q. Will this Manual expire in 12 months or will I have to pay a renewal fee?

A. NO, Absolutely not! You can continue to use this Manual for life without the need to renew or pay any extra. - Q. Will this Manual work on Windows & MAC computers?

A. Yes, it is fully compatible with all Windows & All MAC Computers.

Thanks for looking at this item, please click on the Button.