CLUB CAR GOLF CART KF82 Engine FACTORY Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

KF82 KMOO-KF150

4-stroke air-cooled gasoline engine

WORKSHOP MANOU

INTRODUCTION

Kawasaki 4-stroke gasoline engine models, KF82, KF100 and KF150 are of

the same basic design utilizing a cast iron cylinder, a precision die cast alu-

minum alloy crankcase and side cover, and heavy duty ball bearings mounted

on crankshaft and counter balance shaft.

Other standard features of this series include;

• Electronic Ignition System

The KF100 and KF150 are provided with the contact breaker ignition

system type as an option.

• Automatic Spark Advance

• Electric Starter

The KF150 is equipped with the electric starter as standard. The KF82

and KF100 are provided that as an option.

Each model is available in two types.

One is "D" type which uses an extended crankshaft for power take-off and

other is "G" type which is a 2 to 1 gear reduction model utilizing an extend-

ed camshaft for power take-off. The procedures for assembly, disassembly

and adjustment for all these models are almost identical.

All rights reserved. No part of this publication may be reproduced, stored

in a retrieval system, or transmitted in any form or by any means, electronic

mechanical photocopying, recording or otherwise, without the prior written

permission of Engine Division/Kawasaki Heavy Industries, Ltd. No liability

can be accepted for any inaccuracies or omissions in this publication, al-

though every possible care has been taken to make it as complete and ac-

curate as possible. All procedures and specifications subject to change with-

out prior notice or obligation. Illustrations in this publication are intended

for reference use only and may not depict actual model component parts.

C3NTENTS

A. GENERAL SPECIFICATIONS

B. PERFORMANCE CURVES

C. DIMENSIONAL SPECIFICATIONS

D. OPERATION THEORY AND ADJUSTM

1. CARBURETOR

1-1 Carburetor Theory of Operation

1-2 Carburetor Structure in Practice .

1-3 Carburetor Adjustment

2. IGNITION SYSTEM

2-1 Classification of Ignition System

2-2 Basic Circuit and Operation Theory

2-3 Ignition Timing Adjustment ....

2-4 Automatic Spark Advance System

3. ENGINE SPEED GOVERNOR

3-1 Governor Theory of Operation ..

3-2 Speed Governor Adjustment in Prac

4. VALVE CLEARANCE

4-1 Valve Clearance Check

4-2 Valve Clearance Adjustment

5. REGULATION OF ENGINE R.P.M. ..

5-1 Governed Output Characteristics .

5-2 Idling Adjustment

5-3 No Load Max. R.P.M. Adjustment

6. SPARK PLUG GAP .

E. DISASSEMBLY AND REASSEMBLY PR

1. DISASSEMBLY PROCEDURE

1-1 Fuel Tank and Fuel Filter

1-2 Spiral Case and Electric Starter .

1-3 Muffler, Carburetor and Contact Br

1-4 Flywheel

1-5 Cylinder Head and Side Base (1) .

1-6 Connecting Rod, Piston and Cylind<

1-7 Crankshaft, Camshaft and Balancer

2. REASSEMBLY PROCEDURE

2-1 Camshaft and Crankshaft

2-2 Piston and Connecting rod

2-3 Cylinder and Valves

2-4 Side Base (1) and Cylinder Head ..

2-5 Flywheel, Coil and Trochoid Pump

2-6 Muffler, Carburetor and Contact Br

2-7 Spiral Case and Electric Starter . . .

NT

f Ignition System 8

ce

10

13

13

14

14

14

14

15

15

15

17

17

ker

)CEDURE 18

18

18

18

19

. . 19

20

21

22

22

23

23

24

25

26

28

.29

ker

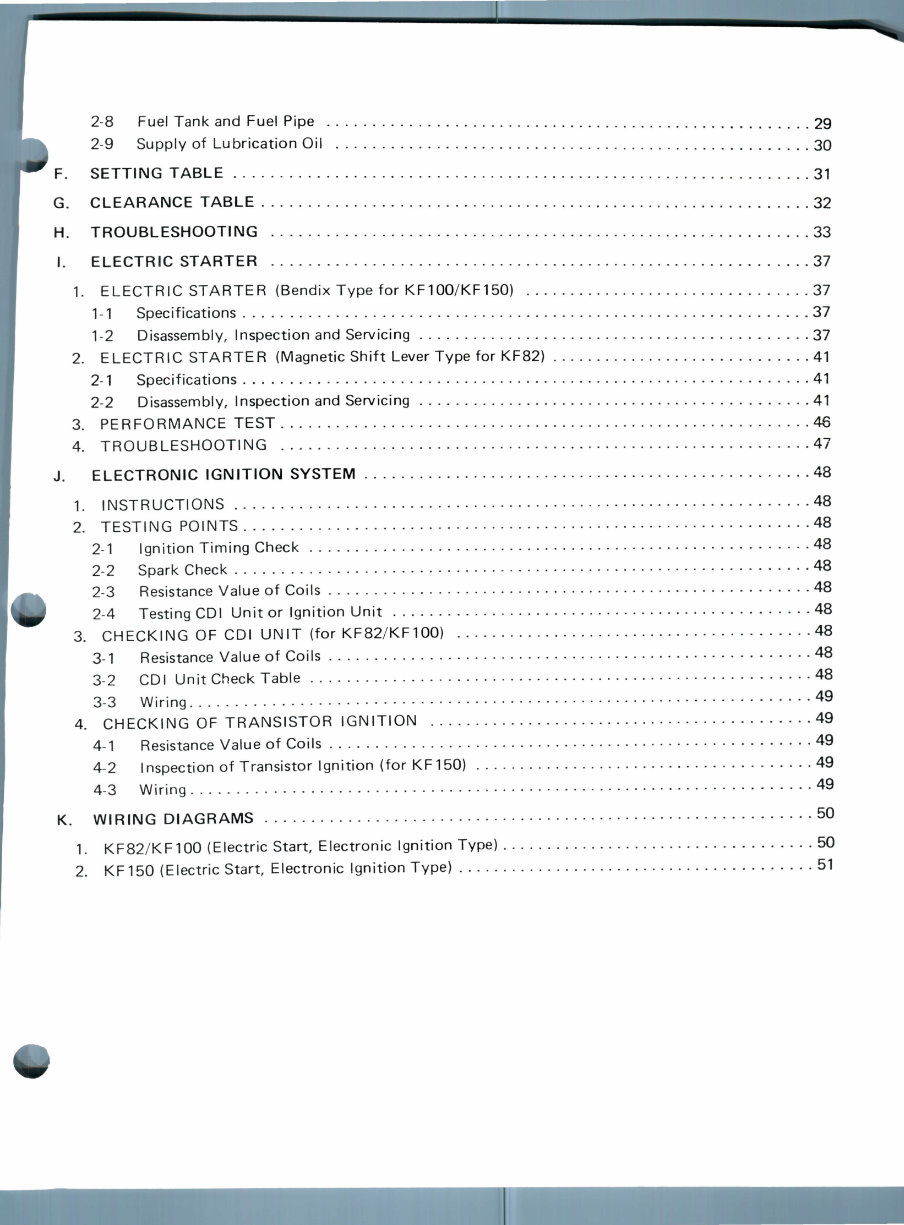

2-8 Fuel Tank and Fuel Pipe 29

2-9 Supply of Lubrication Oil 30

F. SETTING TABLE 31

G. CLEARANCE TABLE 32

H. TROUBLESHOOTING 33

I. ELECTRIC STARTER 37

1. ELECTRIC STARTER (Bendix Type for KF100/KF150) 37

1-1 Specifications 37

1-2 Disassembly, Inspection and Servicing 37

2. ELECTRIC STARTER (Magnetic Shift Lever Type for KF82) 41

2-1 Specifications 41

2-2 Disassembly, Inspection and Servicing 41

3. PERFORMANCE TEST 46

4. TROUBLESHOOTING 47

J. ELECTRONIC IGNITION SYSTEM 48

1. INSTRUCTIONS 48

2. TESTING POINTS 48

2-1 Ignition Timing Check 48

2-2 Spark Check 48

2-3 Resistance Value of Coils 48

2-4 Testing GDI Unit or Ignition Unit 48

3. CHECKING OF GDI UNIT (for KF82/KF100) 48

3-1 Resistance Value of Coils 48

3-2 GDI Unit Check Table 48

3-3 Wiring 49

4. CHECKING OF TRANSISTOR IGNITION 49

4-1 Resistance Value of Coils 49

4-2 Inspection of Transistor Ignition (for KF150) 49

4-3 Wiring 49

K. WIRING DIAGRAMS 50

1. KF82/KF100 (Electric Start, Electronic Ignition Type) 50

2. KF150 (Electric Start, Electronic Ignition Type) 51

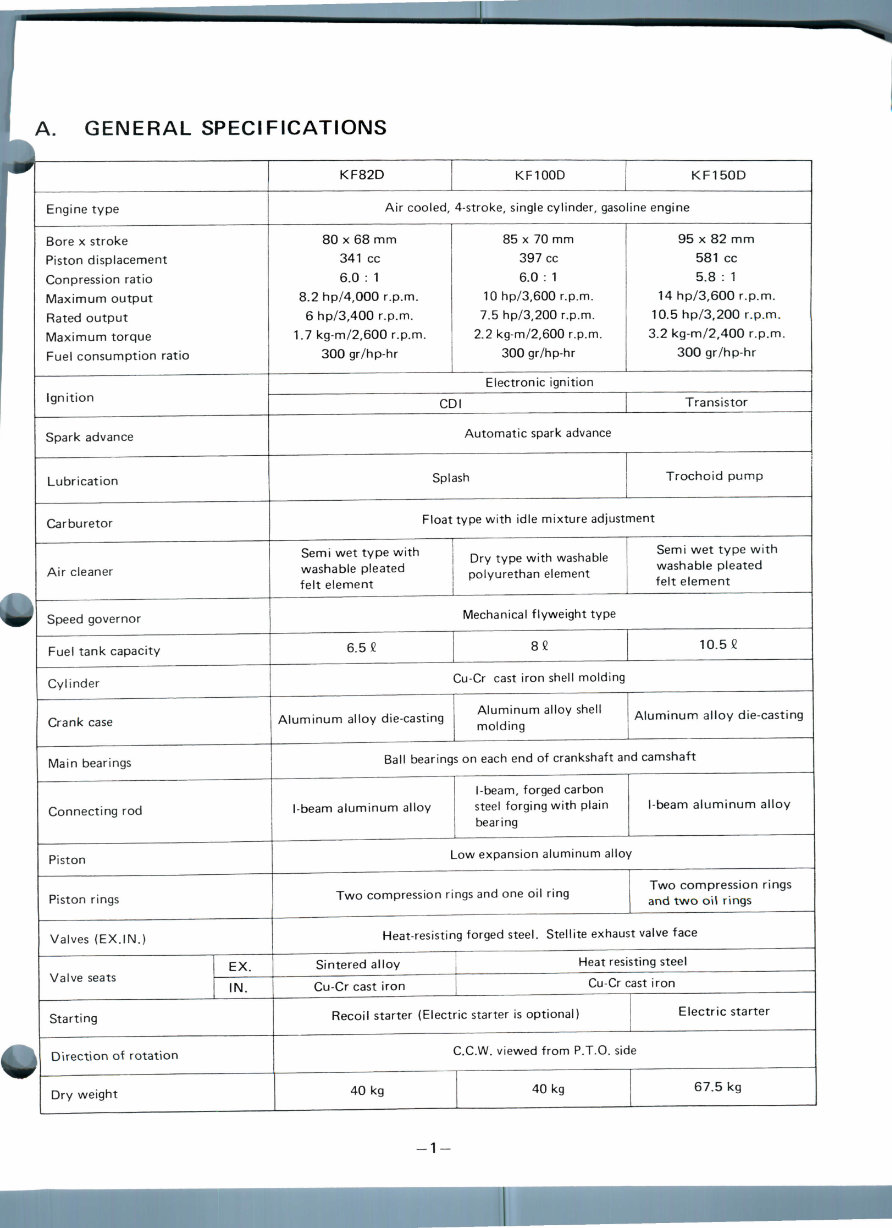

A. GENERAL SPECIFICATIONS

Engine type

Bore x stroke

Piston displacement

Conpression ratio

Maximum output

Rated output

Maximum torque

Fuel consumption ratio

Ignition

Spark advance

Lubrication

Carburetor

Air cleaner

Speed governor

Fuel tank capacity

Cylinder

Crank case

Main bearings

Connecting rod

Piston

Piston rings

Valves (EX. IN.)

EX.

IN.

Starting

Direction of rotation

Dry weight

KF82D

KF100D

KF150D

Air cooled, 4-stroke, single cylinder, gasoline engine

80 x 68 mm

341 cc

6.0 : 1

8.2 hp/4,000 r.p.m.

6 hp/3,400 r.p.m.

1.7 kg-m/2,600 r.p.m.

300 gr/hp-hr

85 x 70 mm

397 cc

6.0 : 1

10 hp/3,600 r.p.m.

7.5 hp/3,200 r.p.m.

2.2 kg-m/2,600 r.p.m.

300 gr/hp-hr

95 x 82 mm

581 cc

5.8 : 1

14 hp/3,600 r.p.m.

10.5 hp/3,200 r.p.m.

3.2 kg-m/2,400 r.p.m.

300 gr/hp-hr

Electronic ignition

GDI Transistor

Automatic spark advance

Splash Trochoid pump

Float type with idle mixture adjustment

Semi wet type with

washable pleated

felt element

Dry type with washable

polyurethan element

Semi wet type with

washable pleated

felt element

Mechanical flyweight type

6.5 £ 82 10.52

Cu-Cr cast iron shell molding

Aluminum alloy die-casting

Aluminum alloy shell

molding

Aluminum alloy die-casting

Ball bearings on each end of crankshaft and camshaft

I-beam aluminum alloy

I-beam, forged carbon

steel forging with plain

bearing

I-beam aluminum alloy

Low expansion aluminum alloy

Two compression rings and one oil ring

Two compression rings

and two oil rings

Heat-resisting forged steel. Stellite exhaust valve face

Sintered alloy

Cu-Cr cast iron

Heat resisting steel

Cu-Cr cast iron

Recoil starter (Electric starter is optional) Electric starter

C.C.W. viewed from P.T.O. side

40 kg 40 kg 67.5 kg

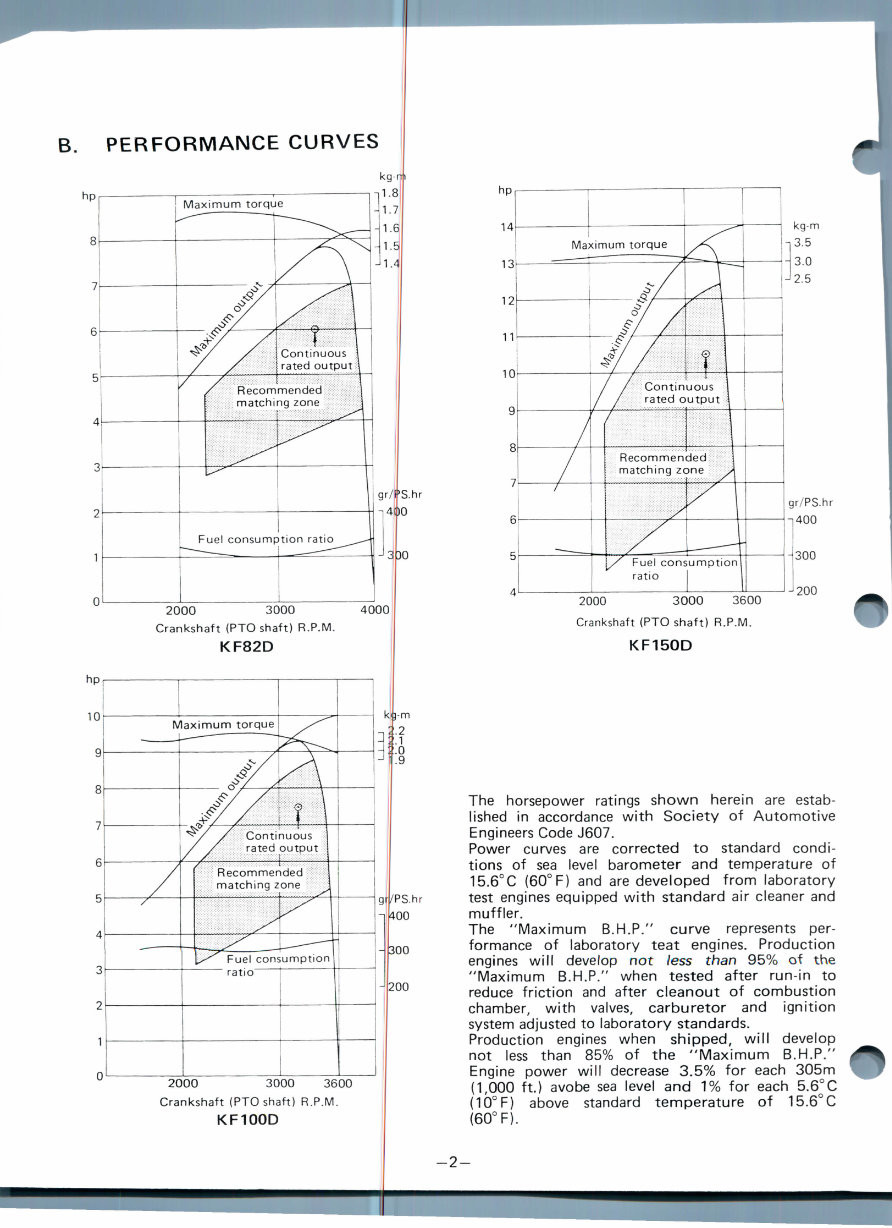

B. PERFORMANCE CURVES

Maximum torque

Continuous

rated output

Recommended

matching zone

Fuel consumption ratio

2000 3000

Crankshaft (PTO shaft) R.P.M.

KF82D

Maximum torque

Continuous

rated output

Recommended

matching zone

2000 3000 3600

Crankshaft (PTO shaft) R.P.M.

KF100D

Recommended

matching zone

gr/PS.hr

400

2000 3000 3600

Crankshaft (PTO shaft) R.P.M.

KF150D

The horsepower ratings shown herein are estab-

lished in accordance with Society of Automotive

Engineers Code J607.

Power curves are corrected to standard condi-

tions of sea level barometer and temperature of

15.6°C (60° F) and are developed from laboratory

test engines equipped with standard air cleaner and

muffler.

The "Maximum B.H.P." curve represents per-

formance of laboratory teat engines. Production

engines will develop not /ess than 95% of the

"Maximum B.H.P." when tested after run-in to

reduce friction and after cleanout of combustion

chamber, with valves, carburetor and ignition

system adjusted to laboratory standards.

Production engines when shipped, will develop

not less than 85% of the "Maximum B.H.P."

Engine power will decrease 3.5% for each 305m

(1,000 ft.) avobe sea level and 1% for each 5.6°C

(10°F) above standard temperature of 15.6°C

(60° F).

-2-

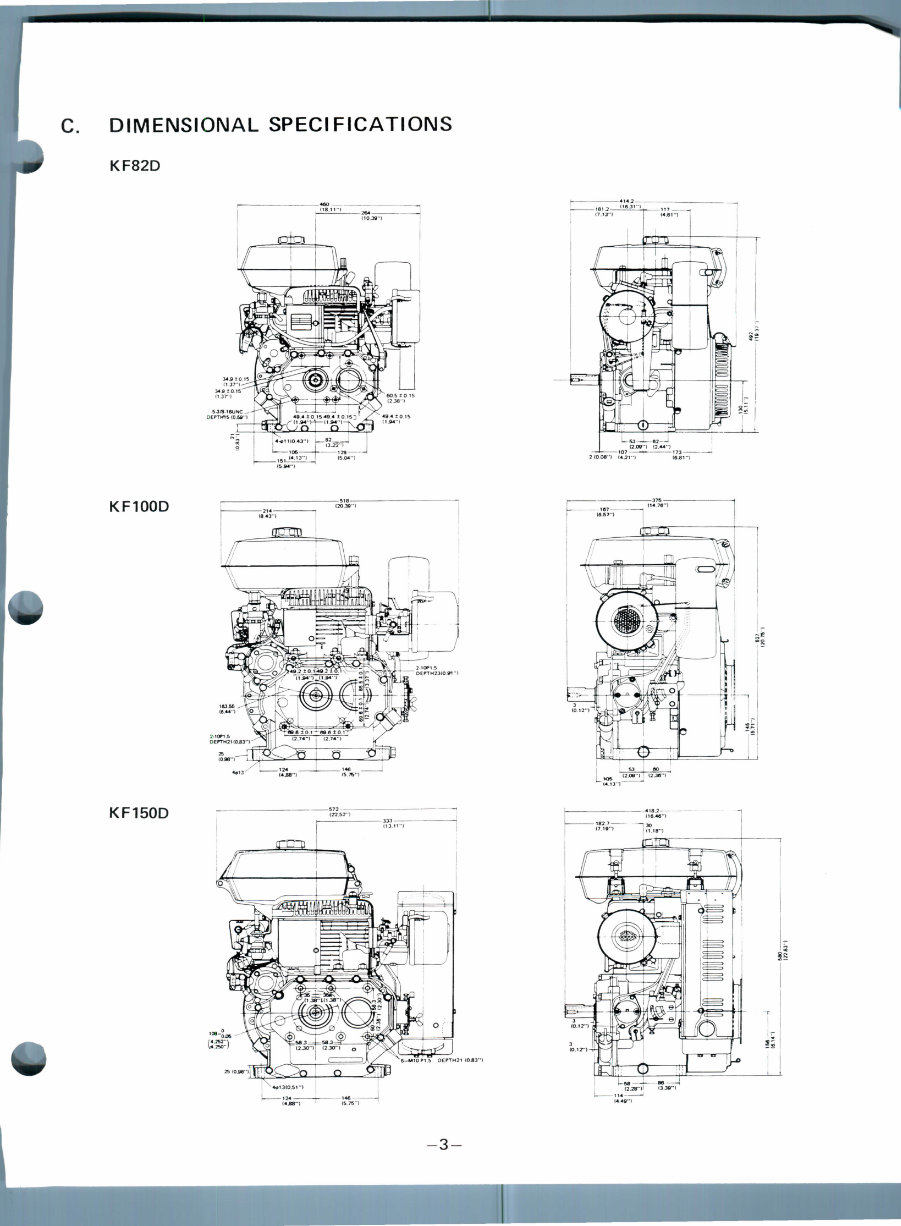

C. DIMENSIONAL SPECIFICATIONS

KF82D

KF100D

KF150D

-3-

D. OPERATION THEORY AND

ADJUSTMEI

1. CARBURETOR

1-1 Carburetor Theory of Operation

The carburetor functions to atomize the filiel

from fuel line and feeds it into the cylinder

as a combustible mixture.

This is a delicate functional component of high

accuracy and has the same operating principle

as a sprayer. (Fig. 001)

a MAIN SYSTEM

Fuel is caused to be mixed with intake air

the negative pressure in the venturi crea

during the intake stroke of piston, as showr

Fig. 001. In this venturi tube, the intake

has high velocity and low static pressi

by

ted

in

air

re,

which draws fuel out of the float chamber.

This fuel is atomized to fine particles by intake

air of high velocity, and is drawn into (the

cylinder as a combustible mixture.

Intake stroke of p

Carburetor

(Fig. 001)

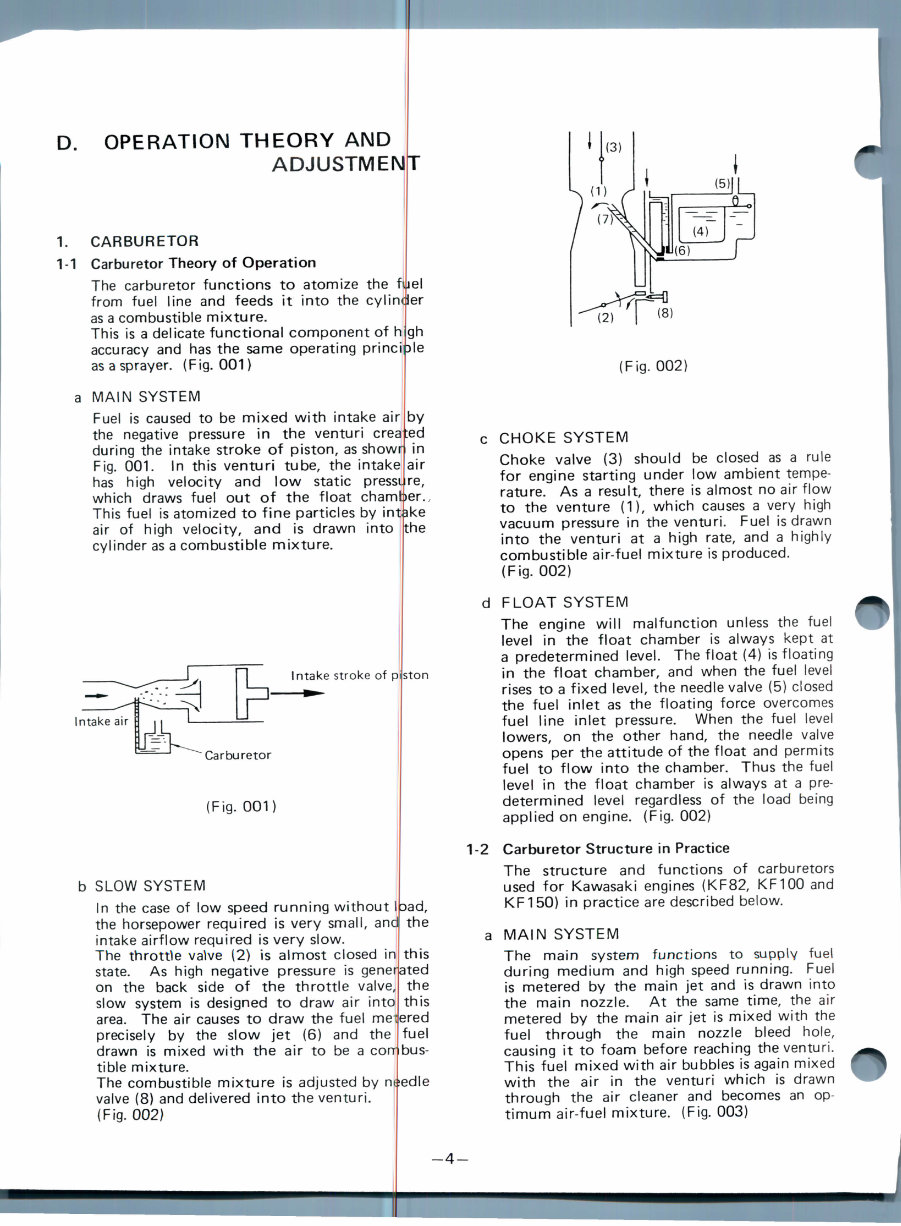

b SLOW SYSTEM

In the case of low speed running without

the horsepower required is very small, ani

intake airflow required is very slow.

The throttle vaWe (2) is almost closed in

ston

the

this

state. As high negative pressure is generated

on the back side of the throttle valve, the

slow system is designed to draw air into this

area. The air causes to draw the fuel melered

precisely by the slow jet (6) and the I fuel

drawn is mixed with the air to be a combus-

tible mixture.

The combustible mixture is adjusted by needle

valve (8) and delivered into the venturi.

(Fig. 002)

(Fig. 002)

c CHOKE SYSTEM

Choke valve (3) should be closed as a rule

for engine starting under low ambient tempe-

rature. As a result, there is almost no air flow

to the venture (1), which causes a very high

vacuum pressure in the venturi. Fuel is drawn

into the venturi at a high rate, and a highly

combustible air-fuel mixture is produced.

(Fig. 002)

d FLOAT SYSTEM

The engine will malfunction unless the fuel

level in the float chamber is always kept at

a predetermined level. The float (4) is floating

in the float chamber, and when the fuel level

rises to a fixed level, the needle valve (5) closed

the fuel inlet as the floating force overcomes

fuel line inlet pressure. When the fuel level

lowers, on the other hand, the needle valve

opens per the attitude of the float and permits

fuel to flow into the chamber. Thus the fuel

level in the float chamber is always at a pre-

determined level regardless of the load being

applied on engine. (Fig. 002)

1-2 Carburetor Structure in Practice

The structure and functions of carburetors

used for Kawasaki engines (KF82, KF100 and

KF150) in practice are described below.

a MAIN SYSTEM

The main system functions to supply fuel

during medium and high speed running. Fuel

is metered by the main jet and is drawn into

the main nozzle. At the same time, the air

metered by the main air jet is mixed with the

fuel through the main nozzle bleed hole,

causing it to foam before reaching the venturi.

This fuel mixed with air bubbles is again mixed

with the air in the venturi which is drawn

through the air cleaner and becomes an op-

timum air-fuel mixture. (Fig. 003)

-4-

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 51 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

The CLUB CAR GOLF CART KF82 FACTORY SERVICE REPAIR MANUAL is a comprehensive guide specifically designed for maintaining and repairing Kawasaki KF82, KF100, and KF150 engines. This manual offers detailed instructions for dismantling and fixing major components, accompanied by a wealth of illustrations and photos to facilitate easy comprehension. Whether you're a professional mechanic or a DIY enthusiast, this manual is an invaluable resource for all your repair needs.

Accessing this manual is quick and convenient, providing you with the essential information you need. You can securely complete your purchase using our trusted server, which accepts both credit card and PayPal payments.