1988-2000 XR600R Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

1988-2000

XRSOOR

..

OJ GENERAL INFORMATION

GENERAL SAFETY

SERVICE RULES

MODEL IDENTIFI CAT ION

SPECIFICATIONS

GENERAL SAFETY

, II

, -,

, -,

' -2

' -3

If, hr rngin, mllst be r"""ing to do some .... ork, make slIn ' Ir e

(I na is "'ell·~"t;laud. Never ru n tir e engine in an encloud

a na. Tire exlraust contains poisonous carbon monoxide gas

tlltl! ell" CIHI5e loss ofconsciousnns and may lead todeat h.

Inhaled asbestos Jibers hQI'I! been found to cause rupiratory

disease and concer.

Never use an air hose or dry brush 10 clean breake or clutch as-

sembliu.

SERVICE RULES

TORQUE VALUES

TOOLS

CAB LE & HARNESS ROUTING

' -5

' -7

' -9

Gasoline is ex t nmdy j1llmmable (llld is uplosire " nder u-

rtoi" conditions. Do not smoke or allow flamu or sparks in

the "'Ork ana or "'he" gasoline is stored.

• Use genuine HONDA or HONDA-recommended parts and lubricants or their equivalents. Parts that do not meet HONDA 's

design specifications may damage the motorcycle .

• Use the special tools designed for this product .

• Install new gaskets , O-rings, cotter pins. lock plates, etc. when reassembling.

• When torquing a series of bolts or nuts , begin with the larger-diameter or inner bolts first, and tighten to the specified

torque diagonally, unless a particular sequence is specified.

• Clean parts in non -flammable or high flash point solvent upon disassembly. lubricate any sliding surfaces before re-

assembly.

• After reassembly, check all parts for proper installation and operation.

• Use only metric tools when servicing this motorcycle. Metric bolts, nuts. and screws are not inte rchangeable with English

fasteners. The use of incorrect tools and fa$teners may damage the motorcycle.

• Route all electrical wires as shown on pages 1-9 through 1-12, Cable and Harness Routing, and away from sharp edges

and areas where they might be pinched between moving parts.

1-1

GENERAL INFORMATION

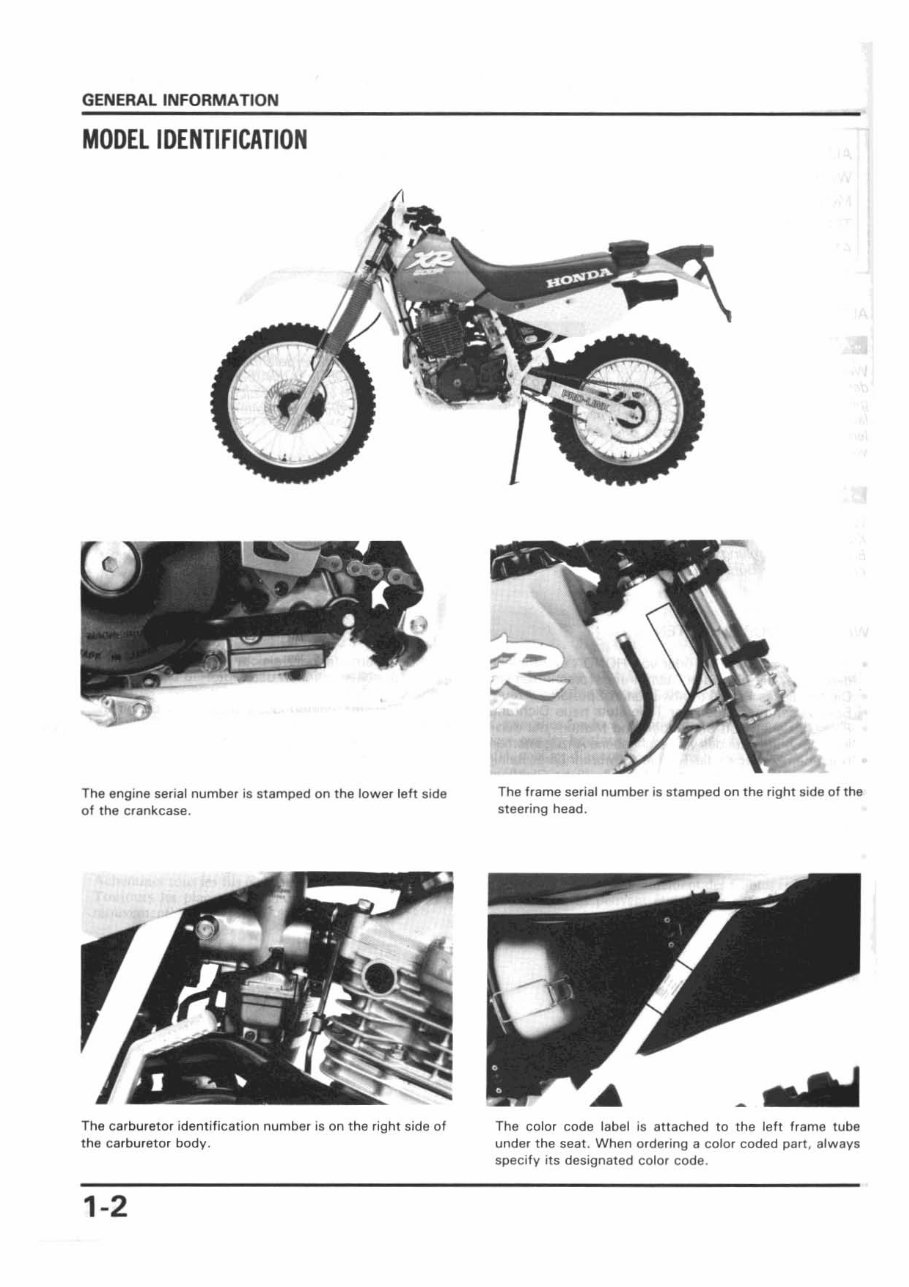

MODEl IDENTIFICATION

The engine serial number is stamped on the lower left side

of the crankcase.

The ca rburetor identifi cation number is on the right side of

the carbu r etor body.

1-2

The frame serial number is stamped on the right side of the

steering head.

The color code label is attached to the left frame tube

under the seat. When ordering a color coded part, always

specify its designated color code.

GENERAL INFORMATION

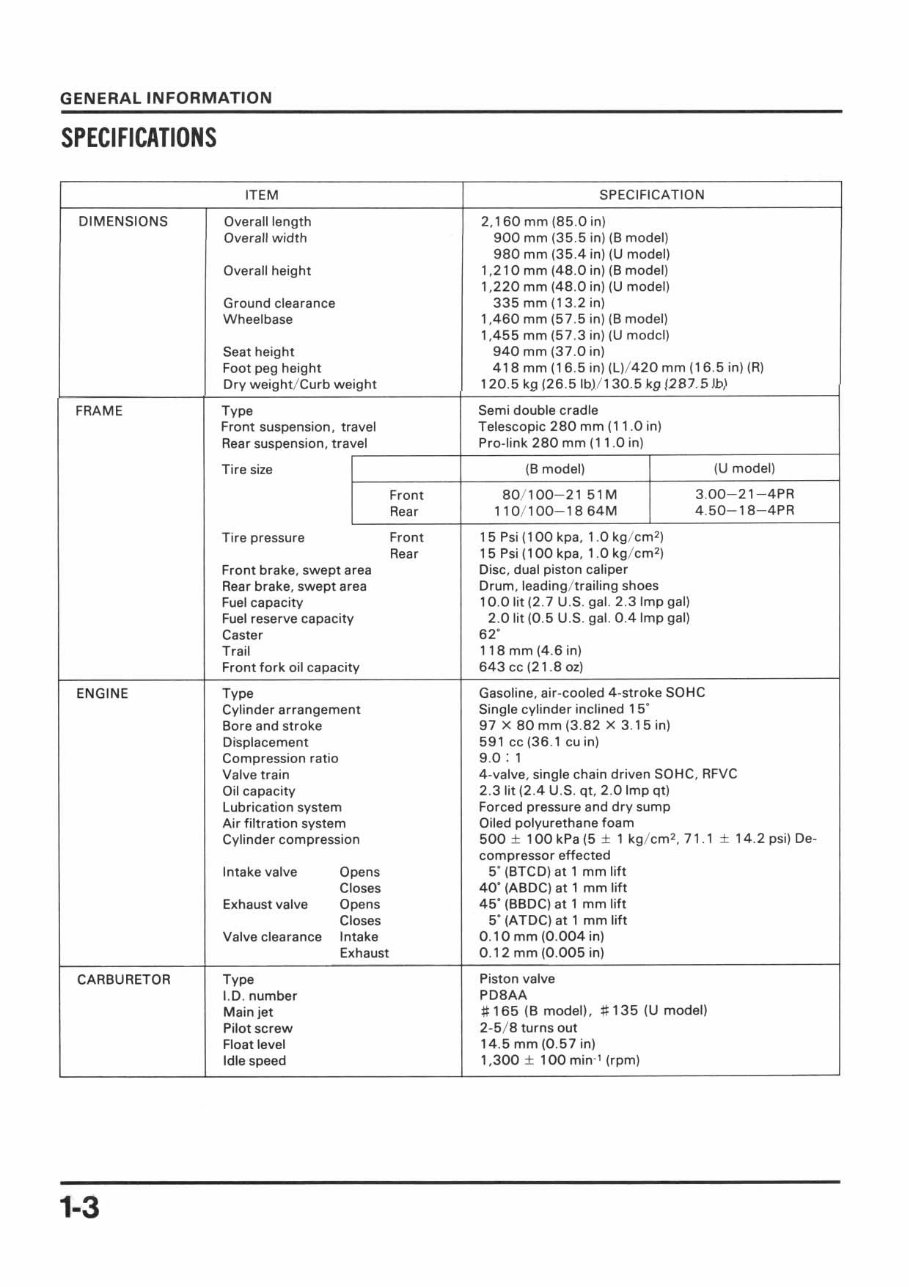

SPECIFICATIONS

ITEM SPECIFICATION

DIMENSIONS Overall length 2,160 mm (85.0 in)

Overall width 900 mm (35 .5 in) (8 model)

980 mm (35 .4 in) (U model)

Overall height 1.210 mm (48 .0 in) (8 model )

1,220 mm (48 .0 in) (U model)

Ground clearance 335 mm ( 13 .2 in)

Wheelbase 1,460 mm ( 57 .5 in ) (8 model)

1,455 mm (57 .3 in) (U model)

Seat height 940 mm (37.0 in)

Foot peg height 418 mm (16 .5 in) (l) / 420 mm (16 .5 in) (R)

Dry weight / Curb weight 120.5 kg (26 . 5Ib)/ 130. 5kg 1 287 .S Jb)

FRAME Type Semi double cradle

Front suspension. travel Telescopic 280 mm 11 ' .0 in)

Rear suspension, travel Pro-link 280 mm ( 11 .0 in)

Tire size (8 model) (U model )

Front 80/ 100- 215IM 3. 00 - 21-4PR

Rear '10/ 10Q- 1864M 4.50 - 18- 4PR

Tire pressure Front 15 Psi ( 1 00 kpa, 1.0 kg /cm

2

)

Rear 15 Psi ( 1 00 kpa, 1.0 kg/ cm

2

)

Front brake , swept area Disc, dual piston caliper

Rear brake, swept area Drum , leading/ trailing shoes

Fuel capacity 10 .0 l it (2 .7 U.S. gal. 2.3 Imp gal)

Fuel reserve capacity 2.0 lit (0.5 U.S. gal. 0.4 Imp gal)

Caster 62'

Trail 118 mm (4 .6 in)

Front fork oil capacity 643 cc (2 1.8 oz)

ENGINE Type Gasoline, air -cooled 4-stroke SOHC

Cylinder arrangement Single cylinder inclined 15"

Bore and stroke 97 x 80mm(3 .B2 x 3. 15in)

Displacement 591 cc (36 .1 cu in)

Compression ratio 9. 0: 1

Valve train 4-valve, single chain driven SOHC, RFVC

Oil capacity 2.31it (2.4 U.S. qt, 2.0 Imp qt)

Lubrication system Forced pressure and dry sump

Air filtration system Oiled polyurethane foam

Cylinder compression 500 ± 100 kPa (5 ± 1 kg/ cm 2, 71 .1 ± 14 .2 psi) De-

compressor effected

Intake valve Opens 5" (BTCD) at 1 mm lift

Closes 40" (ABDC) at 1 mm lift

E)(haust valve Opens 45 " (BBD C) at 1 mm lift

Closes 5" (ATDC) at 1 mm lift

Valve clearance Intake 0. 10 mm (0 . 004 in)

E)(haust 0. 12 mm (0 . 005 in)

CARBURETOR Type Piston valve

1.0 . number PD8AA

Main jet ;I: 165 (B model), ;I: 135 (U model)

Pilot screw 2-5/ 8 turns out

Float level 14.5 mm (0.57 in)

Idle speed 1, 300 ± 100 min ·

1

(rpm )

1-3

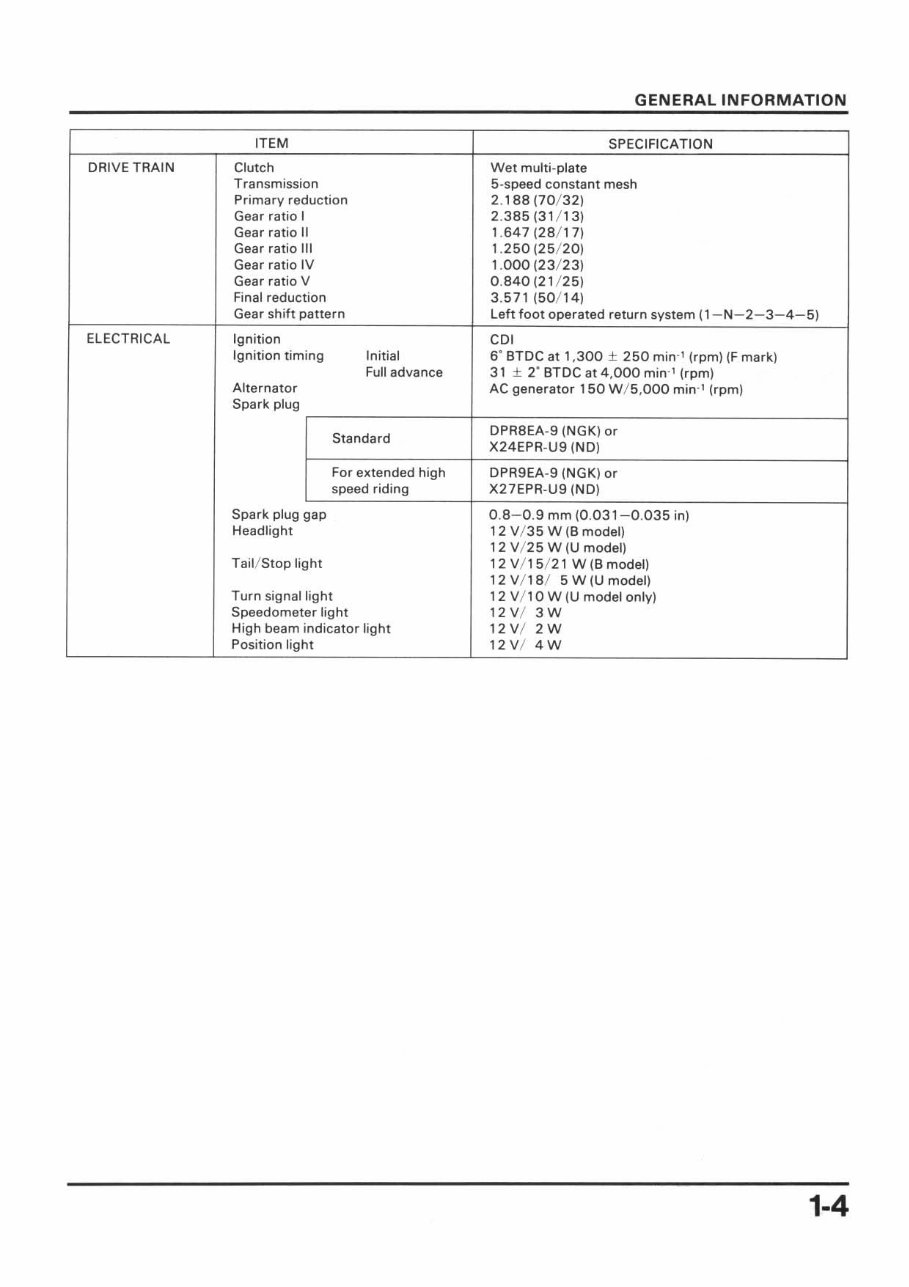

GENERAL INFORMATION

ITEM SPECI FI CATION

DRIVE TRAIN Clutch Wet multi -plate

Transmission 5-speed constant mesh

Primary reduction 2. 188 (70 / 32)

Gear ratio I 2.385(31 / 13)

Gear ratio II 1.647 (28/1 7)

Gear ratio III 1. 250 (25/20)

Gear ratio IV 1.000 (23 / 23)

Gear ratio V 0. 840 (21 / 25)

Final redu ction 3.571 ( 50/ 14)

Gear shift pattern Left foot operated return system (1-N-2-3-4-5)

ELECTRICAL Ignition CDI

Ig nition tim ing Initial 6' BTDC at 1, 300 ± 250 min -' (rpm) (F mark)

Full advance 31 ± 2' BTDC at 4,000 min " (rpm)

Alternator AC generator 150 W / S,OOO min " (rpm)

Spark plug

Standard

DPR8EA-9 (NGK) or

X24EPR- U9 (ND)

For extended high DPR9EA-9 (NGK) or

speed riding X27EPR- U9 (NO)

Spark plug gap 0.8- 0.9 mm (0.031-0.035 in)

Headlight 12 V/ 35 W (8 model)

12 V/ 25 W (U model)

Tai l/ Stop light 12 V/ 15/ 21 W (8 model)

12V/ 18/ 5W(U model )

Turn signal light 12 V/ 1 0 W (U model only)

Speedometer light 12 V/ 3 W

High beam indicator light 12 V/ 2 W

Position light 12 VI 4W

1-4

I

I

GENERAL INFORMATI ON

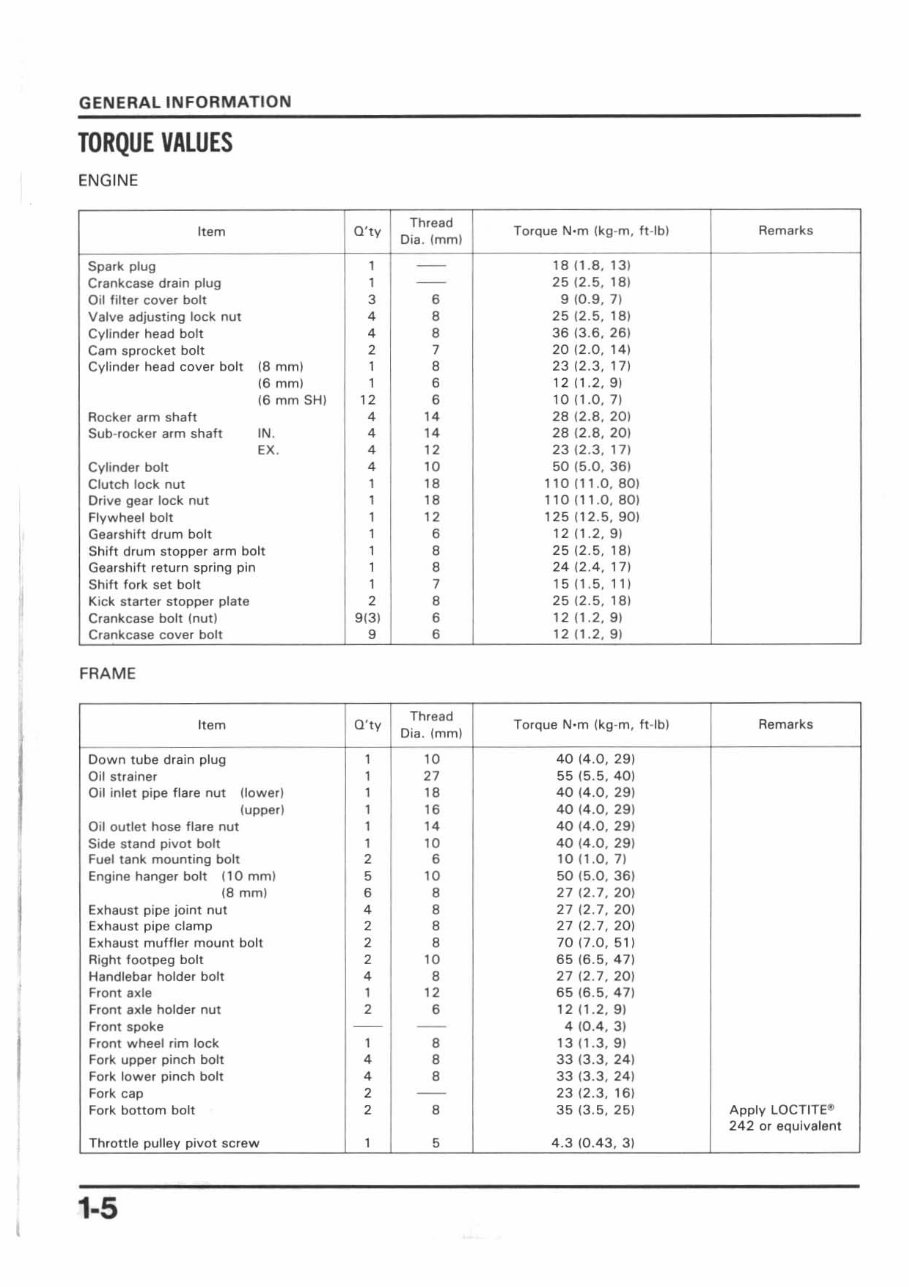

TORQUE VALUES

ENGINE

Item

Spark plug

Crankcase drain plug

Oil filter cover bolt

Valve adjusting lock nut

Cylinder head bolt

Cam sprocket bolt

Cylinder head cover bolt (8 mm)

(6 mm)

(6 rnm SHI

Rocker arm shaft

Sub-rocker arm shaft IN .

EX .

Cylinder bolt

Clutch lock nut

Drive gear lock nut

Flywheel bolt

Gearshi ft drum bolt

Shift drum stopper arm bolt

Gearshift return spring pin

Shift fork set bolt

Kick starter stopper plate

Crankcase bolt (nut)

Crankcase cover bolt

FRAME

I tem

Down tube drain plug

Oil strainer

Oil inlet pipe flare nut (lower )

t upper )

Oil o utlet hose flare nut

Side stand pi vot bolt

Fuel tank mounting bolt

Engine hanger bolt (10 mm)

(Smml

Exhaust pipe joint nut

Exhaust pipe clamp

Exhaust muffler mount bolt

Right footpeg bolt

Handlebar holder bolt

Front axle

Front axle holder nut

Fr ont spoke

Front wheel rim lock

Fork upper pinch bolt

Fork lower pinch bolt

Fork cap

Fork bottom bolt

Throttle pulley pivot screw

1-5

a'ty

Thread

Torque N·m Ikg-m. ft - lbJ Remarks

Oia. (mm)

1 -- 18 ( 1.8 , 13)

1 -- 25 (2.5, 18 )

3 6 9 (0 .9, 7)

•

8 25 (2.5, 18)

•

8 36 (3.6, 26)

2 7 20 (2.0, 14)

1 8 23 (2.3, 17)

1 6 12 (1.2, 9)

12 6 10 (1.0, 7)

•

"

28 (2.8, 20)

•

1. 28 (2.8 , 20)

•

12 23 (2.3, 17)

•

10 50 (5.0, 36)

1 18 110 n 1.0, 80 )

1 18 110 (11.0, 80 )

1 12 125 02.5,90)

1 6 12 (1.2, 91

1 8 25 (2.5,18)

1 8 24 (2.4, 171

1 7 150.5,11'

2 8 25 (2. 5, 1S)

9(3 ) 6 12 (1.2 , 9)

9 6 12/1.2 , 9)

O'ty

Thread

Torque N·m (kg·m, ft · lb) Remarks

Dia. (mm)

1 10 40 (4 .0, 29)

1 27 55 (5.5, 40 )

1 18 40 (4 .0 , 29)

1 16 40 (4.0, 29)

1

,.

40 (4 .0 ,2 9)

1 10 40 (4 .0 , 29)

2 6 10 ( 1.0, 7)

5 10 50 (5.0, 36)

6 8 27 (2.7, 20 )

•

8 27 (2.7, 20)

2 8 27 (2.7, 20)

2 8 70 (7.0, 51)

2 10 65 (6.5, 47)

•

8 27/2 .7, 20)

1 12 65 (6.5, 47)

2 6 12(1.2,9)

-- -- 4 (0.4, 3)

1 8 13 (1.3,9)

•

8 33 (3.3 , 24)

•

8 33 (3.3, 24)

2 -- 23 /2.3, 16)

2 8 35/3.5, 25) Apply lOCTITEe

242 or equivalent

1 5 4.3 10.43, 31

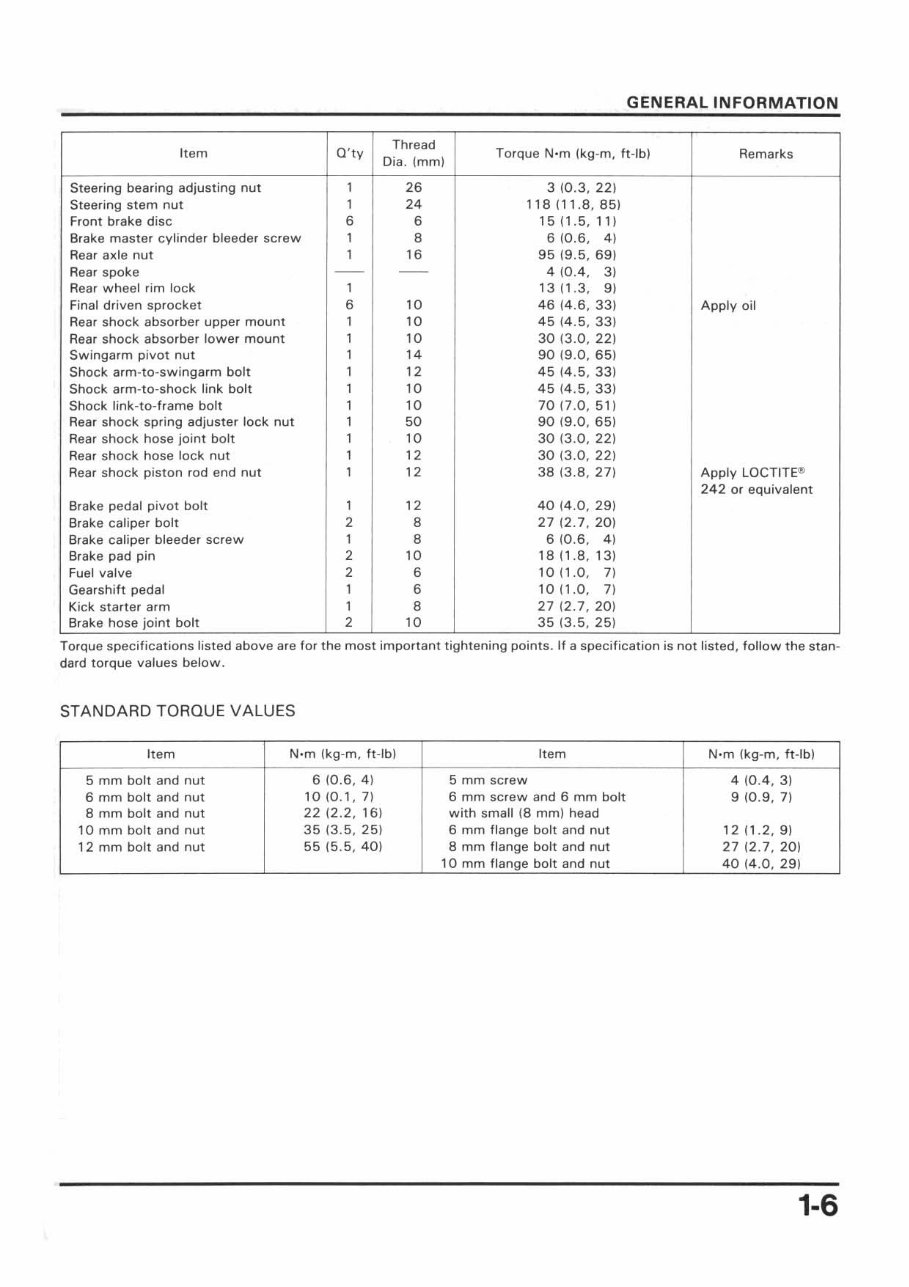

GENERAL INFORMATION

Item Q'ty

Thread

Torque N'm Ikg-m, ft -rb) Remarks

Dia. (m m)

Steering bearing adjusting nut 1 26 3 (0.3, 22\

Steering stem nut 1 24 118 (".8. 85)

Front brake disc 6 6 lS ( l.S,l1f

Brake master cylinder bleeder screw 1 8 6 (0.6, 41

Rear axle nut 1 16 95 (9.5, 69)

Rear spoke -- -- 4 (0.4, 31

Rear wheel rim lock 1 13 (1.3, 91

Final driven sprocket 6 10 46 (4.6, 33 ) Apply oil

Rear shock absorber upper mount 1 10 45 14.5, 331

Rear shock absorber lower mount 1 10 30 (3.0, 22)

Swingarm pivot nut 1 14 90 (9.0, 65)

Shock arm-to-swingarm bolt 1 12 4514.5, 33)

Shock arm-lo -shock link bolt 1 10 45 (4 .5, 33)

Shock link-la-frame bolt 1 10 70(7.0,51)

Rear shock spring adjuster lock nut 1 50 90 (9.0, 65)

Rear s hock hose joint bolt 1 10 30 (3.0, 22)

Rear shock hose lock nut 1 12 30 (3.0, 22)

Rear shock piston rod end nut 1 12 38 (3.8, 27) Apply LOCTITE®

242 or equivalent

Brake pedal pivot bolt 1 12 40 (4.0, 29)

Brake caliper bolt 2 8 27 (2.7, 20)

Brake caliper bleeder screw 1 8 6 (0.6, 41

Brake pad pin 2 10 18 (1.8, 13)

Fuel valve 2 6 10 ( 1.0, 71

Gearshift pedal 1 6 10 (1.0, 71

Kick starter arm 1 8 27 (2.7, 20)

Brake hose joint bolt 2 10 35 (3.5, 25)

Torque specifications listed above are for the most Important tightening POintS. If a specification IS not hsted, follow the stan-

dard torque values below.

STANDARD TORQUE VALUES

Item N·m (kg-m. ft-Ib) Item N·m ( kg -m, ft-Ib)

5 mm bolt and nut 6 (0.6, 4) 5 mm screw 4 (O A, 3)

6 mm bolt and nut 10(0.1,7) 6 mm screw and 6 mm bolt 9 (0.9, 7)

8 mm bolt and nut 22 (2.2, 16) with small (8 mm) head

10 mm bolt and nut 35 (3.5, 25) 6 mm flange bolt and nut 12 (1.2, 9)

, 2 mm bolt and nut 55 (5.5, 40 ) 8 mm flange bolt and nut 27 (2.7, 20)

, ° mm flange bolt and nut 40 (4.0, 29)

1-6

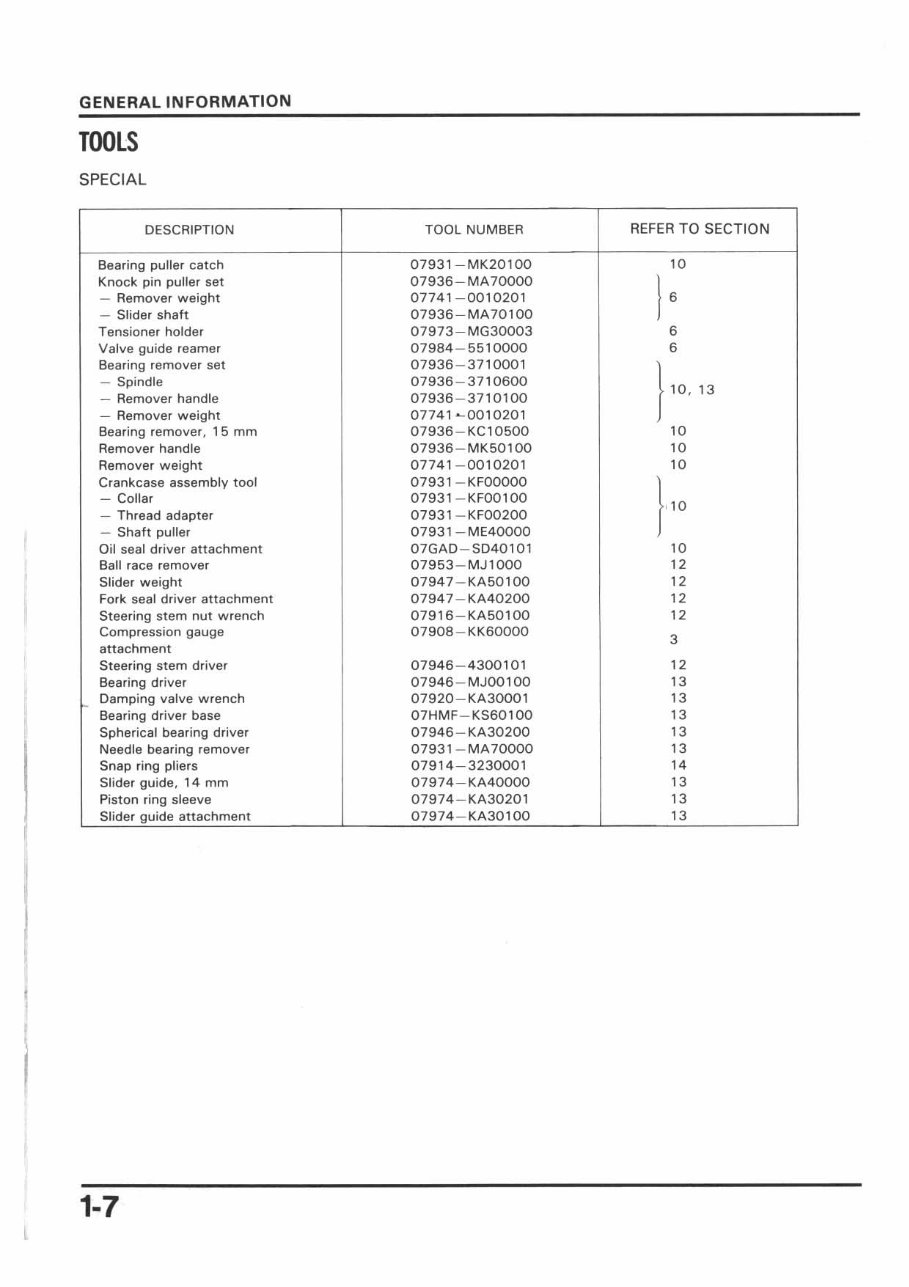

GENERAL INFORMATION

TOOLS

SPECIAL

DESCRIPTION TOOL NUMBER REFER TO SECTION

Bearing puller catch 07931-MK20100 10

Knock pin puller set 07936 - MA70DOO

)6

- Remover weight 07741 - 0010201

- Slider shaft 07936- MA 70100

Tensioner holder 07973-MG30003 6

Valve guide reamer 07984 - 5510000 6

Bearing remover set 07936 - 3710001

} 10 ,

- Spindle 07936 - 3710600

13

- Remover handle 07936 - 3710100

- Remover weight 07741 .... 0010201

Bearing remover. 1 5 mm D7936 - KC1D500 10

Remover handle 07936 - MK50100 10

Remover weight 07741 - 0010201 10

Crankcase assembly tool 07931 - KFOOOOO

}10

- Collar 07931 - KFOO100

- Thread adapter 07931 - KFOO200

- Shaft puller 07931 - ME40000

Oil seal driver attachment 07GAD - SD40101 10

Ball race remover 07953 - MJ1000 12

Slider weight 07947 - KA50100 12

Fo rk seal driver attachment 07947 - KA40200 12

Steering stem nut wrench 07916 - KA50100 12

Compression gauge 07908 - KK60000

3

attachment

Steering stem driver 07946 - 4300101 12

Bearing driver 07946 - MJ00100 13

Damping valve wrench 07920 - KA30001 13

Bea ring driver base 07HMF - KS60100 13

Spherical bearing driver 07946 - KA30200 13

Needle bea ring remover 07931 - MA70000 13

Snap ring pliers 07914 - 3230001 I.

Slider guide, 14 mm 07974 - KA40000 13

Piston ring sleeve 07974-KA30201 13

Slider guide attachment 07974 - KA30100 13

1-7

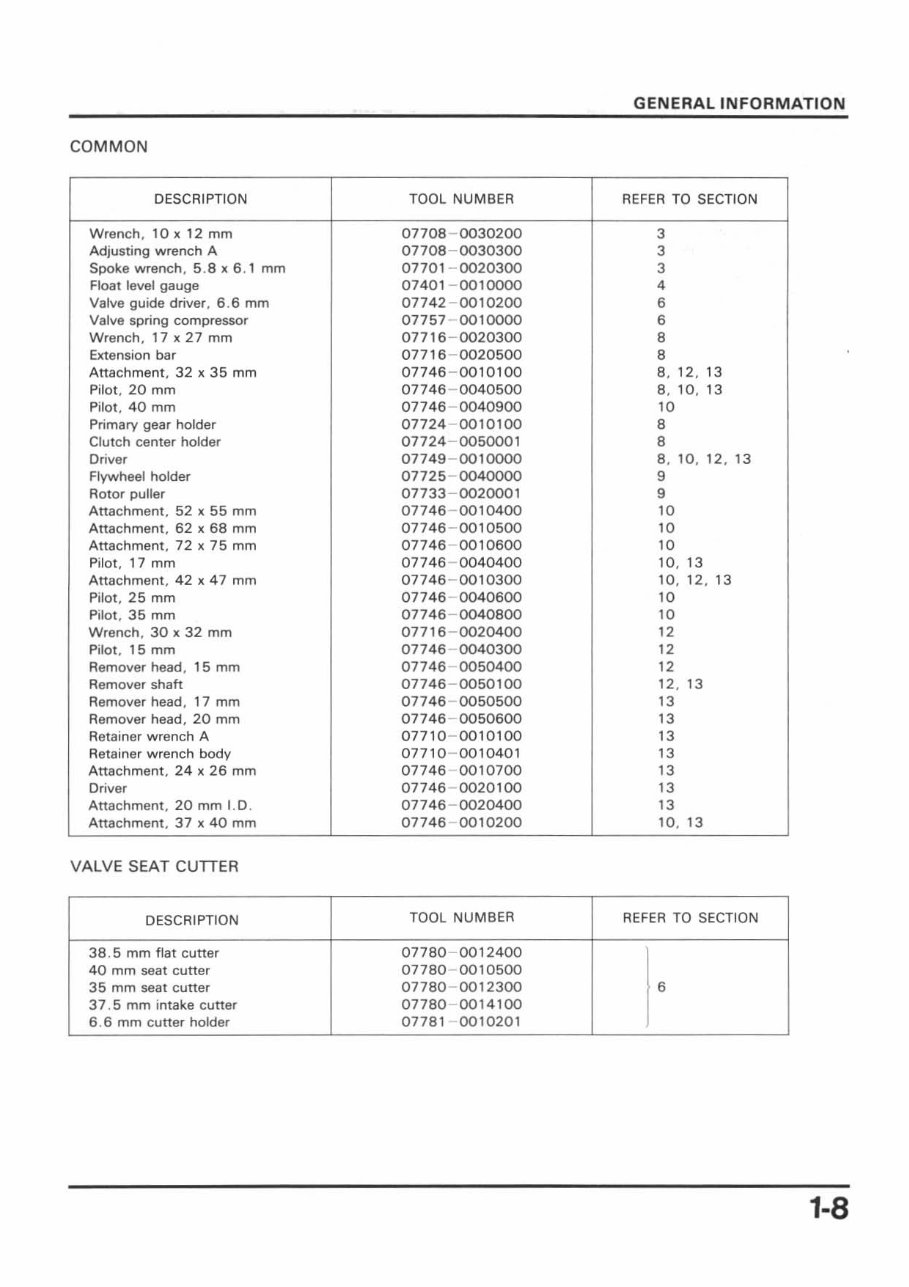

COMMON

DESCRIPTION

Wrench, 10 x 12 mm

Adjusting wrench A

Spoke wrench , 5.8 x 6.1 mm

Float level gauge

Valve guide driver , 6 .6 mm

Valve spring compressor

Wrench, 17 x 27 mm

Extension bar

Attachment, 32 x 35 mm

Pilot, 20 mm

Pilot, 40 mm

Primary gear holder

Clutch center holder

Driver

Flywheel holder

Rotor puller

Attachment , 52 x 55 mm

Attachment, 62 x 68 mm

Attachment, 72 x 75 mm

Pilot, 17 mm

Attachment, 42 x 47 mm

Pilot , 25 mm

Pilot, 35 mm

Wrench , 30 x 32 mm

Pilot , 15 mm

Remover head, 1 5 mm

Remover shah

Remover head, 1 7 mm

Remover head. 20 mm

Retainer wrench A

Retainer wrench body

Attachment, 24 x 26 mm

Driver

Attachment , 20 mm I.D .

Attachment , 37 x 40 mm

VALVE SEAT CUTTER

DESCRIPTION

38 .5 mm flat cutter

40 mm seat cutter

35 mm seat cutter

37 .5 mm intake cutter

6 .6 mm cutter holder

TOOL NUMBER

07708 - 0030200

07708 - 0030300

07701 - 0020300

07401 - 0010000

07742 - 0010200

07757 - 0010000

07716 - 0020300

07716 - 0020500

07746 - 0010100

07746 - 0040500

07746 - 0040900

07724 0010100

07724 - 0050001

07749 - 0010000

07725 - 0040000

07733 - 0020001

07746 - 0010400

07746 - 0010500

07746 0010600

07746 - 0040400

07746 - 0010300

07746 - 0040600

07746 - 0040800

07716 - 0020400

07746 - 0040300

07746 - 0050400

07746 - 0050100

07746 - 0050500

07746 - 0050600

07710 - 00 10100

07710 - 0010401

07746 0010700

07746 - 0020100

07746 - 0020400

07746 - 0010200

TOOL NUM8ER

07780 - 0012400

07780 0010500

07780 - 0012300

07780 - 0014100

07781 0010201

GENERAL INFORMATION

REFER TO SECTION

3

3

3

4

6

6

8

8

8, 12 , 13

8, 10,13

10

8

8

8, 10 , 12 , 13

9

9

10

10

10

10, 13

10, 12, 13

10

10

12

12

12

12 , 13

13

13

13

13

13

13

13

10 , 13

REFER TO SECTION

I 6

1-8

GENERAL INFORMATION

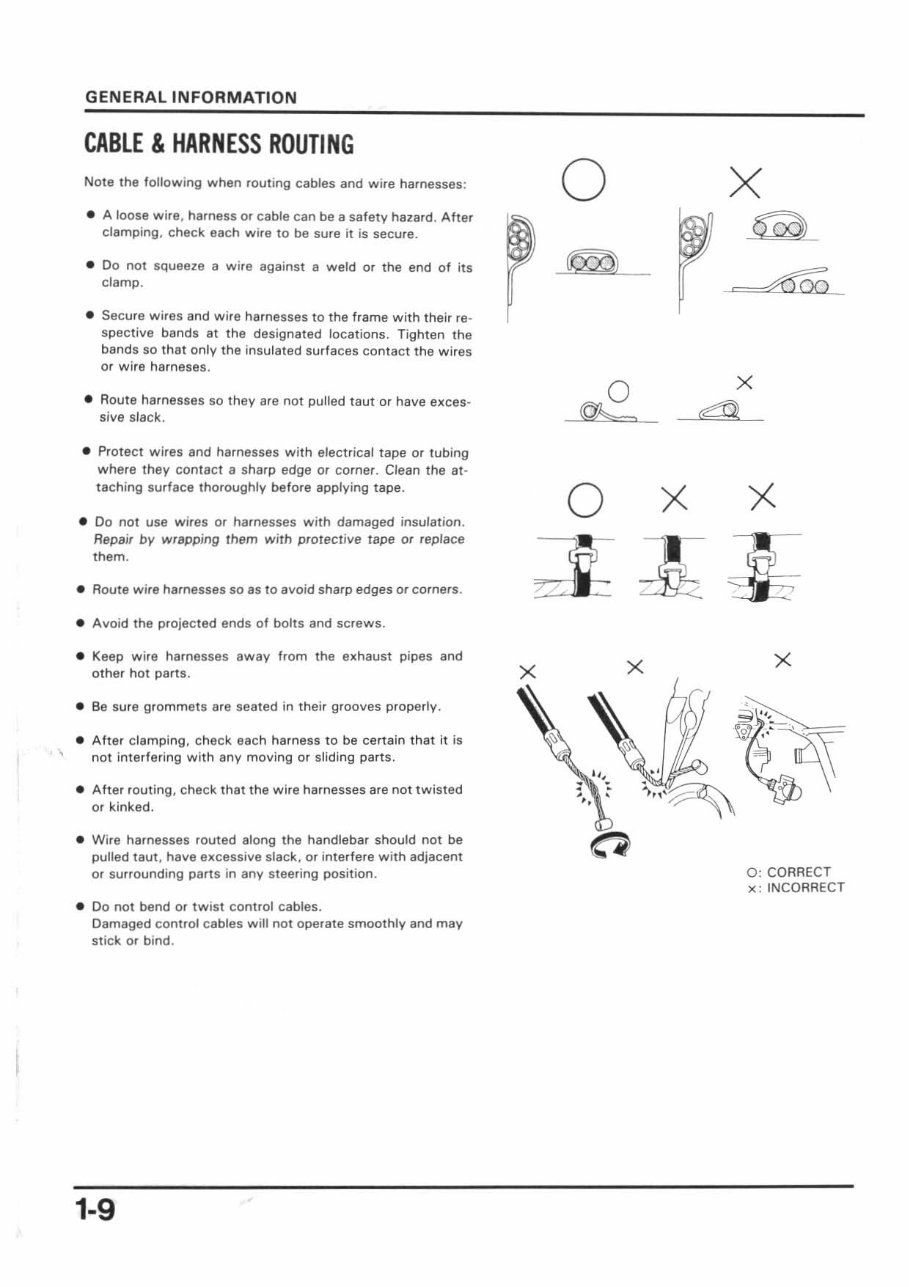

CABLE & HARNESS ROUTING

Note the following when routing cables and wire harnesses:

• A loose wire , harness or cable can be a safety hazard. Ahar

clamping , check each wire to be sure it is secure.

• Do not squeeze 8 wire against a weld or the end of its

clamp .

• Secure wires and wire harnesses to the frame with their re-

spective bands 8t the designated locations. Tighten the

bands so that only the insulated surfaces contact the wires

or wife harneses.

• Route harnesses so they Bre not pulled taut or have exces-

sive slack.

• Protect wires and harnesses with electrical tape or tubing

where they contact a sharp edge or corner. Clean the at-

taching surface thoroughly before applying tape.

• Do not use wires or harnesses with damaged insulation.

Repair by wrapping them with protective tape or replace

them.

• Route wire harnesses so as to avoid sharp edges or corners.

• Avoid the projected ends of bolts and screws .

• Keep wire harnesses away from the exhaust pipes and

other hot parts .

• Be sure grommets are seated in their grooves properly.

• After clamping. check each harness to be certain that it is

not interfering with any moving or sliding parts.

• After routing. check that the wire harnesses are not twisted

or kinked.

• Wire harnesses routed along the handlebar should not be

pulled taut , have excessive slack, or interfere with adjacent

or surrounding parts in any steering position .

• Do not bend or twist control cables.

Damaged control cables will not operate smoothly and may

sti ck or bind.

1-9

o

x

x

x

~

x

0: CORRECT

x: INCORRECT

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 57 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

This is a comprehensive service manual for the 1988-2000 Honda XR600R four-stroke bike. It covers complete tear down and rebuild, including pictures and part diagrams, torque specs, maintenance, troubleshooting, and more. With 258 pages, it provides all the information you need for repairs and maintenance.

Featuring clickable chapters and a searchable interface, this manual allows for easy navigation to find the information you require. There are no restrictions on printing or saving/burning to disc, making it convenient for both professional mechanics and DIY enthusiasts.