1991-1996 XR250L Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

L-~

--

- -~~

91·96

XR250L

•

Important Safety Notice

Indicates a stlOng possibi li ty of severe personal injury Of death if instructions are no t followed .

CAUTION : Indicates a possibility of equ i pment damage if instructions 8re not followed .

NOTE Gives helpful information .

Detailed descriptIons of standard workshop procedures. safety principles and saNiee operations are not included. It

is important to note that this manual contains some warnings and cautions against some specific service methods

which could cause PEASONAllNJURY to service personnel or could damage a vehicle or re nder it unsafe Please

understand that those warnings could not cover all conceivable ways In which service, whether or not recommended

by Honda, might be done or of the possibly hazardous consequences of each conceivable way , nor could Honda

investigate aU such ways . Anyone using service procedures or tools, whether or not recommended by Honda, must

slJtlsly himself thoroughly that neither personal safety no r vehicle safety will be jeopardized by the service methods

or tools selected .

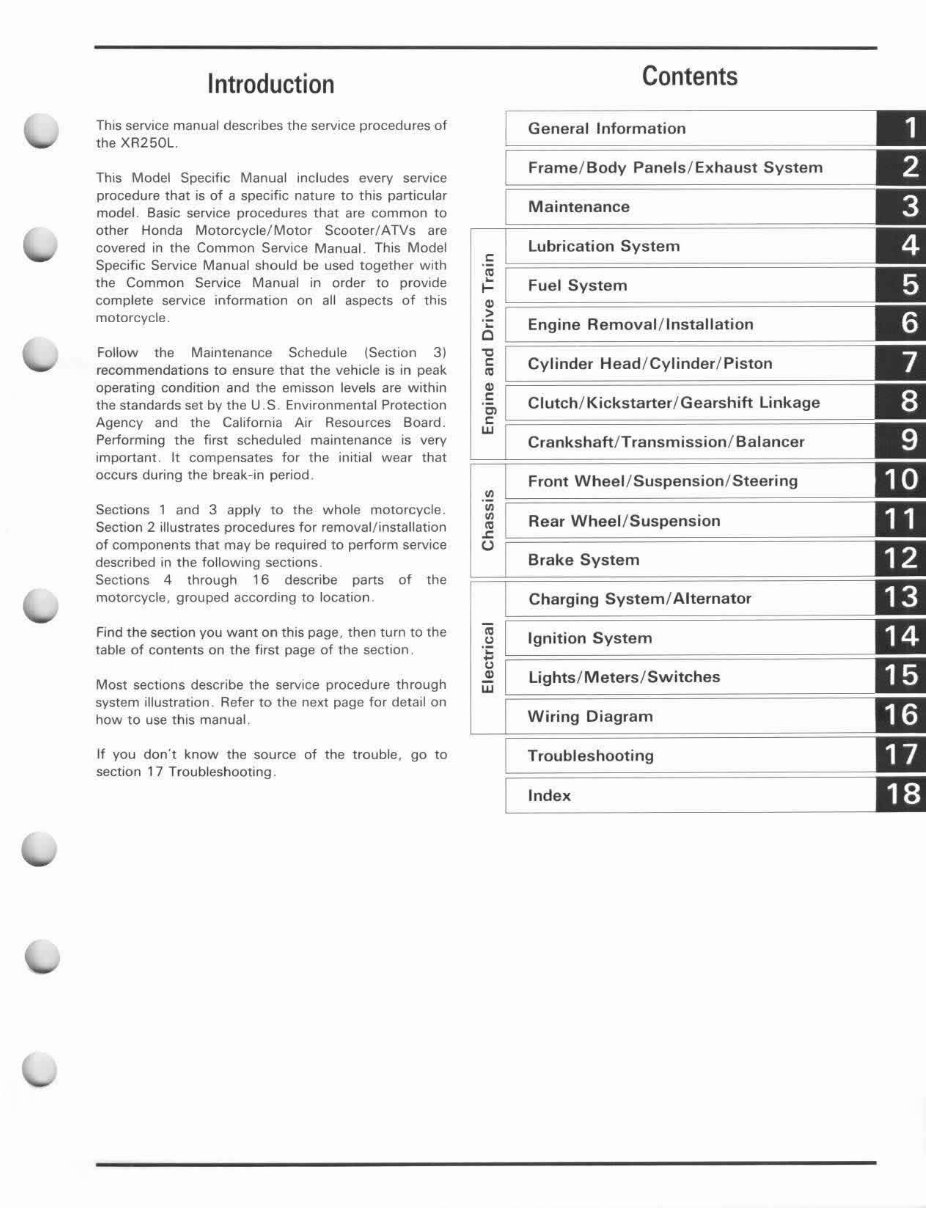

Introduction

This service manual describes the service procedures of

the XR250L.

This Model Specific Manual includes every service

procedure that is of a specific nature to this particular

model. Basic service procedures that are common to

other Honda Motorcycle/Motor Scooter/ATVs are

covered in the Common Service Manual. This Model

Specific Service Manual should be used together With

the Common Service Ma nual in order to provide

comp lete service information on all aspects of this

motorcycle.

Follow the Maintenance Schedule (Section 3)

recommendations to ensure that the vehicle is in peak

operating condition and the emisson levels are Within

the standards set by the U.S. Environmental Protection

Agency and the California Air Resources Board.

Perfo rming the first scheduled maintenance is very

Important . It compensates for the initial wea r that

occurs du ring the break-in period.

Sections 1 and 3 apply to the whole motorcycle.

Section 2 illustrates procedures for removal/ installation

of components that may be required to perform service

described in the following sections .

Sections 4 through 16 describe parts of the

motorcycle, grouped according to location .

Find the section you want on thiS page, then turn to the

table of contents on the first page of the section .

Most sections describe the service procedure through

system illustration. Refer to the next page f or det ail on

how to use t h iS manual.

If you don "t know the source of the trouble , go to

section 17 Tr ou b leshooti ng .

o

•

.::

~

."

o

"tl

o

•

~

Contents

General Information

Frame / Body Panels/ Ex haust Sy stem

Mainten a nce

Lubrica tion Sy ste m

Fuel System

Engine Remova l/In stal l ation

Cy lind er Head/ Cylinder / Pi ston

c: Clutch / Kickstarter / Gearshift Linkage

Jf ~=====================================

Crankshaft / Transmi ss ion / Balan ce r

Front Wheel / Suspension / Steering

Rear Wheel / Suspension

Brake System

Charging System / Altern ator

Ignition System

Light s/ Meters / Switches

Wiring Di agram

Trouble s hooting

Ind ex

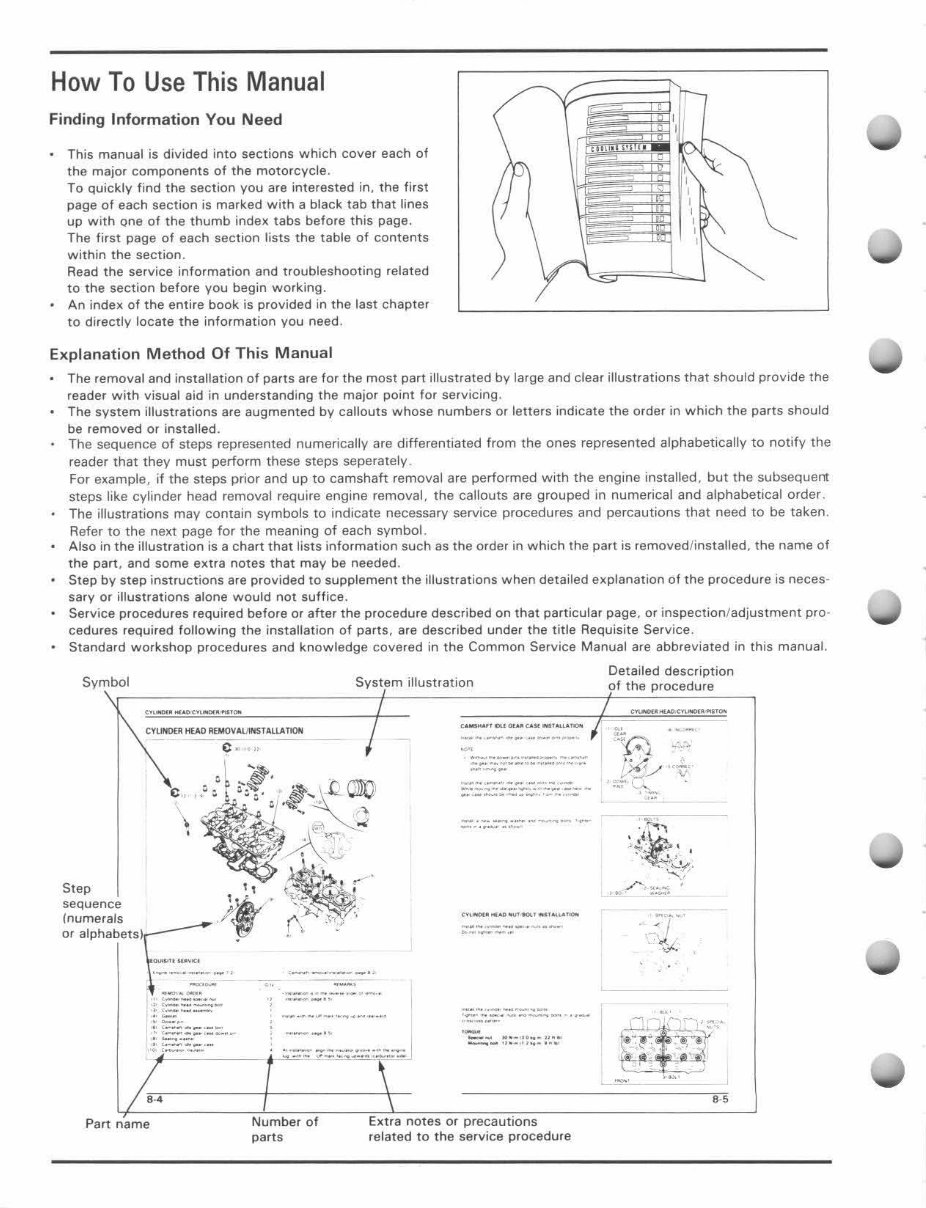

How To Use This Manual

Finding Informati on You Ne ed

This manual is divided into sections which cove r each of

the major components of the moto rcycle.

To quickly find the section you are inte rested in, the fir st

page of each section is marked with a black tab that lines

up with one of the thumb index tabs before this page.

The first page of each section lists the table of contents

within the section.

Read the service information and troubleshooting related

to the section before you begin working.

An index of the entire book is provided in the last chapter

to directly locate the info rmat ion you need.

Explanation M ethod Of This Manual

The removal and installation of parts are for the most part illustrated by large and clear illustrations that should provide the

reader with visual aid in understanding the major point for servicing.

The system illustrations are augmented by caliouts whose numbers or letters indicate the order in which the parts should

be removed or installed.

The sequence of steps represented numerically are differentiated from the ones represented alphabetically to notify the

reader that they must perform these steps seperately .

For example. if the steps prior and up to camshaft removal are performed with the engine installed, but the subsequent

steps like cylinder head removal require engine removal, the callouts are grouped in numerical and alphabetical order .

The illustrations may contain symbols to indicate necessary service procedures and percautions that need to be taken .

Refer to the next page for the meaning of each symbol.

Also in the illustration is a chart that lists information such as the order in which the part is removed/installed, the name of

the part, and some extra notes that may be needed.

Step by step instructions are provided to supplement the illustrations when detailed explanation of the procedure is neces-

sary or illustrations alone would not suffice.

Service procedures required before or after the procedure described on that particular page, or inspection / adjustment pro-

cedures required following the installation of parts, are described under the title Requisite Service.

Standard workshop procedures and knowledge covered in the Common Service Manual are abbreviated in this manual.

Symbol

,

System illustration

1\~~~~V~~TAlUOON -- I

1\ ' ~,

\ f:'A ...

-~~

Step

. " ~ ~ . '.' "- /

sequence ~J.j' ~

't" "'"

(numerals /' ,C . r\ ,. .~-'_~"

0' "Ph'bm'r;;_ , __ ____ "

~ ~=~:~

::::' .... -":'- ., ::=~,,:,~._._ -_.

'~ ~::: :::: =-

,-

" - .

. , '-- -< --

; :=::::.- -_ .. -

::~=":.!:.. -

/

/ e-,

----"

--------.-

____ M_'·M __ ~"_ .. _

--...~.

-.--~----~-'- _",_A_

--.----.---

.. _---

-- -,---~-

,- - -. --~-- .. -

-- .... .... -".~

--.- " .~ .. , ~- , ...

Part name

Number of

parts

Extra notes or precautions

related to the service procedure

Detailed description

of the procedure

c~ .... ",c ......... " ,.

e,

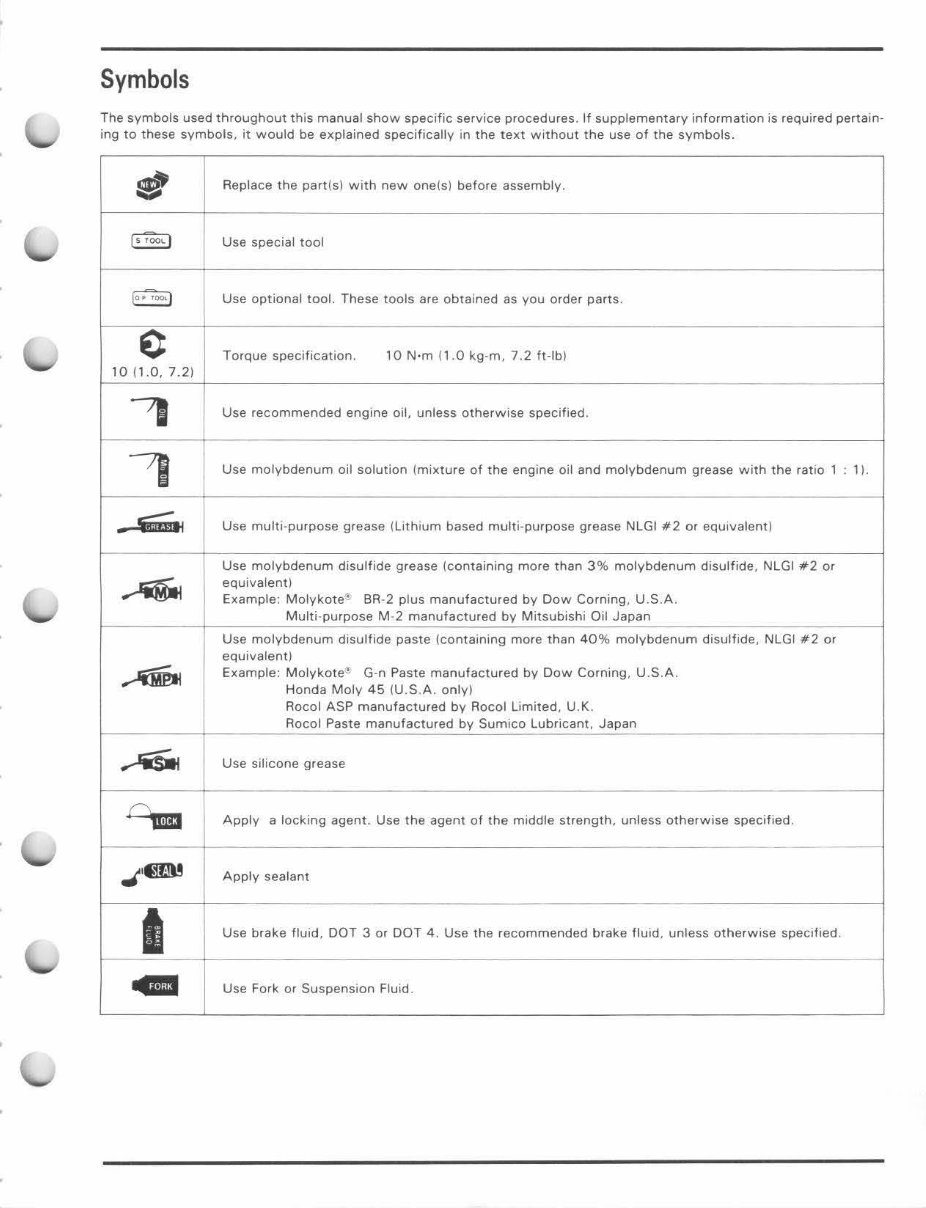

Symbols

The symbols used throughout th is manual show specific service procedures. If supplementary information is required pertain-

ing to these symbols , it would be explained specifically in the text without the use of the symbols .

.. "

-

Replace the part (s) with new one(s) before assembly.

( ~ -;- 00\. )

Use special tool

{o.'"7 "", I

Use optional tool. These tools are obta ined as you order parts .

e Torque specification. 10 N·m ( 1.0 kg -m, 7.2 ft-Ibl

10 ( 1.0, 7.2 1

'I

Use recommended engine oil, unless otherwise specified .

~

Use molybdenum oil solution (mixture of the engine oil and molybdenum grease with the ratio 1 11.

-~

Use mult i- purpose grease i Lithium based mu lti -purpose grease NLGI #2 or equivalent )

Use molybdenum disulfide grease (containing more than 3% molybdenum disulfide , NLGI #2 or

....

equivalent~

Example: Molykote '!. BR -2 plus manufactured by Dow Corning, U.S .A.

Multi -purpose M-2 manufactured by Mitsubishi Oil Japan

Use molybdenum disulfide paste (containing more than 40% molybdenum disulfide, NlGI 112 or

equivalent ~

~

Example: Molykote f!. G-n Paste manufactured by Dow Corning, U.S.A.

Honda Moly 45 (U.S.A. only )

Rocol ASP manufactured by Rocol Limited, U.K.

Rocol Paste manufactured by Sumico Lubricant, Japan

..-'iSitt

Use sil icone grease

o, m

Apply a locking agent. Use the agent 01 the middle strength, unless otherwise specified.

---

J '@ru Apply sealant

I

Use brake fluid. DOT 3 or DOT 4. Use the recommended brake fluid. unless otherwise specified

..

Use Fork or Suspension Fluid .

MEMO

General Safety 1-1

Model Identification 1-3

Specifications 1 -4

Torque Values 1- 14

Tools 1-16

General Safety

Carbon Monoxide

If the engine must be running to do some work, make sure

the area is well ventilated. Never run the engine in an

enclosed area .

The exhaust contains poisonous carbon monoxide

gas that can cause loss of consciousness and may

lead to death .

Run the engine in an open area or with an exhaust

evacuation system in an enclosed area.

Gasoline

Work in a well ventilated area. Keep cigarettes. flames or

sparks away from the wo rk area or where gasoline is

stored.

Gasoline is extremely flammabl e and is explosive

under centain conditions. KEEP OUT OF REACH

OF CHILDREN.

Hot Components

exhust system parts very hot

remain hot for some time after the engine is

run. Wear insulated gloves or wait until the engine

and exhaust system have cooled before handling

these

1. General Information

Lubrication & Seal Points 1-18

Cable & Harness Routing 1 -20

Emission Control System

1- 28

Emission Control Information Labels

(U .S.A. Only)

1-30

Used Engine/ Transmission Oil

Used engine oil (or transmission oil in two-strokes)

may cause skin cancer if repeatedly left in contact

with the skin for prolonged periods. Although this is

unlikely unl ess you handle used oil on a daily

basis, it is still advisable to thoroughly wash your

hands with soap and water as soon as possible

after handling used oil . KEEP OUT OF REACH OF

CHILDREN.

Brake Dust

Never use an air hose or dry brush to clean brake

assemblies. Use an OSHA-approved vacuum cleaner or

alternate method approved by OSHA, designed to

minimize the hazard caused by airborne asbestos fibers.

disease and cancer.

Brake Fluid

CAUTION

Spilling fluid on painted , plastic or rubber parts will

damaga them . Place a clean shop towel over these

parts whenever the system is serviced. KEEP OUT

OF REACH OF CHILDREN.

1-1

II

General Information

Coolant

Under some conditions, the eth ylene glycol in engine

coolant is combustible and its flame is not visible . If the

ethylene glycol does ignite, you will not see any flame. but

you can be burned.

Avoid engine coolant on the exhaust

system or i parts . They may be hot enough to

cause th e coolant to ignite and burn without a

visible flame .

Cool ant (etheylene gl ycol) can cause some skin

irritation and is poisonous if swa llowed. KEEP

OUT OF REACH OF CHILDREN .

Do not remove the radiator cap when the engine is

hot. The coolant is under pressure and could scald

you.

Keep hands and clothing away from the cooling

fan , as it starts automaticall y.

If it contacts your skin, wash th e affected areas

immediately with soap and water. If it contacts your eyes,

flash them thoroughly with fresh water and get immediate

medical attention. If it is swallowed, the victim must be

forced to vomit then rinse mou th and th roat with f resh

water before obtaining medical attention. Because of these

dangers, always store coolant in a safe place, away from

the reach of children.

1-2

Nitrogen Pressure

For shock absorbers with a gas-filled reservoir:

Use only nitrogen to absorber.

The use of an unstable gas can cause a fire or

explosion resul ting in serious injuly .

The shock absorber contains nitrogen under high

pressure . Allowing fire or heat near the shock

absorber could lead to an exp losion that could

result in serious injuly .

Failure to rel ease the pressure from a shock

absorber before disposing of it may lead to a

possible explosion and serious injury if it is heated

0'

To prevent the possibility of an explosion, release the

nitrogen by pressing the valve core. Then remove the valve

stem from the shock absorbr reservoir. Dispose of the oil in

a manner acceptable to the Environmental Protection

Agency (EPA) .

Be for e disposal of the shock absorber, release th e nitrogen

by pressing the va lve core. Then remove the valve stem

from the shock absorber.

Battery Hydrogen Gas & Electrolyte

Th e battery gives off exposive gases: keep spa rk s,

flames and cigarettes away . Provide adequate

ventilation when charging.

The battery contains sulfuric acid (electrolyte).

Contact with skin or eyes may cause severe burns .

Wear protective clothing and a face shield.

- If e lectrolyte gets on your skin, flush with water.

- If electrolyte gets in your eyes, flush with water

for at lea st 15 minutes and call a physician .

Electrolyte is poisonous .

- If swallowed, drink large quantities of water or

milk and follow w ith milk of magnesia or

vegetable oil and call a physician . KEEP OUT OF

REACH OF CH ILDREN .

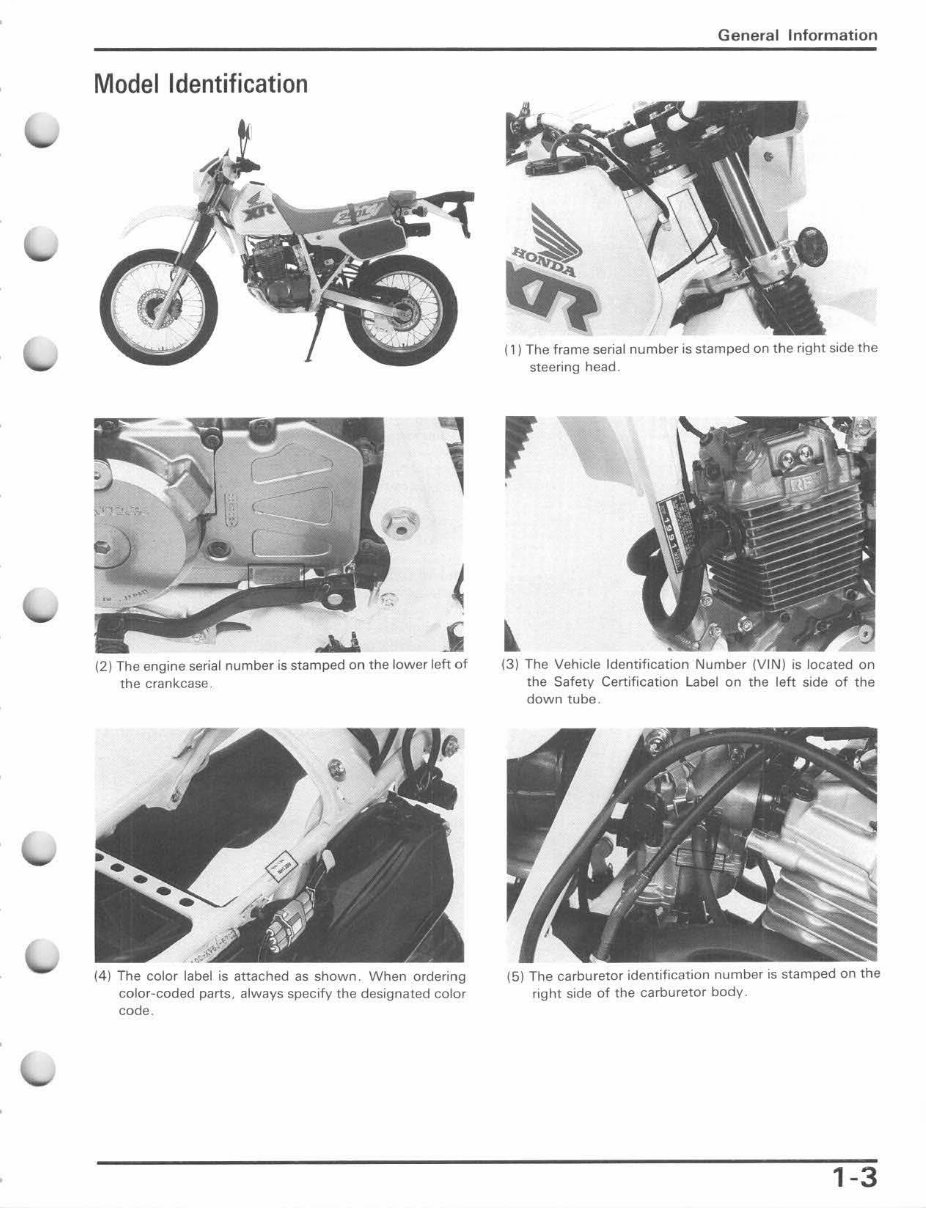

Model Identification

(2) The engine serial number is stamped on the lower leh of

the crankcase.

(4) The color label is attached as shown. When ordering

color-coded parts. always specify the designated color

code.

General Information

(1) The frame serial number is stamped on the right side the

steering head .

(3) The Vehicle Identification Number (VIN) is located on

the Safety Certification Label on the left side of the

down tube .

(5) The carburetor identification number is stamped on the

right side of the carburetor body.

1-3

General In fo rm ati on

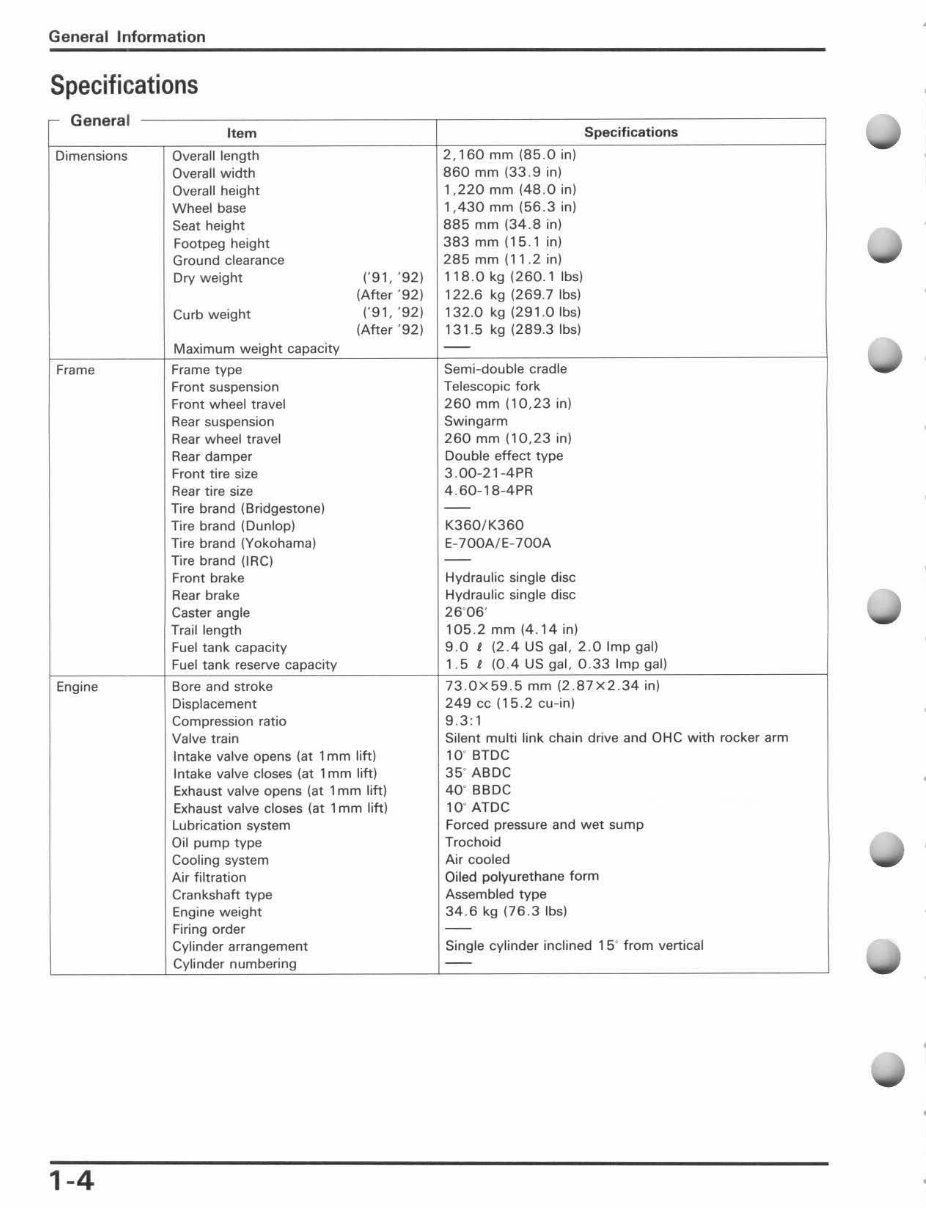

Specifications

r General

Item Speci fi ca ti ons

Dimensions Overall length 2,160 mm (85.0 in)

Overall width 860 mm (33. 9 in)

Overall height 1,220 mm (48 .0 in)

Wheel base 1, 430 mm (56.3 in)

Seat height 885 mm (34 .8 in)

Footpeg height

383 mm (15 . 1 in)

Ground clearance 285 mm (11.2 in)

Dry weight r9 1, ·92) 118 .0 kg (260.1 Ibs)

(After ' 92) 122.6 kg (269 .7 Ibs)

Curb weight

(,91, '92) 132.0 kg (291 .0 Ibs)

(After ·92) 131 .5 kg (289.3 Ibs)

Maximum weight capacity

--

Frame Frame type Semi-double cradle

Front suspension Telescopic fork

Front wheel travel 260 mm ( 10 ,23 in)

Rear suspension Swingarm

Rear wheel travel 260 mm (10,23 in)

Rear damper Double effect type

Front tire size 3.00-21-4PR

Rear tire size 4.60-18-4PR

Tire brand (Bridgestone) --

Tire brand (Dunlop) K360/K360

Tire brand (Yokohama) E -700A/ E -700A

Tire brand (iRC) --

Front brake Hydraulic single disc

Rear brake Hydraulic single disc

Caster angle 26"06·

Trail length 105 .2 mm (4.14 in)

Fuel tank capacity 9.0 I (2.4 US gal, 2 .0 Imp gal)

Fuel tank reserve capacity 1.5 I (0.4 US gal , 0 . 33 Imp gal)

Engine Bore and stroke 73.0x59.5 mm (2.87x2.34 in)

Displacement 249 cc (15 .2 cu-in)

Compression ratio 9. 3: 1

Valve train Silent multi link chain drive and OHC with rocker arm

Intake valve opens (at 1 mm lift) 10' 8TDC

Intake valve closes (at 1 mm lift) 35 " ABDC

Exhaust valve opens (at 1 mm lift) 40' BBDC

Exhaust valve closes (at 1 mm lift) 10' ATDC

Lubrication system Forced pressure and wet sump

Oil pump type Trochoid

Cooling system Air cooled

Air filtration Oiled polyurethane form

Crankshaft type Assembled type

Engine weight 34 .6 kg (76.3 Ibsl

Firing order --

Cylinder arrangement Single cylinder inclined 1 5" from vertical

Cylinder numbering --

1-4

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

$41.99

Viewed 54 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

$41.99

This repair manual covers the 1991-1996 Honda XR250L four-stroke dual sport bike. It includes comprehensive information such as complete tear down and rebuild procedures, part diagrams, torque specifications, maintenance guidelines, and troubleshooting techniques. With 194 pages, this manual provides all the necessary details for professional mechanics and DIY enthusiasts.

Featuring clickable chapters and a searchable interface, users can easily navigate and locate specific information. There are no restrictions on printing or saving/burning to disc, offering convenience and flexibility.

- Complete tear down and rebuild procedures

- Part diagrams and pictures

- Torque specifications

- Maintenance guidelines

- Troubleshooting techniques