2007-2008 CRF450R Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

A Few Words Aboul Safely

Service Information

>

The service and repair Information cOnlained in this manualJs It'Ilended for use by qualified, protessional technicians.

=-

Attempting servICe or repairs WIthout the proper training. 1000s, and equipment couki cause injury to you or others. It could also

damage the vehicle or create an unsafe condition.

This manual descnbes the proper methods and procedures tor performing sel\lice , mamtenance, and repairs. Some procedures

require the use of specially designed tools and dedkated equipment. Arri person who intends to use a replacement part, service

procedure or a tool that is not recommended by Honda, must determme the risks 10 their personal safety and the safe operation of

the vehicle.

If you need to replace a part, use genuine Honda parts WIth the correct part number or an equivalent part We strongly recommend

thai you do not use replacement parts of inferior Qua~ty.

For Your Customer's Safety

Proper service and maintenance are essential to the customer's safety and

the reliability 01 the vehicle. Any error or oversight while servicmg a vehr cle

can resuh in lauhy operation, damage 10 the vehicle, or injury to others.

For Your Safety

Because this manual is intended lor the prolessional service technician. we

do not provIde warnIngs about many basic shop safety practICes (e g ., Hot

parts-wear gloves). II you have not recerved shop safety training or do not

feeJ oonfldent about you r knowledge of sale servicing practrce, we

recommended that you do not attempt to perform the procedures described

In this manual.

Some of the most I mportant general service satety precaubons are given

below. However, we cannot warn you of fNery oonceivable hazard that can

arise in performrng servtee and repaIr procedures. Only you can decide

whether or not you should perform a given task

Important Safety Precautions

AWARNING

Improper service or repairs can create an

unsafe condition that can cause your customer

or others to be seriously hun or killed.

Follow the procedures and precaullons in thrs

manual and other servr ce materials carefully.

AWARNING

Failure to property follow Instructions and

precautions can cause you to be seriously hurt

or killed.

Follow the procedures and precautions in this

manual carefully.

Make sure you have a clear understanding of aJl basic shop safety practICes and that vou are weanng appropriate dothing and

using safety equipment. When performrng any service task. be especially careful of the following:

• Read all of the instructions before you begrn. and make sure you have the tools. the replacement or reparr parts, and the skIlls

required 10 perform the tasks safely and completely.

• Protect your eyes by using proper safety glasses, goggles or face shrelds any time you hammer, drill, gnnd, pry or work around

pressurized aIr or liqUids, and Springs or other stored-energy components . If there is any doubt, put on eye protection.

• Use other protectrve wear when necessary, lor example gloves or salety shoes. Handling hot or sharp parts can cause severe

burns or cuts. Before you grab something that looks like II can hurt you, stop and put on gloves.

• Protect yourse« and others whenever you have the vehICle up In the air. Any time you lift ihe vehicle, either wrth a hoist or a jack,

make sure that it IS always securely supported. Use }a:ck stands.

Make sure the engllle rs ofl before you begin any serv!dng procedures unless the instruction tells you to do otherwise.

Th rs will help elimrnate several potentJaI hazards:

• Carbon mono)tlde poisoning from engine exhaust. Be sure there IS adequate ventilation whenever you run the engine.

• Bums from hot pans or coolant Let the engine and exhaust system cool before working in those areas.

o Inlury from moving parts. II the Instructron tels you to run the engIne, be sure your hands, fingers and dothing are out of the way.

Gasoline w.pors and hydrogen gases from battenes are explosive. To reduce the POSSltlllrty of a fire or explosion. be careful when

wonong around gasoline or battanes.

• Use only a nonflammable solvent, not gasoline, to clean parts.

o Never dra.n or store gasoline in an open container.

• /(aep all cigarettes, sparks and flames aWWf from the battery and atllue l·re lated parts.

..

HOW TO USE THIS MANUAL

~ \hi Ma1!11~ Schedule ,S«IK)n of) recommendallons 10

~"IIIII the vehode Is In peak OJMralong conditlon

~r1olmll'lg tile first ilCheduled mall'ltlnance .. WIry impQf1Anl II

comperIlllt.1 lor 1M Inill'l wear thaI occut. dur.nQ the brea~·ln

-.

SectIorlI , and .. apply 10 tM whole motorcycle SecIJon 3 illu51tal,"

prOC*ll.Ir" lor removaV ... SlabIIOl'l 01 COif~1tS thaI may be

reqund 10 !*form set'IIr» onc:rt>ed on tile toIowwIg MCIIOnI

SecIIOn 5 IhRIug1 17 descnbe pans CIt ~ moIOrq'de grouped

aoootdong 10 Iocablln

Fill(!, ..... MeIiIOn you want on ItlI$ PfIge. then IUm 10 !hi taCIe 01

_ an" tnt page of !he secbOn

Moll ~ SIiIrt WIth an lsaembly or -vtlem *.ISI/liIllon, aeMCII

inIomIatiot> ~d uoubieshootKlg /01 tile HCloon The IWbsequent

paget; 01 .... d&\alled procedure

It you .~ 1'101 familiar w,!h thiS motorcycle. rud Tedlnlcal Feature In _.

II you don1 know the 1IOIJn::e of !he !rouble. IiJO 10 sedIOf1 18

T_

'!bur aatery. 8nCf me salety 01 otnefI. II ~ IIT!pOttant. To help

~ ~ n.:wm.a aaa.oons _ ~ I)f'OVIOed sale!y ~s.agn

~ otItIf ftormallOn IfII'OUo1lOUI m. rnantal 01 fXlIQII, "" no!

~ or poIiSibIe 10 wam you abOuI .. Iha huMos

~ wllh Ii8rw:.1'1j fill wtnICIe

'Ibu " .... use )IOU' own good )udOemerII

'1bu wi! I"wld Iriporlllnt salety InlcltTnlobOn In II '4roety 01 Iorrn$

........

• s.1ety Labels -on the YIIhtele

• Selety Messages - preceded by. ulery aiM symbol 1 Il!1d

01\1 01 IhIM signal words, O .... NGER WARNING, or CAU-

TION

These IIgOBl WOfds mean

You WILL be KILLED or SERIOUSLY

,"I'H':13;' HUFlH you don'tlolIQW IIlStr\.ICtIOrI1:

'Iou CAN be KJUEO or SERIOUSLY

ID'iWiF "W' HURT If you don''''' onstJUChOnS

You CAN be HURT ~ you donI toIow

.. , ........

• InWuaIons - how 10 servICe IfIIIIMI'IICIe correctly and ,,/ely

AI you reed this manutU, you Wj8 find InlormallOn IhiItls precad&d by'

rtJOriCt lymboI The purpose 01 1Il" 1118-0- It; to help prevent

damage to)'OU' vehlCk!, oltler propeny. Of !he erMronmanl

z

"

~

OJ

2:

a:

c

c

z

'"

OJ

;;

"

Z

OJ

en

iii

~

r

<.>

CONTENTS

GENERAL INFORMATION

TECHNICAL FEATURE

MAINTENANCE

LUBRICATION SYSTEM

FUEL SYSTEM

COOLING SYSTEM

ENGINE REMOVAUlNSTALLATION

CYLINDER HEADNALVES

CYLINDER/PISTON

REAR WHEEUSUSPENSION

HYDRAULIC BRAKE

ELECTRICAL SYSTEM

WIRING DIAGRAM

TROUBLESHOOTING

INDEX

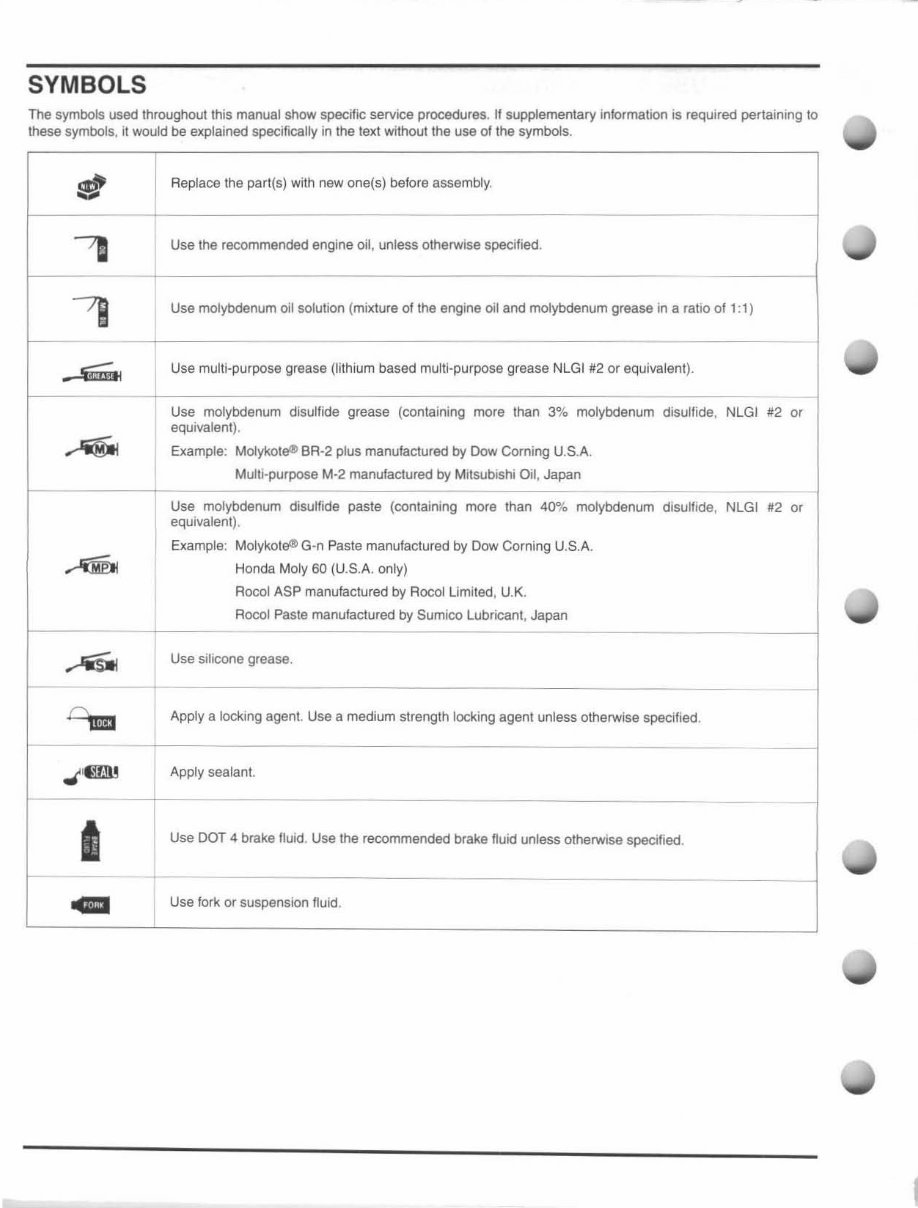

SYMBOLS

The symbols used throughout this manual show specific service procedures. 11 supplementary information is required pertaining to

these symbols, it would be explained specifically in the texl without the use of the symbols.

g

Replace the part(s) with new one(s) before assembly.

-

"D

Use the recommended engine oil, unless otherwise specified.

I

-,

Use molybdenum oil solution (mixture of the engine oil and molybdenum grease in a ratiO of 1:1)

-

• ...m;..

I

Use mUlti-purpose grease (lithium based multi-purpose grease NLGI #2 or equivalent).

Use molybdenum disulfide grease (con taining more than 3% molybdenum disulfide, NLGI #2 or

equivalent) .

~

Example: MoIykole0 BA-2 plus manufactured by Dow Corning U.S.A.

I

Multi-purpose M-2 manufactured by Milsubishi Oil, Japan

-

Use molybdenum disulfide paste (containing more than 40% molybdenum disulfide , NLGI #2 or

I

equivalent).

Example: Molykota® G-n Paste manufactured by Dow Corning U.S.A.

~ Honda Moly 60 (U.S.A. only)

Rocol ASP manufactured by Rocol Limited, U.K.

I

Rocol Paste manufactured by Sumico Lubricant, Japan

~

Use silicone grease.

-

CW

Apply a locking agent. Use a medium strength locking agent unless otherwise specified .

.,( ' ftll!

Apply sealant.

-

I

Use DOT 4 brake fluid. Use the recommended brake fluid unless otherwise specified.

f-

oG

Use fork or suspension Iluid.

1. GENERAL INFORMATION

SERVICE RULES ······ .. ·· .... ········ .......... ········· 1-2

MODEL IDENTIFICATION······················ .. · .. 1-2

GENERAL SPECIFICATIONS ······················ 1-4

LUBRICATION SYSTEM

SPECiFiCATIONS ········································ 1-5

FUEL SYSTEM SPECIFICATIONS ··· ····· ····· · 1-5

COOLING SYSTEM SPECIFICATIONS ...... 1-6

CYLINDER HEADIVALVES

SPECiFiCATIONS ········································ 1-6

CYLINDER/PISTON SPECIFICATIONS ······ 1-7

CLUTCH/ KICKSTARTER/ G EARSHIFT

LINKAGE SPECIFICATIONS ······················· 1-7

CRANKCASE/CRANKSHAFT/

TRANSMISSION/ BALANCER

SPECIFICATIONS ............. .. .......... ............... 1-8

FRONT WHEEL/ SUSPENSION/ STEERING

SPECIFICATIONS ...... .. ......... _ ......... _ ..... ...... 1-8

REAR WHEEL/SUSPENSION

SPECIFICATIONS ················ ·_· ·· ········ ······ ·· .. 1-9

HYDRAULIC BRAKE SPECiFiCATIONS····· 1-9

ELECTRICAL SYSTEM

SPECIFICATIONS ........................... _ ......... 1-10

STANDARD TORQUE VALUES·····_········· 1-11

ENGINE & FRAME TORQUE VALUES ···· 1-11

LUBRICATION & SEAL POINTS ····_········· 1-17

CABLE & HARNESS ROUTING 1'07) ....... 1-21

CABLE & HARNESS ROUTING

(After '07) ............................................ ... ... 1-25

OPTIONAL PARTS ········· ·······_·········_········· 1-30

1-1

GENERAL INFORMATION

SERVICE RULES

1. Use genuine Honda or Honda-recommended parts and lubricants or their equivalents. Parts that do not meet

Honda's design specifications may cause damage to the moto rcycle.

2. Use the special tools designed for this product to avoid damage and incorrect assembly.

3. Use only metric tools when servicing the motorcycle. Metric bolts, nuts and screws are not interchangeable with

English fastener.

4. Install new gaskets, O-rings, cotter pins, and lock plates when reassembling.

5. When tightening bolts or nuts, begin with the larger diameter or inner bolt first. Then tighten to the specified torque

diagonally in incremental steps unless a particular sequence is specified.

6. Clean parts in cleaning solvent upon disassembly . Lubricate any sliding surfaces before reassembly.

7. After reassembly, check all parts fo r proper installation and operatio n.

8, Route all electrical wires as sh own in the Cable and Harness Routing ('07: page 1·21, After ' 07 : page 1·25).

ABBREVIATION

Throughout this manual, the following abbreviations are used to identify the respective parts or systems .

i i

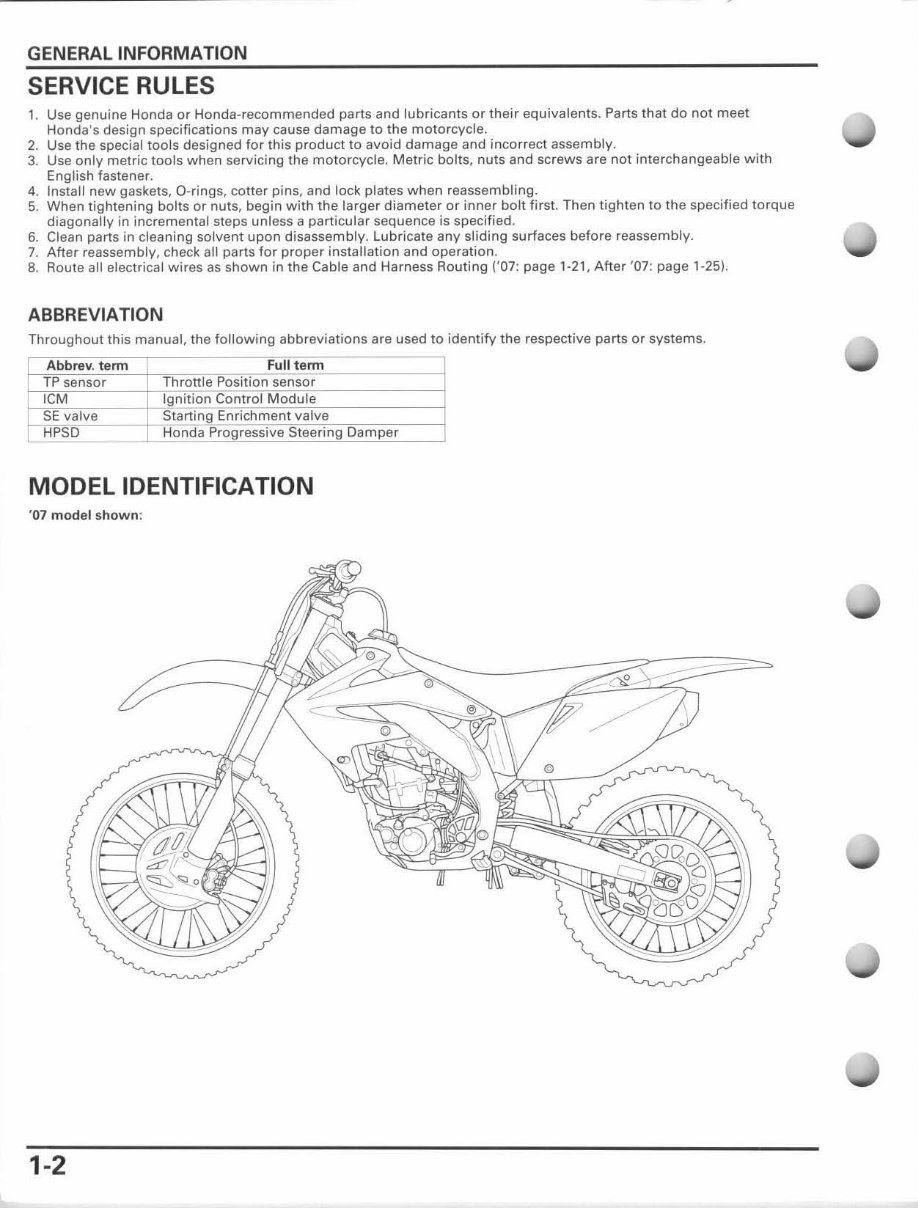

MODEL IDENTIFICATION

' 07 model sh own:

o

=

~ ~.

1-2

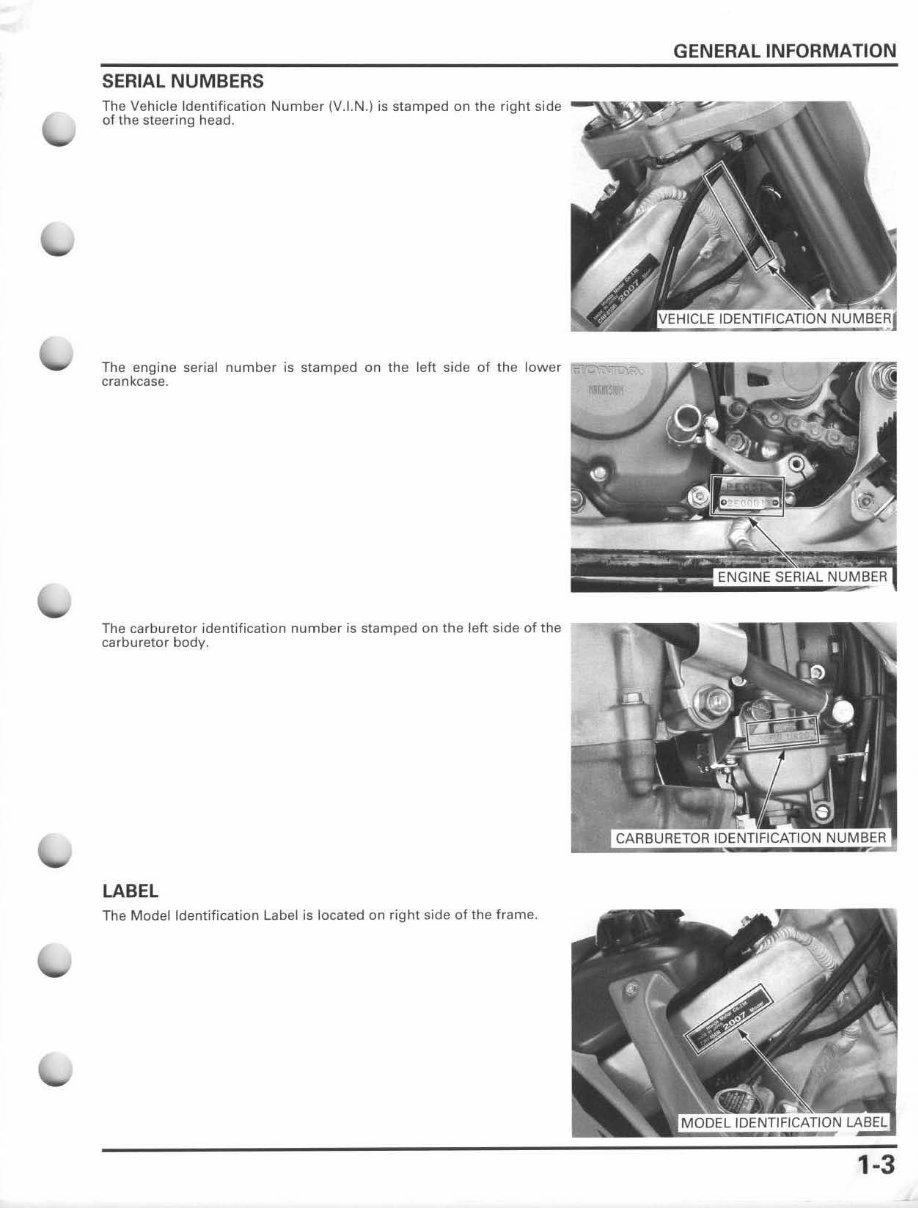

SERIAL NUMBERS

The Vehicle Identification Number (V. i.N.) is stamped on the right side

of the steering head.

The engine serial number is stamped on the left side of the lower .-----.,

crankcase.

The carburetor identification number is stamped on the left side of the

carburetor body .

LABEL

Th e Model Identification Label is located on right side of the f rame.

GENERAL INFORMATION

1-3

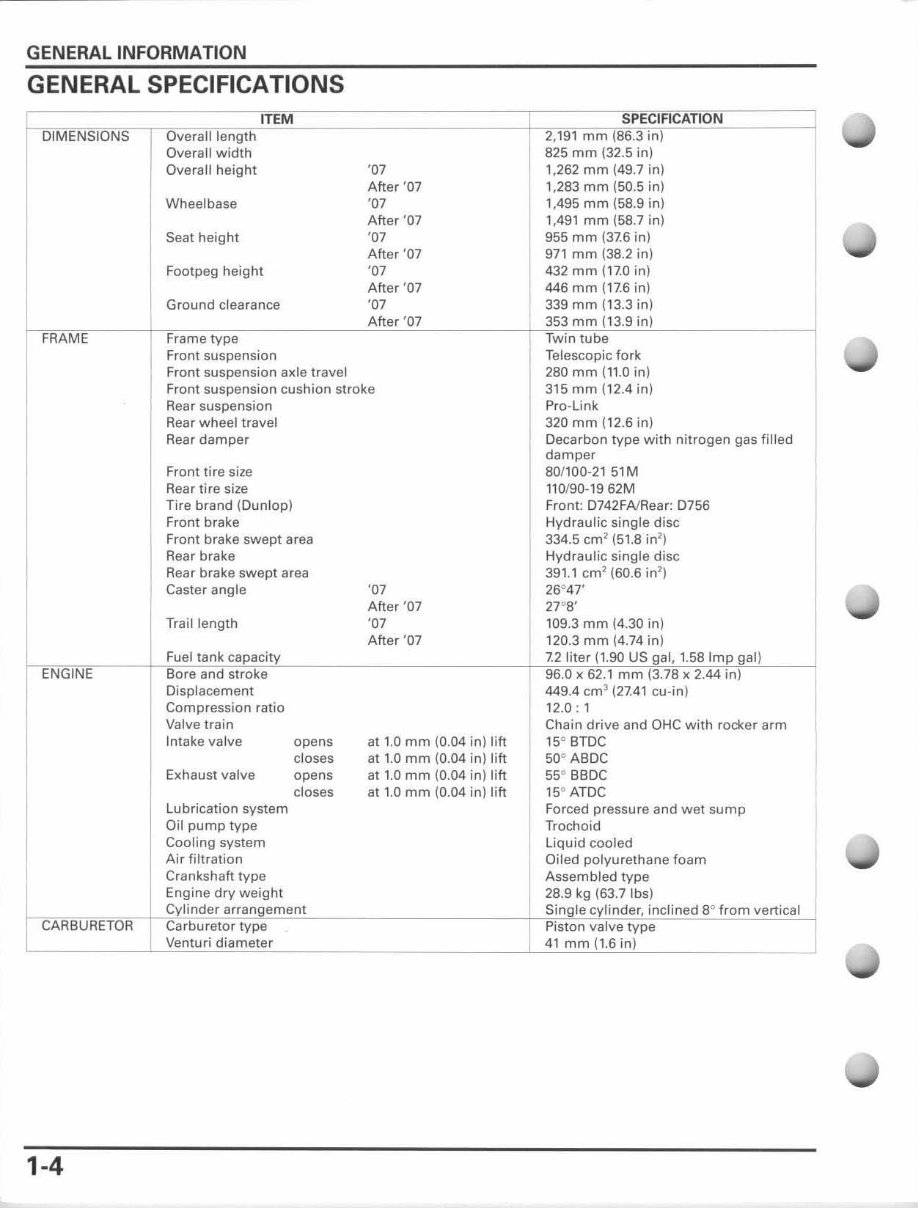

GENERAL INFORMATION

GENERAL SPECIFICATIONS

ITEM SPECIFICATION

-

DIMENSIONS Overall length 2,191 mm (86.3 in)

Overall width 825 mm (32.5 in)

Overall height '07 1,262 mm (49.7 in)

After '07 1,283 mm (50.5 in)

Wheelbase ' 07 1,495 mm (58.9 in)

After '07 1,491 mm (58.7 in)

Seat height ' 07 955 mm (37.6 in)

After '07 971 mm (38.2 in)

Footpeg height '07 432 mm (17.0 in)

After '07 446 mm (17.6 in)

Ground clearance '07

I

339 mm (13.3 in)

After '07 353 mm (13 .9 in)

FRAME Frame type Twin tube

Front suspension Telescopic fork

Front suspension axle travel 280 mm (11.0 in)

Front suspension cushion stroke 315 mm (12.4 in)

Rear suspension Pro-link

Rear wheel travel 320 mm (12.6 in)

Rear damper Decarbon type with nitrogen gas filled

damper

Front tire size 801100-21 51 M

Rear tire size 110/90·1962M

Tire brand (Dunlop) Front: D742FAlRear: 0756

Front brake Hydraulic single disc

Front brake swept area 334.5 cm

2

(51.8 in

2

)

Rear brake Hydraulic single disc

Rear brake swept ar ea 391.1 cm

2

(60.6 ln2)

Caster angle '07 26°47'

After '07 27 ° 8'

Trail length '07 109.3 mm (4.30 in)

After '07 120.3 mm (4.74 in)

Fuel tank capacity 7.2 liter (1.90 US gal, 1.58 Imp gal)

ENGINE Bore and stroke

I

96.0 x 62.1 mm (3.78 x 2.44 in )

Displacement 449.4 cm

3

(27.41 cu-in)

Compression ratio 12.0 : 1

Valve train Chain drive and OHC with rocker arm

Intake valve opens at 1.0 mm (0.04 in) lift 15° BTDC

closes at 1.0 mm (0.04 in) lift 50° ABDC

Exhaust valve opens at 1.0 mm (0.04 in) lift 55° BBDC

closes at 1.0 mm (0.04 in) lift 15° ATDC

Lubrication system Forced pressure and wet sump

Oil pump type Trochoid

Cooling system Liquid cooled

I

Air filtration Oiled polyurethane foam

Crankshaft type Assembled type

Engine dry weight 28.9 kg (63.7 Ibs)

Cylinder arr angement Si ngle cylinder, inclined 8° from vertical

CARBURETOR Carburetor type Piston valve type

Venturi diameter 41 mm (1.6 in)

1-4

GENERAL INFORMATION

ITEM

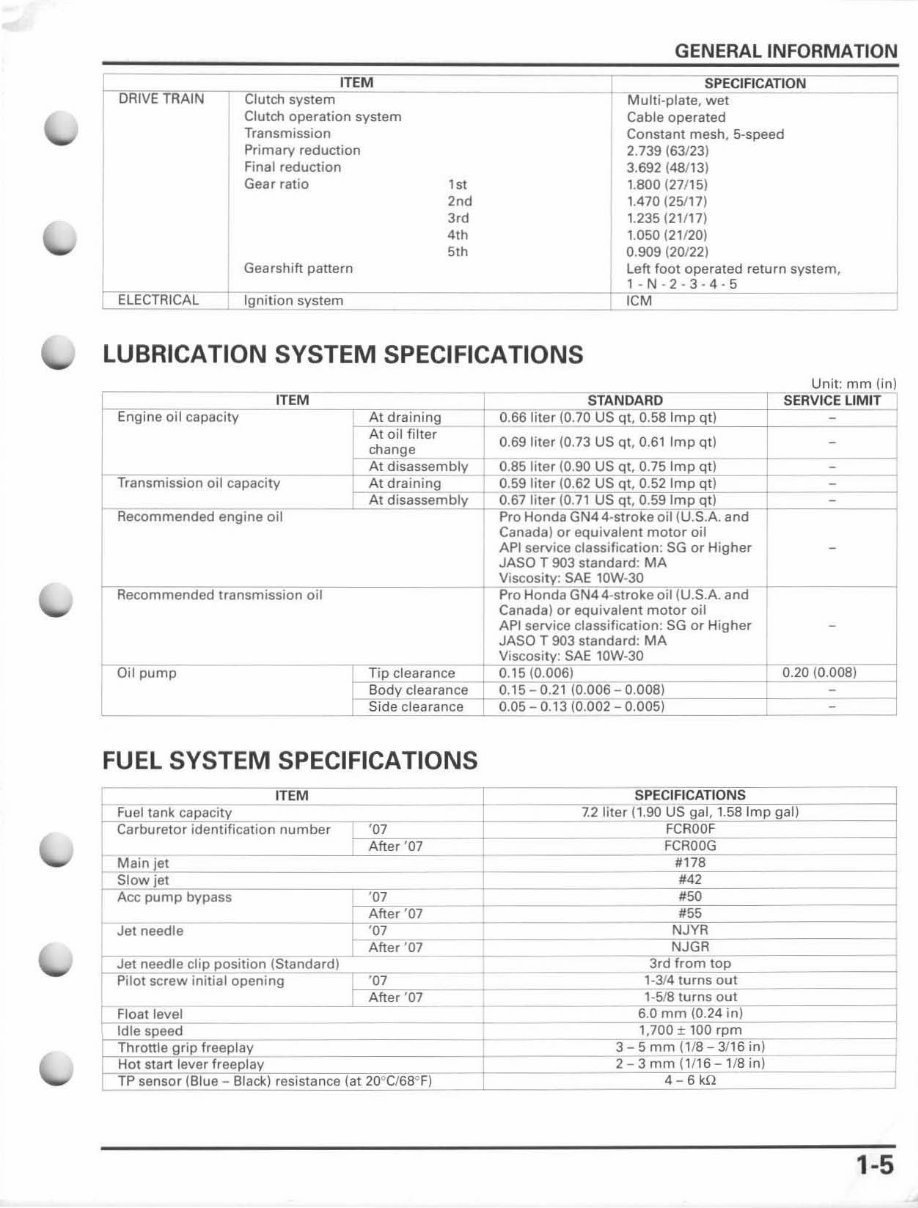

DRIVE TRAIN Clutch system

Clutch operation system

Transmission

Primary reduction

Final reduction

Gear ratio 1st

2nd

3,d

4th

5th

Gearshift panern

, ELECTRICAL Ignition system

LUBRICATION SYSTEM SPECIFICATIONS

SPECIFICATION

Multi-plate, wet

Cable operated

Constant mesh, 5-speed

2.739 ( 63123 )

3.692 (48113)

1800 (27/ 15)

1.470 (25117)

1.235 (2 1/ 17)

1050 (21/20)

0.909 (20/22)

left foot operated return system,

l-N-2-3-4-5

I CM

ITEM

Engine oil capacity

Unit' mm (in)

ST TA iC N "O ;;- A iC R "' O ------,-- "S "' E"RV "I "' C "' E LIMIT j'

At draining 0.66 liter 0.70 US qt, 0.58 Imp qt)

At oil filter

0.69 liter (0.73 US qt. 0.61 Imp qt)

change =-+_,

__ -+--'iAo-t dcci,s~ssembly 0.85 liter (0.90 US qt. O.7S1mp qt) _

At draining 0.59 liter (0.62 US qt. 0.52 Imp qt) Transmission oil capacity

Recommended engine oil

__ ---"--' A-"t" d,,;'=a"",,'e=m=bl~y--t---i0 0.67 liter (0.7 1 US qt, O.591mp qt;,J -;;;::;;-+ _ _ ___ _

Pro Honda GN4 4-stroke oil (U.S.A. and

Canada) or equivalent motor oil

API service classification: SG or Hig her

JASO T 903 standard: MA

-'O=~~~~7CC==C~~CT ________________ ~V~;~scosi~:SAE7'~0~VY7-~3°Tc~","

Recommended transmission oil Pro Honda GN4 4-stroke oil (U.S.A. and

Canada) or equivalent motor oil

API service classification: SG or Higher

JASO T 903 standard: MA

____ ~~~~~o--1~V~;'~'~O"'sit:y:SAE 10VV ~- ~ 3~ 0 ____________ 1- "

_

~'J T~;p~d~e~.,~a~n~,e ~j~ oi . '~5~10J.'~0~06~) 0.20 (0",0",08",1 '--1 -

Body clearance 0.15 - 0.21 (0.006 - 0.008)

Side clearance 0.05 - 0.13 (0.0"0,"2~ - -, 0",O",0,,5,,J _ ____ -,-_____ -.J -

Oil pump

FUEL SYSTEM SPECIFICATIONS

I TEM

Fuel tank capacity

Carburetor identification number '07

After '07

Main jet

Slow jet

r ACC pump bypas s '07

After '07

Jet needle '07

T

I

I

+-

After '07 ___ ~_

Jet needl e clip positio"ni;I::S"ta=n"d"a",d"J,---.,,,, _ _ _

Pilot screw initial ope .. n,~ ;n ~ g ~ _ _ ~~'0~7:e;:'!fi_

_ Aher '07

Float level

Idle speed

Thronle grip freeplay

Hot start lever freeplay

TP sensor (Blue eli'a:C'!.:k'J :: ,e ",";,::ta:: n","e"l a"t"2"OW OC ""1 68

e

F)

SPECIFICATIONS

7.2 fiter (1.90 US gal, 1.58 Imp gal)

FCROOF

FCROOG

#178

#42

#50

#55

NJYR

NJGR

3rd from top

1-314 turns out

1-518 turns out

____ --; 6".0: mm (0. 24 in)

1,700 ± 100 rpm

3 - 5 mm (118 3/16 in)

2 - 3 mm (1/16 118 in)

4 6 kn

J

]

1-5

GENERAL INFORMATION

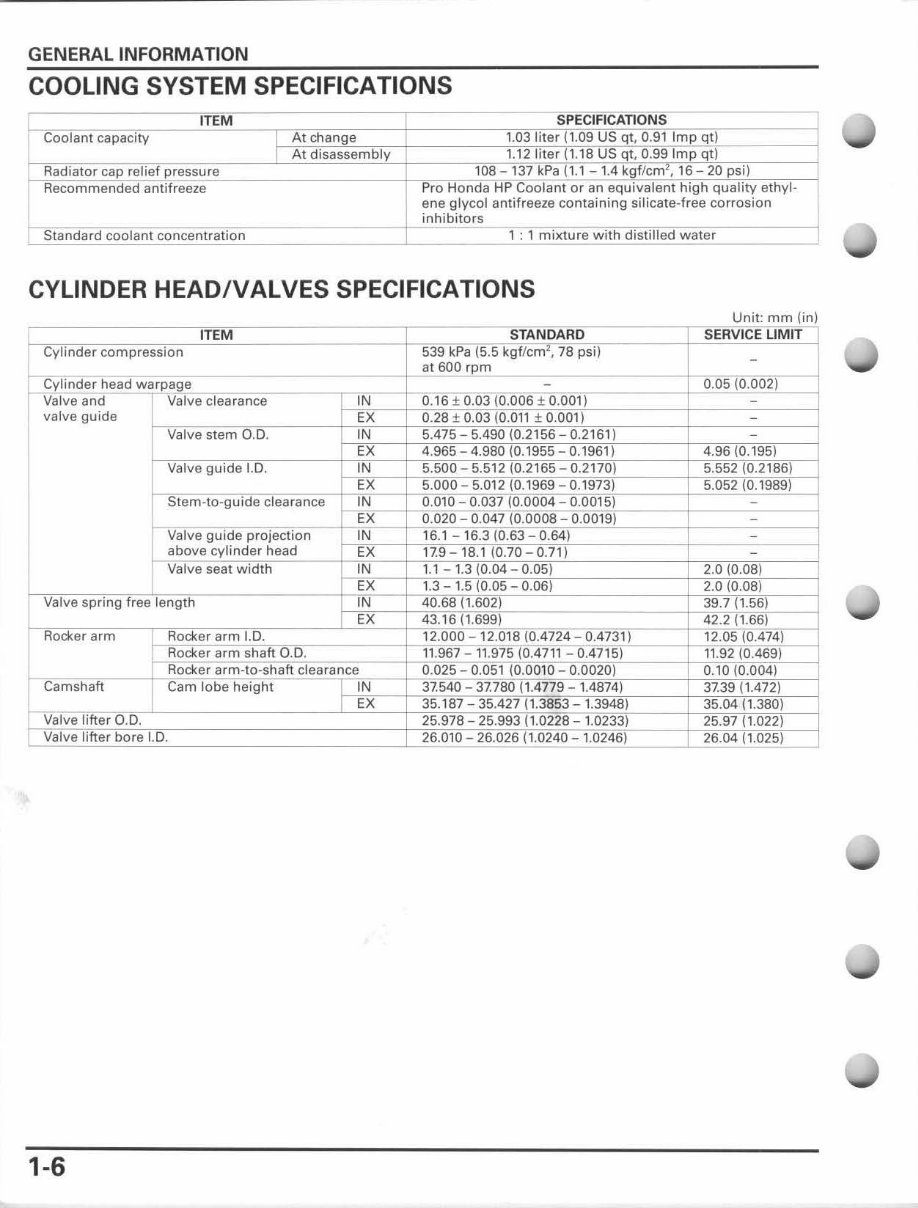

COOLING SYSTEM SPECIFICATIONS

ITEM SPECIFICATIONS

Coolant capacity At change 1.03 liter (l09 US qt, a.9l Imp qt )

At disassembly 1.12 liter (1.18 US qt, 0. 99 Imp qt)

Radiator cap relief pressure l OB 1 37 kPa (1.1 1 .4 kgf/cm. 16 - 20 psi)

Recommended antifreeze Pro Honda HP Coolant or an equivalent high quality ethyl-

ene glycol antifreeze containing silicate-free corrosion

inhibitors

Standard coolant concent ration , : 1 mixture with distilled water

CYLINDER HEADIVALVES SPECIFICATIONS

ITEM

I CYlinde, oomp,,,,'on ;;~~6':~~5 ". ' 7B p,;)

, Cylinder h,~e'~d~:'I'~,~,:," - 0.05 (0.002

IV alve and Valve clea,,,,;;no,,e;---l=~ 1 ~=j:=g~~03

I valve guide ! ± :03 (0: 1 ± .001 -

Valve stem 0.0.

V,lve 'pclng "ee lengto

I

oX

I

).216 I -

. 5-. 45'~ ... 966(0.'95

1W65

0- I ffi69- .

)- . -

. 6-0.00' -

9-1B.lI0.70-~ ' C

1 - 1.3 10.04 - 0.051 2.01(.

1.05 - 0.06J 2.0 (.

!.16 I iifJ

I

- '2 . I1B (. -f; OO . .473 ~==e~;~ 100~ ... 44'7~41=:j

Ro""e, I ~ _. p;; 1.92 (0.

46

i

l

C,m lobe height IN - 37.7BC . 37.39 1.472J

HoCker arm Rooke, oem I.

~; v"v~e~ili: ~,~ bo,~ee I.~. ======~E~X=t~ 32£56;··.'~B77 -jlli 35. '3B53 - i t==t2i ~;5ti··90>ttt74~~5lli~~I~

1-6

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

Viewed 80 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

This manual is a comprehensive guide for repairing the Honda CRF450R 2007-2008, featuring detailed illustrations and step-by-step instructions. It is designed for both DIY enthusiasts and professional mechanics, offering a cost-effective solution for maintaining your bike.

Key topics covered in this manual include:

- General Information

- Lubrication

- Maintenance

- Fuel System

- Engine Removal / Installation

- Cylinder Head / Valves

- Cylinder / Piston

- Clutch / Gearshift Linkage

- Alternator / Cam

- Transmission

- Brake

- Suspension

- Ignition System

- Wiring Diagram

- Troubleshooting

- And Much More

The manual is available in PDF format and is compatible with all versions of Windows and Mac. It is written in English and requires Adobe Reader for access. With instant access and no shipping costs, this manual provides a convenient solution for your repair and service needs.