2003-2013 CRF150F Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

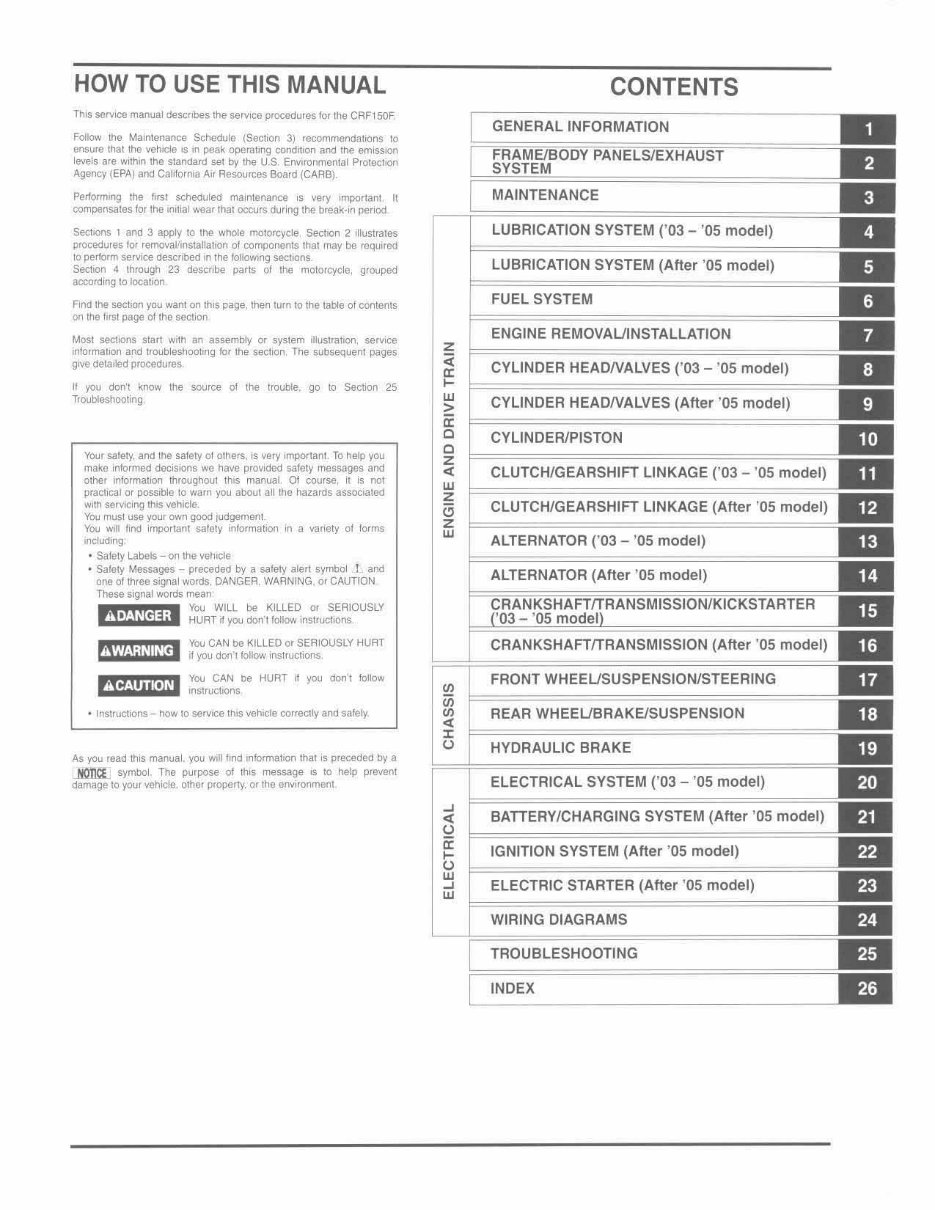

HOW TO USE THIS MANUAL

Th is servICe manua l descnOeS the :;erV1ce procedu res lor the CRFl50F

Follow the Ma intenance Schedule ISect,on 3) recommendat>orlS 10

ensure 1M! the vehtde .s In peak opera~ng cond,hon and !he em ission

levels are wlth,n the standard set by the U.S. EnvIronmental P'ole<;tlOl1

Agency (EPA) and Cal,forma Air Resoortes Board (CARB)

Petform,"ll the f,rst sdleduled maintenance IS very important II

compensates lor Ihe ,ml lal wear that occurs dUring lhe break· ,n penod

Section:; 1 and 3 apply to lhe whole motorcycle SectIOn 2 II Iustra1es

procedures for removal,l,nsl9l lahon ol cOrTlp<l<lenlS thai may be required

to per10rrn service described In lhe 10110\'/'''9 sect.ons

SectIon 4 through 23 describe paris of !he motorcyc l e, grouped

accord ing 10 localKln

Find the sectIon you want on Ih,s page, then IUff'l to tlla table at conlents

on It!e f,rsl page 01 the sec\Jon

Most sectlOllS sta,t ""In an assembly or system ,"us-lrahon. selVlC(l

II1torma11On and Irool}l eshootll1g 10, the sectto~ The subsequent pages

give delal1ed procedures

I[ you oon'l krxow the source of the trouble, go to Sec~oo 25

TrOl.Jbfeshootong

YOIJr safeI)', and the safely 01 others, is very Important. To help you

make ,nformed decisions we have pml'Kled safety messages and

other II110rmauon throughout this manual Of course, it is n<lt

prnC\JC31 Of posMlle to warn you aboul all the IIazards associated

w,lh servicing this vehicle

YOl' must use your own good ludgement

You "". lind Important salety II'lformatlOl1 in a ",nely of forms

II1ciuding

• Safety Labels - on lhe vehICle

• Safety Messages - preceded by a safety alert symbol J and

OM of three sigMI words, DANGER WARNING, or CAUTION

These Signal wtlrds mean

iN.bHMil You WILL be KILLED Of SERIOUSLY

_ ••••• __ ._ HURT d 'fOU don't foflow ir'lslroctions

ft'1

h1

i!.'! i N'

eMI,u.g'

You CAN be KILLED or SERIOUSLY HURT

d you don't follow Instlllctions

You CAN be HURT rt you (1on\ follow

InstructIOnS

• InstrlJCbons - how to servICe Uus valuele correctly aO<! safely

As you read th iS manua l. you WI. hnd Informatoon that IS preceded by a

JfO]eE symbo l. The purpose 01 th iS message IS to help prevent

damage to your vehicle. othsr preperli', or the erlllironmeni

z

"

go

W

>

it

o

o

z

"

w

z

'"

z

w

III

iii

III

"

::t:

o

..J

"

!,1

a:

....

o

W

..J

W

CONTENTS

GENERAL INFORMATION

MAINTENANCE

LUBRICATION SYSTEM (' 03 -' 05 model)

LUBRICATION SYSTEM (After '05 model)

FUEL SYSTEM

ENGINE REMOVAUINSTALLATION

CYLINDER HEADNALVES (' 03 - '05 model)

CYLINDER HEADNALVES (After '05 model)

CYLINDER/PISTON

CLUTCH/GEARSHIFT LINKAGE ('03 - '05 model)

CLUTCH/GEARSHIFT LINKAGE (After '05 model)

ALTERNATOR ('03 - '05 model)

ALTERNATOR (After ' 05 model)

CRANKSHAFTfTRANSMISSION (After '05 model)

FRONT WHEEUSUSPENSIONJSTEERING

REAR WHEEUBRAKEISUSPENSION

HYDRAULIC BRAKE

ELECTRICAL SYSTEM (' 03 -' 05 model)

BATTERY/CHARGING SYSTEM (After ' 05 model)

IGNITION SYSTEM (After '05 model)

ELECTRIC STARTER (After '05 model)

WIRING DIAGRAMS

TROUBLESHOOTING

INDEX

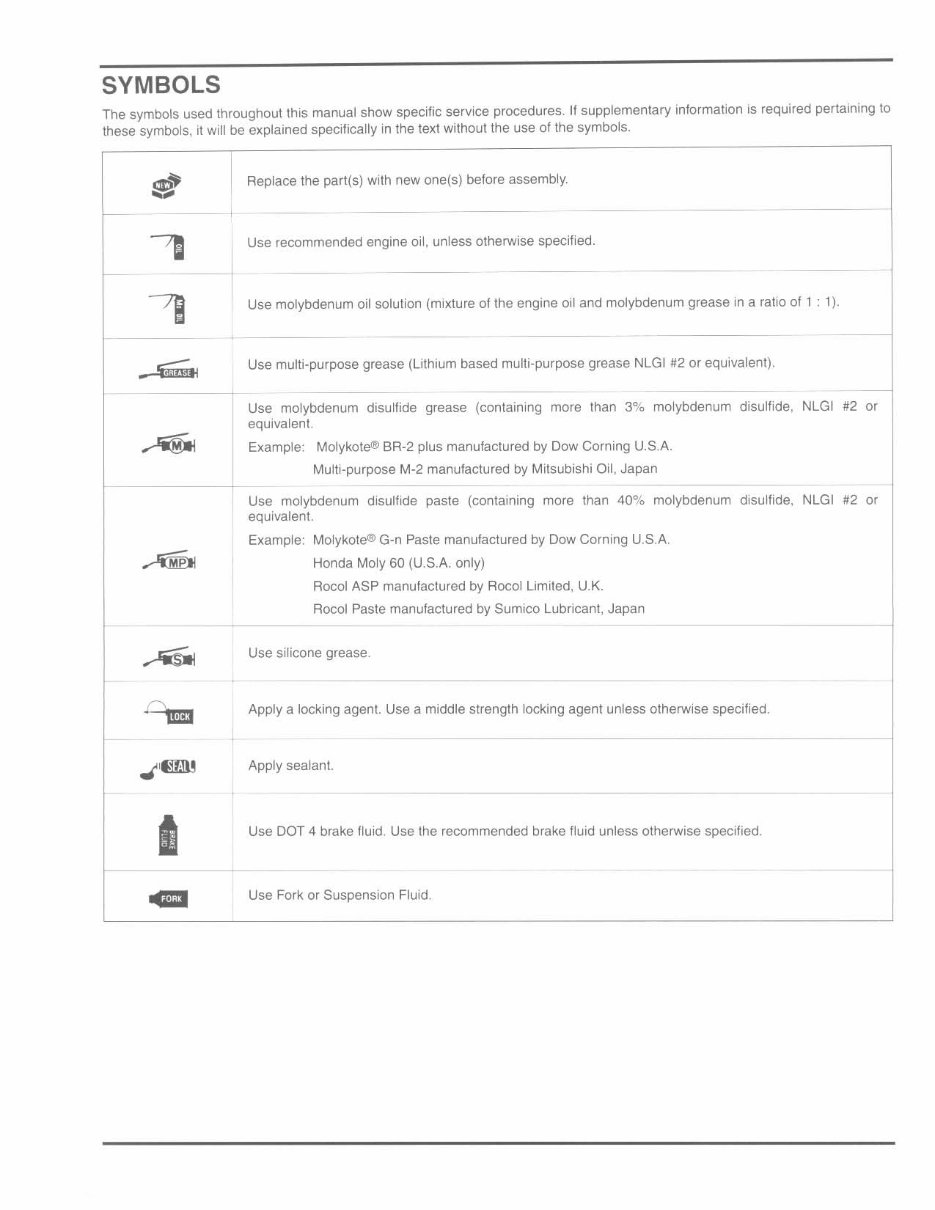

SYMBOLS

The symbols used throughout this manual show specific service procedures. If supplementary information is required pertaining to

these symbols, it will be explained specifically in the text without the use of the symbols.

tt

r-

,

I-

7J

~--..

I

I Replace the part(s) with new one(s) before assembly.

-,

t U,e ,ecommeoded e09ioe oil, oole" olhelWi,e ,pecilied,

Use molybdenum oil solution (mixture of the engine oil and molybdenum grease in a ratio of 1 : 1).

Use mUlti-purpose grease (lithium based multi-purpose grease NLGI #2 or equivalent).

-

-+ -

Use molybdenum disulfide grease (containing more than 3% molybdenum disulfide, NLGI #2 or

equivalent.

Example: Molykote® BR-2 plus manufactured by Dow Corning U.S.A.

Multi-purpose M-2 manufactured by Milsubishi Oil, Japan

---

Use molybdenum disulfide paste (containing more than 40% molybdenum disulfide. NLGI #2 or

equivalent.

Example: Molykote® G-n Paste manufactured by Dow Corning U.S.A.

Honda Moly 60 (U,S.A. only)

Roeol ASP manufactured by Roeol Limited. U.K.

Roeol Paste manufactured by Sumico Lubricant. Japan

Use s il icone grease,

Apply a locking agent. Use a middle strength locking agent unless otherwise specified.

-

Apply sealant.

Use DOT 4 brake fluid. Use the recommended brake fluid unless otherwise specified.

-

Use Fork or Suspension Fluid.

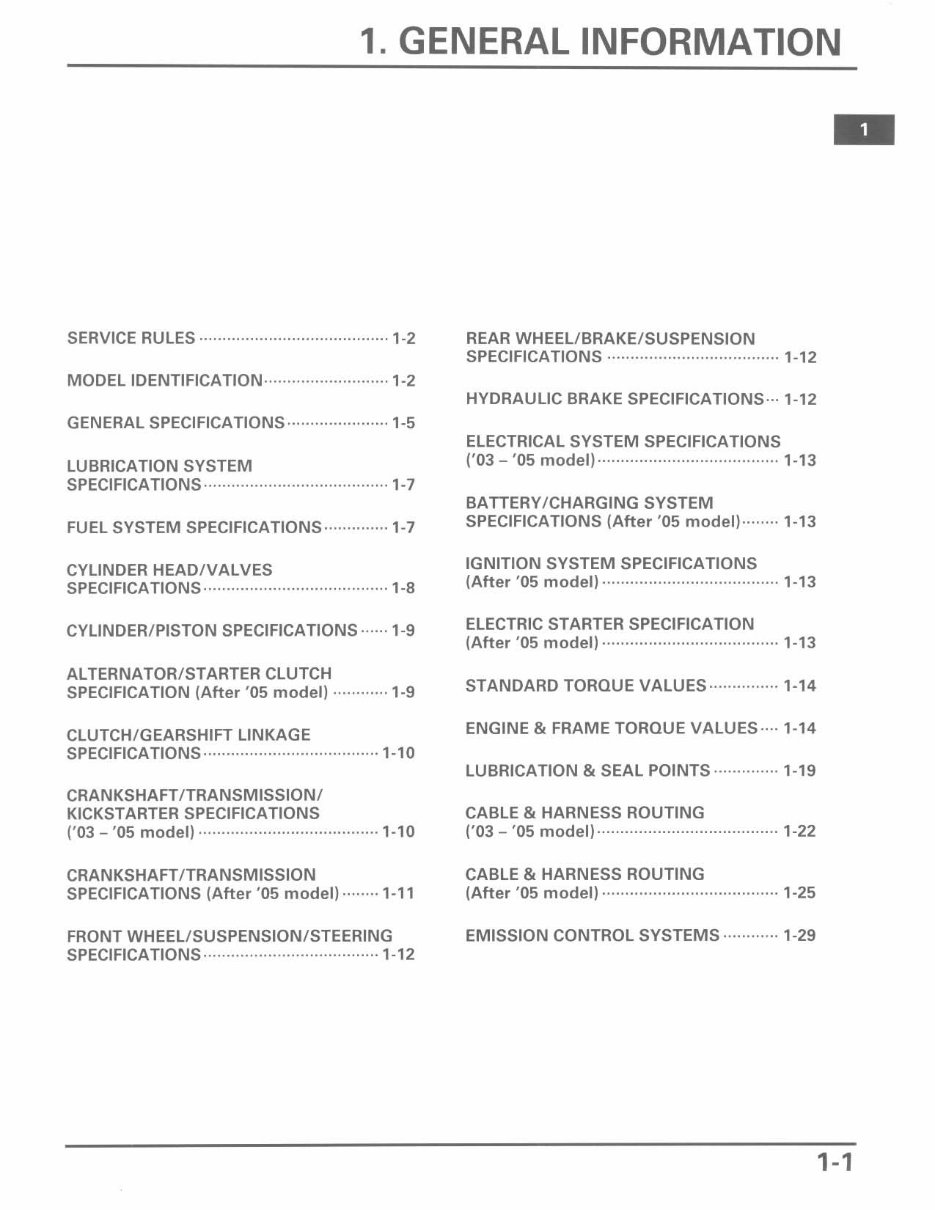

1. GENERAL INFORMATION

SERVICE RULES · .. ·············· .. ······················1-2

MODEL IDENTIFICATION··························· 1-2

GENERAL SPECIFICATIONS ...................... 1-5

LUBRICATION SYSTEM

SPECiFiCATiONS···································· ···1-7

FUEL SYSTEM SPECIFICATIONS·············· 1-7

CYLINDER HEADIV ALVES

SPECiFiCATIONS···························· ···········1-8

CYLINDER/PISTON SPECIFICATIONS ...... 1-9

ALTERNATOR/STARTER CLUTCH

SPECIFICATION (After '05 model) ············1-9

CLUTCH/GEARSHIFT LINKAGE

SPECiFiCATIONS································ ·····1-10

CRANKSHAFT/TRANSMISSION/

KICKSTARTER SPECIFICATIONS

('03 - '05 model) ·······································1-10

CRANKSHAFT/TRANSMISSION

SPECIFICATIONS (After '05 model) ········1-11

FRONT WHEEL/SUSPENSION/STEERING

SPECIFICATIONS······································ 1- 12

REAR WHEEL/BRAKE/SUSPENSION

SPECIFICATIONS ..................................... 1-12

HYDRAULIC BRAKE SPECIFICATIONS··· 1-12

ELECTRICAL SYSTEM SPECIFICATIONS

('03 - '05 model) ....................................... 1-13

BATTERY/CHARGING SYSTEM

SPECIFICATIONS (After '05 model)········ 1-13

IGNITION SYSTEM SPECIFICATIONS

(After '05 model) ······································1-13

ELECTRIC STARTER SPECIFICATION

(After '05 model) ······································1-13

STANDARD TORQUE VALUES··············· 1-14

ENGINE & FRAME TORQUE VALUES···· 1-14

LUBRICATION & SEAL POINTS ··············1-19

CABLE & HARNESS ROUTING

('03 - '05 model)······································· 1-22

CABLE & HARNESS ROUTING

(After '05 model) ······································1-25

EMISSION CONTROL SYSTEMS ............ 1-29

1-1

GENERAL INFORMATION

SERVICE RULES

1. Use genuine Honda or Honda- recommended parts and lubricants or their equivalents. Parts that don't meet Honda's

design specifications may cause damage to the mo torcycl e.

2. Use the special tools designed for this pr oduct to avoid damage and incorrect assembly.

3. Use only metric tools when servicing the motorcycle. Metric bolts, nuts and screws are not interchangeable with

English fasteners.

4. Inslall new gaskets, O-rings, cOlier pins, and lock plates when reassembling.

5. When tightening bolts or nuts, begin with the l arger diamete r or inner bolt first. Then lighten to the specified torque

diagonally in incremental steps unless a particular sequence is specified.

6. Clean parts in cleaning solvent upon disassembly. Lubric ate any sliding surfaces before reassembly.

7. After reassembly. check all parts f or proper installat ion and operation.

S. Route all electrical wires as shown in the Cable and Harness Routing (page 1-22).

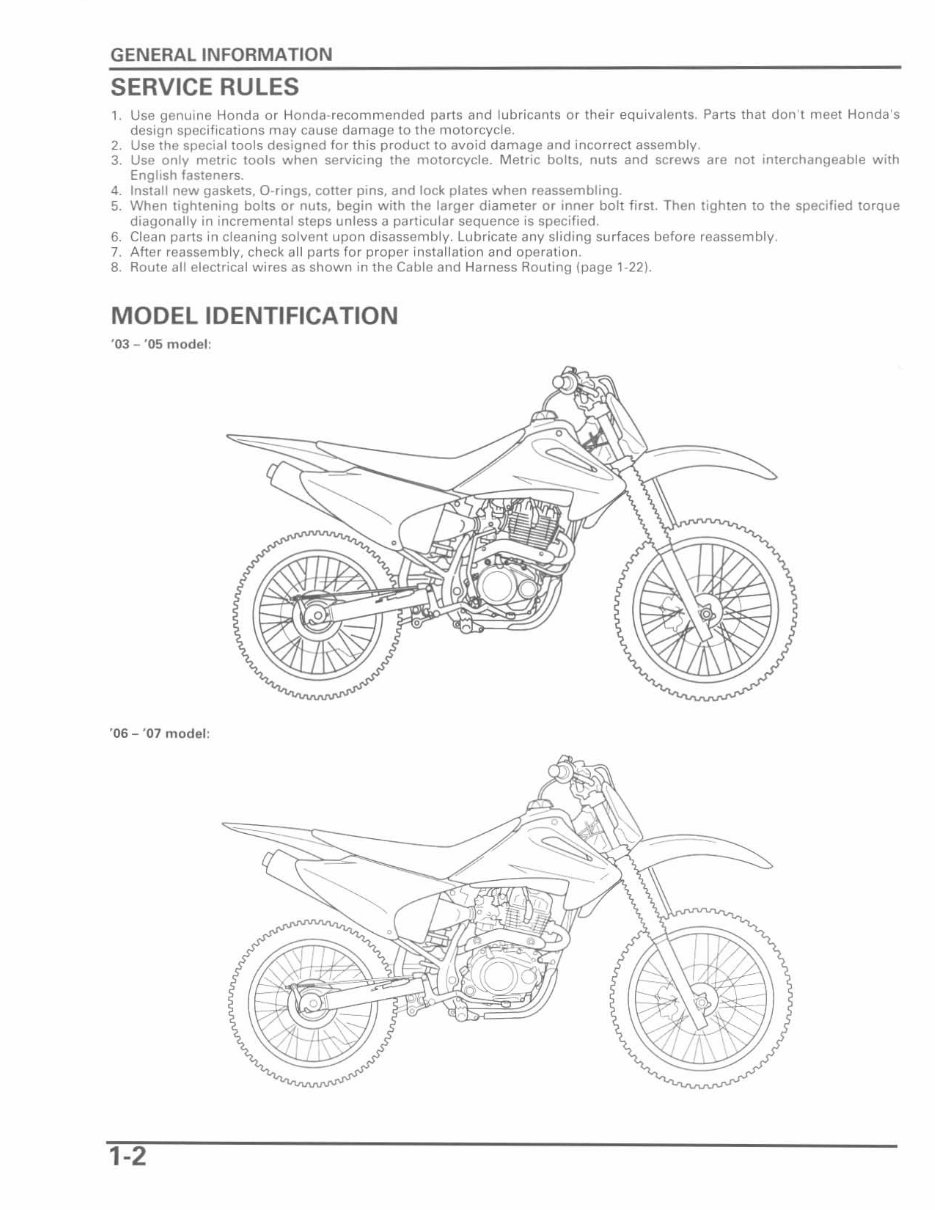

MODEL IDENTIFICATION

'03 - '05 model :

'06 - '07 model :

1-2

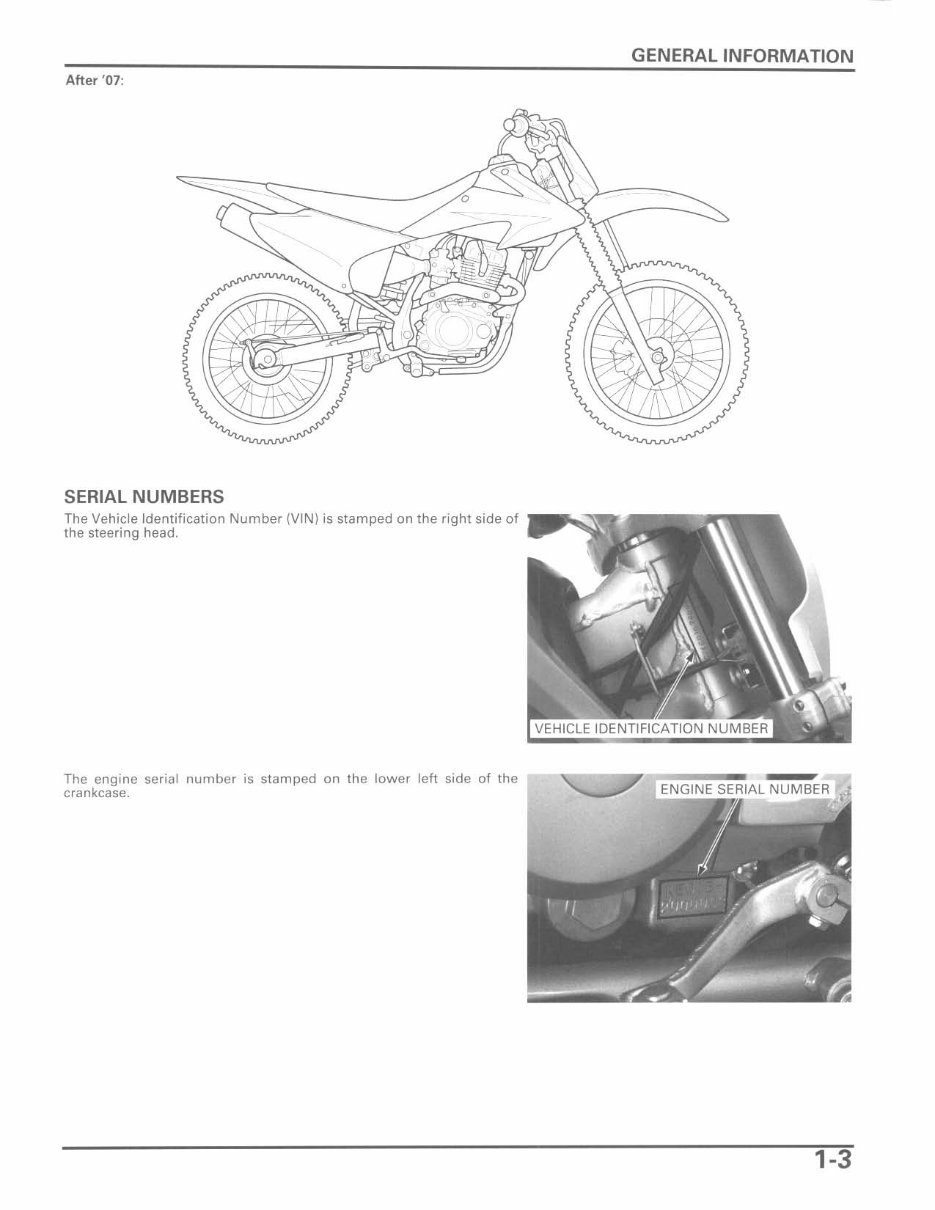

After ' 07 :

SERIAL NUMBERS

The Vehicle Identification Number {VIN} is stamped on the right side of

the steering head.

The engine seria l number is st amped on the lower left side of the

crankcase.

GENERAL INFORMATION

1-3

GENERAL INFORMATION

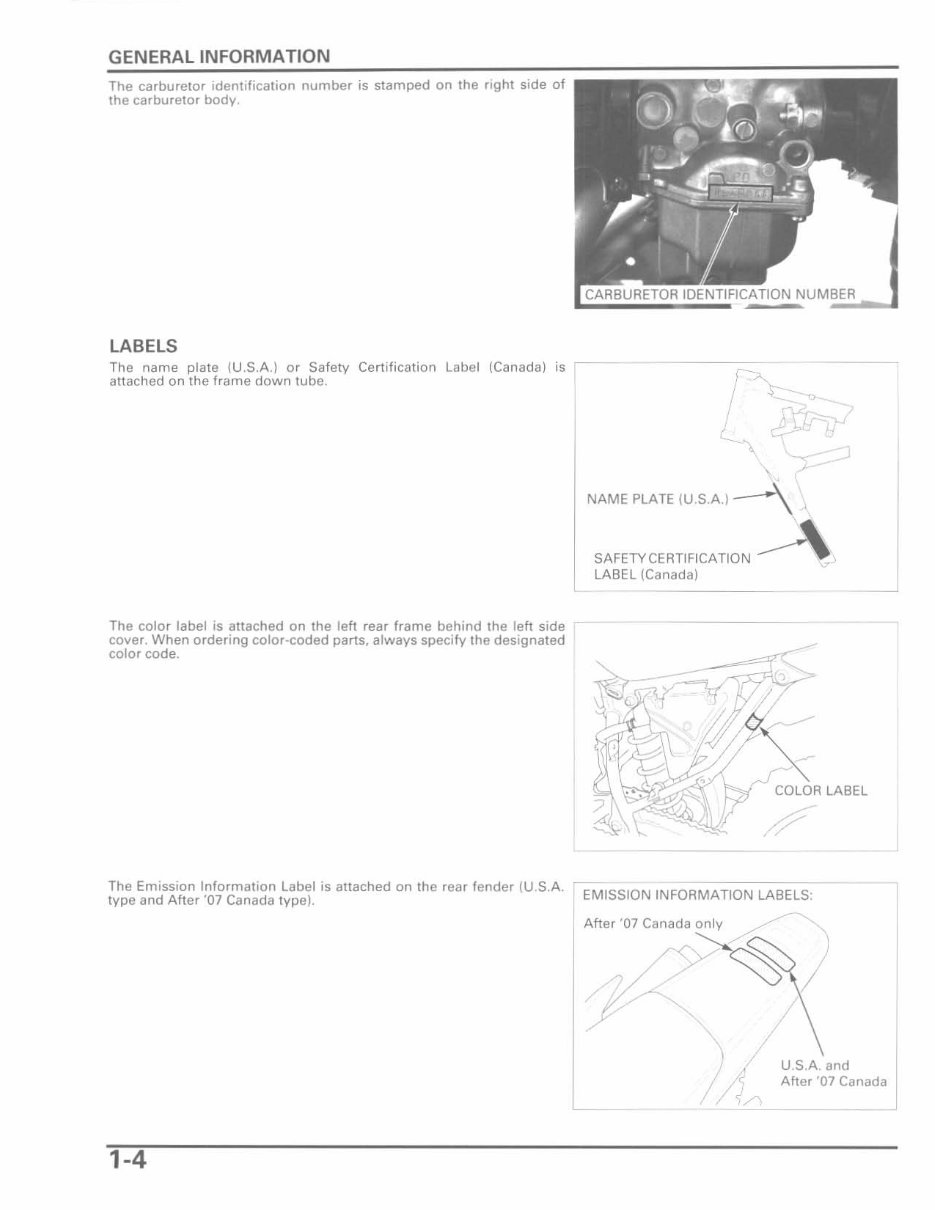

The carbure tor identification number is stamped on the right side of

the carburetor body.

LABELS

The name plate (U.S.A.) or Safety Certification Label (Canada) is - -

attached on the frame down tube.

r~

The color label is attached on the left rear frame behind the left side

cover. When ordering color-coded parts, always specify the designated

color code.

I '

I

!

,

\

\ /-

NAME PLATE (U.S.A.) ~ -'.

c

SAFE1YCERTlFlCATION A

LABEL (Canada)

COLOR LABEL

The Emission Information Label is attached on the rear fender (U.S.A. 'EMISSION INFORMATION LABELS:

type and After '07 Canada type).

Aft" '07 Canada ~

/

U.S.A. and

/

After '07 Canada

1-4

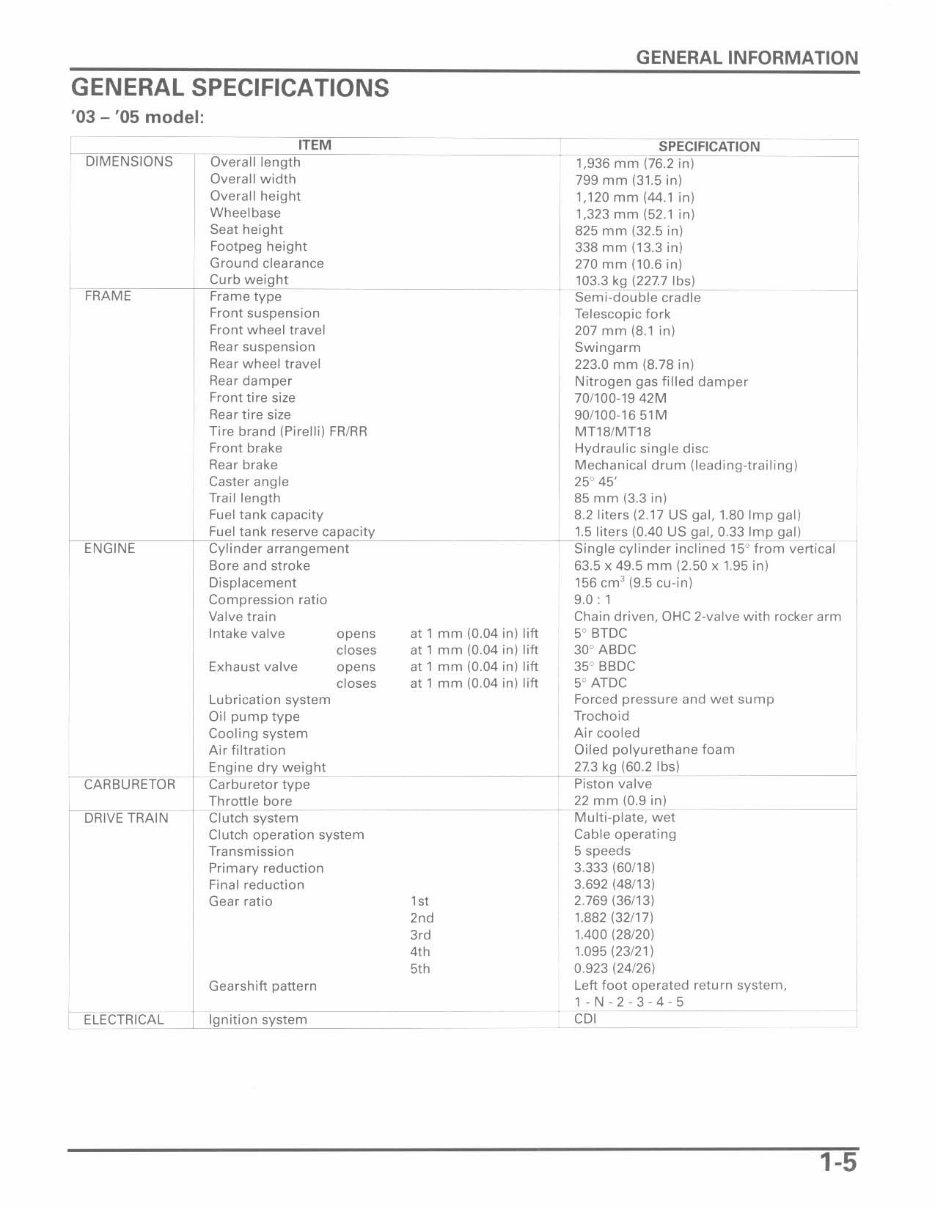

GENERAL SPECIFICATIONS

'03 - '05 model:

I DIMENSIONS

ITEM

Overall length

Overall width

Overall height

Wheelbase

Seat height

Footpeg height

Ground clearance

o _ _ _ f--,C~urb weight

FRAME Frame type

I ENGINE

CARBURETOR

DRIVE TRAIN

ELECTRICAL

Front suspension

Front wheel travel

Rear suspension

Rear wheel travel

Rear damper

Front tire size

Rear tire size

Tire brand (Pirelli) FR/RR

Front brake

Rear brake

Caster angle

Trail length

Fuel tank capacity

Fuel tank reserve capacity

Cylinder arrangement

Bore and stroke

Displacement

Compression ratio

Valve train

Intake valve

Exhaust valve

Lubrication system

Oil pump type

Cooling system

Air filtration

Engine dry weight

Carburetor type

Throttle bore

Clutch system

opens

closes

opens

closes

Clutch operation system

Transmission

Primary reduction

Final reduction

Gear ratio

I Gearshift pattern

1 Ignition system

at 1 mm (0.04 in) lift

at I mm (0.04 in) lift

at 1 mm (0.04 in) lift

at 1 mm (0.04 in) lift

,,,

2nd

3,d

4th

5th

GENERAL INFORMATION

SPECIFICATION

1,936 mm (76.2 in)

799 mm (31.5 in)

1,120 mm (44.1 in)

1,323 mm (52.1 in)

825 mm (32.5 in)

338 mm (13.3 in)

270 mm (10.6 in)

103.3 kg (227.7 Ibs)

Semi-double cradle

Telescopic fork

207 mm (8.1 in)

Swingarm

223.0 mm (8.78 in)

Nitrogen gas filled damper

70/100·1942M

90/100·1651M

MT18/MT18

Hydraulic single disc

Mechanical drum (leading-trailing)

25° 45'

85 mm (3.3 in)

8.2 liters (2.17 US gal, 1.80 Imp gal)

1.5 liters {0.40 US gal, 0.33 Imp gal}

Single cylinder inclined 15" from vertical

63.5 x 49.5 mm (2.50 x 1.95 in)

156 cm

3

(9.5 cu-in)

9.0: 1

Chain driven. OHC 2-valve with rocker arm

5° BTDC

30" ABDC

35° BBDC

5° ATDC

Forced pressure and wet sump

Trochoid

Air cooled

Oiled polyurethane foam

27.3 kg (60.2 Ibs)

-- Piston valve

22 mm (0.9 in)

Multi-plate, wet

Cable operating

5 speeds

3.333 (60/18)

3.692 (48/13)

2.769 (36/13)

1.882 (32/17)

1.400 (28/20)

1.095 (23/21)

0.923 (24/26)

Left foot operated return system.

l-N-2-3-4-5

COl

1-5

GENERAL INFORMATION

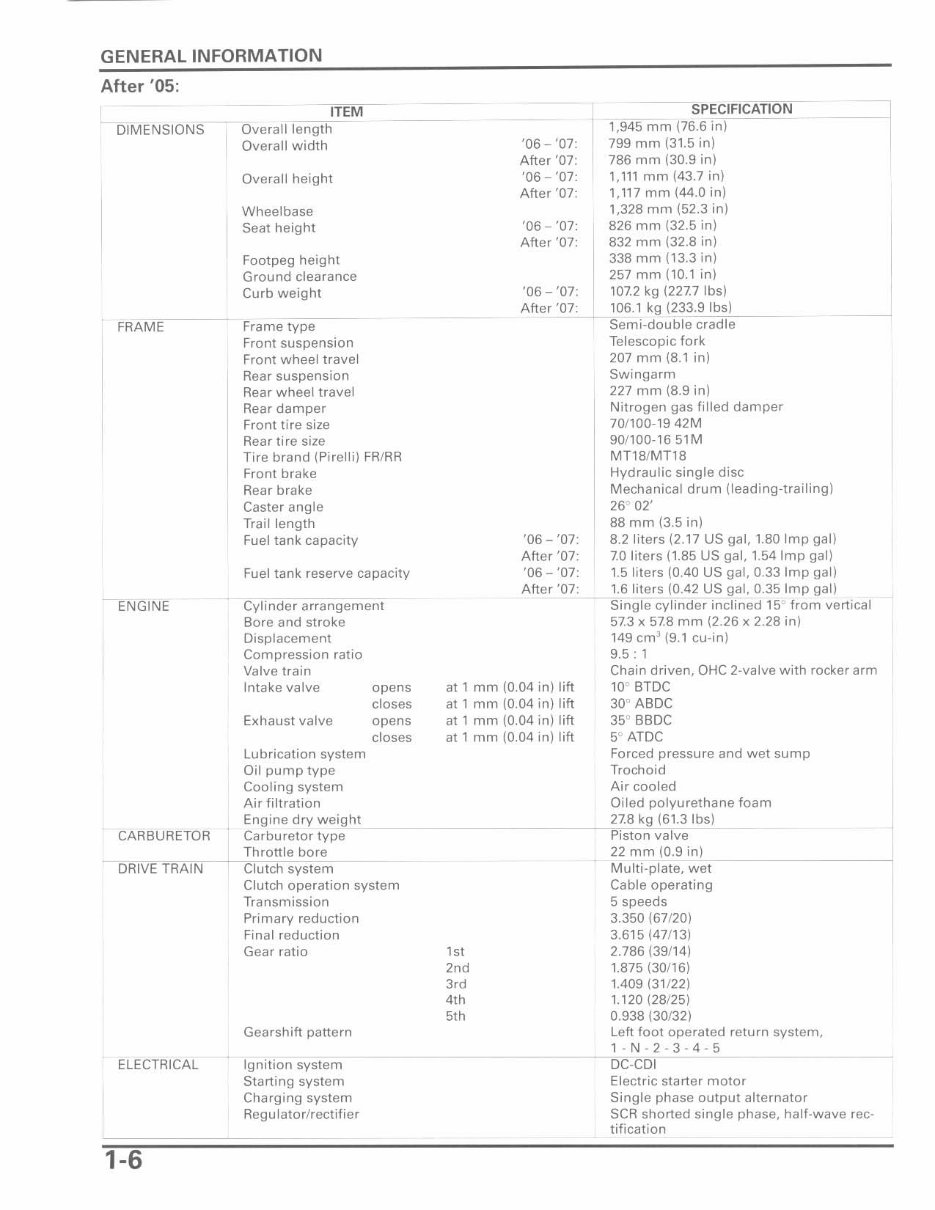

After '05:

DIMENSIONS

FRAME

ENGINE

CARBURETOR

ITEM

Overatllength

Overall width

Overall height

Wheelbase

Seat height

Footpeg height

Ground clearance

Curb weight

Frame type

Front suspension

Front wheel travel

Rear suspension

Rear whee l travel

Rear damper

Front tire size

Rear tire size

Tire brand (Pirelli) FR/RR

Front brake

Rear brake

Caster angle

Trail length

Fuel tank capacity

Fuel tank reserve capacity

Cylinder arrangement

Bore and stroke

Displacement

Compression ratio

Valve train

Intake valve opens

closes

Exhaust valve opens

lubrication syst em

Oil pump type

Cooling system

Air filtration

closes

Engine dry weight

Carburetor type

Throttle bore

DRIVE TR'''A''INCO-~-C;;I:C"~tch system

ELECTRICAL

1-6

Clutch ope r ation system

Transmission

Primary reduction

Final reduction

Gear ratio

Gearshift pattern

Ignition system

Starting system

Charging system

Reg u lato rlrect ifie r

'06 - '07:

After '07:

'06 - '07:

After '07:

'06 - '07:

After '07:

'06 - '07:

After '07:

SPECIFICATION

1,945 mm (76.6 in)

799 mm (31.5 in)

786 mm (30.9 in)

1, III mm (43.7 in)

1,117 mm (44.0 in)

1,328 mm (52.3 in)

826 mm (32.5 in)

832 mm (32.8 in)

338 mm (13.3 in)

257 mm (10.1 in)

107.2 kg (227.7 Ibs)

106.1 kg (233.9 Ibs) .

Semi-double cradle

Telescopic fork

207 mm (8.1 in)

Swingarm

227 mm (8.9 in)

Nitrogen gas filled damper

70/100-1942M

90/100-1651M

MT18/MT18

Hydraulic single disc

Mechanical drum (leading - trailing)

26° 02'

88 mm (3.5 in)

'06 - '07: 8.2 liters (2.17 US gal, 1.80 Imp gal)

After '07: 7.0 lit ers (1.85 US gal, 1.54 Imp gall

'06 - '07: 1.5 liters (OAO US gal, 0.33 Imp gal)

After _ 'O~7~'_~ '~.6~liters (0.42 US gal, 0.35 Imp gal)

Single cylinder inclined 15° f rom vertical

57.3 x 57.8 mm (2.26 x 2.28 in)

149 em' (9.1 cu-in)

9.5 : 1

at I mm (0.04 in) lift

at 1 mm (0.04 in) lift

at I mm (0.04 i n) lift

at 1 mm (0.04 in) lift

Chain driven, QHC 2·valve with rocker arm

10° BTDC

30 ABDC

35° BBDC

5° ATDC

,"

2,d

'cd

4th

5th

Forced pressure and wet sump

Trochoid

Air cooled

Oiled polyurethane foam

__ ~_2",7".8",kg (61.3 Ibs)

Piston valve

22 mm (0.9 in)

Multi·plate, wet

Cable operating

5 speeds

3.350 (67/20)

3.615 (47/13)

2.786 (39/14)

1.875 (30116)

1.409 (31/22)

1.120 (28/25)

0.938 (30/32)

Left foot operated return system,

1- N·2·3·4·5

DC·CDI

Electric starter motor

Single phase output alternator

seR shorted single phase, half·wave rec-

tification

GENERAL INFORMATION

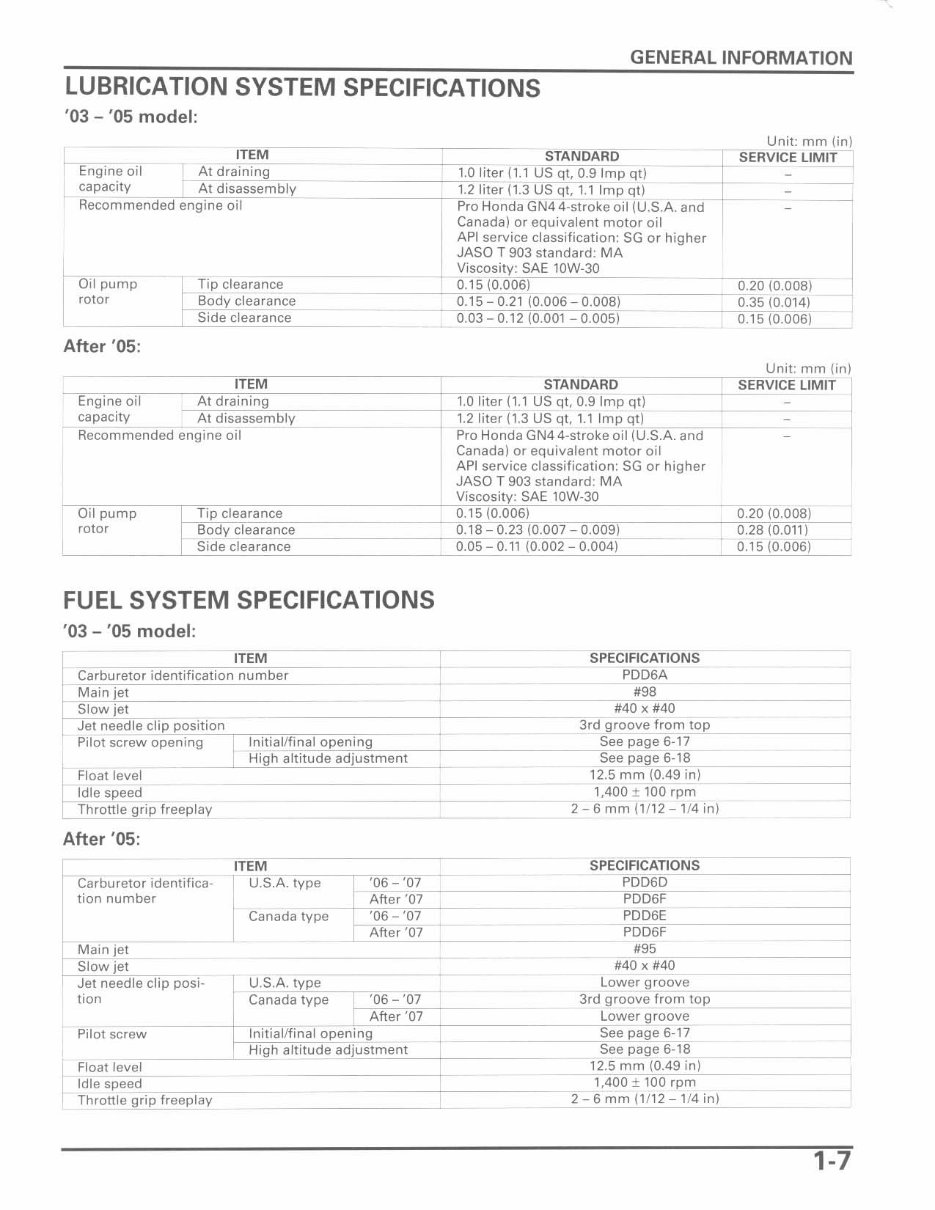

LUBRICATION SYSTEM SPECIFICATIONS

' 03 - '05 model:

ITEM

Engine oil At draining

capacity At disassembly

Recommended engine oil

Oil pump

rotor

Tip clearance

Body clearance

Side clearance

Unit: mm (in)

STANDARD ~ ERVICE LIMIT

-====~1.0 liter (1.1 US qt, 0.9 Imp qt) _

1.2 liter (1.3 US qt, 1.1 Imp qt) - ---

----+-~P~ro Honda GN4 4-stroke oil (U.S.A. and _

Canada) or equivalent motor oil

1

API service classification: SG or higher

JASO T 903 standard: MA

Viscosity: SAE lOW-30 __ ~~=

0.15 (0.006) _____ 0.20 (0.008)

0.15 0.21 {0.006 O.OOB} 0.35 (0.014)

0.03 0.12 (0.001 0.005) 0.15 (O.006)

After '05:

ITEM

Engine oil At draining

capacity At disassembly

Recommended engine oil

Unit: mm (in)

STANDARD ___ + -"S ER VICE LIMIT I

1.0 liter (1.1 US qt, 0.9 Imp qt) ~

1.2 liter (1.3 US qt. 1.1,~lm~p~q~t)~~;:;:;:::==-

Pro Honda GN44-stroke oil (U.S.A. and 1

Canada) or equivalent motor oil

API service classification: SG or higher

JASO T 903 standard: MA

Viscosity: SAE lOW-30

Oil pump

rotor

Tip clearance

Body clearance

Side clearance

0.15 (0.006) 0.20 (0.008)

__ ~",0.,c.'8~- 0.23 (0.007 - 0.0'''09'''1----~---i OC;.2fii8iIOiC.iCo,i'i,i'-1

0.05 0.11 (0.002 - 0.004) 0.15 (0.006)

FUEL SYSTEM SPECIFICATIONS

'03 - '05 model :

ITEM

Carburetor identification number

Main jet

Slow jet

Jet needle clip position

Pilot screw opening Initial/final opening

Float level

Idle speed

Throttle grip freeplay

After ' 05:

I High altitude adjustment

ITEM

SPECIFICATIONS

PDD6A

#98

#40 x #40

3rd groove from top

See page 6·17

Seepage6·18

12.5 mm (O.49 in)

1,400 ± 100 rpm

2 - 6 mm (1/12 -1/4 in)

SPE CIFICATIONS

~~ ________________ ~PDD6D

+~'"-c~-- PDD6F

I Carburetor identifica· U.S.A. type '06 '07

tion number After '07

t

Canada type

Main jet

Slow jet

Jet needle clip posi· U.S.A. type

·06 ·07

After '07

PDD6E

PDD6F

#95

#40 x #40

Lower groove

tion Canada type

I

'06 '07 3rd groove from t~o2P ,-______ _

After '07 Lower groove

___ -iS~'~'~page 6·17

See page 6·18

Pilot screw Initial/final opening

High altitude adjustment

Float level 12.5 mm (0.49 in)

t

Idle speed

,

Throttle grip freeplay

1,400 ± 100 rpm

2 - 6 mm (1/12 - 1/4 in)

1-7

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 77 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get your hands on the comprehensive repair manual for the 2003-2013 Honda CRF150F four-stroke bike. This manual covers everything from complete tear down and rebuild, to pictures and part diagrams, torque specs, maintenance, troubleshooting, and more. With 403 pages, it's a valuable resource for both professional mechanics and DIY enthusiasts.

This manual features clickable chapters and is searchable, making it easy to find the information you need. There are no restrictions on printing or saving/burning to disc, providing you with convenient access to the manual.

- Complete tear down and rebuild

- Pictures and part diagrams

- Torque specs

- Maintenance procedures

- Troubleshooting guidance

- Clickable chapters

- Searchable content

- No restrictions on printing or saving/burning to disc