1995-2007 CR80R / CR85R CR80 CR85 Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

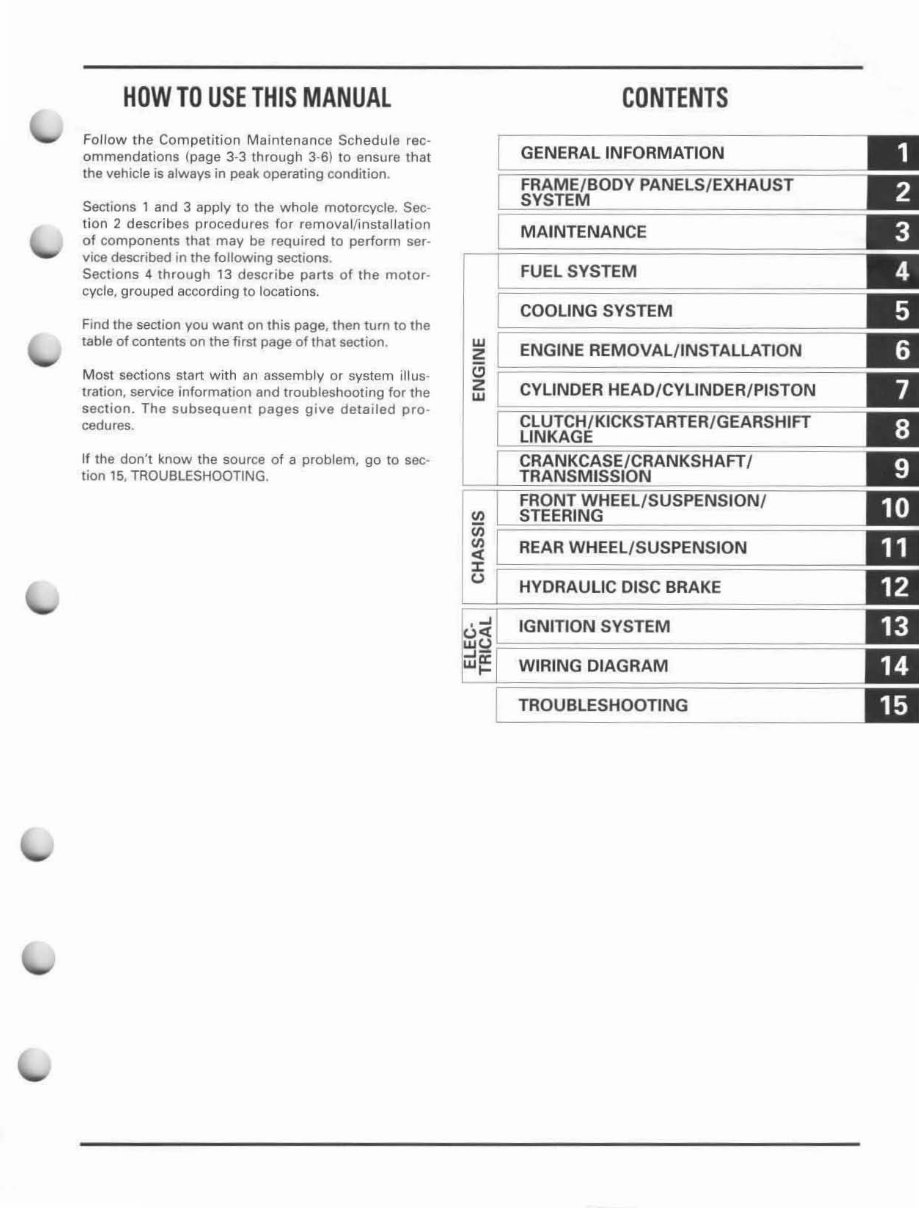

HOW TO USE THIS MANUAL

Follow the Competition Maintenance Schedule rec-

ommendations (page 3-3 through 3-6) to ensure that

the vehicle is always in peak operating condition .

Sections 1 and 3 apply to the whole motorcycle. Sec-

tion 2 describes procedures for remova l/ installation

of components that may be required to perform ser-

vice described in the following sections.

Sections 4 through 13 describe parts of the motor-

cycle, grouped according to locations.

Find the section you want on this page, then turn to the

table of contents on the first page of that section.

Most sections start wi th an assembly or system illus-

tration, service information and troubleshooting for the

section. The subsequent pages give detailed pro -

cedures.

If the don't know the source of a problem, go to sec-

tion 15, TROUBLESHOOTING_

w

Z

C;

Z

w

CONTENTS

GENERAL INFORMATION

MAINTENANCE

FUEL SYSTEM

COOLING SYSTEM

ENGINE REMOVAL/INSTALLATION

REAR WHEEL/SUSPENSION

HYDRAULIC DISC BRAKE

IGNITION SYSTEM

WIRING DIAGRAM

TROUBLESHOOTING

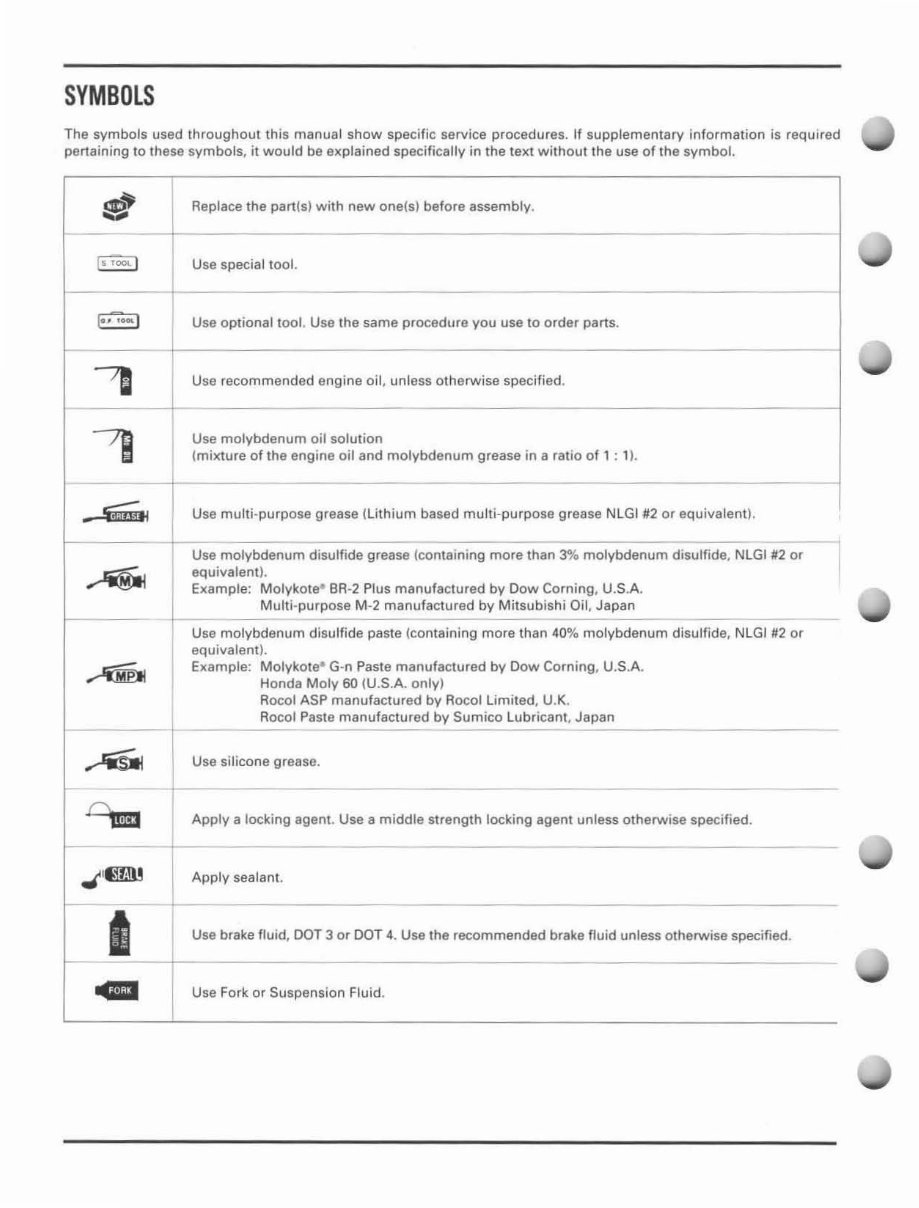

SYMBOLS

The symbols used throughout this manual show specific service procedures. If supplementary information is required

pertaining to Ihese symbols. it would be explained specifically in the texi without the use of the symbol.

!:!~

....

Replace the panls) with new onels) before assembly.

r-

[S TOOL I

Use special tool.

[_ ·"7_ 1

Use optional tool. Use the same procedure you use to order parts.

'I

Use recommended engine oil, unless otherwise specified.

-

, Use molybdenum oil solution

(mixture of the engine oil and molybdenum grease in a ratio of 1 : 1).

-

.-..

Use multi ·purpose grease (lithium basad multi-purpose grease NlGI #2 or equivalent),

Use molybdenum disulfide grease (containing more than 3% molybdenum disulfide, NLGI #2 or

~

equivalent).

Example: Molykote- BR-2 Plus manufac tured by Dow Corning . U.S.A.

Multi · purpose M·2 manufa ctured by Mitsubishi Oil. Japan

Use molybdenum disulfide paste (containing more than 40% molybdenum disulfide, NLGl 1i2 or

equivalent).

~

Example: Molykote- G·n Paste manufactured by Dow Corning . U.S.A.

Honda Moly 60 (U.S.A. only)

Roeol ASP manufactured by Rocol Limited, U .K.

Roeol Paste manufactured by Sumico Lubricant, Japan

..--riSit1

Use silicone grease.

---

C)""

Apply a locking agent. Use a middle strength locking agent unless otherwise specified.

,",' &lID!

Apply sealant.

I

Use brake fluid, DOT 3 or DOT 4. Use the recommended brake fluid unless otherwise specified.

..

I

Use Fork or Suspension Fluid.

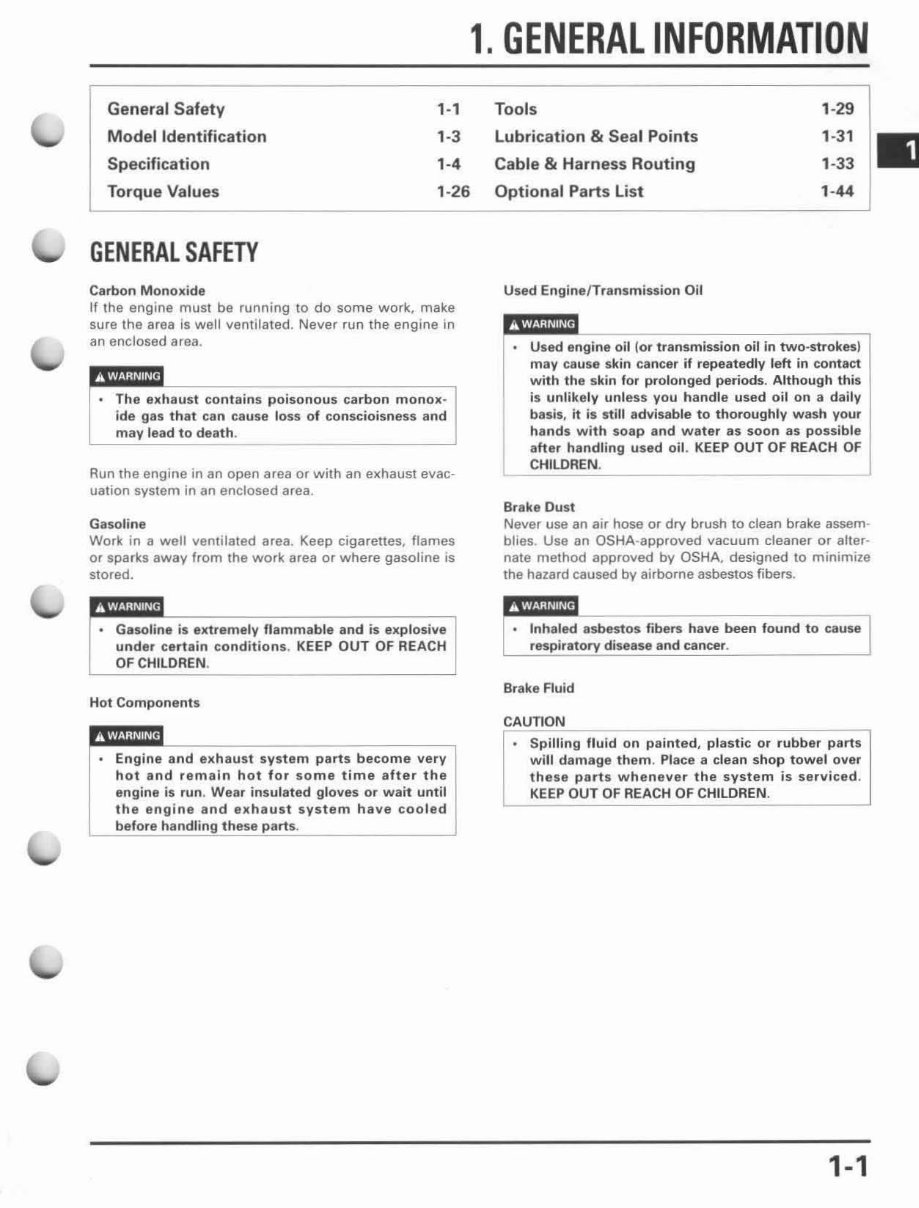

General Safety

Model Identification

Specification

Torque Values

GENERAL SAFETY

Carbon Monoxide

1-1

1-3

1-4

1-26

If th e engine must be r unning to do some work, make

sure the ar ea is well ventilated. Never r un the en gine in

an enclosed area .

The exhaust contains poisonous carbon monox -

Ide gas that un cause loss of conscioisness and

may lead to death .

Run the engine in an open area or with an exhaust evac-

uation system in an enclosed area.

Gasoline

Work in a well ventilated area. Keep cigarett es. flames

or sparks away fr om the wo rk area or whe re gaso l ine is

stored.

Gasoline is 8.lCtremely flammable and is explosive

under certain conditions . KEEP OUT OF REACH

OF CHILDREN.

Hot Component s

Engine and exhaust system parts become very

hot and remain hot for some time after the

engine is run . Wear insulated gloves or wait until

the engine and eKhaust system have cooled

before these

1. GENERAL INFORMATION

Tools

lubrication & Seal Points

Cable & Harness Routing

Optional Parts list

Used Engine/Transmission Oil

1-29

1 -31

1-33

1-44

Used engine oil (or transmission oil in two-strokes)

may cause skin cancer if repeatedly left in contact

with the skin for prolonged periods. Although this

is unlikely unless you handle used oil on a daily

basis, it is still advisable to thoroughly wash your

hands with soap and water as soon as possible

after handling used oil. KEEP OUT OF REACH OF

CHILDREN.

Brake Dust

Never use an air hose or dry brush to dean brake assem·

blies. Use an OSHA-app r oved vacuum deaner or alter-

nate me t hod approved by OSHA, designed to minimize

the hazard caused by airborne asbestos fibers.

Inhaled asbestos fibers have been found to cause

Brake Fluid

CAUTION

Spilling f luid on painted, plastic or rubber parts

will damage them . Place a clean shop towel over

these parts whenever the system is serviced .

KEEP OUT OF REACH OF CHILDREN .

1-1

GENERAL INFORMATION

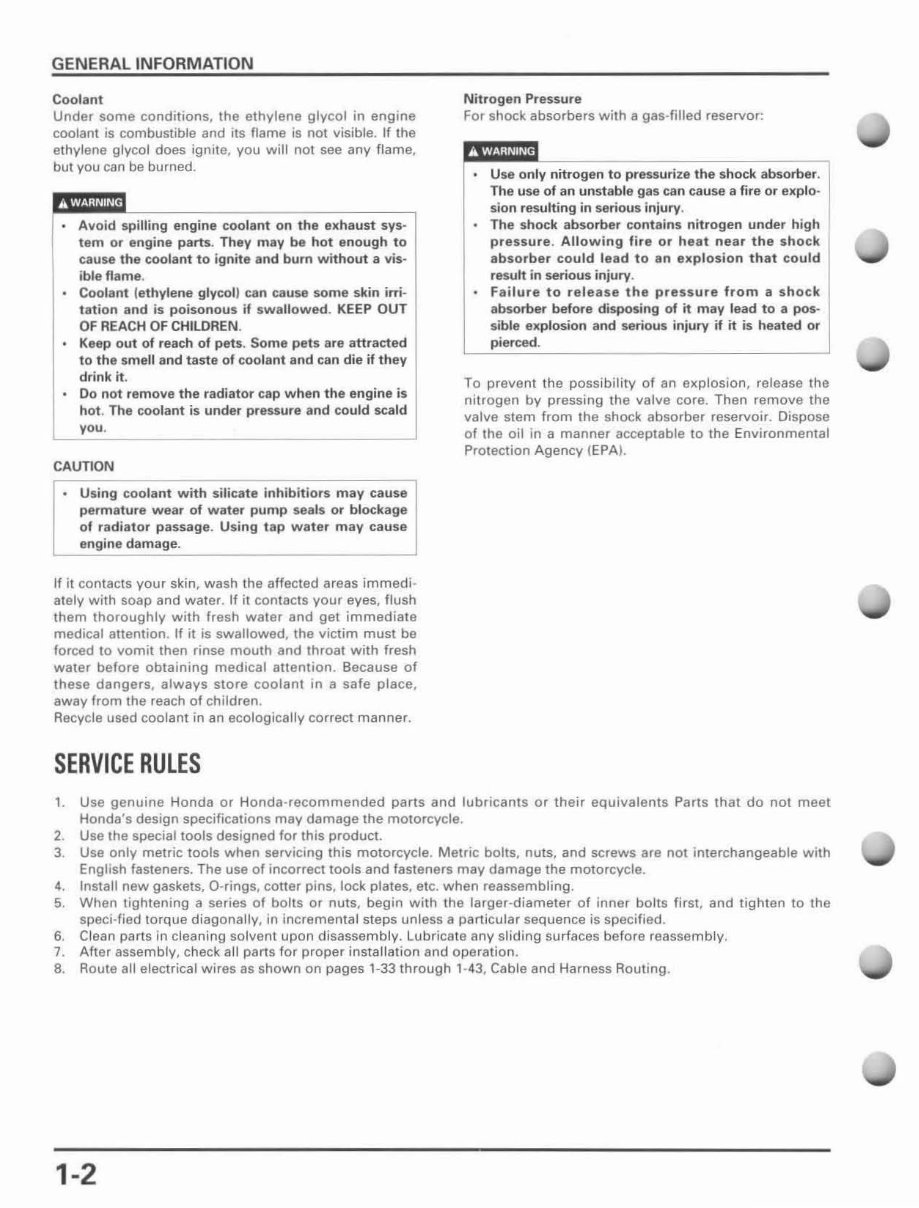

Coolant

Under some condi tions, the ethylene glycol in engine

coolant is combustible and its flame is nol visible. If the

ethylene glycol does ignite, you will not see any flame,

but you can be burned.

A void spilling engine cool ant on the exhaust sys-

tem or engine parts. They may be hot enough to

cause the coolant to ignite and bum without a vis-

ibleflame .

Coolant (ethylene glycol! can cause some skin irri-

tation and is poisonous if swa llowed. KEEP OUT

OF REACH OF CHILDREN.

Keep out of reach of pets . Some pets are attracted

to th e smell and taste of coolant and can die if they

drink it.

00 not remove the radiator cap when the engine is

hot . The coolant is under pressure and could sca ld

CAUTION

Using coo lant with silicate inhibitiors may cause

permature wear of water pump seals or blockage

of radiator passage. Using tap wa ter may cause

engine damage.

If it contacts your skin, wash th e affected areas immedi -

ately with soap and water. If it contacts your eyes, flush

them thoroughly with fresh water and get immedia te

medical attention. If it is swallowed, the victim must be

forced to vomit then rinse mouth and throat with fresh

water before obtaining medical atlention. Because of

these dangers, always store coolant in a safe place ,

away from the reach of children .

Recycle used coolant in an ecologically correct manner.

SERVICE RULES

Nitrogen Pressure

For shock absorbers with a gas-filled reservor:

Use only nitrogen to pressuri ze the shock absorber.

The use of an unstable gas can cause a fire or explo-

sion r es ulting in serious injury.

The shock absorber contains nitrogen under high

pressure . Allowing fire or heat near the shock

absorber co uld lead to an explosion that could

r esult in serious injury.

Failure to relea se the pressure from a sh ock

absorber before disposing of it may lead to a pos-

sible eKplosion and serious injury if it is heated or

To prevent the possibility of an explosion, release the

nitrogen by pressing the valve core. Then remove the

valve stem from the shock absorber reservoir. Dispose

of the oil in a manner acceptable to the En vironmental

Protection Agency (EPA ).

,. Use genuine Honda or Honda - recommended parts and lubricants or their equivalents Parts that do not meet

Honda 's design specifications may damage the motorcycle.

2. Use the special tools designed for this product.

3. Use only metric tools when servicing this motorcycle. Metric bolts, nuts, and screws are not interchangeable with

English 'asteners. The use of incorrect tools and fasteners may damage the motorcycle.

4. Install new gaskets, O-rings, cotter pins, lock plates, etc. when reassembling.

5. When tightening a series of bolts or nuts, begin with the l arger-diameter of inner bolts first, and tighten to the

speci-fied torque diagonally, in increment al steps unless a particular sequence is specified.

6. Clean parts in cleaning solvent upon disassembly. Lubricate any sliding surfaces before reassembl y.

7. After assembly, check all parts for proper installation and operation.

S. Route all electrical wires as shown on pages '-33 through '- 43 , Cable and Harness Routing.

1-2

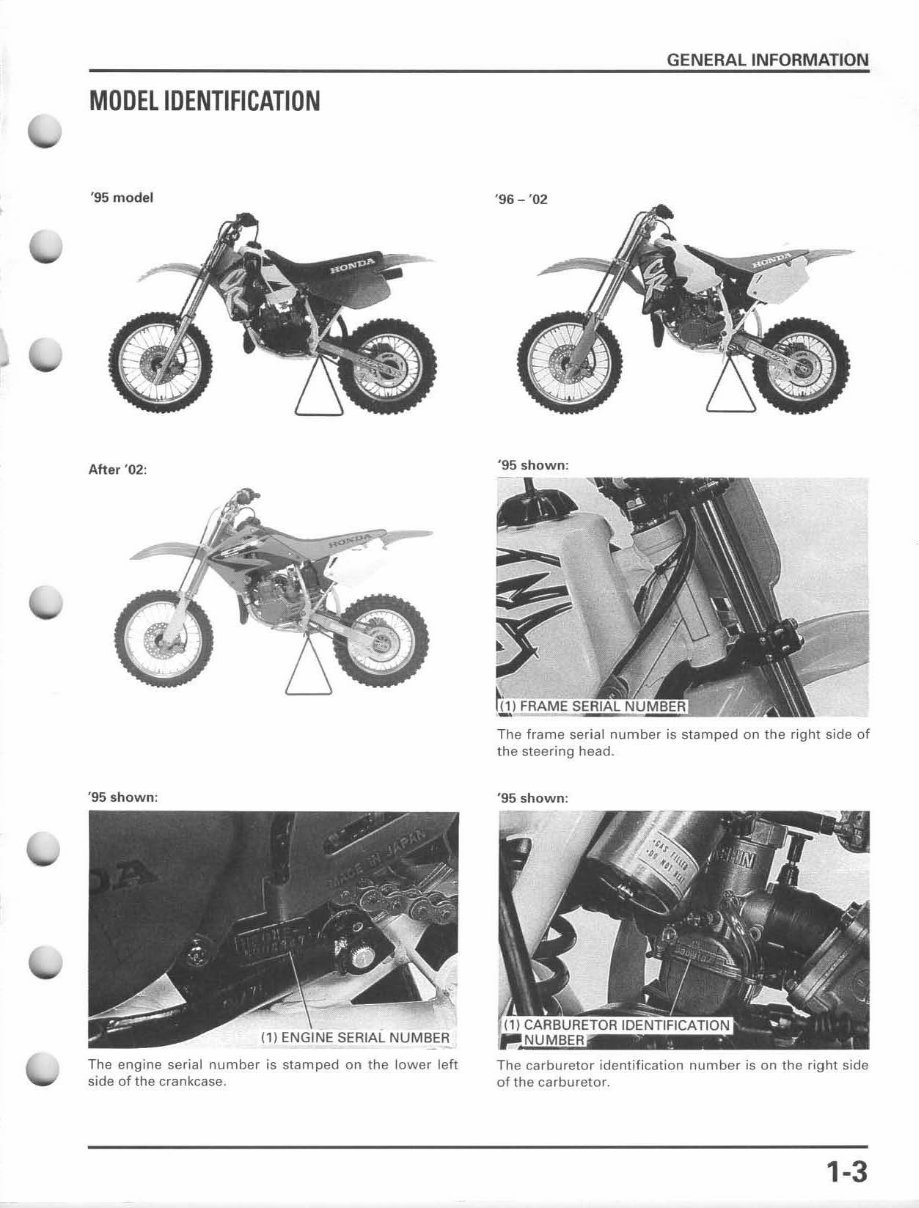

MODEL IDENTIFICATION

'95 model

After '02:

'95 s hown:

The engine serial number is stamped on the lower left

side of the crankcase.

GENERAL INFORMATION

' 96- ' 02

'95 shown :

The frame serial number is stamped on t he right side of

the steering head.

'95 shown:

The carburetor identification number is on the right side

of the carburetor.

1-3

GENERAL INFORMATION

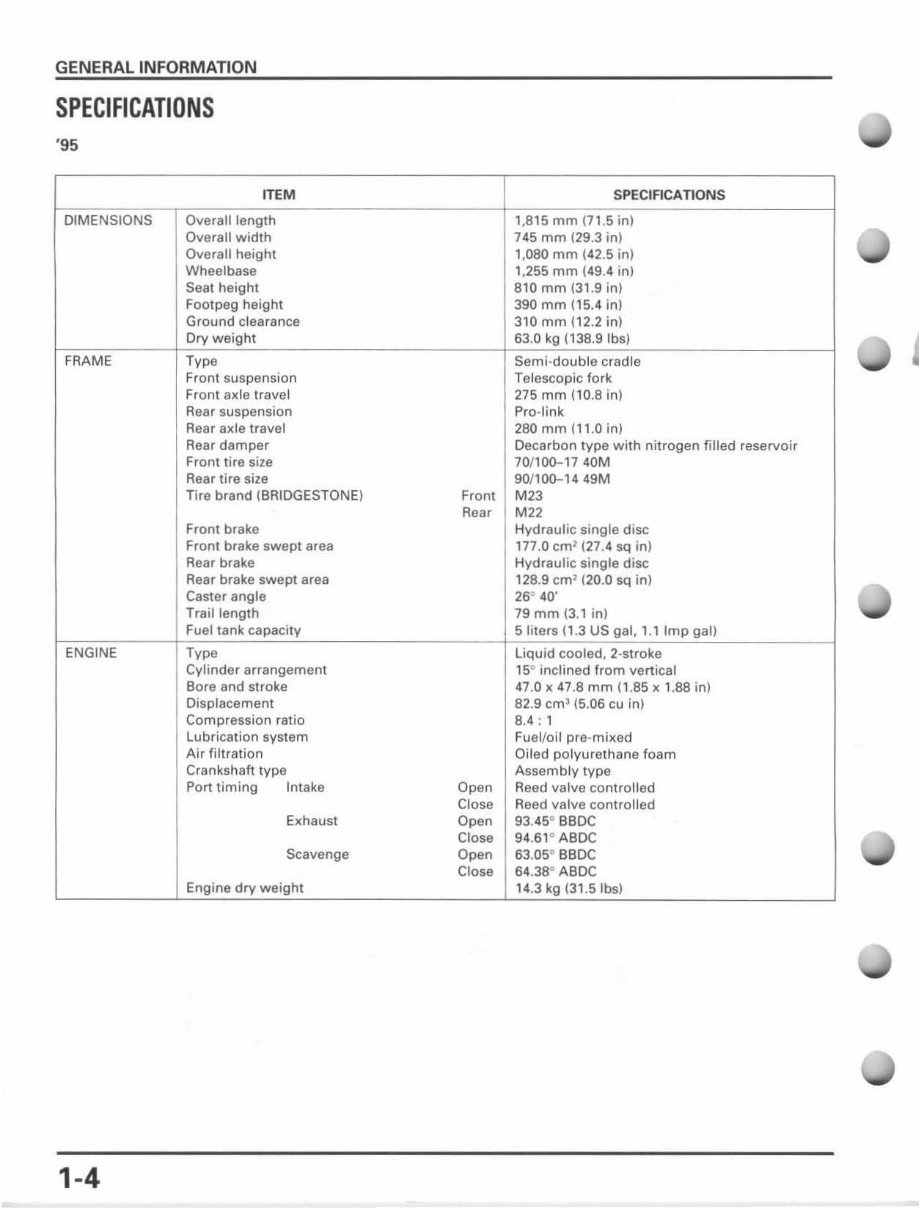

SPECIFICATIONS

'95

ITEM SPECIFICATIONS

DIMEN SIONS Overall length 1,815 mm (71.5 in)

Overall width 745 mm (29.3 in)

Overall height 1,080 mm (42.5 in)

Wheelbase 1,255 mm (49.4 in)

Seat height 810 mm (31.9 in)

Footpeg height 390 mm (15.4 in)

Ground clearance 310 mm 112.2 in)

Dry weight 63 .0 kg (138.9 Ibs)

FRAME Type Semi-double cradle

Front suspension Telescopic fork

Front axle travel 275 mm (10.8 in)

Rear suspension Pro-link

Rear axle travel 280 mm (11.0 in)

Rear damper Decarbon type with nitrogen filled reservoir

Fronllire size 70/100-17 40M

Rear tire size 90/ 100-1449M

Tire brand (BAIDGESTONE ) Fr ont M23

Rear M22

Front brake Hydraulic single disc

Front brake swept area 177.0 cm

1

(27.4 sq in)

Rear brake Hydraulic single disc

Rear brake swept area 128.9 cm

1

( 20 .0 sq in)

Caster angle 26" 40'

Trail length 79 mm 13. 1 in)

Fuel tank capacity 5 liters 11.3 US gal. 1.1 Imp gal)

ENGINE Type liquid cooled, 2-stroke

Cylinder arrangement 15" inclined from vertical

Bore and stroke 47 .0 x 47 .8 mm 11.85 x 1.88 in)

Displacement 82.9 em' (5.06 cu in)

Compression ratio 8.4 : 1

lubrication system Fuel/oil pre·mixed

Air filtration Oiled polyurethane foam

Crankshaft type Assembly type

Port timing Intake Open Reed valve controlled

Close Reed valve controlled

Exhaust Open 93 .45" BBDC

Close 94 .61 " ABDC

Scavenge Open 63 .05" BBDC

Close 64 .38" ABDC

Engine dry weight 14.3 kg (31.5 Ibs)

1-4

GENERAL INFORMATION

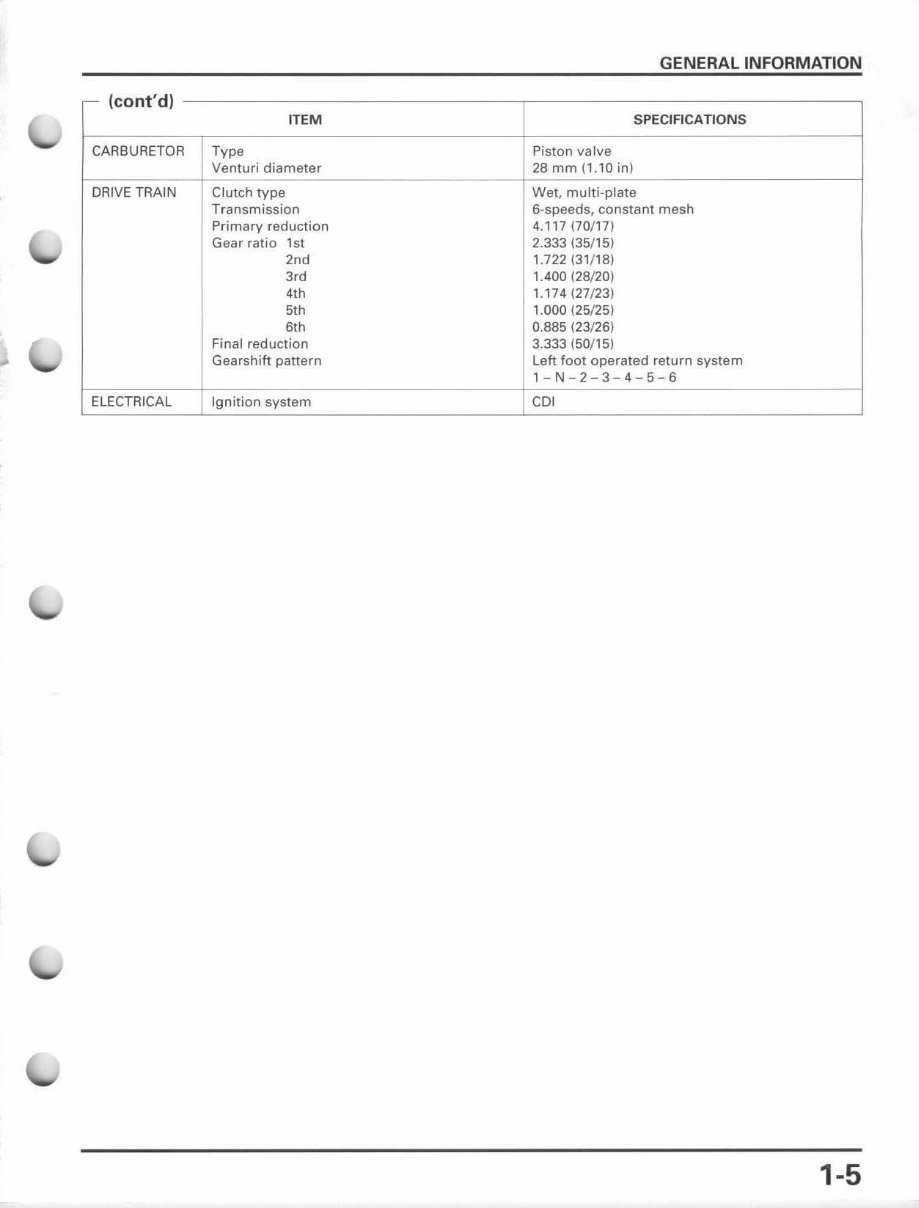

- (c ant 'd)

ITEM SPECIFI CA TION S

CARBURETOR Type Piston valve

Venturi diameter 28 mm (1.10 in )

DRIVE TRAIN Clutch type Wet, multi-plate

Transmission 6-speeds, constant mesh

Primary reduction 4.117 (70/17)

Gear ratio 1st 2.333 (35/ 15 )

2nd 1.722 (31 / 18)

3,d 1.400 (28/20)

4th 1.174 (27/23)

5th 1.000 (25/25)

6th 0.B85 (23/26)

Final reduction 3.333 (50/ l5 )

Gearshift pattern Left foot operated return system

l-N-2-3-4-5-6

ELECTRICAL Ignition system COl

1-5

GENERAL INFORMATION

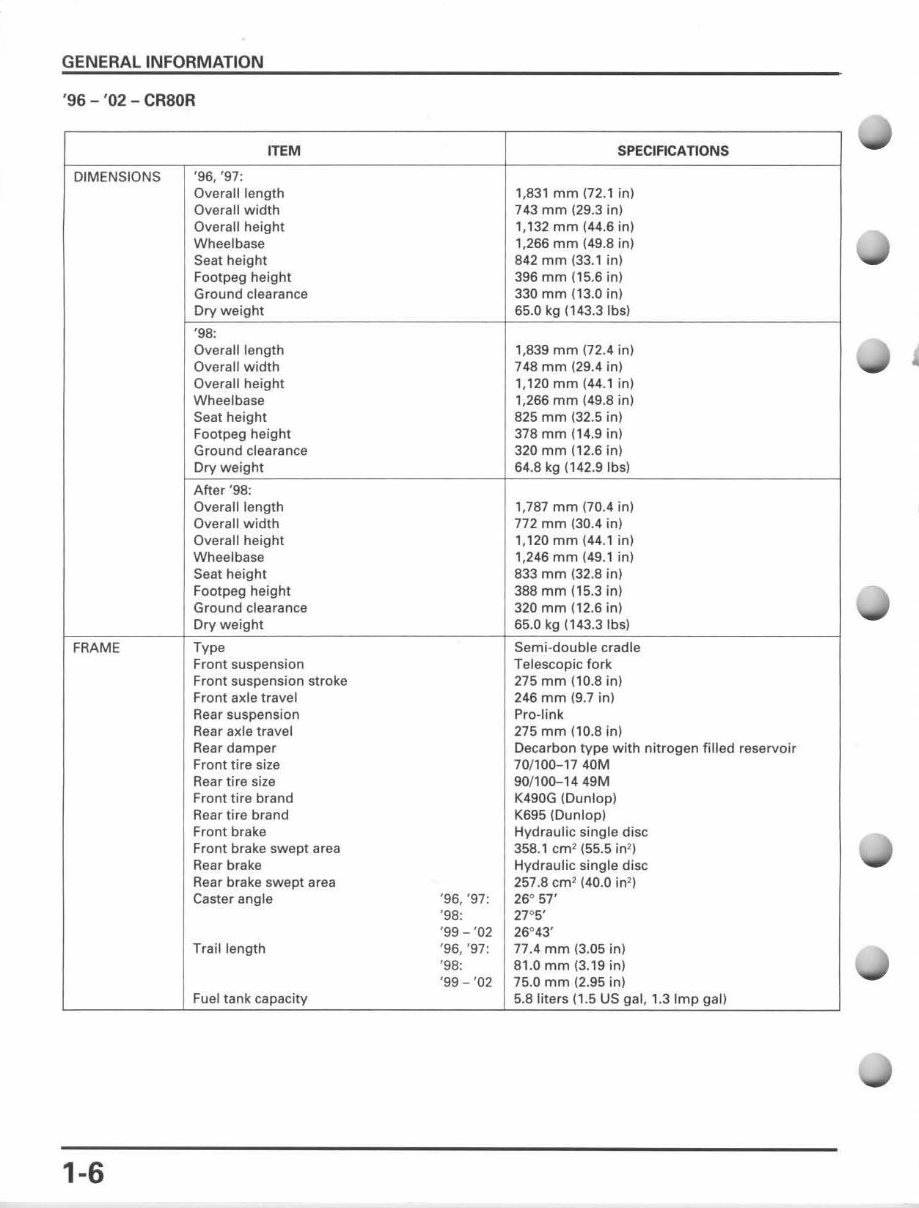

'9 6 - '02 - CR80R

ITEM SPECIFICATIONS

DIMENSIONS '96, '97:

Overall length 1,831 mm (72.1 in)

Overall width 743 mm (29.3 in)

Overall height 1,132 mm (44.6 in)

Wheelbase 1,266 mm (49.8 in)

Seat height 842 mm (33. 1 in)

Footpeg height 396 mm (15.6 in)

Ground clearance 330 mm (13.0 in)

Dry weight 65.0 kg (143.3Ibs)

'98:

Overall length 1,839 mm (72.4 in)

Overall width 748 mm (29.4 in)

Overall height ',,20mm(44.' in)

Wheelbase 1,266 mm (49.8 in)

Seal height 825 mrn (32.5 in)

Footpeg height 378 mm (14.9 in)

Ground clearance 320 mm (12.6 in)

Dry weight 64.8 kg (142.9 Ibs)

Aher '98:

Overall length 1,787 mm pO.4 in)

Overall width 772 mm (30.4 in)

Overall height 1,120 mm (44.1 in)

Wheelbase 1,246 mm (49.1 in)

Seat height 833 mm (32.8 in)

Footpeg height 388 mm (15.3 in)

Ground clearance 320 mm (12.6 in)

Dry weight 65.0 kg (143.3 Ibs)

FRAME Type Semi-doub le cradle

Front suspension Telescopic fork

Front suspension stroke 275 mm (10.8 in)

Front axle travel 246 mm (9.7 in)

Rear suspension Pro-link

Rear axle travel 275 mm (10.8 in)

Rear damper Decarbon type with nitrogen filled reservoir

Front tire size 70/100-17 40 M

Rear tire size 90 /100-14 49M

Front tire brand K490G (Dunlop)

Rear tire brand K695 (Du nlo p)

Front brake Hydraulic single di sc

Front brake swept area 358.1 cm

2

(55.5 inl )

Rear brake Hydraulic single disc

Rear brake swept area 257.8 cm2 (40.0 inl )

Caster angle '96, '9 7: 26

0

57'

' 98 : 27° 5'

' 99 -' 02 26°43'

Trail length ' 96 , '97: 77.4 mm (3.05 in)

' 98 : 8 1.0 mm (3.19 in)

'99 - ' 02 75.0 mm (2.95 in)

Fuel tank capacity 5.8 liters (1.5 US gal, 1.31mp gal)

1-6

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 91 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

This repair manual covers the 1995-2007 Honda CR80R and CR85R two-stroke bikes, including the following models:

- 1995-2002 Honda CR80R

- 1995-2002 Honda CR80RB Expert

- 2003-2007 Honda CR85R

- 2003-2007 Honda CR85RB Expert

It includes comprehensive information such as complete tear down and rebuild, part diagrams, torque specs, maintenance, troubleshooting, and more, spanning across 302 pages. The manual features clickable chapters and is searchable for easy navigation. There are no restrictions on printing or saving the manual.