CR250R service manual repair 2000-2001 CR250

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

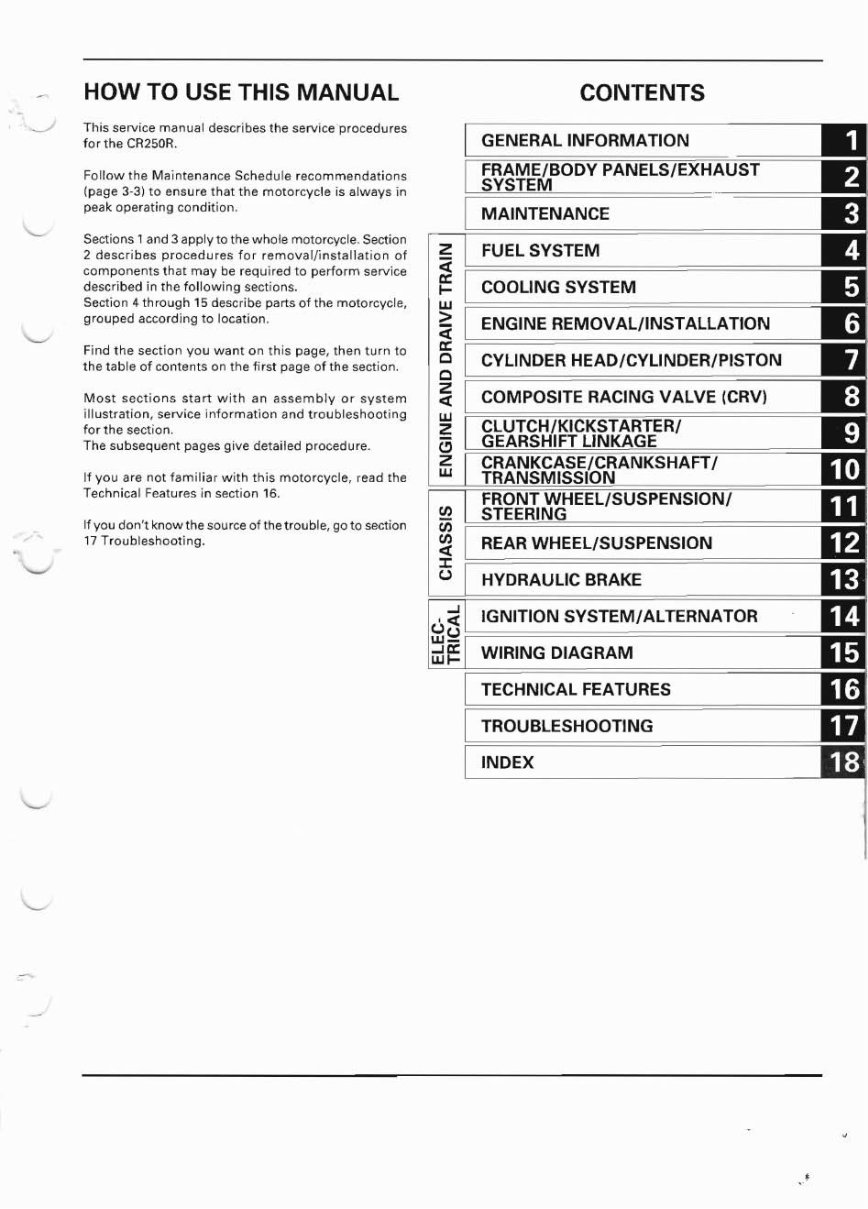

HOW TO USE THIS MANUAL

This service manual describes the service procedures

fo r the CR250R.

Follow the M~ i nleM nce Schedule recommendations

(page 3-31 to enSU re that the mOlorcycl " is II l w~y s in

pea k operating condition.

Sect i ons 1 and 3 app ly to the who le motorcycle. S~ion

2 descr ibes procedures for remova l/inSTallati on 01

components thai may be required \0 perform service

described in the following sections.

Section' through 15 desc ribe parts of the motorcycl e.

grouped according to location.

Find Ihe secti,1n you want o n Ihis page, lhen Wrn 10

Ihe lable of contents on the fi rst page of the sect io n.

Mos! sect i ons start with an asse mb ly Or system

ill ustratio n, service information iUld t rou bleshooting

for Ihe sed lan.

The s ub S<'!quenl pages gille detailed procedure.

If yo u a re not fllm il iar with this motorc ycle, read the

Technical F eat urM in ~ion 16 .

If you don't kn ow the SOurCe of th e troub le, goto section

17 Tr oub leshoot ing.

z

g

w

~

C

C

~

w

Z

(;

Z

w

'"

iii

'"

'"

:J:

"

CONTENTS

GENERAL INFORMATION

MAINTENANCE

FUEL SYSTEM

COOLING SYSTEM

ENGINE REMOVAL/ INSTALLATION

CYLINDER HEAD/ CYLINDER/ PISTON

COMPOSITE RACING VALVE (CRVI

REAR WHEELfSUSPENSION

HYDRAULIC BRAKE

IGNITION SYSTEMfALTERNATOR

WIRING DIAGRAM

TECHNICAL FEATURES

TROUBLESHOOTING

INDEX

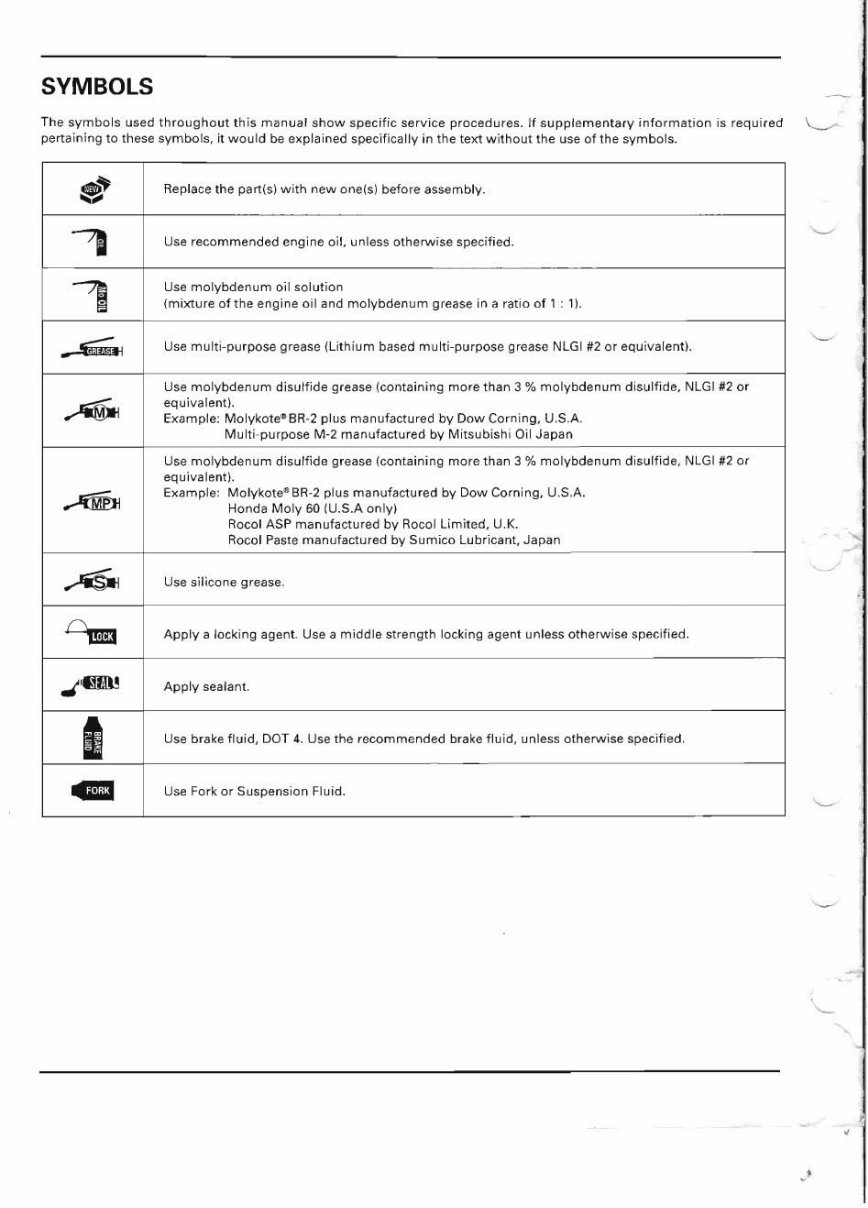

SYMBOLS

The symbo ls used t hrougllo ul this m8~ u a' sh ow s peci f ic se rvice procedures. If supplementa'v informat ion is requ ired

pe"" ,ning te these symbo ls, ~ wou ld be e ~plained specifically in the text without the use of Ih e symbols .

. ~

""

Replace Ihe pa" (5) with new enelsl before assembly.

.,.

Use rec ommended engi ne oil. unless ot herwise specified.

-,

Use mo lybdenum oi l sol ut ion

(mi xtI,J '" of the e ngine o il a nd molybde nu m g re ase jr) a ralio o f 1 : H.

•

,.;;;;;.,

Use multi-purpose grea se lli t hi um based mu lti-pu rposo grease NLGI 1I2 or equivalenU.

Use m o lybdenum disulfide grease Icontaining more than 3 % mo lybdenum di sulfide. NlG I 1I2 or

~

equiva le nt).

EKampl e: Mo lykote

S

BR·2 plus manufactured by Dow Cor ni n... USA

Multi-purpose M· 2 manufactured by Mit subishl Oi l Japan

Use mo lybde num disulfide grease leomaini nG morl! than 3 % mo lybdenum disulfide, NLGI 1I2 or

equivalent) .

~

Ex ample: M olykot eO BR·2 plus manufactule d by Dow Com ing, U.S.A.

Honda Moly 60 (U.S.A on lYI

Rocol ASP manufactured by Rocol Limi ted, U,K .

Rocol Paste manufactuled by Sumico Lubr icant, Japan

--6

Use si licone 91ease.

em

Apply a locking agent. Use a midd le strength locking agent unless othelwistl spe.;ified.

",.roll Apply sealant.

I

Use brake fluid, DOT .t. U se the reeom mertded brake flu id, unless olherwise specified,

..

Use Fork or Suspensi on Fl ui d.

.'

1. GENERAL INFORMATION

GENERAL SAFETY

S ERVICE RUl~S

MODEl IDENTIFICATION

S PE CIFICATIONS

TORQUE VALUE S

GENERAL SAFETY

CARBON MONOXIDE

1-1

1-2

1-3

1-'

1-12

If the engi,.,e must be funning 10 do some wor k, ma ke su re

the area is well ventilated. Neve r 'U" the ~ ngjne in an

endosed area.

Tht! ">rhaustCl)ntains pOis onous carbon monoxide gas that

c..n c4us" lou of consclousne" and m.9y lead!O death .

Run t he ""gi ne in an open area Or with an e~ haust

..vacuation system in an enclosed area_

GASOLINE

Work in II well vem ilated area_Keep cigarettes, flames or

sparks away from the wc. ,~ area or where gasoline is stored .

Ei.% ;,lIliM

GnoHne is eX/Fern .. '" IJamm" bJe lind is eJlpl,uj"" under

certain conditions. KEEP OUT OF REACH OF CHILDREN.

HOT COMPONENTS

tl i0 i.\iii I[d

Eng in .. . lJ nd .. xlulUS! "'vst~m parU becom .. verr hot and

, .. mlJin hot for some l ime lJlt..r th l! I!ngine is ,un. W .. ",

insul;nttl glov..J or wlti, !JnfillhtJ engi".. IIncJ " ", hausl s)'Stem

hlJve tooled belo,e hlJndling thes e parts.

TOOLS

LUBRICATION & SEAL POINTS

CABLE & HARNESS ROUTING

OPTIONAL PARTS

USEO ENGINE Oil

M'hI, iiild

' -15

1-17

' -19

1-24

Used " ngine oil m'y tltusa skin ClJncer if repeatedl y le ft in

contllct with the skin for prolonglJd p .. ,iods. Although this

is unlikely unles5 you handle used oil on It daily basis, it is

still lJdvisllble /0 tho,oughly WlJs/' you' hlJnds wil l, soap

and wale, lJS 500n as possibl .. a ft er handling usttl 0/1. KEEP

OUT OF REACH OF CHILDREN.

BRA KE DUST

Neller use Itn ~ ; r hose or dry brUsh to clean the bra ke

assemblies . Use OS HA·approved vacuum cleaner or

alternate me l hod app r oved by OSHA, designed 10 minimi, ..

the hala,d ceused ny Itirborne aSbestos fibe,s .

/nhe/ttl asbeSTOS fibers hlJve b"" lound to calISe respiratory

diselJse and clt nt er.

BRAKE FlUID

CA UTION

Spillingl/uid on pai nted, plastit Of" rubber pJlrtJ will tMmagfl

Ihem. Pla tl! It clean shop 'owel OV" , Ihl!s l! f1lJrfS whl!nl!v..r

Ihlt s)'Slem is sl!rvkl!d KEEP OUT OF REACH OF CHILOREN.

1-1

GENERAL INFORMATION

COOLANT

Under somocondilions, Ihe ethylene gl ycot in engi ne coolant

i$ combusti b le and its Ilame is nol visiblQ. IIlhe et hylene

glycol does ignit e, yo" will not see any Hem". but y ou can

be b"rned .

Avoid spilling Itngin~ cooilln! on tllll exllllust s~tero 0'

engine p"rtS. Tillty roilY bll 1I0t en ough 10 cau SII tile

coolllnt to ignite and burn without a visibllt flame.

Co o/eM (erhvlene glvco /) can caUse some skin irriration

end is poi~onous if swallow&d. KEEP OUT OF REACH OF

CHILDREN.

Do not remove rhe radilltO' CliP when the e ngine is 1I0t.

Til e cool"M is unde, pressu,e "nd could scald yal/.

K eep h"nds lind clothingllway from th e cooling (en. u it

st"rts automatically.

CAUTION

Using coolant wit ll silicate corrosion inlribitors m"y clluSe

premllture wellr of war .... pump SiMls o,blocka ge of radia tor

passegu. Us ing rap w llter mlly t.1UH enginlt damaglt.

If rl contacts your skin, wash t ho affected areas imm edial el y

wi th soap and water . II it contacts you, eyes. flush them

t horoug hly with fresh waler and gel j mme rli ~te medical

~t1e ntion . II il is swallowed. Ihe victim m ust be forced to

"om it t hen rinse mou th end t hroat with fresh waler bef ore

obtaining medical 1I110ntion. Because of t hese da ngers,

always stOfe cool1lnt in ~ safe place. always away from the

reach 01 chi ld,,,n. Ruycle USQd coolanl In an eco logicall y

correct m~nnor.

SERVICE RULES

NITROGEN PRESSURE

For shock absorber with II gas_tilled reservoir.

Us e onl v nit'ogen ro p'essurl~e rh a shoc k " bsorber. Th e

usa of an unstable glls c"n caus e /I fire 0' explosi on

resulting in serious injury.

The slrock abso,b ar conUins nitrogen unde, Irigh

p'ft5sure. Allowi ng fi'e or Irltat ne a, r he slrock sbsorber

could le ad to sn a" plo,ion th ll f could result in serious

injury.

Failurlt to rltlasss tire pre ssurlt f,om a shock abso rber

before disposing of it mav lead to a po ssible explosion

and sa,ious injury if if is h e. ted or p; erted,

To pre"ent the po ssib ili ty of an " "p l osion, rele~se t he

nitroge n by pressing the valvo COf O. Then remove tha valve

stem ftom the s hoc~ absorber ,eservoir. Dispose of the oil

in a m anner acce pt ab le to the Environmental Protection

Agency (EPA).

Befor e disposal of the shoc~ absorber, release the nitrogen

by pressing the valve Core. Than remove the valv e stem

f,om the shock abso,ber .

1. Use genuine HONDA or HONDA-recommended parts and lubroc8nts o' t he ir eQuivalents. Part s th at don 't meel HONDA's

design specifications may cause damage to th e motorcycle_

2. Use the special tools d eSIgned for this produCl to avoid damage and incorr ect assembly _

3. Use on ly m et ric tools wh~n servicing the motorcycle . Metric bo lts. nuts and screw.; are nOl i"terchang ea ble with English

fast~ ners.

4. Install new gaskets. O·rings. cotter pins. and lock plates w hen reassembling.

5. W hen tig hte ning bolts or r.uts, begin wi th the la'gQr diamet er or inner boll firs\. Then ti ghten to th e spec ilied torque

diagonally in in c'emental steps unlass II particular sequence is specified.

6. Clean pans In cleaning solvent upon disassembly. Lubricate any s li dir.g surfaces befo'" reasse mbly_

7_ After reassembly. check al l parts lor prope r installation ar.d o pe ration_

S. Route all electrocal wires as show on pages 1· 1gt hr ough 1·23, Ca b le and Harness Routing_

1-2

(

-~

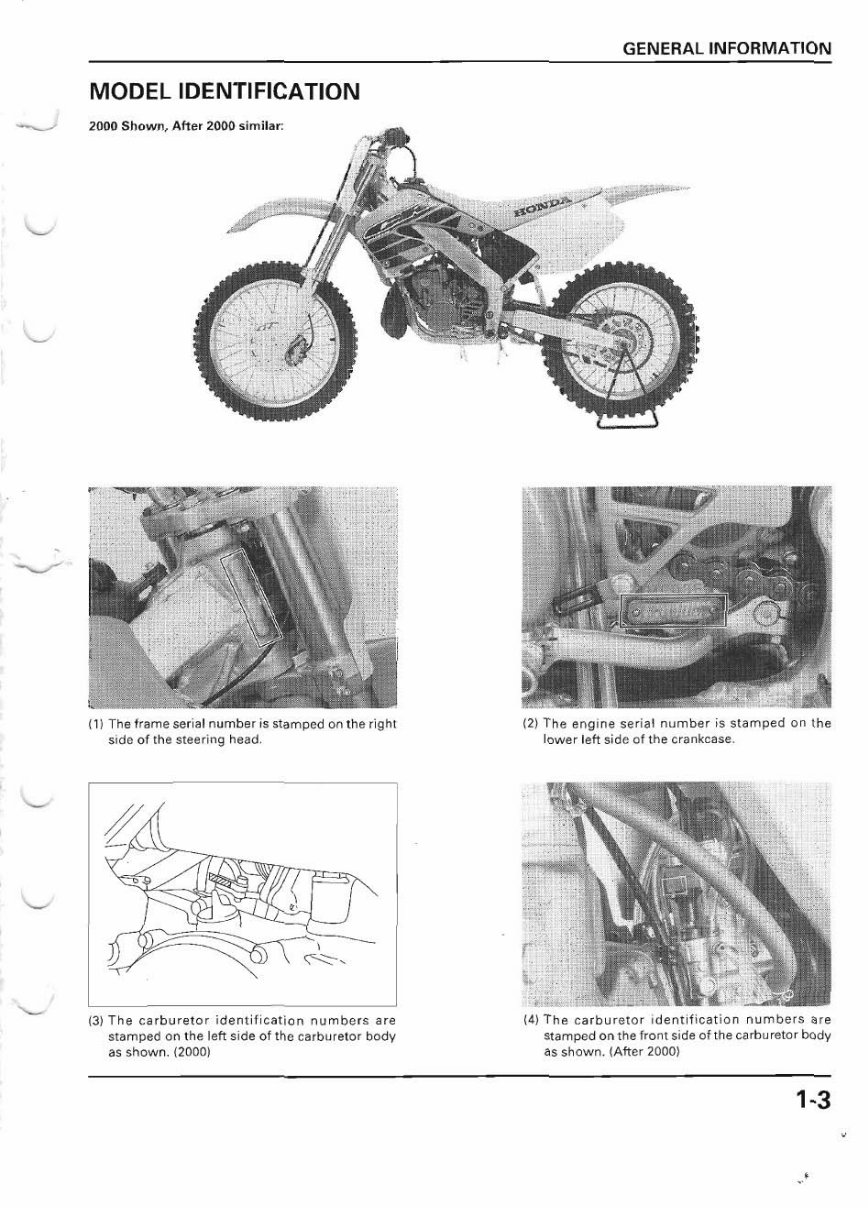

MODEL IDENTIFICATION

2000 Shown, After 2000 similar:

(11 The frame seri ~ 1 n umber is stamped on the right

s,do of the steering head

(3) The c8rburelo r identif ication nu mbors are

stamped on the left side of tho carburet or body

as shown. (2000)

GENERAL INFORMATION

(2) The engine seri~ ' number is stamped on the

lo wer left si de of the crankcase.

14) Th e c arbu retor Ident ificat ion n umbers are

SlamlX'd on the fron t sid ~ of the carbu retor tx..dy

as shown. ( After 2000)

1·3

GENERAL INFORMATION

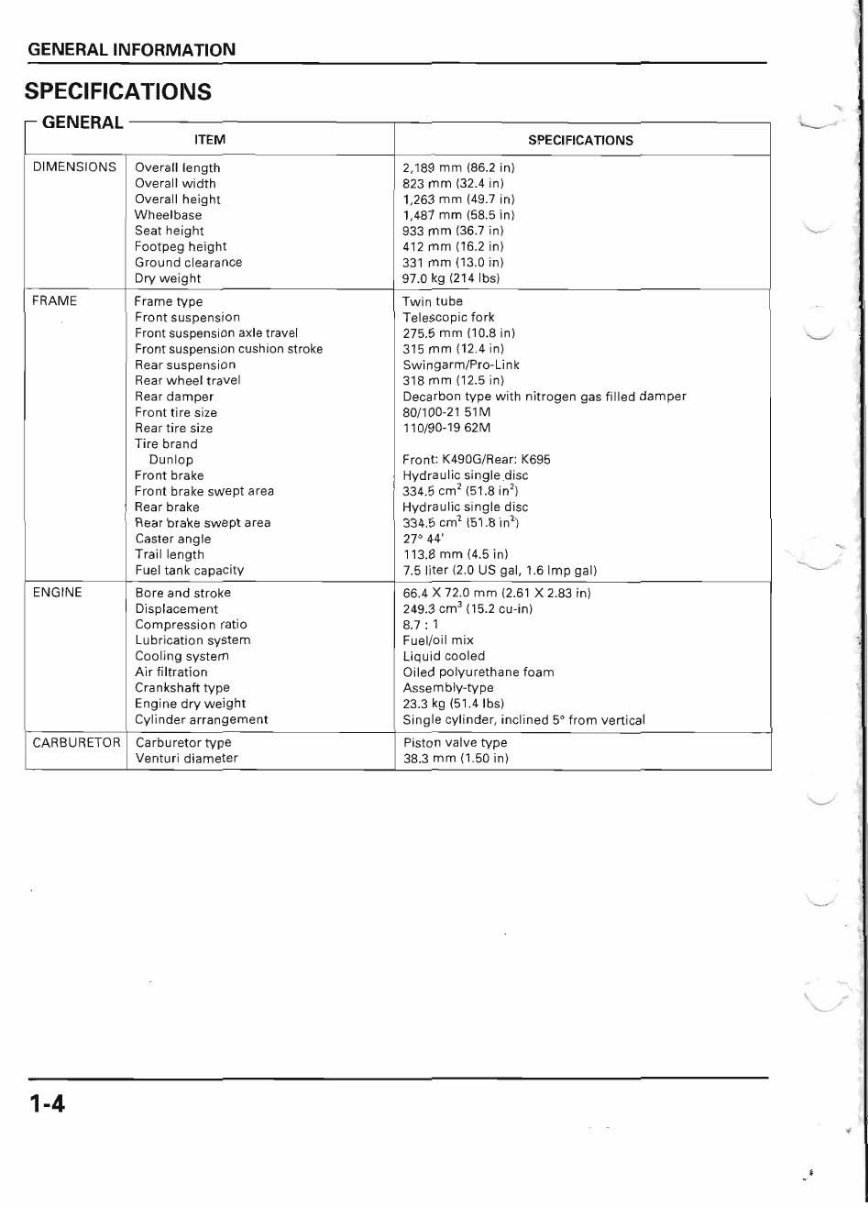

SPECIFICATIONS

GENERAL

'''M

S!'ECI FI CA nONS

DI MENSIONS Overall length 2,189 mm 186.2 inl

Overall width 823 (rim (32.4 inl

Ove r~ 1 1 heighl 1.263 mm 149.7 in)

Whef!lbase 1.487 mm (58.5 in)

Seal height 933 mm 136.7 in)

Foolpeg heighl 412mm(16.2in)

Ground clearance 331 (rim 03.0 in)

Dry weight 97.0 kg (214 Ibs)

FRAME Frame type Twin lUbe

Fronl suspension Telescopic fork

Front suspensipn axl e I rave l 275.5 mm (10.8 in)

FlOnl suspensiOn cushIon stroke 315 mm (124 in)

Rear $u$pensipn Swinga'm/F'ro-Link

Rear wheel I "lvel 318mm( 12.5 in)

Rear damper Deca,bon type w ilh nilrogen gas filled damper

Front tire Si18 801100-21S1M

Rear tire size 11 0/90-1962M

Tire brand

Dunlop Front K490G/Rear:

'695

Fronl brake Hydraulic single ,disc

Fronl brake swepl area 33 45 em' 15 1.8 in')

Rear br ake Hydraulic single disc

Ra ar bfa ~e swept area 334. 1) em' \5 1.8 in')

Caster angle 27· 44 '

Tr ai l length 113.8 mm (4.5 in)

Fuel tank capacily 7.5l i ler 12.0 US gal, 1.6 1mp gal)

ENGINE Bore and stroke 66.' X no mm 12.S1 X 2.83 in)

Oisplace melll 249.3 cm' 05.2 cu -i n)

Compression ratio 8.7 : 1

Lubrication syslem FueVoi l mi M

Cooling syste m liquid cooled

Air fiUration Oiled polyurethane foam

Crankshaft type Assembfy-typo

Engine dry wei ght 23.3 kg (51.4 lbs)

Cylinder arrangement Single cyl ill d er, inclined S' from ven ical

CARBURETOR Carburetor type PiSIOn valve tvpe

VenlUri diameler 38.3 mm (1.50 in)

1-4

GENERAL INFORMATION

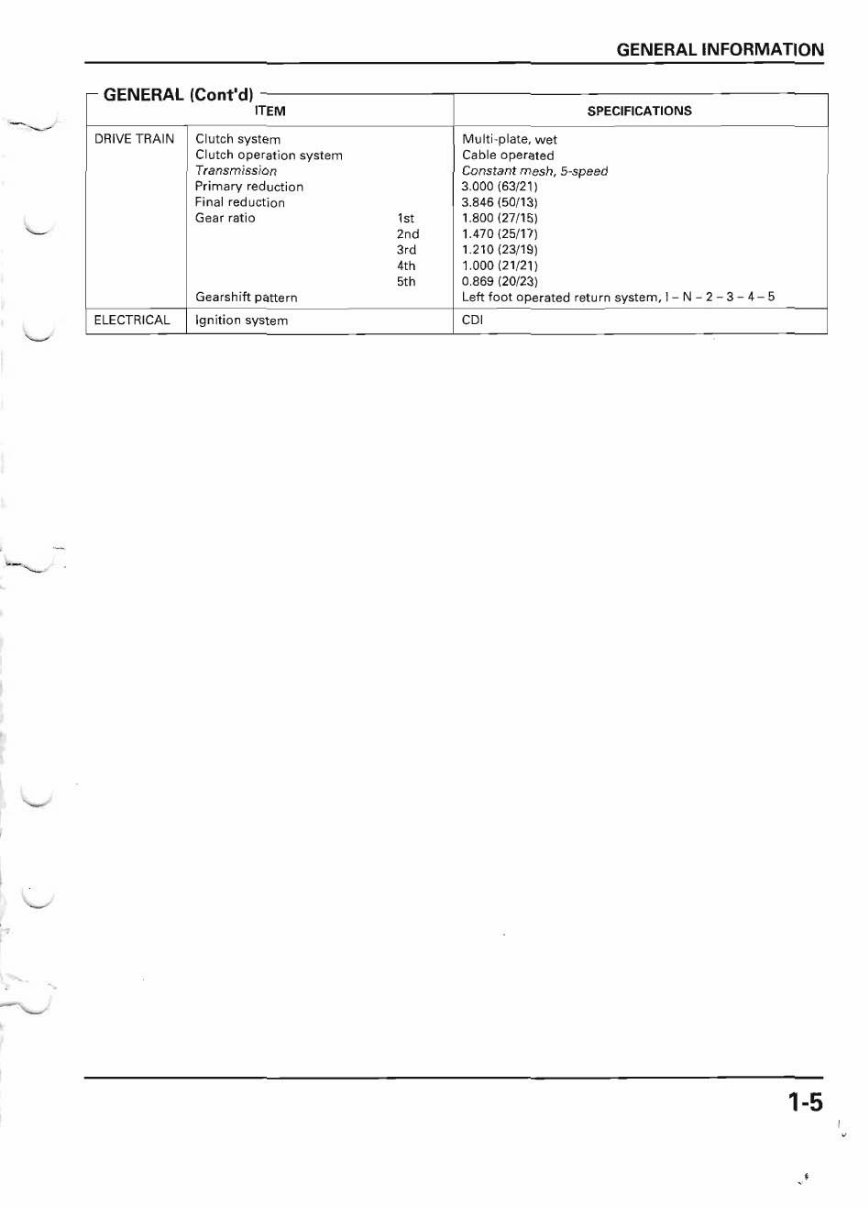

GENERAL (Cont'd)

ITE M SPECIFICATI ON S

DRIVE TRAIN Clutch system Multi-plate, wet

Clutch opera ti on system Cllble opa ral l!d

Transmi5Si(>n Consu mt mes n, 5-3paoo

Primary re duction 3_000 (S3R1)

Final reduction 3.1046(50/13)

Gear ,alio

,,,

1.1000 (2711!i)

2"

1.470 (25/11)

3"

1_ 210123/19)

""

1.000(2 1/ 21 )

""

0.869 (20123)

GearShift P ~tt8rn Lett foot op.er~led return system, 1- N - 2 - 3 - 4 - 5

ELECTRICAL Ignition system

CD'

1-5

GENERAL INFORMATION

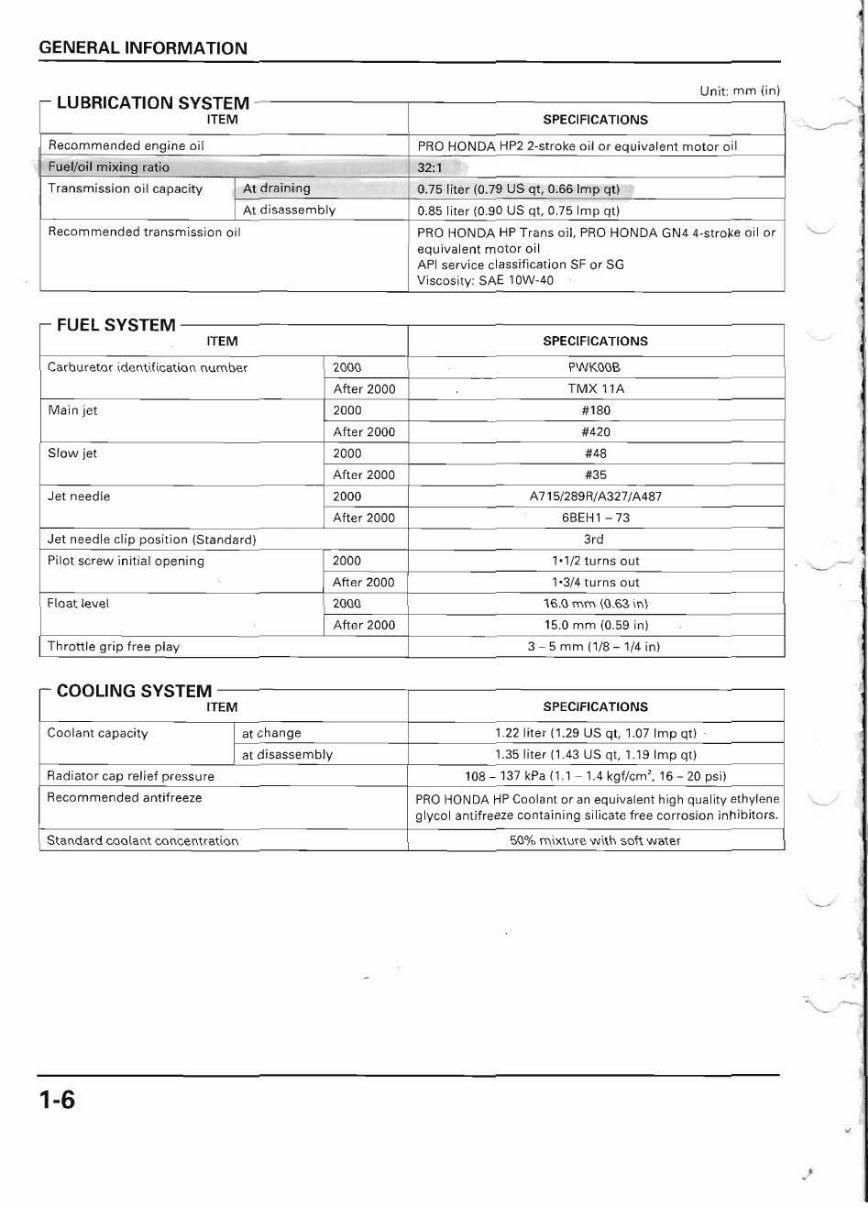

LUBRICATION SYSTEM

Unit mm lin)

ITEM S PE CIFICATIO NS

Racommendod eng ine oil PRO HO NDA HP2 2-Slroke oi l Or e Cj uivale nt mo t or oil

FU/:IVoil mixing rat io 32:1

Trll ns m issio n oil capacity At draining 0.75 lit er (O. W US ql, 0. 661mp qU

At disa s sembl y 0.85 li te r (0 .90 US qt, 0.75 1 mp qlf

Recomme nded transmi ssion o il PRO HONDA HP Trans oi l, P RO HO NDA G N4 ( ·stro~e o il or

equi va le nt motor oil

API service c la ss ific" ti on SF or SG

Vise,»il y: SAl: 10W_40

r FUEL SYSTEM

ITE M S PE CIFI CATIONS

Carbureto r id,, " ti{i cat Klrl nu moor

"""

PWKOOB

-

After 2000 TM X l 1A

Mai n )01 2000 # 180

After 2000 1 420

Slow jet 2000

"8

After 2000

'"

Jet needle 2000 A71S/289 R/A3 27 fA 487

Aft er 2000 6BE HI -73

Jet need le dip pos i ti on ISt andftrd)

3"

Pi l ot serew in itIa l ope ning 2000 1'1/2 tur ns Out

Afte r WOO 1-3{4 (urns out

Fl'Ht ~"el 2 000 1 £0 mm \0.£3 if'll

Afte r 2000 15.0 mm lO.S9 in)

Throttle grip free pl ay 3 S mm 11 18- 1/4 in)

COOLING SYSTEM

'''M

SPECI FICATIONS

Cool~nt capacity at chenge I_ U liler (1.29 US 'It, 1.07 Imp qt)

al disassembl y 1.35 liter 11. 43 US Qt. 1_19 Imp 'lit

Ra diator cap relief P1"essure

""

137 kPa (1.1 1. 4 ~gffcm', 16 - 20 psi)

Recommend ed a nt if r eele

PRO HONDA HP Co ol a nt or an equivalent high qu a li ly ethylene

g lyco l antif r eele containing s il ieate free corrosion inllibilors.

St8!1da,d coolftnt cono:e!l\' e\ iQ(', 50% mllm "e with soft w~te'

\

1-6

,

-

GENERAL INFORMATION

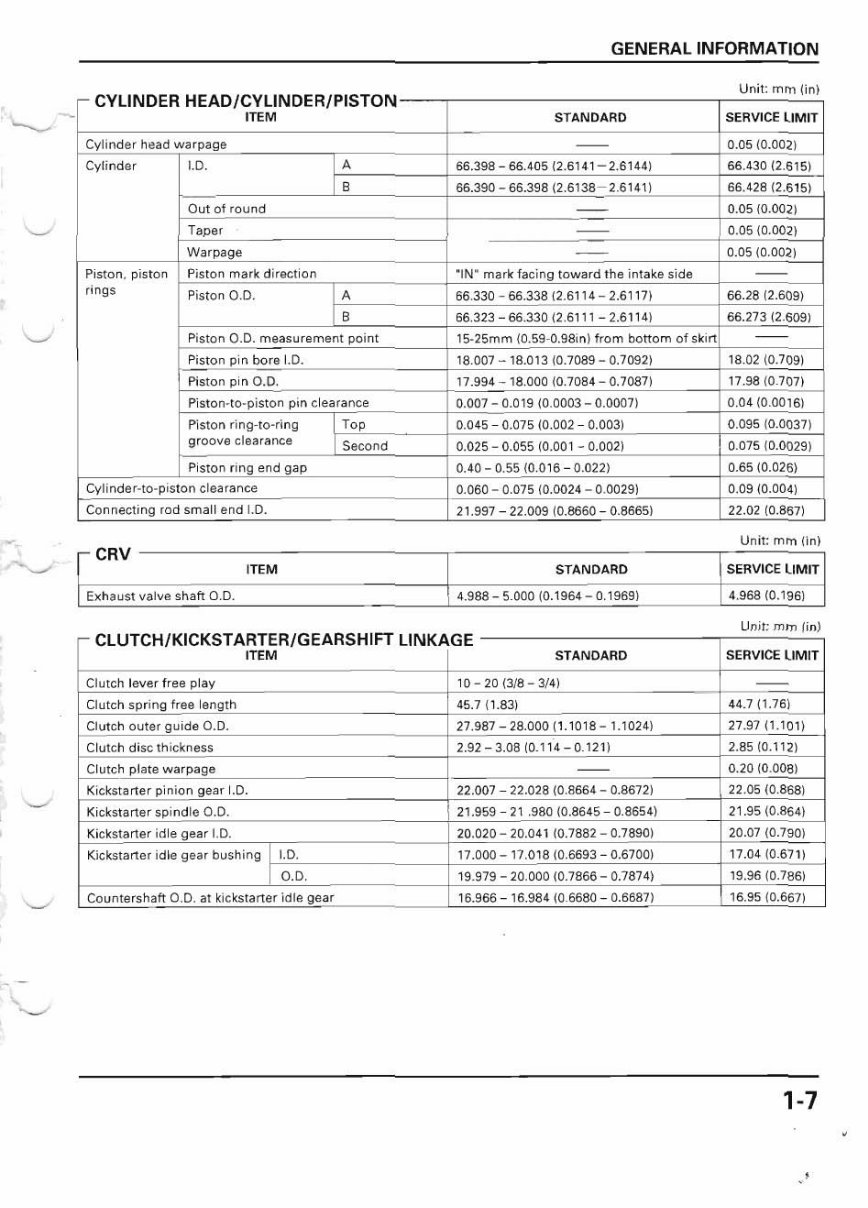

CYLINDER HEAD/ CYLINDER/ PISTON

Unit· mrn (Inl

nEM ST ANDARD SERVI CE LIMIT

Cylinder head warpage

-- 0.0510.002)

Cylinder 1.0. A 66.398 - 66.405 /2.61 41 2.(144) 66.430/2.615)

B 66.390 - 66.398 (2 .6138 2. 61(1) 66.428 (26 15)

Out of round 0.05/0.002)

Taper 0.05 (0.002)

Warpage 0.05 (0.0021

Piston. pis t on Piston mark directi on " IN " mark facing towa rd t he int ake side

rings

Piston 00. A 66.330 - 66.338 (2 .6114 - 2.( 117) 66.28 12.609)

B 56323 - 66330 126111 - 2.(11 4) 66.273 (2.6091

Piston 0.0. me asur e ment point 15·25mm (0.59-0.98in) from bottom of sk,rt

Pis ton pi rl borel.O. 18.007 - 18.013 (0 . 7Q.89 - 0.10921 18.Q2 (0.709)

Piston pirl 0.0. 17 .994 - 18.000 1O.7Q.8 4 - 0.70871 17.98 (0.707)

Piston· to·pis ton pin cl ear a nce 0.007 - 0.019 (0.0003 - 0.(007) 0.0 4 (0.0016)

Piston ring-to· ring

'o p

0.045 0.07510.002 0.0031 0.095 (0.0031i

groove clea rance

Second 0.025 - 0.055 (0.001 - 0.0021 0.075 ((W029)

Pi ston ring end ga p 0.40 - 0.55 (0.016 - 0.022) 0. 65 (0.026)

Cylinde r- la-pi ston ciearano::e

0.050 - 0.075 10.0024 - 0.0029) 0.0910.0041

Connecting rod s mall end 1.0. 21.997 - 22.009 (0.8660 - 0.98651 22.a2 la.8611

CRV ________________ -, ______________ -r-'u""" ;'C'cmcm~nC")l

I TEM

Ex haust valve shaft 0.0.

STANDARD

4.988 _ 5.000 (0.1964 - O. 1 9691

ClUTCH / KICKSTARTER/ GEARSHIFT LINKAGE

"'M

S TANDARD

Clutch lever fr ee pl ay 1 0-20(318-3/41

Clutch sp ring free l englh 45.711.83)

ClUtc h OUter guide 0.0. 27.981 _ 28.000 (1. 10 18 - 1.1024)

ClutCh dis<: thi ckness 2.92 _ 3.08 (0.114 _ 0. 12 11

Clutch plate w arpage

Kickst arte r pinion gea r 1 .0. 22.007 - 22.028 (0.8664 - 0.88721

Kicksl arte r spin d l" 0.0. 21.959 - 21 .980 (0.8645 - 0.8(5 4)

Kic kstarte r I rl le gea r 1.0. 20.0 20 - 20.0 41 10.7882 - 0.789()

K Ic kstarter id le gear be>shing 1.0. 17.000 -17.018 (0.6693 - 0.67001

0.0. 19.979 - 20.000 (0.7866 - 0.7874)

CO ll nlershaft 0 .0 . al klckstarter idlll gllar 16.966 - 16.984 (0.6680 _ 0.6687)

SERVI CE LIMIT

4.968 (0.1 961

Uni/" mm li n)

SE RVI CE LIMIT

44.1 (1.76)

27.9711.1011

2.85 (0.112)

0.20/0 .008)

21. 0510.868)

21.95 (0.864)

20m (0.7901

17.04 (0.67 11

19.96 (0.1861

16.95 (0.0671

'·7

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 79 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get your hands on the repair manual for the 2000-2001 Honda CR250R two-stroke bike. This comprehensive manual covers complete tear down and rebuild, including pictures and part diagrams, torque specs, maintenance, troubleshooting, and more. With 286 pages, it has clickable chapters and is searchable, making it easy to find the information you need. There are no restrictions on printing or saving the manual, providing you with convenient access to the valuable content.