1992-1996 CR250R Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

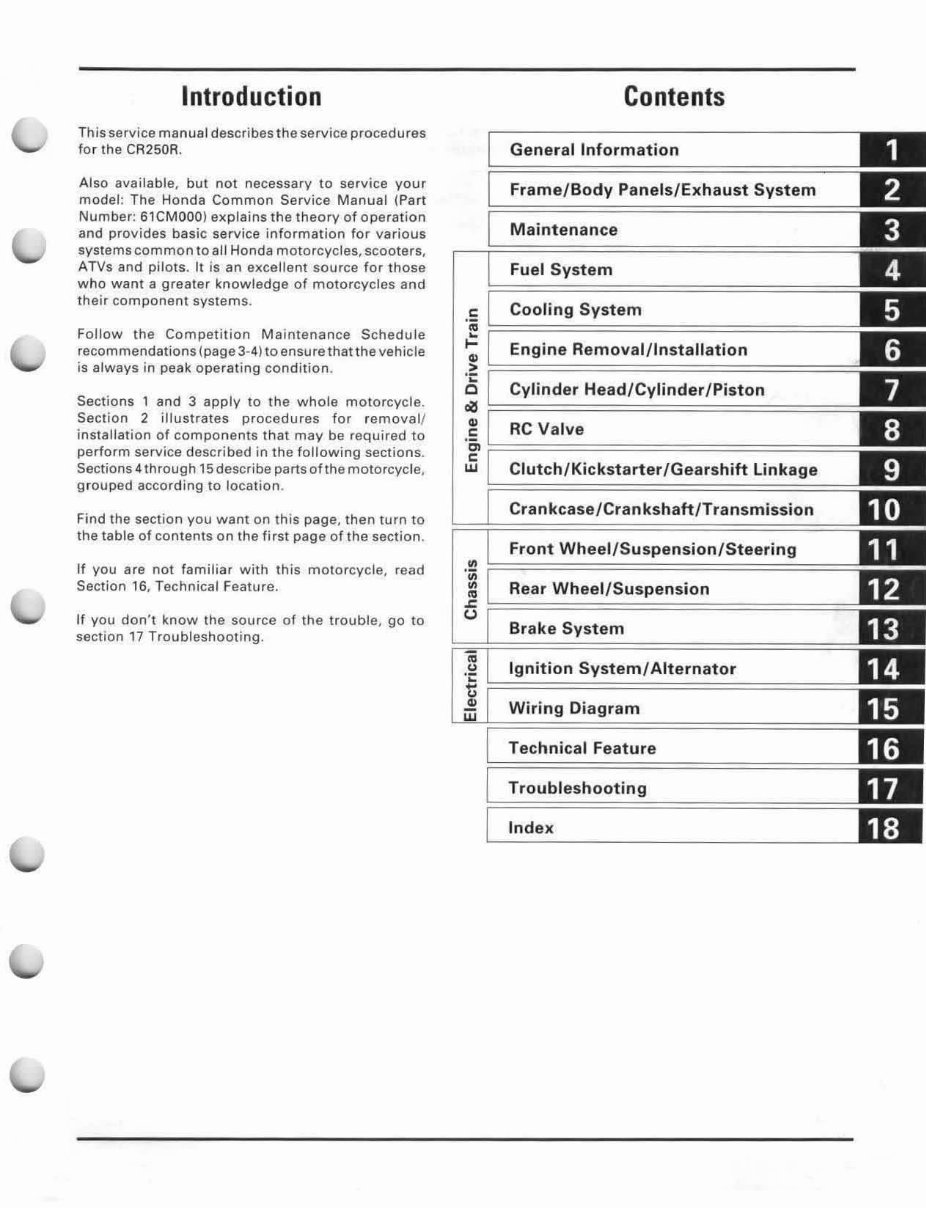

Introduction

This service manua l describes the service procedures

fo r the CR250R.

Also available , but not necessary to service you r

model : The Honda Common Service Manual (part

Number: 61CMOOO) explains the theory of operation

and provides basic service information for var ious

systems common to all Honda motorcycles, scooters,

ATVs and pilots . It is an excellent sou rce for those

who want a grealer knowledge of mOTorcycles and

the ir component systems .

Follow the Competition Ma i ntenance Schedule

re commendations (page 3- 4) 10 ensure that the vehicle

is always in peak operating co nd iti on .

Sections 1 and 3 apply to th e whole motorcycle.

Seclion 2 illustrates procedures for removal /

installation of compone nts that may be required to

perform service describ ed in the fo l lowing sections .

Sections 4through 15describe parts of the motorcycle.

gr ouped according to location .

Find the section you want on this page, then turn to

the table of contents on the first page of the section .

If you are not familiar with this motorcycle, read

Section 16, Technical Featu re .

If you don't know the so urce of the trouble , go to

sect io n 17 Troubleshoot i ng.

~

' iij

,::

Contents

General Information

Frame/Body Panels/Exhaust System

Maintenance

Fuel System

Cooling System

Engine Removal/Installation

~

d I Cylinder Head/Cylinder/Piston

~ ~=====================

~ I Re Valve

'~ ~================================

w

Clutch/Kickstarter/Gearshift linkage

Crankcase/Crankshaft/Transmission

Front Wheel/Suspension/Steering

Rear Wheel/Suspension

Brake System

Ignition System / Alternator

Wiring Diagram

Technical Feature

Troubleshooting

Index

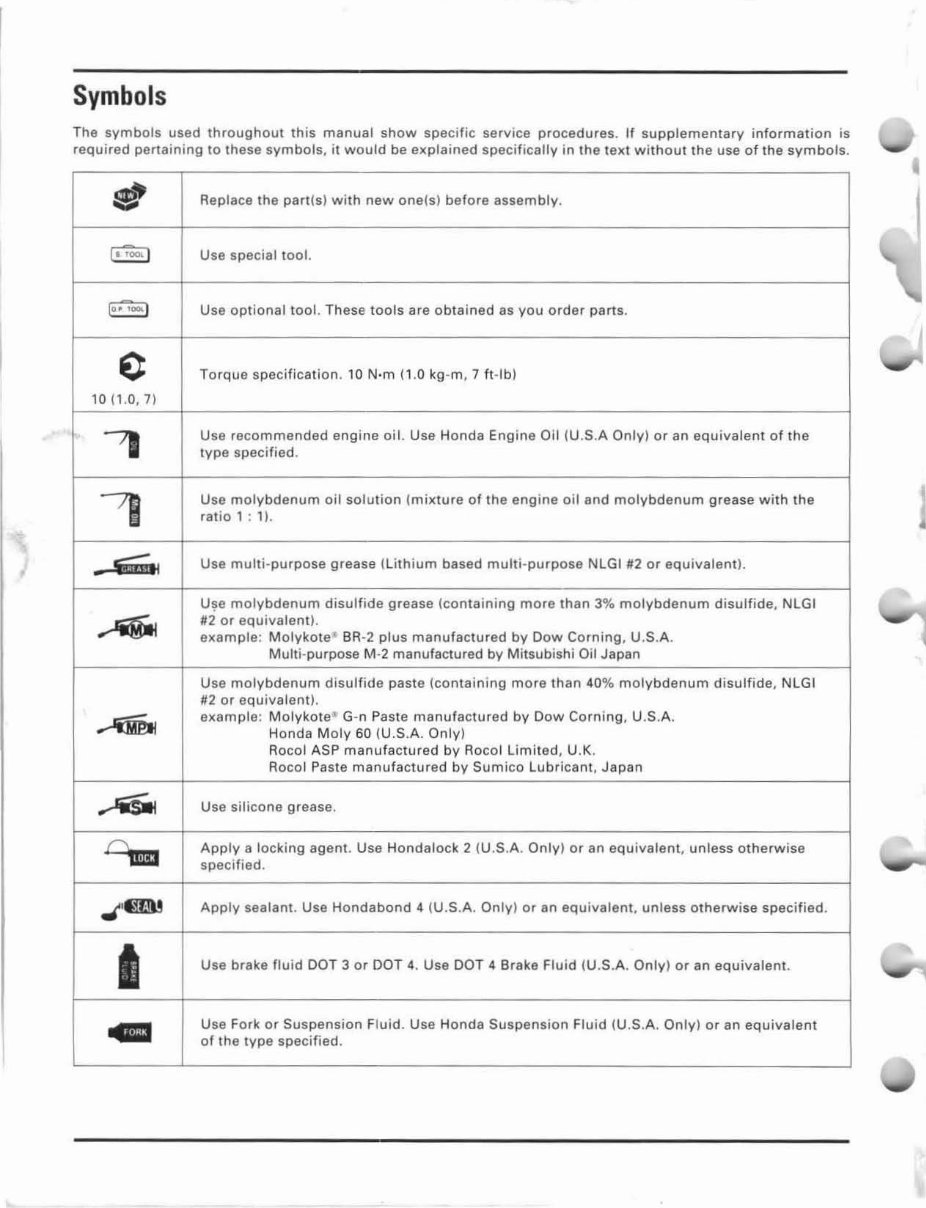

Svmbols

The symbols used throughout this manual show spec ifi c service procedures . If supplementary information is

required pena i ning to these symbols . it would be explained specif ically in the texl without the use of the symbols .

~

Replace the pan(s ) with new one(s) before assembly.

(. Tw.. !

Use spec iatloo!.

[0 , "7_ 1

Use optional tool. These tools are obtained as you order parts .

e Torque specification. 10 N'm 11 .0 kg·m, 1 ft· lbl

100 .0, 7)

'I

Use recommended engine oil. Use Honda Engine Oil (U.S.A Only) or an equivalent of the

type specified .

,

Use molybdenum oil solution ( mixture of the engine oil and molybdenum grease with the

ratio 1 : 1) .

-

-

Use multi - purpose grease (lithium based multi - purpose NlGI1I2 or equivalent).

U~e molybdenum disulfide grease (containing more than 3% molybdenum disulfide, NlGI

~

112 or equivalent ).

example : Molykote " BA ·2 plus manufactured by Dow Corning, U.S.A.

Multi -purpose M-2 manufactured by Mitsub ishi Oil Japan

Use molybdenum disulfide paste (containing more than 40% molybdenum disulfide, NlGI

#2 or equivalent).

~

example: Molvkote~ G-n Paste manufactured by Dow Corning, U.S.A.

Honda Moly 60 (U.S.A. Only)

Aocol ASP manufactured by Aocollimited , U.K.

Aocol Paste manufactured by Sumico lubricant , Japan

..-liSiII

Use silicone grease.

n Apply a locking agent . Use Hondalock 2 (U.S.A. Only) or an equivalent , unless otherwise

1'1"

specified .

..,oru Apply sealant. Use Hondabond 4 (U.S.A. Only) or an equivalent. unless otherwise specified .

I

Use brake fluid DOT 3 or DOT 4. Use DOT 4 Brake Fluid (U.S.A. Only ) or an equivalent .

..

Use Fork or Suspension Fl uid . Use Honda Suspension Fluid (U.S.A. Only) or an equivalent

of the type specified.

•

General Safety

Service Rules

Model Identification

Specifications

Torque Values

General Safety

Carbon Monoxide

1-1

1-2

1-3

1-4

1-12

If the engine must be running to do some work , make

sure the area is well ventilated. Never run the engine in

an enclosed area.

Theexhaust contain s poisonous ca rbon mono xi de

gas that can cause l oss of consciousness and

may l ead to death .

Aun the engine in an open area or with an exhaust

evacuation system in an enclosed area.

Gasoline

Work in a we ll ven t ilated area . Keep ciga r ettes, flames

or sparks away from the work area or where gasoline is

stored .

Gasoline is extremely flammable and is explosive

under certain conditions. KEEP OUT OF REACH

OF CHILDREN.

Hot Components

Engine and exhaust system parts become very

hot and remain h ot for sometime after the engine

is run . Wear insulated gloves or wait until th e

engine and exhaust system have coo led before

these

1. General Information

Tools 1- 15

Lubrication & Seal Points 1-17

Cable & Harness Routing 1- 19

Optional Parts List 1-25

Used Engine / Tran s mi ss ion Oil

Used engine oil (o r transmis si on oil intwo· stroke)

may cause skin cancer if repeatedly left in contact

with the skin for prolonged periods . Although

this is unlikely unless you handle used oi l on a

daily basis , it is still advisable to thoroughly

w ash your hands with soap and water as soon as

po ss ible after handling used oil . KEEP OUT OF

REACH OF CHILDREN.

Brake Dust

Brake dust may contain asbestos.

Never use an air hose or dry brush to clean brake

assemblies . Use and OSHA - approved vacuum cleaner

or alternate method app r oved by OSHA, designed to

minimize the hazard caused by airborne asbestos fibers .

Inhaled asbestos fibers have been found to ca use

respiratory disease and cancer .

Brake Fluid

CAUTION

Spilling fluid on pained , plastic or rubber parts

will damage them. Place a cle an shop tow el over

these parts whenever the syste m is serviced .

KEEP OUT OF REACH OF CHILDREN.

1-1

General Information

Coolant

Under some conditions, the ethylene glycol in engine

coo l ant is combustible and its flame is not vis ible. If the

ethylene glycol does i gnite, you will not see any flame,

but you can be burned.

Avoid spilling engine coo lant on the exhaust

system or engine parts . They may be hot enough

to cause the coolant to ignite and burn without a

visible flame .

Coolant (ethylene glycol) can cause some skin

irritation and is poisonous if swallowed . KEEP

OUT OF REACH OF CHILDREN.

Keepout of reach of pets . Some pets are attracted

to the smell and taste of coolant and can die if

they drink it .

Do not remove the radiator cap when the engine

is hot . The coolant is under pressure and could

scald you.

If it con tacts your skin, wash the affe cte d areas

immediate ly with soap and water. If it contacts your

eyes, flush them thoroughly with fresh water and get

immediate medical attention. If it is swallowed, the

victim must be forced to vomit then rinse mouth and

throat with fresh water before obtaini ng medical

attention. Because of these dangers, always store coolant

in a safe place, away from the reach of children.

Recycle used coolant in an ecologically correct manner.

Service Rules

Nitrogen Pressure

For shock absorber with a gas -f illed reservoir.

Use only nitrogen to pressurize the shock absorber.

The use of an unstable gas can cause a fire or

exp l osion resulting in serious injury.

The shock absorber contains nitrogen under high

pressure. Allowing fire or heat near the shock

absorber could lead to and explosion that could

result in serious injury.

Failure to release the pressure from a shock

absorber before disposing of it may lead to a

possible explosion and serious injury if it is heated

or pierced .

To pr event the possibility of an explosion, release the

nitrogen by pressing the valve core. Then remove the

valve stem from the shock absorber reservoir. Dispose

of the oi l in a manner acceptable to the Environmental

Pr otection Agency (EPA ).

Before disposal of the shock absorber, release the

nitrogen by pressing the valve core. Then remove the

valve stem from the shock absorber .

1. Use genuine HONDA or HONDA-re commen ded parts and lubricants or their equivalent. Parts that do not meet

HONDA's design sp ecificatio ns may damage the motorcyc le.

2. Use the special tools designed for this product.

3. Install new gaskets, O-rings, cotter pins, lock plates, etc. when reassembling.

4. When torquing bolts or nuts, begin with lager-diameter or inner bolt first, and tighten to the specified torque,

diagonally, in inc r ementa l steps unless a particular sequence is specified.

5. Clean parts in non-flammable or hi gh flash point solvent upon disassembly. Lubricate any sl iding surfaces before

reassembly.

6. When installing a new oil seal, make sure that the sealing lip is lubricated with grease. If any oil seal and related

parts have been washed, apply proper grease to the lip of the oil seal.

7. After reassembly, check all parts for proper i nstallation and operation.

8. Use only metric tools when servicing this motorcycle. Metric bolts, nuts, and screws are not int erchangeable with

any other type of fasteners. The use of incorrect tools and fasteners may damage the motorcycle.

1-2

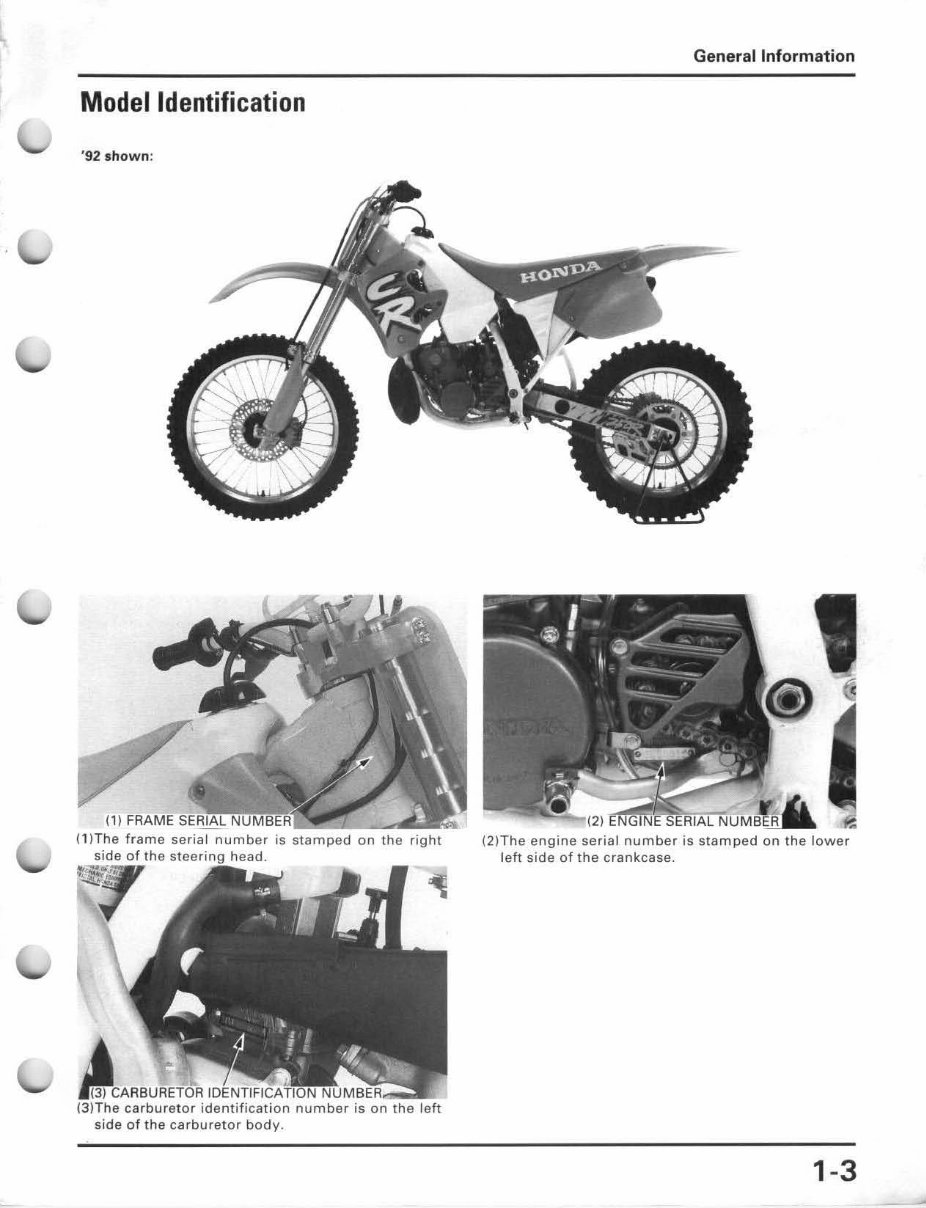

Model Identification

'92 shown :

(l iThe frame serial number is stamped on the right

side of the head.

'CARBURETOR I I I

(3lThe carburetor identification number is on the left

side of the carburetor body.

General Information

(2)The engine serial number is stamped on the lower

left side of the crankcase.

1-3

General Information

Specifications

- General

It em Specifications

Dim ensio ns Overall length '92: 2,161 mm (85.1 in)

'93: 2,165 mm (85.2 in)

After '93: 2,177 mm (85.7 in)

Overall width '92-'93: 825 mm (32.5 in)

After '93: 835 mm (32.9 in)

Overal l height '92: 1,262 mm (49.7 in)

'93: 1,243 mm (48.9 in)

After '93: 1,2 42 mm (48.9 in)

Wheelbase '92: 1,467 mm (57.8 in)

'93: 1,471 mm (57 .9 in)

After '93: 1,483 mm (58.4 in)

Seat height '92: 970 mm (38.2 in )

After '92: 958 mm (37.7 in)

Footpeg height '92: 445 mm (17.5 in)

'93: 436 mm (17.2 in)

After '93: 448 mm (17.6 in)

Ground clearance '92: 350 mm (13.8 in)

'93: 343 mm (13.5 in)

After '93: 345 mm (13.6 in)

Dry weight '92-'93: 96.5 kg (2 12.7 Ibs)

After '93: 97.0 kg (213.8 Ibs)

Frame

Type Semi-double cradle

Front suspension Te l escopic

Front wheel travel 309 mm (12.2 in)

Rear suspension SwingarmlPro-Link

Rear wheel tr avel 320 mm (12.6 in)

Aear dampe r Decarbon type with nitrogen filled reservoir

Front tire size 80/100-2 1 51M

Rear tire size 110/100 - 1864 M

Tire brand (Dunlop) Front K990

Rear K990

Front brake .Hydrauli c single disc

Front brake swept area 306 cm~ (47.4 in

2

)

Rear brake Hydraulic single disc

Rear brake swept area 303 cm~ (47.0 in

2

)

Caster angle '92 : 26° 03'

'93 : 26° 45'

After '93: 27° 17'

Trail length '92: 103.7 mm (4.08 in)

'93: 104.1 mm (4. 10 in)

After '93: 111.5 mm (4.39 in)

Fuel tank capacity 7.5 liter (2 .0 US gal, 1.6 Imp gal)

Engine Bore and stroke 66.4 x 72.0 mm (2.612 x 2.83 in)

Displacement 249.3 cm

3

(15.2 cu-in)

Compression ratio 8.7 : 1

Lubrication system Fuel/ oil mix

Cool ing system Liquid cooled

Aire filtration Oiled polyurethane foam

Crankshaft type Assembled type

Engine dry weight 23.3 kg (51.4 Ibs)

Cylinder arrangement Single cylinde r, in clined 5° from vertical

1-4

General Information

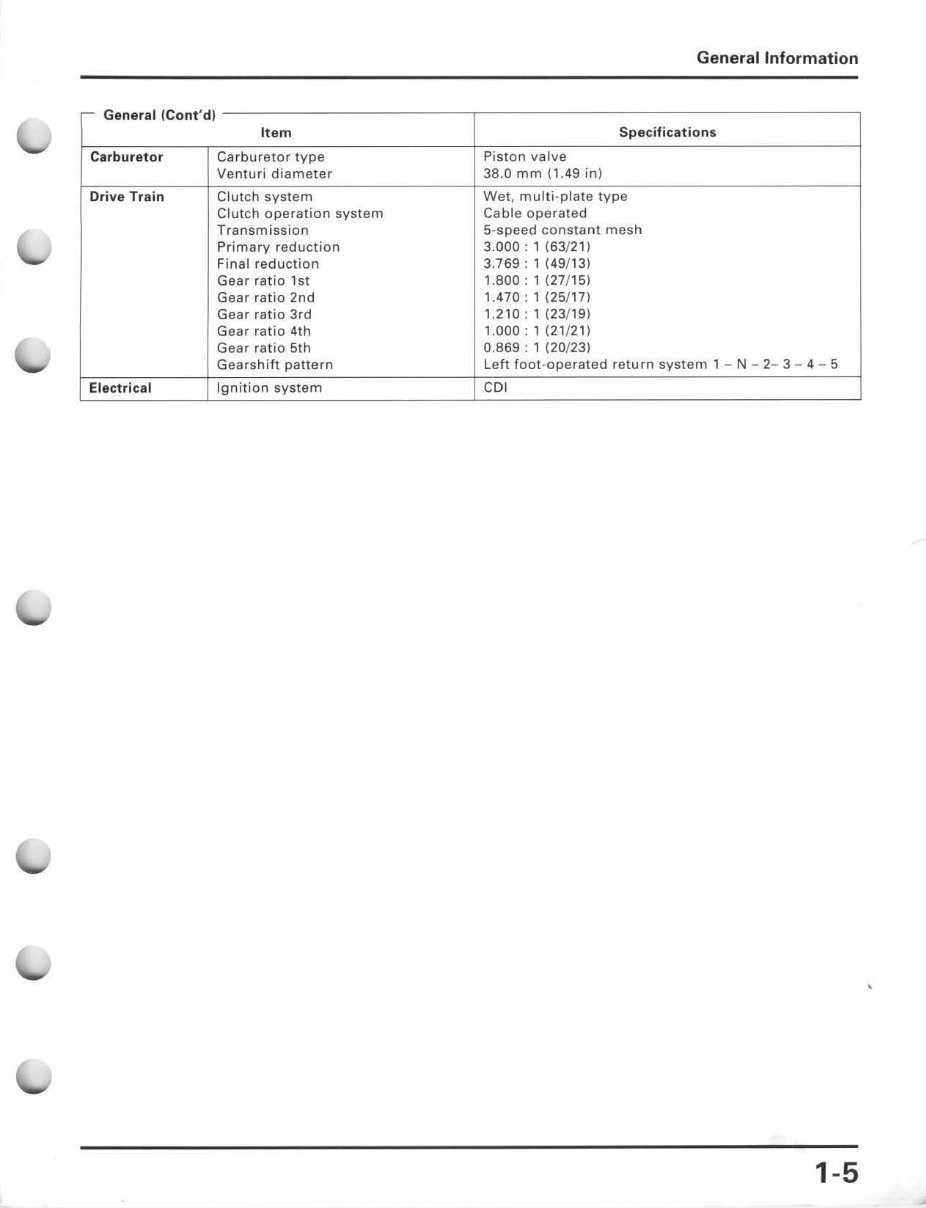

r General (Cont 'd)

Item Spec ifica ti ons

Carburetor Carburetor type Piston va l ve

Venturi diameter 38.0 mm (1. 49 in )

Dri ve Tr ain Clutch system Wet , mult i- plate type

Clutch operation system Cable operat ed

Transmission 5"speed c onstant mesh

Primary reduction 3.000 : 1 (63/ 21 )

Final reduction 3.769 : 1 (49/13)

Gear rat io 1st 1.800 : 1 ( 27/ 15 )

Gear ratio 2nd 1.470 : 1 (25/17 )

Gea r rat io 3rd 1.210 : 1 ( 23 / 19 )

Gear rat io 4th 1.000: 1 ( 21 / 21 )

Gear ratio 5th 0.869 : 1 (20/ 23 )

Gearshift pattern Left foot - operated return system 1 - N - 2- 3 - 4 - 5

Electrical Ignition system COl

1-5

General Information

Unit · mm (in)

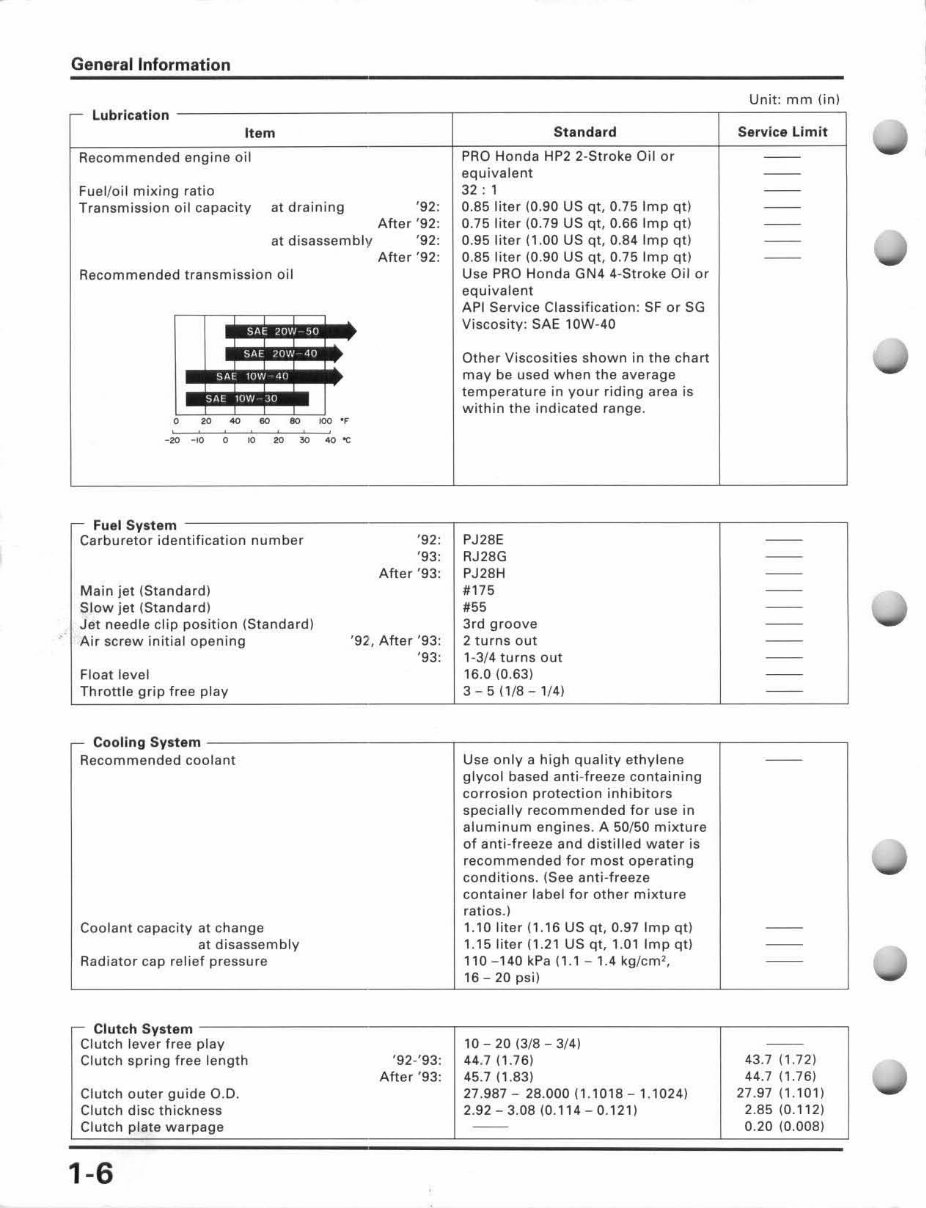

r Lubrication

Item Standard Service Limit

Recommended engine oil PRO Honda HP2 2-Stroke Oil or --

equivalent --

Fuel/ oi l mixing ratio 32 : 1 --

Transmission oil capaci ty at draining '92: 0.85 lite r (0.90 US qt, 0.75 Imp qt) --

Aher '92: 0.75 l ite r (0.79 US qt , 0.66 Imp qt) --

at disassembl y '92: 0.95 liter (1.00 US qt, 0.84 Imp qt ) --

Afte r '92: 0.85 liter (0.90 US qt, 0.75 Imp qt) - -

Recommended transmission oil U se PRO Honda GN4 4-Stroke Oil or

equivalent

API Service Classification: SF or SG

Viscosity : SAE 10W-40

Other Viscosities shown in the chart

may be used when the average

I

temperature in your riding area is

within the indicated range .

,

~ ~ M ~

00 "

,

-~ -0

,

0 ~ ~ ~<

r- Fuel Sy st em --------------,--- ---- - ------ ,-------,

Carburetor identification number

Ma in jet (Stan dard)

Sl ow jet (Standard)

Jet needle clip position (Standard)

Air screw initial opening

Float leve l

Throttle grip free play

'92:

'93:

After '9 3:

'92, After '93:

'93:

PJ28E

AJ28G

PJ28H

#175

#55

3rd gr oove

2 turns out

1-3/4 turns out

16.0 (0.63)

3 - 5 (1 /8 - 1/4)

r- Cooling System ------------ --,--- -------- ----,--- ----,

Recommended coolan t

Cool ant capacity at change

at disassembly

Radiator cap relief pressure

Use only a high quality ethylene

glycol based anti -free ze containi ng

corrosion protection inhi bi tors

specially recommended for use in

aluminum engines . A SO/50 mixt ure

of anti-freeze and distilled wate r is

recommended for most operating

condit i ons. (See anti-freeze

container label for other mix t ure

ratios .)

1.10 l iter (1.16 US qt, 0.97 Imp qt)

1.15 liter (1.21 US qt, 1.01 Imp qt)

110 - 140 kPa (1.1 - 1. 4 kg/ cm

l

,

16 - 20 psi)

r Clutch System -------------,--------------,--------,

Clutch lever free play

Clutch spring free length

Clutch outer guide 0.0.

Clutch disc thickness

Clutch plate warpage

1-6

10 - 20 (3/8 - 3/ 4)

'92-' 93: 44.7 (1.76)

After '93: 45.7 (1.83)

27.987 - 28.000 (1 .1018 - 1.1024)

2.92 - 3.08 (0.114 - 0.12 1)

43.7 (1.72)

44.7 (1.76)

27.97 (1. 101)

2.85 (0. 112)

0.20 (0.008)

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 14 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get your hands on the comprehensive repair manual for the 1992-1996 Honda CR250R two-stroke bike. This manual covers everything from complete tear down and rebuild to torque specs, maintenance, troubleshooting, and more. With 244 pages, it provides extensive information to cater to your repair needs.

This manual features clickable chapters and is searchable, allowing you to easily locate the information you require. Additionally, it comes with no restrictions on printing or saving, providing you with the flexibility you need.

- Complete tear down and rebuild

- Torque specs

- Maintenance procedures

- Troubleshooting guides

- Clickable chapters for easy navigation

- Searchable content for quick information retrieval

- No restrictions on printing or saving