1986-1991 CR250R Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

HOW TO USE THIS MANUAL

Follow the Competition Maintenance

Schedule recommendations (page 3-2 ) to en-

sure that the vehicle is always in peak

operating cond iti on.

Sections 1 through 3 apply to the whole

motorcyc le, while sections 4 through 1 5

describe parts of the motorcycle , grouped ac-

cording to location.

Find the section you want on th is page, then

turn to the table of conte nt s on page 1 of that

sect ion .

M ost sections start with an assembly or

syste m illustration and specifications , torque

values, general instructions, tools and

troubleshooting for the section . The subse-

Quent pages give detailed procedures for the

sect ion.

If you are not familiar wit h this motorcycle .

rea d Section 16. Technical features.

If you don't know the source of the trouble,

see section 17, Troubleshooting.

w

;!!:

to

Z

w

CONTENTS

GENERAL INFORMATION

LUBRICATION

MAINTENANCE

FUEL SYSTEM

ENGINE REMOVAL/INSTALLATION

CYLINOER HEAO/CYLINOER/PISTON

H.P.P (Honda Power Port)

/

COOLING SYSTEM

!!1 REAR WHEEL/BRAKE/SUSPENSION

~ ~============================

«

:r HYORAULIC BRAKE

(J=~==

IGNITION SYSTEM

TECHNICAL FEATURES

TROUBLESHOOTING

INDEX

I

l

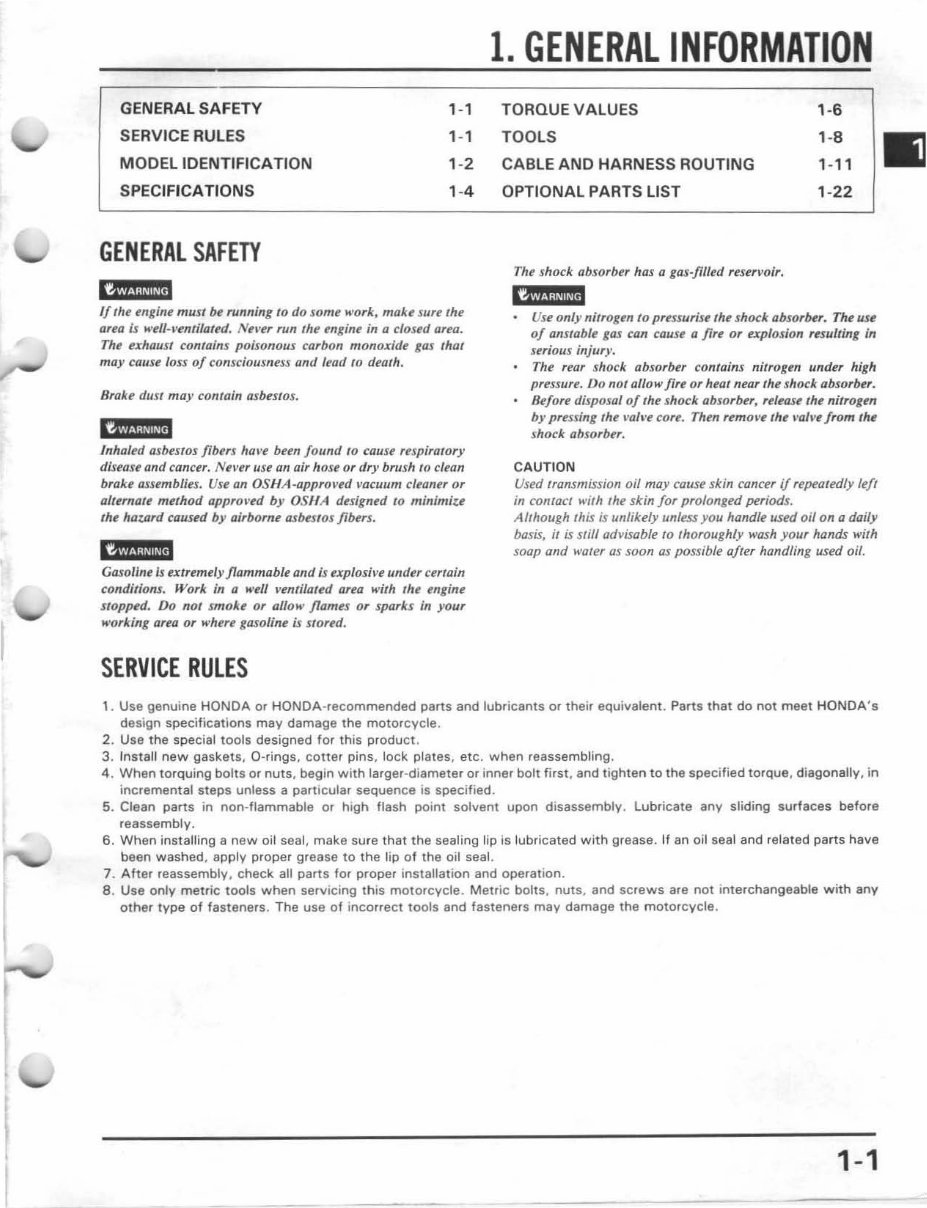

GENERAL SAFETY

SERVICE RULES

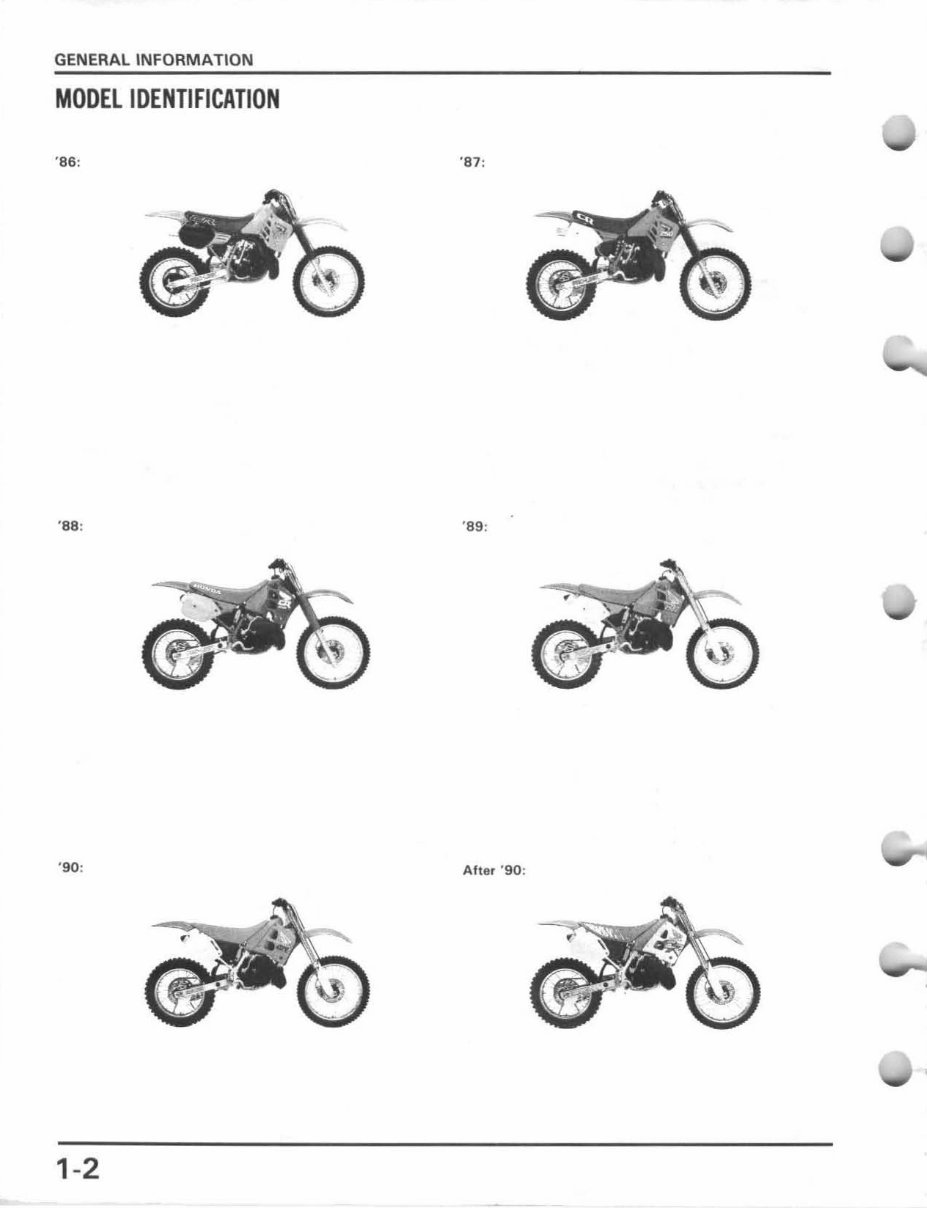

MODEL IDENTIFICATION

SPECIFICATIONS

GENERAL SAFETY

@. i;i.!@i

1-1

1-1

1 -2

1 -4

1/ the mgine muSI be running to do some ... ·ork , moh sure the

area is we/I-I't'ntilaud. Nel'er run the engine in a closed area.

The exhaust contains poisonous carbon monoxide gtu that

may cauu loss 0/ consciousness Qnd lead 10 dealh.

Brake dust rna)' contain asbestos.

.u.

Inhaled asbestos jibl!f$ hal'l! been found to cauu respiratory

distase and cancer. Nel·er use an air host or dr)' brush (0 clean

brake assemblies. Use an OSHA-approl' td vacuum delmer or

a/ternote method apprm'ed by OSHA designed to minimize

the hazard caused by airborne asbestos jibers.

GasolJne Is alremtly flammable and; s explosive under certain

conditions. Work in a tlrel/ ventilated area with the engine

Slopped. Do not smoke or allow flam~s or sparks in your

working area or K'h~r~ gasoli,,~ is stored.

SERVICE RULES

1. GENERAL INFORMATION

TOR QUE VALUES

TOOLS

CA BLE AND HARNESS RO UTING

OPTI ONAL PARTS LIST

The shock absorber has a gas·filled reservoir,

, . 1,

1 -6

1-B

1-11

1-22

Use only nitrogen to pr~ssuris~ th~ shock absorber, The use

0/ anstab/~ gas can cause a fire or explosion resulting in

serious injur)'.

The rear shock absorber contains nitrogen under high

pressure, Do not allow /ire or heat near the shock absorber,

B~/ore disposal oj the shock absorber, rtltQS~ the nitrogen

b)' prening the I'ah'e core. Then remolle the I'all'e /rom the

shock absorber.

CAUTI ON

Used transmission oil may cause skin cancer if repeatedly lejt

in conlact with the skin /or prolonged periods.

AI/hough this is unlikely unless you handle used oil on a daily

basis, il is sli/l advisable 10 thoroughly wash your hands with

soap and waler us soon as possible a/ter handling used oil.

1. Use genuine HONDA or HONDA-recommended parts and lubricants or theit equivalent. Parts that do not meet HONDA 's

design specifications may damage the motorcycle ,

2, Use the special tools designed for this product.

3. Install new gaskets, O-rings, cotter pins, lock plales, etc. when reassembling.

4. When torquing boilS or nuts, begin with larger-diameter or inner bolt first, and tighten to the specified torque, diagonally, in

incremental steps unless a particular sequence is specified.

5. Clean parts in non-flammable or high flash point solvent upon disassembly. lubricate any sliding surfaces before

reassembly.

6. When installing a new oil seal, make sure that the sealing lip is lubricated with grease, If an oil seal and related parts have

been washed, apply proper grease to the lip of the oil seal.

7. After reassembly, check all parts for proper installation and operation.

S. Use only metric tools when servicing this motorcycle. Metric bolts, nuts, and screws are not interchangeable with any

other type of fasteners. The use of incorrect tools and fasteners may damage the motorcycle.

1-1

GENERAL INFORMATION

MODEL IDENTIFICATION

' 86 : ' 87 :

' 88 : ' 89 :

'90:

After ' 90 :

1-2

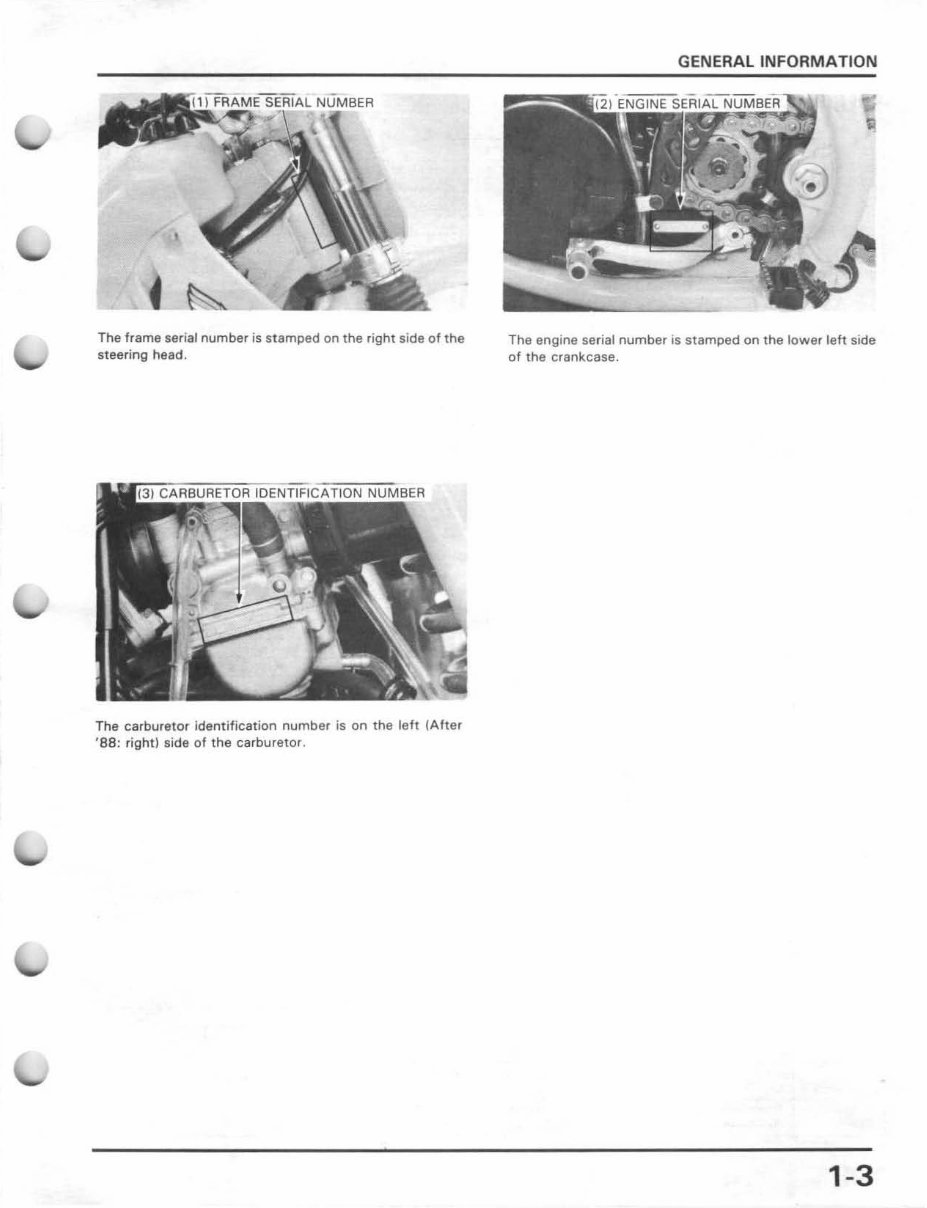

The frame serial number is stamped on the r ight side of the

steering head.

The carburetor identification number is on the left IAlter

'88: right) side of the carburetor.

GENERAL INFORMATION

The engine serial number is stamped on the lowe r left side

of the crankcase.

1-3

GENERAL INFORMA nON

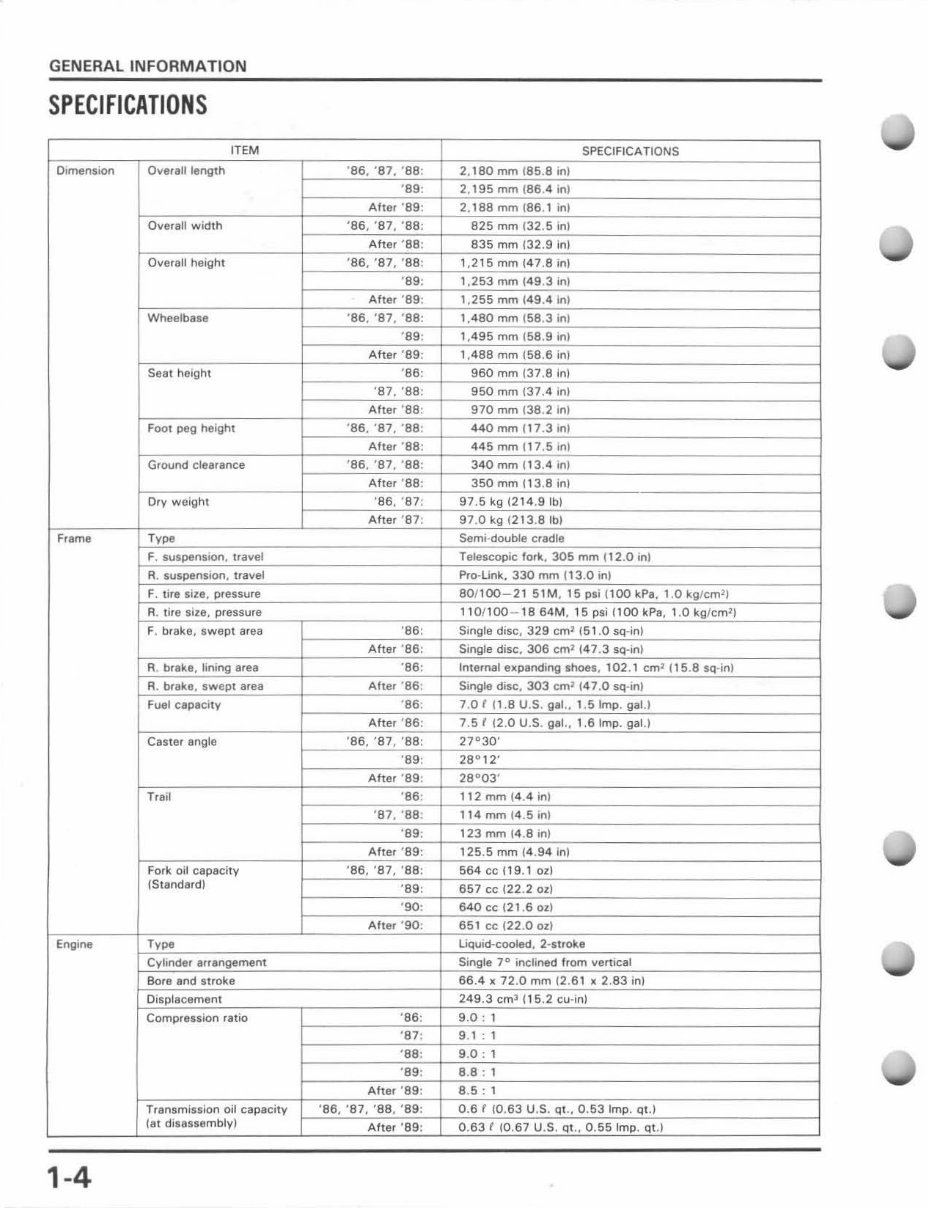

SPECIFICATIONS

ITEM SPECIFICATIONS

Dimension O", erall length ' 86 , ' 87 , ' 88 : 2,180 mm 185.8 in)

' 89 : 2. 195 mm (86 .4 inj

Alter ' 89 : 2, 188 mm IS6 . 1 in)

Overall wi dth '86, ' 87 , ' S8 : 825 mm 132.5 in )

After ' 88 : 835 mm 132.9 in)

Overall height '86 , '87, ' 88 : 1.215 rnm 147.B in)

' 89 : 1, 253 mm 1 49 .3 in)

After ' 89 : 1. 255 mm (49 .4 inj

Wheelbase ' 86 , ' 87 , ' S8 : 1.480 mm (58 .3 inj

' 89 : 1, 495 mm (5 8.9 in j

After ' 89 : , ,488 mm 158.6 inj

Soal height ' 86: 960 mm 137.8 in)

'87 . ' 88 : 950 mm 137.4 inj

After ' 88 : 970 mm 138.2 Inl

FOOl peg heighl ' 86, 'S7. ' 88 : 440 mm 117.3 inj

Afte. ' 88 : 445 mm 1 17 .5 in )

Ground clearance ' 86 , ' 87 , ' 8S : 340 mm (13.4 in)

After ' 88 : 350 mm 03 .8 in)

Drv weight '86, '87: 97.5 kg 1214. 9Ib)

After ' 87 : 97 .0 kg 1213.81bl

frame

Ty"

Semi-double cradle

F. suspension, trallel Telescopic forlt, 305 mm (12 .0 in !

R. suspension , nallel Pro· Unit. 330 mm 113.0 in!

F. tire sil.e. pressure 801100 21 51M, 15 psi (100 ItPII , 1.0 kg/cm1)

R. tira size, pressure 110/ 100 18 64M. 1 5 psi (100 ItPII, 1.0 Itg/ cmtl

F. bralte, swept area '86 : Single disc, 329 cm

t

(5 1.0 sq-inl

After '66: Single disc, 306 cm' 1 47 .3 sq·inl

R. brake, lining area '66: Internal expanding shoes , 102 .1 cm' 115.8 sq·;n!

R. bllke . swept area After ' S6 : Single disc, 303 cml147.0 sq·inl

Fuel capaci ty ' 86 : 7. 0t 11.8 U.S. ga!., 1 .5 Imp. gal.)

After ' 86 : 7. 5' 12.0 U.S. gal., 1 .6 Imp. gal.l

Caster angle '86, '87, '88: 27°30'

'89 : 28"12'

Alter ' 89 : 28 " 03'

Trail ' 86 : 112 mm 14 .4 inl

' 87 , '88: 114 mm 14 .5 inl

' 89 : 123 mm 14 .8 inl

After ' 69 : 125.5 mm (4.94 inl

Fork oil capacity '86, '87, '86: 564 cc (19 . 1 ozl

(Standard)

'89: 657 cc 122.2 oll

'90: 640 cc 12 1.6 oll

After ' 90 : 651 cc 122.0 ol l

Engine

TV"

liquid-cooled, 2-snoke

Cylinder arrangement Single 7" inclined from lIenical

Bora and Itroke 66.4)( 72 .0 mm 12.6 1 I( 2.831nl

Displacement 249.3 cm] (15.2 cu-In)

Compression ratio '8 6: 9 .0 : ,

' 87 : 9.1 : 1

' 88 : 9.0 : 1

'89: 8.8 : 1

After ' 89 : 8.5 : 1

Trllnsmission oil capacity 'B6, '87, '88 , '8 9: 0.6' (0.63 U.S. qt., 0.53 Imp. qt.1

(It disassemblyl

After ' 89 : 0.63' (0. 67 U. S. Qt .. 0.55 Imp . Qt .)

1-4

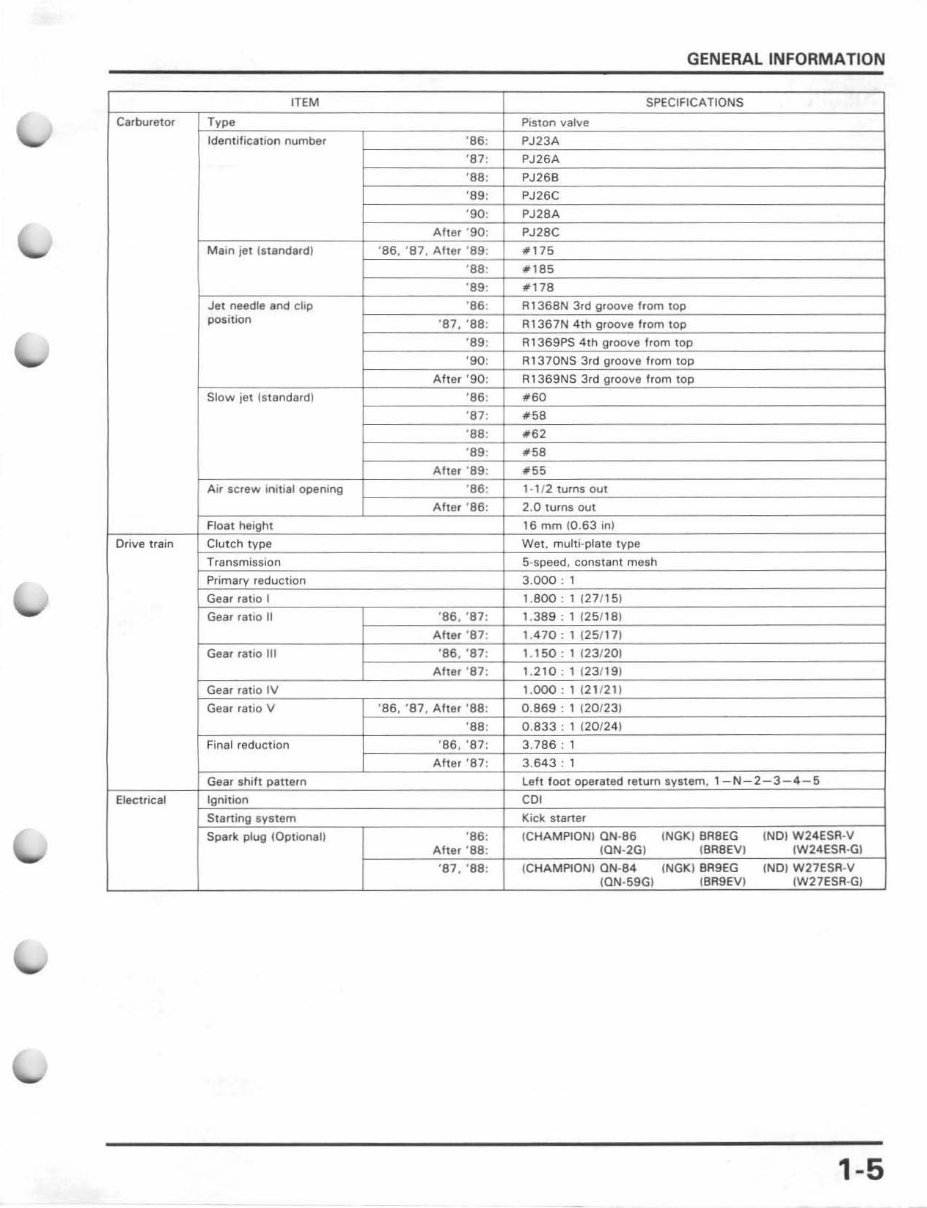

Drive train

Electrical

ITEM

Main Jel tSlandard]

I J" . """ 'M 'hp

poSitIOn

Slow jet Istandard]

Air screw initial opening

FI," ho',",

Clo"h "po

P,'m", ,

G .... "" I

Gear ratio II

Gear rClllO III

G •• , ,Ol" IV

G8,1I rat io V

,, p."",

"''''40

I "".m

Sp'" ~o, '

GENERAL INFORMATION

AI<" PJ28C

' B6 , ' 87 , AI,,, ' 89 , '175

AI", '90, R'369N5 3,' '''". h,m "P

~----~~~' r~ .,:~::--------------------~

AI,,, ' 86 , 2.0'010' '0'

'86, '87, AI, .. ' 88 ,

'6 mm 10. 63 "I

Woo, I "'".

,m .. h

3.000 ,

1.800 , I 1271151

. 389, 1251181

1.470, I 12511"

1.150' I 1231201

, 1.210 , ~91

1.000, I 1211211

1. 869, 1201231

0.833, I 120124)

3.786,

3. 643 ,

Lo" 100' '''10m ,,,10m, '- N- :

COl

INGKI BR9EG INDI

I

1-5

GENERAL INFORMATION

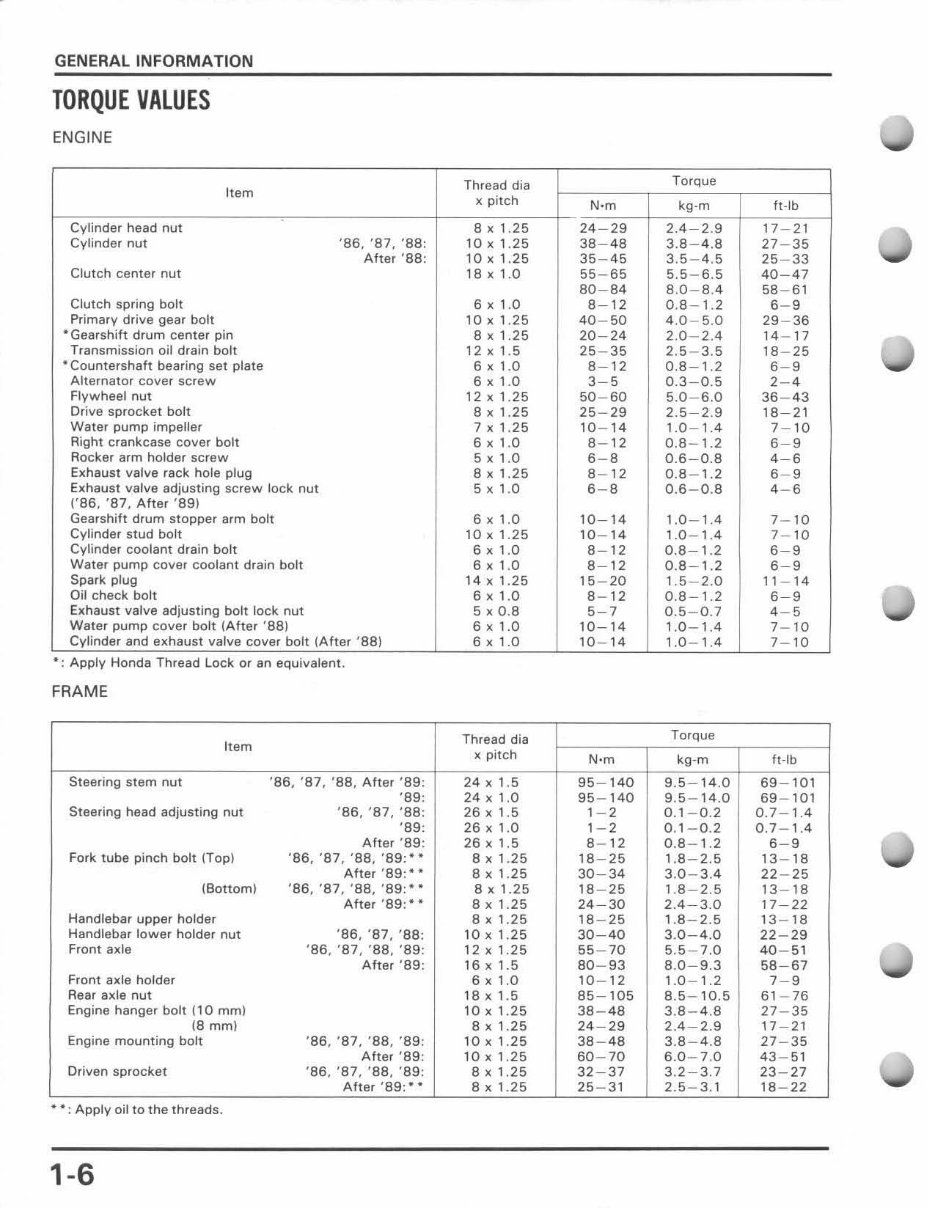

TORQUE VALUES

ENGINE

Thread dia

Torque

Item

x pitch

N·m kg -m ft-Ib

Cy linder head nut 8 x 1.25 24-29 2.4-2.9 17 - 21

Cylinder nut '86, '87, '88: 'Oxl.2S 38 - 48 3.8 - 4.8 27 -35

After '88: 10x1.25 35 - 45 3.5 - 4.5 25 -3 3

Clutch center nut 18 x 1.0 55 - 65 5.5-6.5 40 - 47

80 - 84 B.0-8.4 58 - 61

Clutch spring bolt 6 x 1.0 8- 12 0.8 - 1.2 6- 9

Primary drive gear bolt 10 xt.2S 40 - 50 4 .0 - 5.0 29 - 36

• Gearshift drum center pin 8 x 1. 25 20-24 2.0 - 2.4 14 - 17

Transmission oil drain bolt 12 x 1.5 25-35 2.5 - 3.5 18 - 25

·Countershaft bearing set plate 6 x 1.0 8-12 0.8 -1 .2 6 -9

Alternator cover screw 6 x 1.0 3- 5 0.3-0 .5 2- 4

Flywheel nut 12x1.25 50 - 60 5.0-6.0 36 - 43

Drive sprocket bolt B x 1.25 25 - 29 2.5-2.9 18-21

Water pump impeller 7 x 1.25 10 - 14 1.0 - 1.4 7-10

Right crankcase cover bolt 6 x 1.0 8- 12 0.8 - 1.2 6-9

Rocker arm holder screw 5 II: 1 .0 6- 8 0.6-0.8 4-6

Exhaust valve rack hole plug 8 x 1.25 8- 12 0.8 - 1.2 6-9

Exhaust valve adjusting sc rew lock nut 5 x 1.0 6- 8 0.6 - 0.8 4- 6

(,86, '87, After '89)

Gearshift drum stopper arm bolt 6 x 1.0 10 - 14 1.0 - 1A 7- 10

Cylinder stud bolt 10x1.25 10-14 1.0 - 1.4 7- 10

Cylinder coolant drain bolt 6 x 1.0 8- 12 0.8-1.2 6-9

Water pump cover coolant drain bolt 6 x 1.0 8- 12 0.8-1.2 6-9

Spark plug 14x1.25 15 - 20 1. 5-2.0 11 -14

Oil check bolt 6 x 1 .0 8- 12 0.8 - 1.2 6-9

Exhaust valve adjusting bolt lock nut 5 x 0.8 5 -7 0.5 - 0.7 4- 5

Water pump cover bolt (After '88) 6 x 1.0 10 -14 1.0 - 1 A 7- 10

Cylinder and exhaust valve cover bolt (After '88) 6 x 1.0 10 - 14 1.0 - ' A 7- 10

.: Apply Honda Thread Lock or an equivalent.

FRAME

Thread dia

Torque

Item

x pitch

N·m kg·m ft·lb

Steering stem nut '86, '87, '88, After '89: 24 x 1.5 95 - 140 9.5 -1 4.0 69-101

'89: 24 x 1,0 95 - 140 9.5- 14.0 69 - 101

Steering head adjusting nut ' 86, '87, '88: 26 xl ,S 1- 2 0.1 - 0.2 0.7 - 1.4

'89: 26 x 1.0 1- 2 0.1 - 0.2 0.7 - 1.4

After '89: 26 x 1,5 8- 12 0.8- 1.2 6- 9

Fork tube pinch bolt IT op) '86, '87, '88, '89:

0

• 8 x 1.25 18 - 25 1.8 - 2,5 13- 18

After '89:* 0 8 x 1.25 30 - 34 3.0 - 3A 22 - 25

(Bottom) '86, '87, '88, '89:"' 8 x 1.25 18-25 1.8- 2.5 13- 18

After '89:" • 8 x 1.25 24-30 2A-3 .0 17-22

Handlebar upper holder 8 x 1.25 18- 25 1,8- 2.5 13- 18

Handlebar lower holder nut '86, '87, '88: 10xl.25 30 - 40 3.0 - 4.0 22 - 29

Front axle '86, '87, '88, '89: 12xl.25 55-70 5.5-7,0 40 - 51

After '89: 16 x 1.5 80 - 93 8.0- 9.3 58-67

Front axle holder 6 x 1.0 10 - 12 1.0 - 1.2 7- 9

Rear axle nut 18xl ,5 85 - 105 8.5- 10.5 61 - 76

Engine hanger bolt ( 10 mm) 10x1 .25 38- 48 3.8 - 4,8 27-35

(8mml 8 x 1.25 24-29 2.4-2.9 17-21

Engine mounting bolt '86, '87, '88, '89: 10xl.25 38 - 48 3.8 - 4.8 27- 35

After '89 : 10x1,25 60 - 70 6.0 - 7.0 43 - 51

Driven sprocket '86, '87, '88, '89: 8 x 1,25 32-37 3.2-3.7 23 - 27

After '89:'" 8 x 1.25 25 - 31 2.5 - 3.1 18-22

" . : Apply all to the threads.

1-6

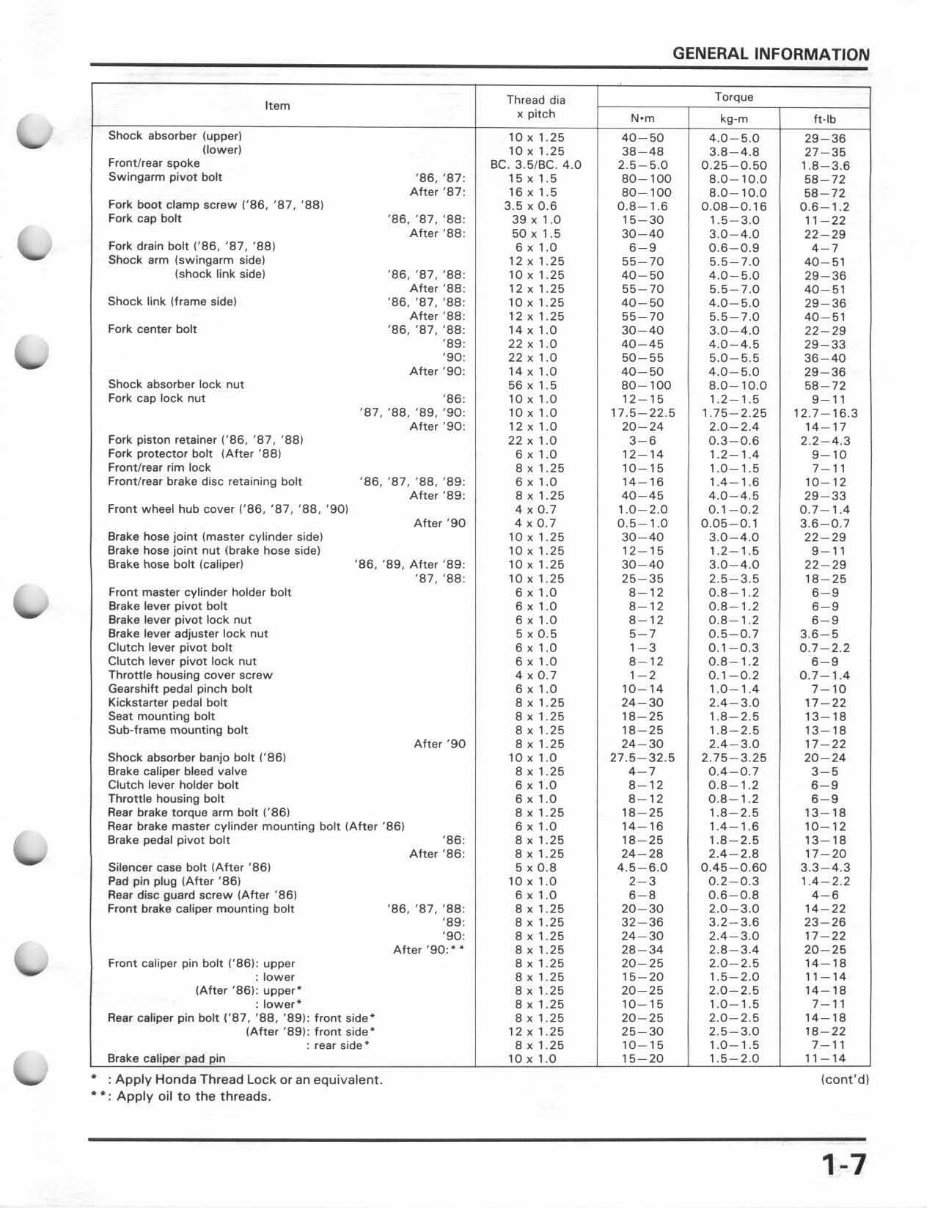

Shock absorber (upper)

(lower)

Front/rear spoke

Swingarm pivot bolt

Item

Fork boot clamp screw (' 86. '87. ' 88)

Fork cap bolt

Fork drain bolt ('86, '87. '88)

Shock arm (swin9arm side)

(shock link side)

Shock link (frama side)

Fork center bolt

Shock absorber lock nut

Fork cap lock nut

Fork piston retainer /'S6, 'S7, '88)

Fork protector bolt (After '88 )

Front/rear rim lock

Front/rear brake disc retaining bolt

Front wheal hub COVflr I'S6, 'S7, 'SS , ' 901

Brake hose joint Imaster cylinder side )

Brake hose joint nut (brake hose side)

818ke hose bolt (caliper)

Front master cylinder holder bolt

Brake level pivot bolt

Brake lever pivot lock nut

Brake lever adjuster lock nut

Clutch lever pillot bolt

Clutch leller pillot lock nut

Thronle housing cover screw

Gearshift pedal pinch bolt

Kickstarter pedal bolt

Seat mounting bolt

Sub-frame mounting bolt

Shock absorber banjo bolt 1'86)

Brake caliper bleed vallie

Clutch lever holder bolt

Thronle hoosing bolt

Rear brake torque arm bolt /'86)

' 86, '87 :

After '87:

'S6, ' 87, ' S8:

After 'S8 :

'86. ' 87. 'S8 :

Alter'S8 :

'S6, ' 87. ' S8:

After 'S8 :

'86 , ' 87 . ' 88 :

' S9 :

' 90 :

After ' 90:

'S6:

'87 , '8S, '89. ' 90 :

After '90 :

' S6 , ' 87 , ' 8S. 'S9 :

After 'S9:

After '90

'86 . ' 89 , After ' 89 :

' 87, '88:

After ' 90

Rear brake master cylinder mounting bolt (After '86)

Brake pedal pillot bolt ' 86:

Silencer case bolt (After 'S6)

Pad pin plug [After '86)

Rear disc guerd screw (After '86)

Front brake caliper mounting bolt

Front caliper pin bolt ('86): upper

: lower

(After '86) : upper"

: lowe,"

Rear caliper pin bolt ('87 , '88, ' 89): front side "

(After '89) : front side"

: tear side"

Brake caliper pad pin

• : Apply Honda Thread Lock or an equivalent.

•• : Apply oil to the threads.

After '86:

' 86 , '87. ' 88 :

' 89:

'90 :

After ' 90:""

Thread die

)( pitch

10)( 1.25

10 Jt 1. 25

Be . 3.S/ Be . 4.0

15)( 1.5

16)( 1.5

3.5)( 0.6

39)( 1.0

50)( 1.5

6)( 1.0

12 it 1. 25

10)( 1.25

12)(1.25

10)( 1.25

12)( 1.25

14)( 1.0

22 x 1.0

22 x 1.0

14 )( 1.0

56)( 1.5

10)( 1.0

10 x 1.0

'2 x 1.0

22 x 1.0

6)( 1.0

B)( 1.25

6 x 1.0

8 x 1.25

4 x 0.7

4 xO .7

'0)( 1.25

10 x 1.25

10x1.25

10x1 .25

6 x 1.0

6 x 1.0

6)( 1.0

5 x 0.5

6)( 1.0

6 x 1.0

4 x 0.7

6)( 1.0

B x 1.25

8 x 1.25

8 x 1.25

B x 1.25

10 x 1.0

ex 1.25

6 x 1.0

6 x 1.0

8 x 1.25

6 x 1.0

8 x 1.25

8 x 1.25

5 x 0.8

10 x 1.0

6 x 1.0

8)( 1. 25

8 x 1.25

8 x 1.25

8 x 1.25

8 x 1.25

8)( 1.25

8 x 1.25

8 II 1. 25

8 x 1.25

12 x 1.25

8 x 1.25

10 x 1.0

GENERAL INFORMA nON

40 50

38~48

2.5 - 5.0

80 - 100

80-'00

0 .8 - 1.6

15 - 30

30 - 40

6-9

55-70

40 - 50

55 - 70

40 - 50

55-70

30 - 40

40 - 45

50 - 55

40 - 50

80 - 100

12 - '5

17.5 - 22.5

20-24

3- 6

12-'4

10-'5

14 - 16

40 - 45

1.0 - 2.0

0. 5-1.0

30 - 40

12 - 15

30 - 40

25 - 35

8- 12

8- 12

8-12

5- 7

1- 3

8- 12

1- 2

10-14

24 - 30

18 - 25

18 - 25

24 - 30

27.5- 32 .5

4-7

8-12

8- 12

18 - 25

14 - 16

18-25

24 - 28

4.5 - 6.0

2- 3

6-8

20 - 30

32-36

24 - 30

28 - 34

20-25

15 - 20

20-25

10 - 15

20 - 25

25-30

10 - 15

15-20

Torque

4.0 5 .0

3.8 - 4 .8

0. 25-0.50

8 .0 - 10.0

8.0 - 10.0

0.08-0. 16

1.5- 3.0

3.0- 4.0

0.6 - 0.9

5.5 - 7.0

4.0-5.0

5.5 - 7.0

4.0 - 5.0

5.5- 7.0

3. 0-4.0

4 .0 - 4.5

5.0 - 5.5

4.0 - 5.0

8.0-10.0

1.2-1.5

1.75 - 2. 25

2.0- 2.4

0.3 - 0.6

1.2 - 1.4

1.0 - 1.5

1.4 - 1.6

4.0 - 4.5

0.1 - 0.2

0.05 - 0.1

3.0-4.0

1.2 - 1.5

3.0- 4.0

2.5- 3.5

0.8 - 1.2

0.8 - 1.2

0.8-1.2

0.5- 0.7

0.1- 0.3

0.8- 1.2

0.1 - 0.2

1.0-1.4

2.4 - 3.0

1.8 - 2.5

1.8 - 2.5

2.4-3.0

2. 75 - 3. 25

0.4-0.7

0.8 - 1.2

0.8- 1.2

1.8- 2.5

1.4 - 1.6

1.8-2.5

2.4 - 2.8

0.45 - 0.60

0.2-0.3

0.6-0.8

2.0 - 3.0

3.2-3 .6

2.4- 3.0

2.8 - 3.4

2.0-2.5

1.5 - 2.0

2.0-2 .5

1.0 - 1.5

2.0 - 2.5

2.5- 3.0

1.0 - 1.5

1.5 - 2.0

ft-Ib

29 36

27-35

1.8 - 3.6

58-72

58 - 72

0 .6 - 1.2

11 - 22

22 - 29

4- 7

40 - 51

29 - 36

40-51

29-36

40 - 51

22 - 29

29 - 33

36 - 40

29 - 36

58 - 72

9- 11

12.7- 16.3

14 - 17

2.2- 4.3

9- 10

7- 11

10 - 12

29 - 33

0.7- 1.4

3.6- 0.7

22 - 29

9- 11

22 - 29

18 - 25

6- 9

6- 9

6- 9

3.6 -5

0.7- 2.2

6- 9

0.7 - 1.4

7-10

17 - 22

13 - 18

13 - 18

17 - 22

20 - 24

3- 5

6- 9

6- 9

13 - 18

10 - 12

13 - 18

17 - 20

3.3 - 4.3

1.4 - 2.2

4-6

14 - 22

23-26

17 - 22

20 - 25

14 - 18

11 - 14

14 - 18

7- 11

14 - 18

18 - 22

7- 11

11 - 14

{ cont'dl

1-7

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 38 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

This repair manual is tailored for the 1986-1991 Honda CR250R two-stroke bike, offering comprehensive coverage for complete tear down and rebuild, including detailed pictures and part diagrams. It encompasses torque specifications, maintenance procedures, troubleshooting techniques, and much more, making it an indispensable resource for both professional mechanics and DIY enthusiasts.

With 309 pages of valuable content, this manual features clickable chapters and a search function, enabling users to easily locate the information they need. Additionally, there are no restrictions on printing or saving the manual, providing convenient access to the wealth of knowledge it contains.

- Complete tear down and rebuild

- Comprehensive pictures and part diagrams

- Torque specifications

- Maintenance procedures

- Troubleshooting techniques

- Clickable chapters

- Searchable content

- No printing or saving restrictions