1976-1990 Honda CG125 CG 125 Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Honda

CG125

Owners

Workshop

Manual

by Pete Shoemark

with an additional Chapter on the 1985 on models

by Jeremy Churchill

Models covered

CG125. 124cc. June 1976 to May 1978

CG125K1. 124cc. May 1978 to March 1981

CG125-B. 124cc. March 1981 to March 1982

CG125-C. 124cc. March 1982 to November 1984

CG125-E. 124cc. November 1984 to April 1985

CG125(BR)-E/F. 124cc. April 1985 to April 1988

CG125(BR)-J. 124cc. April 1988 to September 1991

CG125(BR)-K. 124cc. September 1991 on

ISBN 1 85010 918 4

© Haynes Publishing 1994

All rights reserved. No part of this book may be reproduced or transmitted in

any form or by any means, electronic or mechanical, including photocopying,

recording or by any information storage or retrieval system, without permission

in writing from the copyright holder.

Printed in the USA (433-4T9)

Haynes Publishing

Sparkford Nr Yeovil

Somerset BA22 7JJ England

Haynes Publications, Inc

861 Lawrence Drive

Newbury Park

California 91320 USA

British Library CataloGuing in Publication Data

A catalogue record for this book is available

from the British Library

~

Acknowledgements

Our thanks are due to APS Motorcycles of Wells (formerly

Fran Ridewood & Co), Paul Branson Motorcycles of Yeovil, and

CSM of Taunton, who supplied the machines featured in this

manual.

We would also like to thank the Avon Rubber Company, who

kindly supplied information and technical assistance on tyre

fitting; NGK Spark Plugs (UK) Ltd for information on spark plug

maintenance and electrode conditions and Renold Limited for

advice on chain care and renewal.

About this manual

The author of this manual has the conviction that the only

way in which a meaningful and easy to follow text can be

written is first to do the work himself, under conditions similar

to those found in the average household. As a result, the hands

seen in the photographs are those of the author. Even the

machines are not new: examples that have covered a consider-

able mileage were selected so that the conditions encountered

would be typical of those found by the average owner.

Unless specially mentioned, and therefore considered

essential, Honda service tools have not been used. There is

invariably some alternative means of slackening or removing

some vital component when service tools are not available and

risk of damage has to be avoided at all costs.

Each of the six Chapters is divided into numbered Sections.

Within the Sections are numbered paragraphs. In consequence,

cross reference throughout this manual is both straightforward

and logical. When a reference is made 'See Section 5.12' it

means Section 5, paragraph 12 in the same Chapter. If another

Chapter were meant, the text would read 'See Chapter 2,

Section 5.12'. All photographs are captioned with a

Section/paragraph number to which they refer and are always

relevant to the Chapter text adjacent.

Figure numbers (usually line illustrations) appear in

numerical order, within a given Chapter. Fig. 1.1 therefore refers

to the first figure in Chapter 1. Left-hand and right-hand

descriptions of the machines and their component parts refer to

the right and left of a given machine when the rider is seated

normally.

Motorcycle manufacturers continually make changes to

specifications and recommendations, and these, when notified,

are incorporated into our manuals at the earliest opportunity.

We take great pride in the accuracy of information given in

this manual, but motorcycle manufacturers make alterations and

design changes during the production run of a particular

motorcycle of which they do not inform us. No liability can be

accepted by the authors or publishers for loss, damage or injury

caused by any errors in, or omissions from, the information given.

Contents

Acknowledgements

About this manual

Introduction to the Honda CG125

Model dimensions and weight

Ordering spare parts

Safety first!

Routine maintenance

Quick glance maintenance adjustments and capacities

Recommended lubricants

Working conditions and tools

Chapter 1 Engine, clutch and gearbox

Chapter 2 Fuel system and lubrication

Chapter 3 Ignition system

Chapter 4 Frame and forks

Chapter 5 Wheels, brakes and tyres

Chapter 6 Electrical system

Chapter 7 The 1985 on models

Wiring diagrams

Conversion factors

Index

Page

2

2

5

5

6

7

8

13

13

/

15

52

60

67

80

93

107

103, 124

125

126

I

The Honda CG125 model

The Honda CG125-C model

Introduction to the Honda CG125

The CG125 model first appeared in the UK in June 1976. It

can be regarded in many ways as a utility version of the popular

CB1 25 with which it shares many features. The basic difference

between the two models is the CG125's use of pushrod

operated overhead valves in place of the more popular overhead

camshaft arrangement. The unit provides surprisingly brisk

performance coupled with good fuel economy. The machine in

general is functional and sensibly equipped, and does not suffer

the surfeit of gadgetry so often found on its contemporaries. Its

inherent simplicity makes it an ideal learner's or commuter's

mount, both in terms of ease of riding and in its ease of

maintenance. A noteworthy feature is the adoption of a full rear

chain enclosure. Although this is by no means a new idea,

having appeared and disappeared many times over the years

with the changing dictates of fashion, it is, nevertheless, an

eminently sensible feature, greatly extending chain life.

Despite remaining basically unchanged, the CG125 has

received several modifications and has been altered slightly in

appearance to keep up with its rivals. Five distinct versions have

appeared, with differences of varying significance, which are

identified (where applicable) in this Manual by their Honda

model code suffixes. Identification details, as available, are

given below with the approximate dates of import; note that the

latter need not necessarily coincide with the machine's date of

registration.

The CG125 model (no identifying suffix) has the frame

numbers CG125-1023061 to 1111090. Engine numbers are

not available. Identified by its shrouded, external spring, front

forks, this model Was imported from June 1976 to May 1978.

The CG125K1 model has the frame numbers

CG125-1114636 to 1162518. Engine numbers not available.

It differed most noticeably from the CG125 model in having

front forks with internal springs and exposed stanchions, and

was imported from May 1978 to March 1981.

The CG125-B model has the frame numbers

CG125-1202755 to 1223689; its engine numbers start at

CG125E-1374586. It can be distinguished from the K1 model

only by its different paintwork and graphics and was imported

from March 1981 to March 1982.

The CG125-C model has the frame numbers

CG125-1272831 to 1286692; its engine numbers start at

CG125E-1513928 on. Fitted with revised tail lamp, flashing

indicator lamps, handlebar switches and the usual detail

changes to paintwork and graphics. This model is also fitted

with a higher compression engine and the (T)PFC carburettor

for greater fuel economy. Note also that the ignition switch is

combined in a new warning lamp cluster, mounted next to the

speedometer. Imported from March 1982 to November 1984.

The CG125-E model has the frame number

CG 125-1288790 to 1293380 and the engine numbers

CG125E-1689761 to 1694851. Identical to the C model

except for detail changes to the graphics, this model was

imported from November 1984 to April 1985.

All the aforementioned models are of Japanese

manufacture and are covered in Chapters 1 to 6. Later models

were manufactured in Brazil and known as the CG125(BR)

models; refer to Chapter 7 for further information.

Model dimensions and weight

Overall length

Overall width

Overall height

Wheelbase

Seat height

Ground clearance

Dry weight

1840 m m (72.4 in)

735 m m (28.9 in)

1025 mm (40.4 in)

1200 m m (47.2 in)

755 m m (29.7 in)

135 m m (5.3 in)

95 kg (209 Ib)

Ordering spare parts

*

When ordering spare parts for the CG125 models, it is

advisable to deal direct with an official Honda agent, who will

be able to supply many of the items required ex-stock. It is

advisable to get acquainted with the local Honda agent, and to

rely on his advice when purchasing spares. He is in a better

position to specify exactly the parts required and to identify the

relevant spare part numbers so that there is less chance of the

wrong part being supplied by the manufacturer due to a vague

or incomplete description.

When ordering spares, always quote the frame and engine

numbers in full, together with any prefixes or suffixes in the

form of letters. The frame number is found stamped on the

right-hand side of the steering head, in line with the forks. The

engine number is stamped on the left-hand side of the

crankcase, immediately behind the oil strainer cap.

Use only parts of genuine Honda manufacture. A few

pattern parts are available, sometimes at a cheaper price, but

there is no guarantee that they will give such good service as

the originals they replace. Retain any worn or broken parts until

the replacements have been obtained; they are sometimes

needed as a pattern to help identify the correct replacement

when design changes have been made during a production run.

Some of the more expendable parts such as spark plugs,

bulbs, tyres, oils and greases etc., can be obtained from

accessory shops and motor factors, who have convenient

opening hours and can often be found not far from home. It is

also possible to obtain them on a Mail Order basis from a

number of specialists who advertise regularly in the motorcycle

magazines.

Frame number location Engine number location

Safety first!

Professional motor mechanics are trained in safe working

procedures. However enthusiastic you may be about getting on

with the job in hand, do take the time to ensure that your safety

is not put at risk. A moments lack of attention can result in an

accident, as can failure to observe certain elementary

precautions.

There will always be new ways of having accidents, and the

following points do not pretend to be a comprehensive list of all

dangers; they are intended rather to make you aware of the

risks and to encourage a safety-conscious approach to all work

you carry out on your vehicle.

Essential DOs and DON'Ts

DON'T start the engine without first ascertaining that the

transmission is in neutral.

DON'T suddenly remove the filler cap from a hot cooling

system - cover it with a cloth and release the pressure gradually

first, or you may get scalded by escaping coolant.

DON'T attempt to drain oil until you are sure it has cooled

sufficiently to avoid scalding you.

DON'T grasp any part of the engine, exhaust or silencer without

first ascertaining that it is sufficiently cool to avoid burning you.

DON'T allow brake fluid or antifreeze to contact the machine's

paintwork or plastic components.

DON'T syphon toxic liquids such as fuel, brake fluid or

antifreeze by mouth, or allow them to remain on your skin.

DON'T inhale dust - it may be injurious to health (see Asbestos

heading).

DON'T allow any spilt oil or grease to remain on the floor —

wipe it up straight away, before someone slips on it.

DON'T use ill-fitting spanners or other tools which may slip and

cause injury.

DON'T attempt to lift a heavy component which may be

beyond your capability - get assistance.

DON'T rush to finish a job, or take unverified short cuts.

DON'T allow children or animals in or around an unattended

vehicle.

DON'T inflate a tyre to a pressure above the recommended

maximum. Apart from overstressing the carcase and wheel rim,

in extreme cases the tyre may blow off forcibly.

DO ensure that the machine is supported securely at all times.

This is especially important when the machine is blocked up to

aid wheel or fork removal.

DO take care when attempting to slacken a stubborn nut or

bolt. It is generally better to pull on a spanner, rather than push,

so that if slippage occurs you fall away from the machine rather

than on to it.

DO wear eye protection when using power tools such as drill,

sander, bench grinder etc.

DO use a barrier cream on your hands prior to undertaking dirty

jobs — it will protect your skin from infection as well as making

the dirt easier to remove afterwards; but make sure your hands

aren't left slippery. Note that long-term contact with used

engine oil can be a health hazard.

DO keep loose clothing (cuffs, tie etc) and long hair well out of

the way of moving mechanical parts.

DO remove rings, wristwatch etc, before working on the vehicle

- especially the electrical system.

DO keep your work area tidy - it is only too easy to fall over

articles left lying around.

DO exercise caution when compressing springs for removal or

installation. Ensure that the tension is applied and released in a

controlled manner, using suitable tools which preclude the

possibility of the spring escaping violently.

DO ensure that any lifting tackle used has a safe working load

rating adequate for the job.

DO get someone to check periodically that all is well, when

working alone on the vehicle.

DO carry out work in a logical sequence and check that

everything is correctly assembled and tightened afterwards.

DO remember that your vehicle's safety affects that of yourself

and others. If in doubt on any point, get specialist advice.

IF, in spite of following these precautions, you are unfortunate

enough to injure yourself, seek medical attention as soon as

possible.

Asbestos

Certain friction, insulating, sealing, and other products -

such as brake linings, clutch linings, gaskets, etc - contain

asbestos. Extreme care must be taken to avoid inhalation of

dust from such products since it is hazardous to health. If in

doubt, assume that they do contain asbestos.

Fire

Remember at all times that petrol (gasoline) is highly

flammable. Never smoke, or have any kind of naked flame

around, when working on the vehicle. But the risk does not end

there - a spark caused by an electrical short-circuit, by two

metal surfaces contacting each other, by careless use of tools,

or even by static electricity built up in your body under certain

conditions, can ignite petrol vapour, which in a confined space

is highly explosive.

Always disconnect the battery earth (ground) terminal

before working on any part of the fuel or electrical system, and

never risk spilling fuel on to a hot engine or exhaust.

It is recommended that a fire extinguisher of a type suitable

for fuel and electrical fires is kept handy in the garage or

workplace at all times. Never try to extinguish a fuel or electrical

fire with water.

Note: Any reference to a 'torch' appearing in this manual

should always be taken to mean a hand-held battery-operated

electric lamp or flashlight. It does not mean a welding/gas torch

or blowlamp.

Fumes

Certain fumes are highly toxic and can quickly cause

unconsciousness and even death if inhaled to any extent. Petrol

(gasoline) vapour comes into this category, as do the vapours

from certain solvents such as trichloroethylene. Any draining or

pouring of such volatile fluids should be done in a well

ventilated area.

When using cleaning fluids and solvents, read the instruc-

tions carefully. Never use materials from unmarked containers -

they may give off poisonous vapours.

Never run the engine of a motor vehicle in an enclosed

space such as a garage. Exhaust fumes contain carbon mon-

oxide which is extremely poisonous; if you need to run the

engine, always do so in the open air or at least have the rear of

the vehicle outside the workplace.

The battery

Never cause a spark, or allow a naked light, near the

vehicle's battery. It will normally be giving off a certain amount

of hydrogen gas, which is highly explosive.

Always disconnect the battery earth (ground) terminal

before working on the fuel or electrical systems.

If possible, loosen the filler plugs or cover when charging

the battery from an external source. Do not charge at an

excessive rate or the battery may burst.

Take care when topping up and when carrying the battery.

The acid electrolyte, even when diluted, is very corrosive and

should not be allowed to contact the eyes or skin.

If you ever need to prepare electrolyte yourself, always add

the acid slowly to the water, and never the other way round.

Protect against splashes by wearing rubber gloves and goggles.

Mains electricity and electrical equipment

When using an electric power tool, inspection light etc,

always ensure that the appliance is correctly connected to its

plug and that, where necessary, it is properly earthed

(grounded). Do not use such appliances in damp conditions

and, again, beware of creating a spark or applying excessive

heat in the vicinity of fuel or fuel vapour. Also ensure that the

appliances meet the relevant national safety standards.

Ignition HT voltage

A severe electric shock can result from touching certain

parts of the ignition system, such as Ihe HT leads, when the

engine is running or being cranked, particularly if components

are damp or the insulation is defective. Where an electronic

ignition system is fitted, the HT voltage is much higher and

could prove fatal.

Routine maintenance

Refer to Chapter 7 for information relating to the 1985 on Brazilian models

Introduction

Periodic routine maintenance is a continuous process that

commences immediately the machine is used. It must be

carried out at specified mileage recordings, or on a calendar

basis if the machine is not used frequently, whichever is the

sooner. Maintenance should be regarded as an insurance policy,

to help keep the machine in the peak of condition and to ensure

long, trouble-free service. It has the additional benefit of giving

early warning of any faults that may develop and will act as a

regular safety check, to the obvious advantage of both rider and

machine alike.

The various maintenance tasks are described under their

respective mileage and calendar headings. Accompanying

diagrams are provided, where necessary. It should be remem-

bered that the interval between the various maintenance tasks

serves only as a guide. As the machine gets older or is used

under particularly adverse conditions, it would be advisable to

reduce the period between each check.

For ease of reference each service operation is described in

detail under the relevant heading. However, if further general

information is required, it can be found within the manual under

the pertinent section heading in the relevant Chapter.

In order that the routine maintenance tasks are carried out

with as much ease as possible, it is essential that a good selec-

tion of general workshop tools is available.

Included in the kit must be a range of metric ring or com-

bination spanners, a selection of crosshead screwdrivers and at

least one pair of circlip pliers.

Additionally, owing to the extreme tightness of most casing

screws on Japanese machines, an impact screwdriver, together

with a choice of large and small crosshead screw bits, is

absolutely indispensable. This is particularly so if the engine has

not been dismantled since leaving the factory.

prevent the risk of unexpected failure of any component while

riding the machine and, with experience, can be reduced to a

simple checklist which will only take a few moments to

complete. For those owners who are not inclined to check all

items with such frequency, it is suggested that the best course

is to carry out the checks in the form of a service which can be

undertaken each week or before any long journey. It is essential

that all items are checked and serviced with reasonable

frequency.

/ Check the engine oil level

With the machine standing upright on its centre stand on

level ground, start the engine and allow it to idle for a few

seconds so that the oil can circulate, then stop the engine. Wait

one or two minutes for the level to settle and unscrew the

dipstick/filler plug from the rear of the crankcase right-hand

cover. Wipe it clean and insert it into the filler orifice; do not

screw it in, but allow it to rest. Withdraw the dipstick; the oil

level should be between the maximum and minimum level lines,

ie in the cross-hatched area.

If topping up is necessary use only good quality

SAE10W/40 engine oil of the specified type. Do not allow the

level to rise above the top of the cross-hatched area on the

dipstick, and never use the machine if the level is found to be in

the plain area below the cross-hatching; top up immediately.

Tighten the dipstick securely and wash off any spilt oil.

2 Check the fuel level

Checking the petrol level may seem obvious, but it is all too

easy to forget. Ensure that you have enough petrol to complete

your journey, or at least to get you to the nearest petrol station.

Daily (pre-ride check)

It is recommended that the following items are checked

whenever the machine is about to be used. This is important to

3 Check the brakes

Check the front and rear brakes work effectively and

without binding. Ensure that the cable or rod linkage is

lubricated and properly adjusted.

Rest dipstick in position to obtain correct reading Dipstick shows allowable oil level range

Routine maintenance

4

Check the tyre pressures and tread wear

Check the tyre pressures with a gauge that is known to be

accurate. It is worthwhile purchasing a pocket gauge for this

purpose because the gauges on garage forecourt airlines are

notoriously inaccurate. The pressures, which should be checked

with the tyres cold, are specified at the end of Routine

maintenance and in Chapter 5.

At the same time as the tyre pressures are checked,

examine the tyres themselves. Check them for damage,

especially splitting of the sidewalls. Remove any small stones or

other road debris caught between the treads. When checking

the tyres for damage, they should be examined for tread depth

in view of both the legal and safety aspects. It is vital to keep

the tread depth within the UK legal limits of 1 mm of depth over

three-quarters of the tread breadth around the entire circumfer-

ence with no bald patches. Many riders, however, consider

nearer 2 mm to be the limit for secure roadholding, traction, and

braking, especially in adverse weather conditions, and it should

be noted that Honda recommend minimum tread depths of 1.5

mm (0.06 in) for the front tyre and 2.0 mm (0.08 in) for the rear;

these measurements to be taken at the centre of the tread.

Renew any tyre that is found to be damaged or excessively

worn.

5 Safety check

Check that the front and rear suspension is operating

correctly, that the chain is lubricated and adjusted correctly and

that the battery is in good condition. Check the throttle and

clutch cables and levers, the gear lever and the footrests and

stand to ensure that they are adjusted correctly, functioning

correctly, and that all nuts and bolts are securely fastened.

6 Legal check

Check that all lights, turn signals, horn and speedometer are

working correctly to make sure that the machine complies with

all legal requirements in this respect. Check also that the

headlamp is correctly aimed to comply with local legislation.

Monthly or every 600 miles (1000 km)

/ Check the battery

The battery should be checked regularly to ensure that the

electrolyte level is maintained between the level lines on the

casing, that the terminals are clean and securely fastened and

that the vent tube is correctly routed and free from blockages.

Refer to Chapter 6.5 for details.

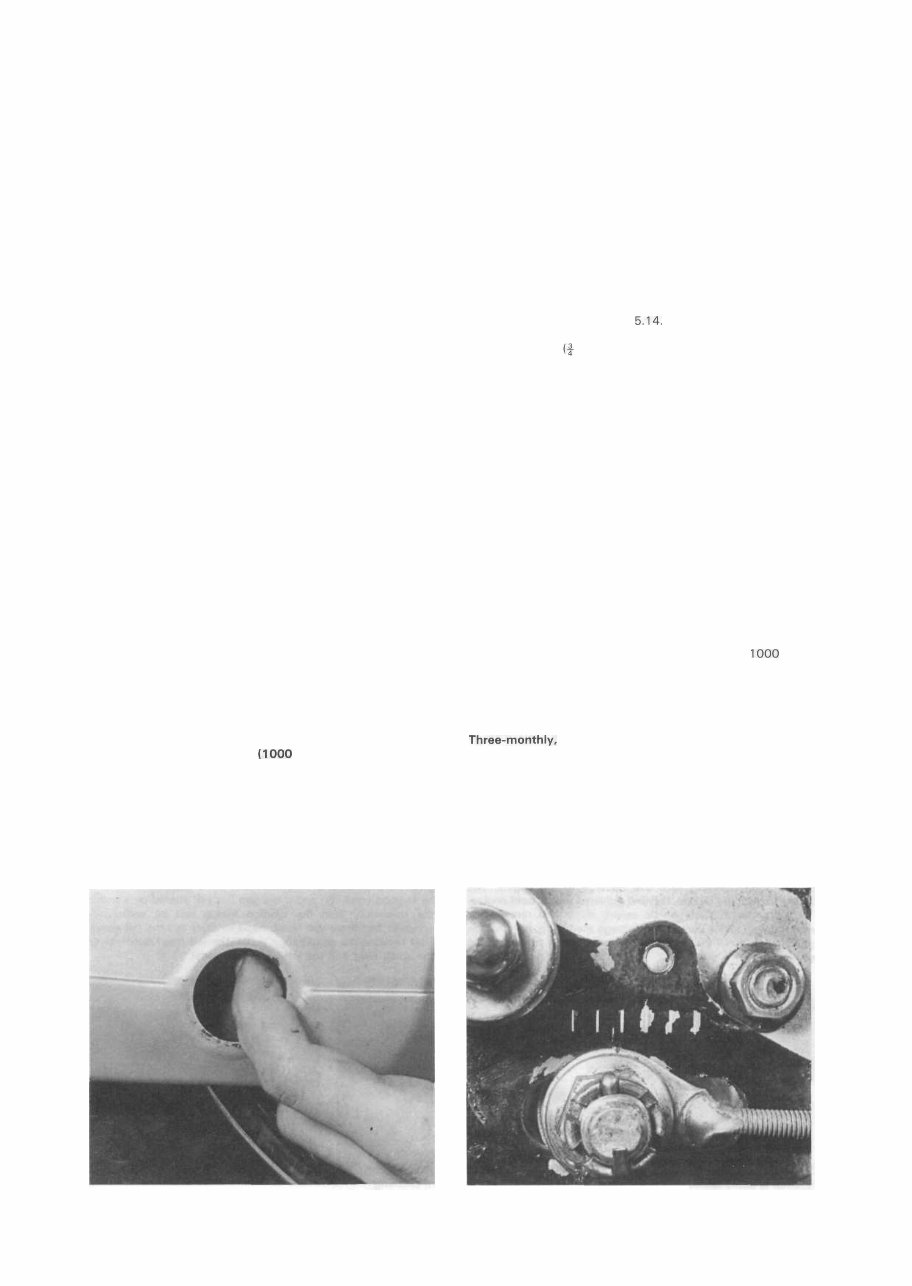

2 Check the final drive chain

Despite its full enclosure, the final drive chain requires

regular attention to ensure maximum chain life. Remove the

rubber plug from the chaincase inspection aperture to check the

tension and carry out temporary lubrication. The best lubricant

is commercial chain lubricant, contained in an aerosol can;

engine oil or gear oil are better than nothing but are flung off too

quickly to be of any real use. Best of all are the special chain

greases described in Chapter 5.14.

Adjust the chain after lubrication, so that there is approx-

imately 20 mm (|- in) slack in the middle of the lower run.

Always check with the chain at the tightest point as a chain

rarely wears evenly during service.

Adjustment is accomplished after placing the machine on

the centre stand and slackening the spindle nut, so that the

wheel can be drawn backwards by means of the drawbolt

adjusters in the swinging arm fork ends.

The torque arm nut and the rear brake adjuster must also be

slackened during this operation. Adjust the drawbolts an equal

amount to preserve wheel alignment. The fork ends are clearly

marked with a series of parallel lines above the adjusters, to

provide a simple visual check.

3 Additional engine oil change

Since the engine relies so heavily on the quantity and

quality of its oil, and since the oil in any motorcycle engine is

worked far harder than in other vehicles, it is recommended that

the engine oil is changed at more frequent intervals than those

specified by the manufacturer. This is particularly important if

the machine is used at very high speeds for long periods of time,

and even more important if the machine is used only at very

slow speed or for very short journeys. The oil should be changed

at approximate intervals of every month or every 1000 miles,

depending on usage. Honda specify that the oil should be

changed at least once annually or every 1 800 miles (3000 km),

whichever comes first.

Three-monthly, or every 1800 miles (3000 km)

1 Change the engine oil and clean the filter gauze

This is the specified interval at which the engine/gearbox oil

should be changed; in normal use it should be regarded as the

maximum permissible.

It is recommended that the oil be changed after a run to

ensure that the engine is warm. This helps the oil to drain

thoroughly. Obtain a container of at least 1 litre (1.76 pints)

Free play can be felt via the inspection hole Move each adjuster by an equal amount

'

10 Routine maintenance

capacity and place it beneath the engine unit to catch the old

oil. Unscrew the drain plug on the underside of the crankcase

and allow the oil to drain.

Remove the large hexagon-headed plug which is located

just below the left-hand engine casing. Remove the plug,

followed by the spring and gauze element, and then wash all

these components carefully in a suitable solvent. Wipe out any

residual oil from the housing with a clean lint-free rag prior to

reassembly. Refit the drain plug, tightening it to a torque setting

of 2.0 - 3.5 kgf m (14.5 - 25 Ibf ft), and refill the engine with

the correct quantity and grade of oil.

Six-monthly, or every 3600 miles (6000 km)

Repeat all service operations listed under previous

headings, then carry out the following:

/ Clean the air filter

Pull off the right-hand side panel and remove the two nuts

which secure the air filter cover. Withdraw the cover, checking

that the sealing gasket is in good condition, pull out the

retaining spring and withdraw the element assembly. Peel off

the inner and outer foam sleeves. Wash all components in white

spirit (Stoddard solvent) or in warm water and detergent and

dry them thoroughly. Soak the foam sleeves in the specified oil,

then squeeze them gently (do not wring them out or they will be

damaged) to expel all surplus oil. Refit the sleeves to the

element frame. On reassembly ensure that all components are

correctly fitted so that unfiltered air cannot bypass the element.

2 Check the spark plug

Remove the spark plug cap, unscrew the plug and check its

condition, comparing it with the photographs on page

65. If it is badly worn or fouled it must be renewed. If it is fit for

further service check the gap and reset it if necessary, as

described in Chapter 3.8.

3 Check the valve clearances

It is important that the correct valve clearance is

maintained. A small amount of free play is designed into the

valve train to allow for expansion of the various components. If

the setting deviates greatly from that specified, a marked drop

in performance will be evident. In the case of the clearance

becoming too great, it will be found that valve operation will be

noisy, and performance will drop off as a result of the valves not

opening fully. If on the other hand, the clearance is too small

the valves may not close completely. This will not only cause

loss of compression, but will also cause the valves to burn out

very quickly. In extreme cases, a valve head may strike the

piston crown, causing extensive damage to the engine. The

clearances should be checked and adjusted with a cold engine.

Place the machine on its centre stand and remove the

rocker cover, taking care not to damage the 0 ring. Remove the

gearchange pedal and the left-hand outer cover to expose the

generator rotor.

Remove plug and allow old oil to drain

Remove the spark plug, then slowly rotate the engine anti-

clockwise by way of the generator rotor, watching the inlet

valve. When it has opened and closed again (sunk down and

risen up to its original position), rotate the engine further until

the T mark on the rotor periphery aligns exactly with the raised

index mark which is positioned between 12 and 1 o'clock (from

the crankshaft) on the generator stator. The engine will then be

in the correct position for checking the valve clearances, namely

at Top Dead Centre (TDC) on the compression stroke; check

that there is free play at both rockers.

Using a 0.08 mm (0.003 in) feeler gauge, check the

clearance between the top of each valve stem and its cor-

responding rocker. The feeler gauge must be a light sliding fit,

with the rocker and valve stem just nipping it. If necessary,

slacken the locknut, and turn the small square-headed adjuster

to obtain the correct setting. Tighten the locknut, holding the

adjuster at the same time to prevent it from moving. Finally,

recheck the setting and then repeat the procedure on the other

rocker.

4 Check the contact breaker points and ignition

timing

Note: since the generator stator plate is located by its

countersunk retaining screws, the ignition timing can only be

altered by opening or closing the contact breaker gap; therefore

both operations are described as one. The full procedure is

given here for ease of reference, but if the points are found to

be in good condition and if the gap has not altered or is within

the tolerance, then the ignition timing will be sufficiently

accurate and there will be no need to carry out the full check.

First remove the gearchange pedal, the left-hand outer cover,

the spark plug and the left-hand side panel.

Strainer is easily removed for cleaning Dismantle the element for cleaning -j- mark should align as shown

and lubrication

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 25 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

- This comprehensive service manual is essential for owners of CG125 motorcycles manufactured between 1976 and 1991. It contains all the vital information required for bike maintenance and servicing.

- The manual provides detailed instructions for various CG125 models, covering the range from the initial 1976 version to the latest model released in September 1991. Each model is clearly identified with its corresponding year range, ensuring that owners have the correct information for their specific bike.

- Whether you own the CG125 from 1976 to 1978, the CG125K1 from 1978 to 1981, the CG125-B from 1981 to 1982, the CG125-C from 1982 to 1984, the CG125-E from 1984 to 1985, the CG125(BR)-E/F from 1985 to 1988, the CG125(BR)-J from 1988 to 1991, or the CG125(BR)-K from September 1991 onwards, this manual serves as the ultimate resource for all these models.

By following these instructions, you can effectively rephrase the product description while maintaining the existing information and improving clarity and coherence.