Harley-Davidson Touring Models Workshop Service Manual 2012

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

2012 Touring Models Service Manual

99483-12

©2011 H-0.

Harley-Davidson motorcycles conform to all applicable U.S.A. Federal Motor Vehicle Safety Standards

and U.S.A. Environmental Protection Agency regulations effective on the date of manufacture.

To maintain the safety, dependability, and emission and noise control performance, it is essential that

the procedures, specifications and service instructions in this manual are followed.

Any substitution, alteration or adjustment of emission system and noise control components outside of

factory specifications may be prohibited by law.

IMPORTANT NOTICE

Harley-Davidson Motor Company

2012 Touring Models Service

Manual

©2011 H·D.

ALL RIGHTS RESERVED

99483-12

Printed in the U.S.A.

VISIT THE HARLEY-DAVIDSON WEB SITE

http: l/www.harley-davidson.com

READER COMMENTS

Please comment on the completeness, accuracy, organization, usability, and readability of this manual.

Please list the page, item, and part number(s) of any errors you find in this manual.

Please tell us how we can improve this manual.

Occupation:

Name: Dealer ship:

Street: Depar tment:

City: State: Zip:

Please clip out and mail to:

Service Communications Department

Harley-Davidson Motor Company

P.O. Box 653

Milwaukee, WI USA 53201

The Harley-Davidson Service Communications Department maintains a continuous effort to improve the quality

and usefulness ofi ts publications. To do this effectively, we need user feedback - your critical evaluation of

this manual.

2012 Touring Models Service Manual (99483-12)

NOTES

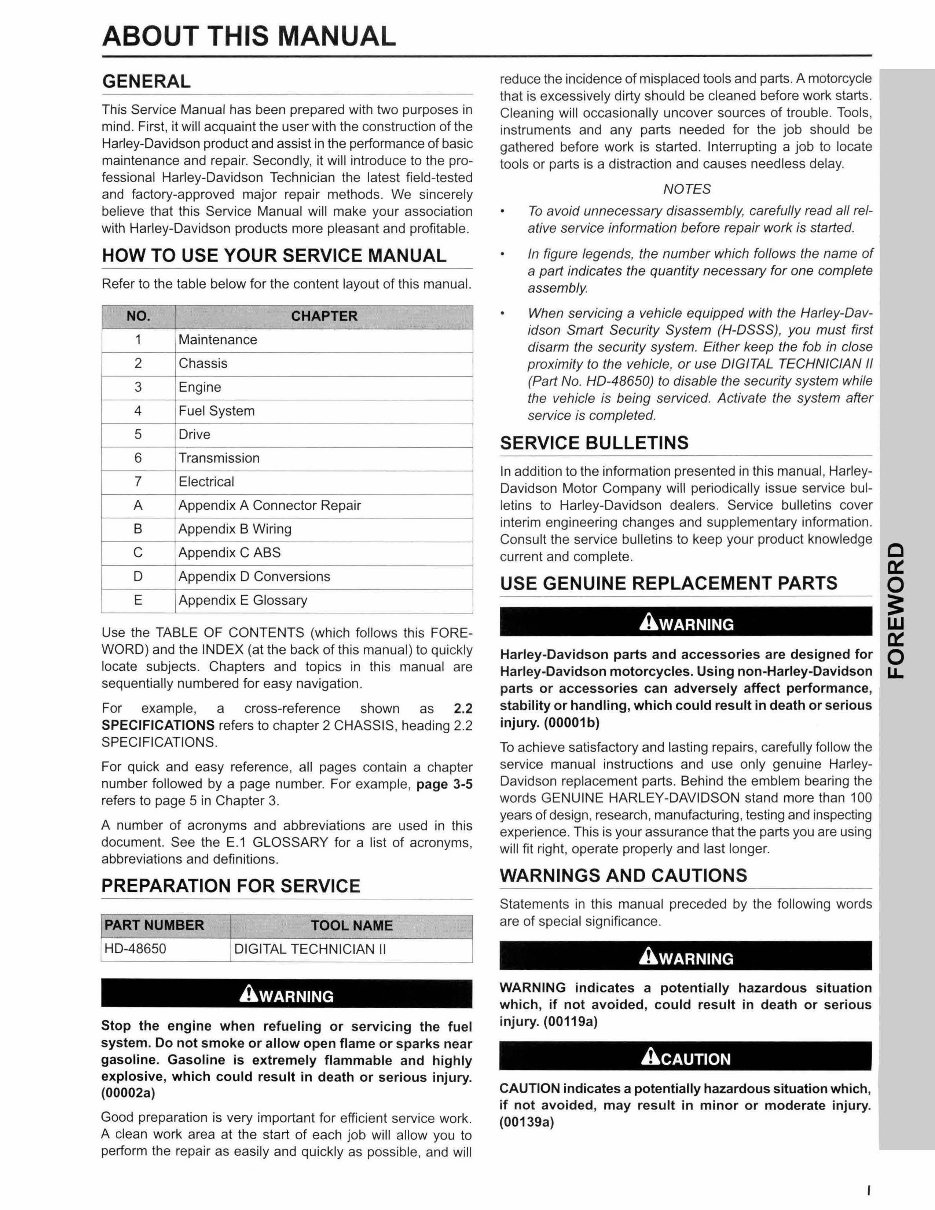

ABOUT THIS MANUAL

GENERAL

This Service Manual has been prepared with two purposes in

mind. First, it will acquaint the user with the construction of the

Harley-Davidson product and assist in the performance of basic

maintenance and repair. Secondly, it will introduce to the pro-

fessional Harley-Davidson Technician the latest field-tested

and factory-approved major repair methods. We sincerely

believe that this Service Manual will make your association

with Harley-Davidson products more pleasant and profitable.

HOW TO USE YOUR SERVICE MANUAL

Refer to the table below for the content layout of this manual.

NO. CHAPTER

1 Maintenance

2 Chassis

3 Engine

4 Fuel System

5 Drive

6 Transmission

7 Electrical

A Appendix A Connector Repair

B Appendix B Wiring

c Appendix C ABS

D Appendix D Conversions

E Appendix E Glossary

Use the TABLE OF CONTENTS (which follows this FORE-

WORD) and the INDEX (at the back of this manual) to quickly

locate subjects. Chapters and topics in this manual are

sequentially numbered for easy navigation.

For example, a cross-reference shown as 2.2

SPECIFICATIONS refers to chapter 2 CHASSIS, heading 2.2

SPECIFICATIONS .

For quick and easy reference, all pages contain a chapter

number followed by a page number. For example, page 3-5

refers to page 5 in Chapter 3.

A number of acronyms and abbreviations are used in this

document. See the E.1 GLOSSARY for a list of acronyms,

abbreviations and definitions.

PREPARATION FOR SERVICE

PART NUMBER TOOL NAME

HD-48650 DIGITAL TECHNICIAN II

A wARNING

Stop the engine when refueling or serv1cmg the fuel

system. Do not smoke or allow open flame or sparks near

gasoline. Gasoline is extremely flammable and highly

explosive, which could result in death or serious injury.

(00002a)

Good preparation is very important for efficient service work.

A clean work area at the start of each job will allow you to

perform the repair as easily and quickly as possible. and will

reduce the incidence of misplaced tools and parts. A motorcycle

that is excessively dirty should be cleaned before work starts.

Cleaning will occasionally uncover sources of trouble. Tools.

instruments and any parts needed for the job should be

gathered before work is started . Interrupting a job to locate

tools or parts is a distraction and causes needless delay.

NOTES

To avoid unnecessary disassembly, carefully read all rel-

ative service information before repair work is started.

In figure legends, the number which follows the name of

a part indicates the quantity necessary for one complete

assembly.

When servicing a vehicle equipped with the Harley-Dav-

idson Smart Security System (H-DSSS), you must first

disarm the security system. Either keep the fob in close

proximity to the vehicle, or use DIGITAL TECHNICIAN II

(Part No . HD-48650) to disable the security system while

the vehicle is being serviced. Activate the system after

service is completed.

SERVICE BULLETINS

In addition to the information presented in this manual , Harley-

Davidson Motor Company will periodically issue service bul-

letins to Harley-Davidson dealers. Service bulletins cover

interim engineering changes and supplementary information.

Consult the service bulletins to keep your product knowledge C

current and complete. 0::

USE GENUINE REPLACEMENT PARTS 0

A wARNING

3:

w

0::

Harley-Davidson parts and accessories are designed for 0

Harley-Davidson motorcycles. Using non-Harley-Davidson LL

parts or accessories can adversely affect performance,

stability or handling, which could result in death or serious

injury. (00001b)

To achieve satisfactory and lasting repairs, carefully follow the

service manual instructions and use only genuine Harley-

Davidson replacement parts. Behind the emblem bearing the

words GENUINE HARLEY-DAVIDSON stand more than 100

years of design , research , manufacturing, testing and inspecting

experience. This is your assurance that the parts you are using

will fit right, operate properly and last longer.

WARNINGS AND CAUTIONS

Statements in this manual preceded by the following words

are of special significance.

A wARNING

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury. (00119a)

AcAUTION

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

(00139a)

NOTICE

NOTICE indicates a potentially hazardous situation which,

if not avoided, may result in property damage. (00140b)

NOTE

Refers to important information, and is placed in italic type. It

is recommended that you take special notice of these items.

Proper service and repair is important for the safe, reliable

operation of all mechanical products. The service procedures

recommended and described in this manual are effective

methods for performing service operations.

A wARNING

Always wear proper eye protection when us ing ha mme rs,

arbor or hydrau li c presses, gear pullers, spring com-

pressors, slide hammers and similar tools. Flyi ng parts

cou ld result in death or se ri ous injury. (00496b)

Some of these service operations require the use of tools

specially designed for the purpose. These special tools should

be used when and as recommended. It is important to note

that some warnings against the use of specific service methods,

which could damage the motorcycle or render it unsafe, are

stated in this manual. However, remember that these warnings

are not all -inclusive. Inadequate safety precautions could result

in death or serious injury.

Since Harley-Davidson could not possibly know, evaluate or

advise the service trade of all possible ways in which service

might be performed , or of the possible hazardous con-

sequences of each method, we have not undertaken any such

broad evaluation. Accordingly, anyone who uses a service

procedure or tool which is not recommended by Harley-Dav-

idson must first thoroughly satisfy himself that neither his nor

the operator's safety will be jeopardized as a result. Failure to

do so could result in death or serious injury.

PRODUCT REFERENCES

A wARNING

Read and follow warnings and di rections on all product s.

Fa ilu re to follow warnings and directions can result in

death or se ri ous injury. (00470 b)

When reference is made in this manual to a specific brand

name product, tool or instrument, an equivalent product, tool

or instrument may be substituted.

II FOREWORD

Kent-Moore Products

All tools mentioned in this manual with an "HD", "J" or "8"

preface must be ordered through SPX Kent-Moore. For ordering

information or product returns, warranty or otherwise, visit

www.spx.com.

Loctite Sealing and Threadlocking Products

Some procedures in this manual call for the use of Loctite

products. If you have any questions regarding Loctite product

usage or retailer/wholesaler locations, please contact Loctite

Corp. at www.loctite.com.

PRODUCT REGISTERED MARKS

Apple, Alcantara S.p.A ., Allen, Amp Multilock, 81uetooth,

8rembo, Delphi, Deutsch, Dunlop, Dynojet, Fluke, G.E.

Versilube, Garmin, Gunk, Hydroseal, Hylomar, iPhone, iPod,

Kevlar, Lexan, Loctite, Lubriplate, Keps, K&N, Magnaflux,

Marson Thread-Setter Tool Kit, MAXI fuse , Molex, Michelin,

MPZ, Mulitilock, nano, NGK, Novus, Packard, Pirelli, Permatex,

Philips, PJ1 , Pozidriv, Robinair, S100, Sems, Snap-on, Teflon ,

Threadlocker, Torca, Torco, TORX, Tufoil, Tyco, Ultratorch,

Velcro, X-Acto, XM Satellite Radio, and zOmo are among the

trademarks of their respective owners.

H-D MICHIGAN, INC. TRADEMARK

INFORMATION

Bar & Shield , Cross Bones, Digital Tech , Digital Technician ,

Digital Technician II , Dyna, Electra Glide, Evolution, Fat Bob,

Fat Boy, Glaze, Gloss, H-D, H-Dnet.com, Harley, Harley-Dav-

idson, HD, Heritage Softail, Low Rider, Night Rod, Nightster,

Night Train , Profile, Revolution , Road Glide, Road King , Road

Tech , Rocker, Screamin' Eagle, Softail, Sportster, Street Glide,

Street Rod, Sun Ray, Sunwash, Super Glide, SYN3, Techlink ,

Techlink II , Tour-Pak, Twin Cam 88, Twin Cam 88B, Twin

Cam 96, Twin Cam 968 , Twin Cam 103, Twin Cam 103B , Twin

Cam 110, Twin Cam 110B, Ultra Classic, V-Rod, VRSC and

Harley-Davidson Genuine Motor Parts and Genuine Motor

Accessories are among the trademarks of H-D Michigan, Inc.

CONTENTS

All photographs, illustrations and procedures may not neces-

sarily depict the most current model or component, but are

based on the latest production information available at the time

of publication .

Since product improvement is our continual goal, Harley-Dav-

idson reserves the right to change specifications, equipment

or designs at any time without notice and without incurring

obligation .

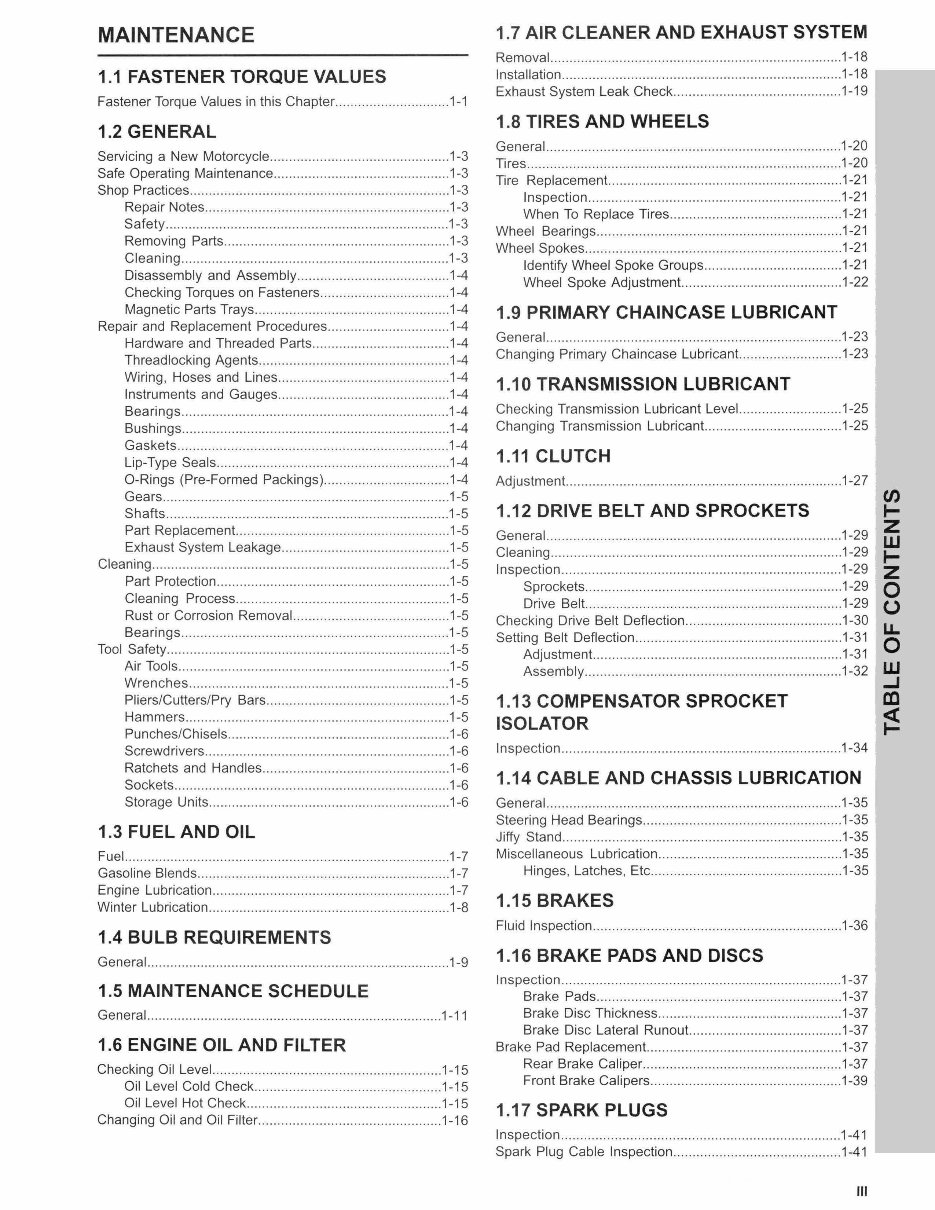

MAINTENANCE

1.1 FASTENER TORQUE VALUES

Fastener Torque Values in this Chapter ....................... ....... 1-1

1.2 GENERAL

Servicing a New Motorcycle ....... .......... ..... .... ..................... 1-3

Safe Operating Maintenance .. ...... ... ................................... 1-3

Shop Practices .. ..... .. ....... .. ... ..... ... ....................................... 1-3

Repair Notes ................................................................ 1-3

Safety .... .. ......... ... ........ ........ ........ ....... ......... ..... ... ..... ... 1-3

Removing Parts ....................................... ... ..... ............ 1-3

Cleaning ....... ...... ....... .... .............. .... ....... ... ........ ... .. ... .. 1-3

Disassembly and Assembly ........................................ 1-4

Checking Torques on Fasteners ............................. ..... 1-4

Magnetic Parts Trays ............................................... .. .. 1-4

Repair and Replacement Procedures .. ...... ..... ..... ........ .... .. 1-4

Hardware and Threaded Parts ............................ .. ...... 1-4

Thread locking Agents .................................................. 1-4

Wiring, Hoses and Lines ............................................. 1-4

Instruments and Gauges ................................. ... ... ...... 1-4

Bearings ........... .......... ....... .... ... ........................ ... ........ 1-4

Bushings .... ............ .. .. ... ....................... .......... .. ............ 1-4

Gaskets ... ... ... .............. ................ ... ............ ..... ....... ..... 1-4

Lip-Type Seals ............................................................. 1-4

0-Rings (Pre-Formed Packings) ................................. 1-4

Gears ............. ...... ......... .... ................. .. .......... ............ .. 1-5

Shafts ....... .............. ..... .... ... .......... .... ..... ......... ... .......... 1-5

Part Replacement. ..... ... ....... ..... .................... ........ ....... 1-5

Exhaust System Leakage ............................................ 1-5

Cleaning .... ... ... ..... ..... ......... ..... ..... .... ..... ................ ... .. .... ... .. 1-5

Part Protection ........... ........ .......................................... 1-5

Cleaning Process ........................................................ 1-5

Rust or Corrosion Removal ......................................... 1-5

Bearings ... ....... .. .... ..... ..... .... ..... .. ...... ... .... .. ...... ...... ... ... 1-5

Tool Safety ............ ......... ...... ........... .. ..... ...... .... .... .... .. .. .. ... .. 1-5

Air Tools ............................................ .. ..... .......... ... ....... 1-5

Wrenches .... ................................................................ 1-5

Pliers/Cutters/Pry Bars ........................................... ... .. 1-5

Hammers ............................................ .. .............. ......... 1-5

Punches/Chisels .. .. ........... .... .... ............... ................ .. .. 1-6

Screwdrivers ........ ....... .................... ................. .. ........ .. 1-6

Ratchets and Handles ........... ....... ........... .......... .. ... .. ... 1-6

Sockets .................. ..... ........ ......................................... 1-6

Storage Units ............................................................... 1-6

1.3 FUEL AND OIL

Fuel. ............ ................. .. ...... .... ........ .... .. ........ .... ................. 1-7

Gasoline Blends .................... ............ .. ........... ....... .............. 1-7

Engine Lubrication ..... ..... ... ............ .... ................................. 1-7

Winter Lubrication ..... .... ......... ...... ........... ........ .. ............... ... 1-8

1.4 BULB REQUIREMENTS

Genera I...... ..... .... .. ...... ........ .......... ............. ...... ... ..... .. ... ... ... 1-9

1.5 MAINTENANCE SCHEDULE

General. ......... .... ....................................... ........................ 1-11

1.6 ENGINE OIL AND FILTER

Ch ecking Oil Level. ................................. .... .. .. ............... ... 1-15

Oil Level Cold Check ................................................. 1-15

Oil Level Hot Check .... .......... ............. ........................ 1-15

Changing Oil and Oil Filter .. ...... .. .................... .. ................ 1-16

1.7 AIR CLEANER AND EXHAUST SYSTEM

Removal. .... ....... ... ........ ............ ...... ... ..... .... .. ......... .. .. .. ... ... 1-18

Installation ............. .... .. ...................................... .. ..... .. .. ..... 1-18

Exhaust System Leak Check ............ ....................... .. .. .... . 1-19

1.8 TIRES AND WHEELS

General ............. ............. .. .. ... ..... ... ............... ............... ...... 1-20

Tires ..... ........... ............. ........... ... ... .. .... ...... ............. ........... 1-20

Tire Replacement. ......... .. ....................... .. ...... .. ................ 1-21

lnspection ... ....... .... .. ............. ........ .... .......... ... .... ........ 1-21

When To Replace Ti res ........................................ .. ... 1-21

Wheel Bearings ........ ......... ........................................ .. ... .. 1-21

Wheel Spokes .... ............................. ... ... ......... ... ......... .. ..... 1-21

Identify Wheel Spoke Groups .. ....... ............ .. ...... ....... 1-21

Wheel Spoke Adjustment... .. .. ...... .... .... .... ................. 1-22

1.9 PRIMARY CHAINCASE LUBRICANT

General ...... .. .......... ....... .. .. .... .... ... .... ..... ............................ 1-23

Changing Primary Chaincase Lubricant... ..................... .. . 1-23

1.10 TRANSMISSION LUBRICANT

Checking Transmission Lubricant Level. .......................... 1-25

Changing Transmission Lubricant.. ...... .... ...................... .. 1-25

1.11 CLUTCH

Adjustment. .. ... .. .......................... .... ........ ........ .................. 1-27

1.1 2 DRIVE BELT AND SPROCKETS

en

.....

z

General. ............ ........ ........ .... .... ..... ... ........... ....... ... ........... 1-29 W

Cleaning ..................... .. ......... .... ........ .... ... ........ ... .............. 1-29 t-

lnspection ........ .... ..... ......................... .......... ...... ... ........ ... . 1-29 z

Sprockets ........ .. ........ ... .. .... .. .... ..... .. ........................... 1-29 0

Drive Belt. ............... .... ... ... ....... .... ...... ..... ....... .... ........ 1-29 0

Checking Drive Belt Deflection ......................................... 1-30 U.

Setting Belt Deflection .... .... ............ .. ..................... .. ... ...... 1-31 O

Adjustment.. ...................... .. ....... ...... ........ ... ............ ... 1-31

Assembly .. ......... .... .................................................... 1-32 W

...J

1.13 COMPENSATOR SPROCKET

ISOLATOR

lnspection ................. .... ... ...... .. ... ... .. .. .... ... ....... ... ..... ......... 1-34

1.14 CABLE AND CHASSIS LUBRICATION

General. .. ... ...... ........... .......... .... .. ............................. .. ....... 1-35

Steering Head Bearings ...... ......... ... .. ... ..... ..................... ... 1-35

Jiffy Stand .................. ...................... .. ....... .... ......... ... .. ...... 1-35

Miscellaneous Lubrication ............ ... ... .. .. ... .... ..... .. ... ......... 1-35

Hinges, Latches, Etc ..... ......... ................ .. .................. 1-35

1.15 BRAKES

Fluid lnspection .................... ............................. .. .............. 1-36

1.1 6 BRAKE PADS AND DISCS

lnspection ... ..... ........ ..... ............. .... ........ ........... ....... .... ..... 1-37

Brake Pads ............................................. ... .......... ...... 1-37

Brake Disc Thickness ............ ......... .. .. ............. ......... . 1-37

Brake Disc Lateral Runout... ..................................... 1-37

Brake Pad Replacement. ........ .... ...... .. ... ................. .. ...... .. 1-37

Rear Brake Caliper .................. ..... ...... ... ... ....... .......... 1-37

Front Brake Calipers .................................................. 1-39

1.17 SPARK PLUGS

lnspection .... .... .................... ............. .... ..... ............. ........ .. 1-41

Spark Plug Cable lnspection ............................................ 1- 41

Ill

m

~

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

$51.99

Viewed 69 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

$51.99

This workshop service manual for Harley-Davidson All Touring Models 2012 provides comprehensive information on maintenance, tune-up, repair, and overhaul. It includes over a thousand original photos and illustrations based on a complete disassembly of the machine, combined with hands-on text, to facilitate safe and efficient procedures. The manual is designed for both professional mechanics and DIY enthusiasts, with all pages being printable for easy reference in the garage or workshop.

- Detailed substeps expand on maintenance and repair procedure information

- Notes, cautions, and warnings throughout each chapter pinpoint critical information

- Numbered instructions guide you through every repair procedure step by step

- Bold figure numbers help you quickly match illustrations with instructions

- Detailed illustrations, drawings, and photos guide you through every procedure

- Enlarged inset helps you identify and examine parts in detail

- Numbered table of contents for easy and fast information retrieval

- Troubleshooting and electrical service procedures combined with detailed wiring diagrams for ease of use

File Format: PDF

Language: English

Printable: Yes, without any restriction

Requirements: Adobe Reader