Meritor forward tandem drive axles maintenance service manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Maintenance Manual 5L

Single-Reduction Forward Differential

Carriers on Tandem and Tridem Axles

Revised 08-15

Service Notes

Information contained in this publication was in effect at the time the publication was

approved for printing and is subject to change without notice or liability. Meritor Heavy

Vehicle Systems, LLC, reserves the right to revise the information presented or to

discontinue the production of parts described at any time.

Meritor Maintenance Manual 5L (Revised 08-15)

About This Manual

This manual provides maintenance and service information for the

Meritor forward tandem drive axles, including the RT-140; -144;

-145; -149; -160; -169; RZ-166; -186 and -188 Series models.

Before You Begin

1. Read and understand all instructions and procedures before

you begin to service components.

2. Read and observe all Warning and Caution hazard alert

messages in this publication. They provide information that can

help prevent serious personal injury, damage to components,

or both.

3. Follow your company’s maintenance and service, installation,

and diagnostics guidelines.

4. Use special tools when required to help avoid serious personal

injury and damage to components.

Hazard Alert Messages and Torque

Symbols

WARNING

A Warning alerts you to an instruction or procedure that you

must follow exactly to avoid serious personal injury and

damage to components.

CAUTION

A Caution alerts you to an instruction or procedure that you

must follow exactly to avoid damage to components.

@ This symbol alerts you to tighten fasteners to a specified torque

value.

How to Obtain Additional Maintenance,

Service and Product Information

Visit Literature on Demand at meritor.com to access and order

additional information.

Contact the Meritor OnTrac™ Customer Call Center at

866-668-7221 (United States and Canada); 001-800-889-1834

(Mexico); or email OnTrac@meritor.com.

If Tools and Supplies are Specified in

This Manual

Contact Meritor’s Commercial Vehicle Aftermarket at

888-725-9355 to obtain Meritor tools and supplies.

SPX Kent-Moore, 28635 Mound Road, Warren, Michigan, 48092.

Call the company’s customer service center at 800-345-2233, or

visit their website at spxkentmoore.com.

Kiene Diesel Accessories, Inc., 325 S. Fairbanks Street, Addison, IL

60101. Call the company’s customer service center at

800-264-5950, or visit their website at kienediesel.com.

SPX/OTC Service Solutions, 655 Eisenhower Drive, Owatonna, MN

55060. Call the company’s customer service center at

800-533-6128, or visit their website at otctools.com.

pg. pg.

Contents

1 Section 1: Exploded Views

Single-Reduction Forward Differential Carrier

4 Section 2: Introduction

Description

Forward Tandem Axle

Axle Models Covered in This Manual

Optional Pressurized Lubrication System

Optional Driver-Controlled Main Differential Lock (DCDL)

5 Inter-Axle Main Differential (IAD)

Stall-Testing Can Damage a Drive Axle

Use of Traction Chains

Identification

Model Number

7 Section 3: Removal and Disassembly

Removal

Axle Shafts

Axle Shaft Removal Methods

9 Axle Shafts from the Axle Housing

10 Thru-Shaft

11 Differential Carrier from the Axle Housing

12 Disassembly

Thru-Shaft and Output Bearing Cage Assembly

13 Removal

Bearing Cone from the Thru-Shaft

Measure Ring Gear Backlash

14 Input Shaft and Inter-Axle Differential Assembly

16 Disassembly

Input Shaft, Bearing Cage, Oil Pump and Inter-Axle

Differential

19 Removal

Inter-Axle Differential Lock IAD Shift Unit

20 Driver-Controlled Main Differential Lock (DCDL)

Main Differential Case and Ring Gear Assembly

21 Disassembly

Main Differential Case and Ring Gear

22 Removal

Ring Gear from the Differential Case

23 Drive Pinion Assembly

Before You Work on a Differential Carrier

Assembly Procedures

25 Section 4: Prepare Parts for Assembly

Clean, Dry and Inspect Parts

Clean and Inspect Yokes

26 Clean Ground and Polished Parts

Clean Rough Parts

Clean Axle Assemblies

26 Drying Parts After Cleaning

Prevent Corrosion on Cleaned Parts

Inspect Parts

28 Repair or Replace Parts

Welding on Axle Housings

29 Do Not Bend or Straighten a Damaged Drive Axle Housing

Removing Fasteners Secured with Adhesive

30 New Fasteners with Pre-Applied Adhesive

Original or Used Fasteners

Meritor Specification 2297-T-4180 Adhesive in the

Differential Bearing Bores

Carrier-to-Housing Joint Sealing Procedure

32 General Yoke and U-Joint Reassembly

Identification

Gear Sets

33 Check for Mismatched Ratios on Tandem Axles

Hypoid Gear Set Ratios Listed on the Identification Tags

Rotate the Forward Drive Shaft to Check the Hypoid Gear

Set Ratio

34 Hypoid Gear Set Teeth Numbers Stamped on the Forward

and Rear Axle Drive Pinions

35 Verify the Actual Hypoid Gear Set Ratios

Inspection

Yoke

36 Tire Matching for Tandem and Tridem Axles

37 Section 5: Assembly and Installation

Installation

Installing the Drive Pinion and Adjusting Pinion Depth and

Preload

Adjustment

Shim Pack Thickness for a New Drive Pinion

38 Assembly

Drive Pinion Assembly

40 Installation

Drive Pinion Assembly

41 Adjustment

Drive Pinion Bearing Preload

45 Assembly

Main Differential and Ring Gear

47 Check the Rotating Resistance of the Differential Assembly

48 Installation

Main Differential Case and Ring Gear Assembly Into the

Carrier

50 Adjustment

Differential Bearings Preload

52 Ring Gear Runout

Ring Gear Backlash

Contents

pg. pg.

53 Gear Set Tooth Contact Patterns, Backlash

57 Installation

Thrust Screw (If Equipped)

Air Shift Unit for the Inter-Axle Differential Lock

59 Assembly

Input Shaft, Bearing Cage, Oil Pump and Inter-Axle

Differential

63 Installation

Input Shaft Assembly

64 Inspection

Adjust the Input Bearing End Play

67 Installation

Driver-Controlled Main Differential Lock

Output Bearings and Thru-Shaft

68 Inspection

Adjust the Output Bearing End Play

Installation

Unitized Pinion Seal

71 Installing a Multiple-Lip Seal (MLS)

75 Clean and Inspect the Yoke After Installing a Unitized

Pinion Seal

76 Tight Fit Yokes and POSE™ Seal

77 Output Yoke or Flange and Oil Seal for the Output Bearing

Cage

78 Differential Carrier into the Axle Housing

81 Axle Shaft

83 Fill the Axle with Lubricant

84 Section 6: Driver-Controlled Main

Differential Lock

Description

Removal

Differential Carrier from the Axle Housing

85 Engagement or Lockout of the DCDL

86 Differential and Gear Assembly and Main Differential Lock

89 Installation

Differential Shift Assembly

94 Differential Lock Assembly Cover Plates

Differential Carrier Into the Forward Axle Housing

96 Check the Differential Lock

DCDL Driver Caution Alert Label

97 Driver Instruction Information Available

98 Section 7: Lubrication

Specifications

100 Section 8: Specifications

105 Section 9: Adjustment

107 Section 10: Special Tools

Specifications

Carrier Repair Stand

108 How to Make a Yoke Bar

109 How to Make a Drive Flange Retainer Tool

110 Unitized Pinion Seals and Seal Drivers

112 Section 11: Vehicle Towing Instructions

Type of Axle

Forward Tandem Axle, with Driver-Controlled Main

Differential Lock (DCDL — Screw-In DCDL Shift

Assembly) and with Inter-Axle Differential (IAD)

116 Forward Tandem Axle, with Driver-Controlled Main

Differential Lock (DCDL — Bolt-On DCDL Shift

Assembly) and with Inter-Axle Differential (IAD)

119 Forward Tandem Axle, without Driver-Controlled Main

Differential Lock (DCDL), with Inter-Axle Differential

(IAD)

121 Section 12: Diagnostics

Troubleshooting

Vehicle Will Not Move

123 Differential Making Noise

125 Oil Leak

126 Contaminated Lubricant Found During Preventive

Maintenance

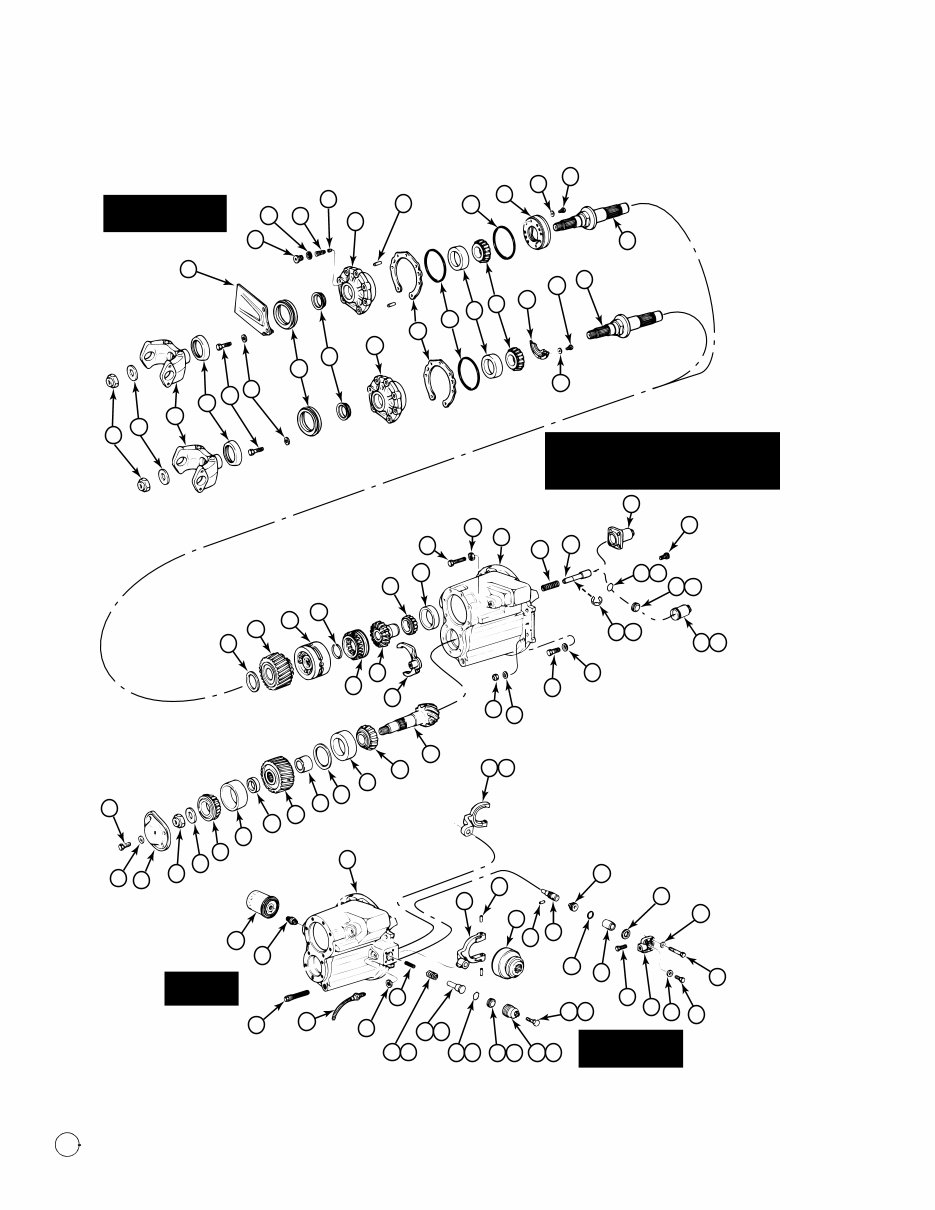

1 Exploded Views

1 Meritor Maintenance Manual 5L (Revised 08-15)

1 Exploded Views

Single-Reduction Forward Differential Carrier

Item Description

1 Nut — Input Yoke

1A Washer — Input Yoke

2 Input Yoke

3 Deflector

4 Capscrew — Cage-to-Carrier

5 Washer — Cage-to-Carrier

6 Oil Seal — Triple-Lip (Main) Seal

6A POSE™ Seal

7 Input Bearing Cage

8 Shims

9 O-Ring — Input Bearing Cage

10 Bearing Cup — Input Shaft

11 Bearing Cone — Input Shaft

12 Oil Baffle (Units Without Oil Pump)

13 Washer — Oil Baffle

14 Capscrew — Oil Baffle

15 Input Shaft

16 Thrust Washer — Helical Drive Gear

17 Helical Drive Gear

18 Inter-Axle Differential Case

Assembly

19 Snap Ring — Inter-Axle Differential

Case

20 Clutch Collar — Inter-Axle

Differential Case

21 Rear Side Gear

22 Shift Fork

23 Bearing Cone — Rear Side Gear

24 Bearing Cup — Rear Side Gear

25 Adjusting Screw — Shift Shaft

26 Jam Nut — Adjusting Screw

27 Spring — Shift Shaft

28 Shift Shaft and Piston

28A “E” Clip (Reverse Shift IAD Only)

29 Air Shift Chamber Assembly —

Bolt-On IAD

29A Air Shift Chamber Assembly —

Screw-In IAD

30 Capscrew — Air Shift Chamber

Assembly

31 Differential Carrier and Caps

32 Washer — Differential

Carrier-to-Axle Housing

33 Nut — Differential Carrier-to-Axle

Housing

34 Capscrew — Differential

Carrier-to-Axle Housing

35 Ring Gear and Drive Pinion

36 Inner Bearing Cone — Drive Pinion

37 Inner Bearing Cup — Drive Pinion

38 Shims

39 Inner Spacer

40 Helical Driven Gear

41 Outer Spacer

42 Outer Bearing Cup — Drive Pinion

43 Outer Bearing Cone — Drive Pinion

44 Washer — Drive Pinion

45 Nut — Drive Pinion

46 Cover — Drive Pinion

47 Washer — Drive Pinion Cover

48 Capscrew — Drive Pinion Cover

49 Bearing Adjusting Ring

50 Cup — Main Differential Bearing

51 Cone — Main Differential Bearing

52 Capscrew — Main Differential Case

Halves

53 Washer — Main Differential Case

Halves

54 Main Differential Case Assembly

55 Bolt — Ring Gear (145 and 160

Series)

56 Washer — Differential Bearing Cap

57 Capscrew — Differential Bearing

Cap

58 Roll Pin, Cotter Pin or Capscrew —

Differential Bearing Cap

59 Thrust Washer — Main Differential

Side Gear

60 Side Gear — Main Differential

61 Spider — Main Differential

62 Pinion Gear — Main Differential

63 Thrust Washer — Main Differential

63A NoSPIN

Main Differential

1

64 Washer — Ring Gear (145 and 160

Series)

65 Nut — Ring Gear (145 and 160

Series)

66 Sensor Switch — Main Differential

Lock

67 Locknut — Main Differential Lock

Sensor Switch (Early Design)

68 Spring — Main Differential Lock

68A Spring — Main Differential Lock —

Current Design

69 Lock Pin — Spring Retaining (Early

Design)

70 Shift Shaft — Main Differential Lock

Item Description

70A Shift Shaft — Main Differential Lock

— Current Design

71 Piston — Main Differential Lock

71A Piston — Main Differential Lock —

Current Design

72 O-Ring — Piston

72A O-Ring — Piston — Current Design

73 DCDL Cylinder — Shift Shaft

73A DCDL Cylinder — Shift Shaft —

Current Screw-In DCDL Design

74 Copper Gasket — Cover (160

Series)

75 Capscrew — Manual Engaging

75A Capscrew — Manual Engaging —

Current Design

76 Cover — Main Differential Lock

(Early Design)

77 Plug — Manual Engaging (Early

Design)

78 Washer — Manual Engaging

Capscrew

79 Capscrew — Cover (Early Design)

80 Washer — Cover (Early Design)

81 Shift Collar — Main Differential

Lock

82 Shift Fork — Main Differential Lock

82A Shift Fork — Main Differential Lock

— Current Design

83 Roll Pin — Shift Fork (Early Design)

84 Oil Filter Shield

85 Plug — Oil Pressure Relief Valve

86 Washer — Oil Pressure Relief Valve

87 Spring — Oil Pressure Relief Valve

88 Oil Pressure Relief Valve

89 Dowel — Input Cage to Oil Pump

(Early Design)

90 O-Ring — Oil Pump

91 Oil Pump

92 Washer — Oil Pump

93 Capscrew — Oil Pump

94 Oil Filter

95 Adapter — Oil Filter

96 Oil Screen and Plug Assembly

1

NoSPIN

is a registered trademark of Tractech, a

division of Dyneer Corp.

Item Description

1 Exploded Views

2 Meritor Maintenance Manual 5L (Revised 08-15)

Figure 1.1

L.H. SIDE

INPUT WITH

OIL PUMP PARTS

STANDARD DIFFERENTIAL

CARRIER WITHOUT DIFFERENTIAL

LOCK AND WITHOUT OIL PUMP

OIL PUMP

PARTS

DIFFERENTIAL

LOCK PARTS

93

92

15

91

90

15

14

12

13

11

10

9

8

7

6

6A

5

4

3

2

1A

1

84

85

86 87

88

7

89

30

29

28

27

31

26

25

24

23

22

21

20

19

18

17

16

48

47

46

45

44

43

42

41

40

39

38

37

36

35

94

95

96

66

67

68

31

33

32

34

32

82

83

81

69

70

71

72

73

74

75

76

78

77

79

80

75 A

73 A 71 A 72 A

70 A

68 A

28 A

29 A

82 A

71 A

72 A

1003392a

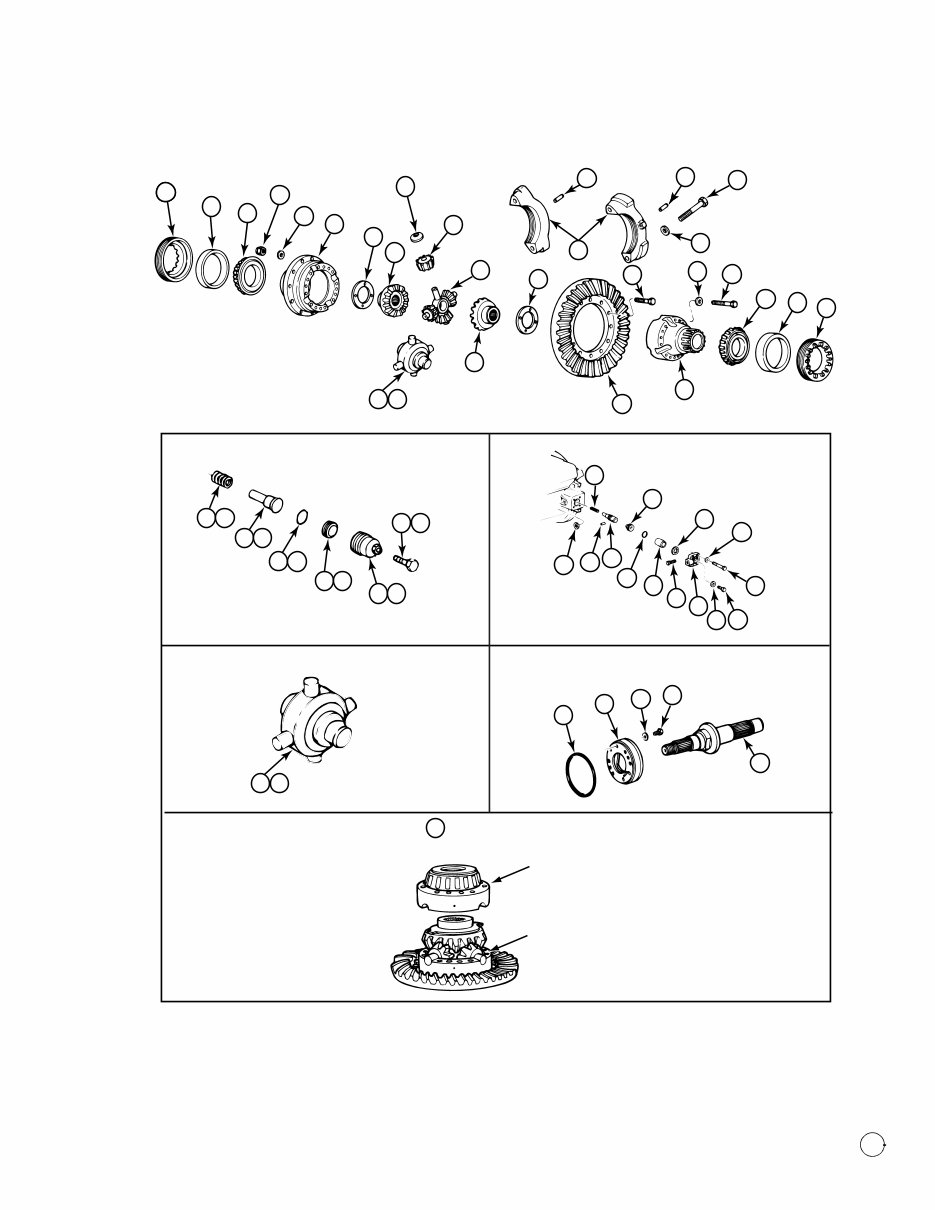

1 Exploded Views

3 Meritor Maintenance Manual 5L (Revised 08-15)

Figure 1.2

R.H. SIDE

PLAIN

CASE HALF

GEAR

CASE HALF

49

54 MAIN DIFFERENTIAL

CASE ASSEMBLY

49

50

51

65

64

54

59

60

63

62

61

60

59

31

58 58

57

56

55

53

52

49

50

51

54

35

EARLY DESIGN DCDL

68

71

74

80

79

77 78

76

75

73

72

70

69

67

OIL PUMP

90

91

92

93

15

CURRENT DCDL

68 A

70 A

72 A

71 A

73 A

75 A

NoSPIN

®

ASSEMBLY

63 A

63 A

1002701c

2 Introduction

4 Meritor Maintenance Manual 5L (Revised 08-15)

2 Introduction

Description

Forward Tandem Axle

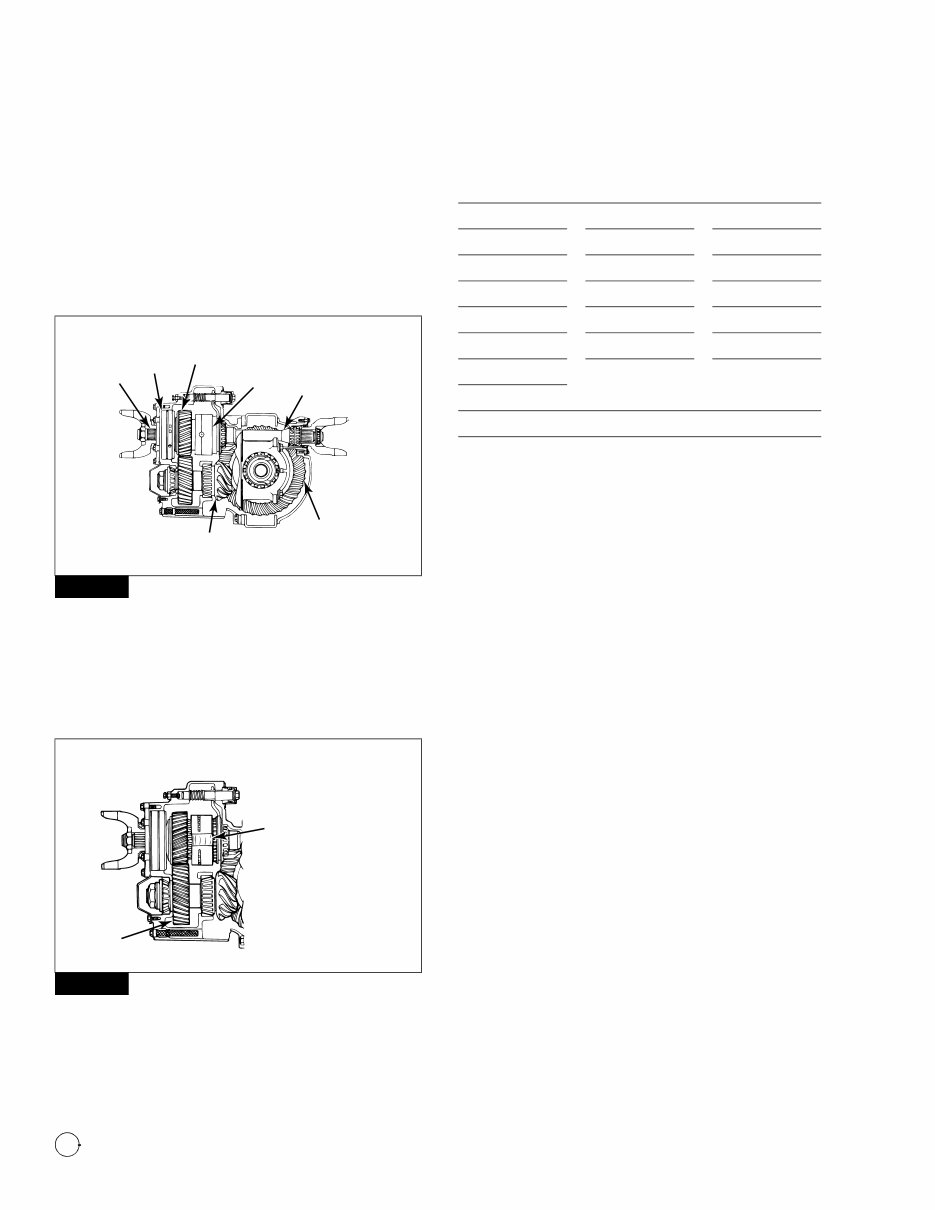

The inter-axle differential is located behind the helical gear on the

input shaft. The forward side gear of the inter-axle differential is part

of the upper helical gear hub. The thru-shaft is splined to the rear

side gear of the inter-axle differential. Figure 2.1.

Figure 2.1

The Meritor 140, 145 and 160 forward tandem axles use a

single-reduction, thru-drive carrier. The drive gearing is a

two-helical gear train and a hypoid ring gear and pinion. Bevel gears

are used in the main differential and the inter-axle differential.

Figure 2.1 and Figure 2.2.

Figure 2.2

Axle Models Covered in This Manual

NOTE: For service procedures on rear carriers, refer to

Maintenance Manual 5, Single-Reduction Differential Carriers, for

models preceding RS-, RT- and RF-Series, and Maintenance Manual

5A, Single-Reduction Differential Carriers, for MX-, RS-, RT- and

RF-Series. To obtain these publications, refer to the Service Notes

page on the front inside cover of this manual.

Optional Pressurized Lubrication System

The forward axles can be equipped with an optional pressurized

lubrication system. This filtered system has an oil pump driven by

the input shaft. The pump circulates lubricant to the journals in the

forward and rear input shaft bearings and directly to the inter-axle

differential.

Optional Driver-Controlled Main Differential

Lock (DCDL)

Both the forward and rear axles can be equipped with an optional

driver-controlled main differential lock (DCDL). The differential lock

is operated by an air-actuated shift unit located on the forward axle

carrier.

When the differential lock is activated, the shift collar moves

along the splines of the axle shaft toward the differential case.

When the collar splines engage with the splines on the

differential case, the axle shaft and the differential assembly lock

together.

When the carrier operates with the DCDL in the locked position,

there is no differential action between the wheels.

When the carrier is operated in the unlocked position, there is

normal differential action between the wheels at all times.

Figure 2.1

Figure 2.2

OIL

PUMP

HELICAL

GEAR

INTER-AXLE

DIFFERENTIAL

OUTPUT

SHAFT

RING

GEAR DRIVE

PINION

INPUT

SHAFT

1002702c

Notch on inter-axle

differential case.

Notches are provided

for clearance in

assembly and

disassembly.

HELICAL

DRIVEN

GEAR 1002703c

RT-160 SERIES SHOWN

Tandem Models

RT-34-140 RT-40-145P RT-46-160

RT-34-144 RT-40-149 RT-46-160EH

RT-34-145 RT-40-160 RT-46-160P

RT-34-145P RT-40-169 RT-46-169

RT-40-140 RT-44-145 RT-50-160

MT-40-143 RT-44-145P RT-50-160P

RT-40-145 RT-46-16H EH RT-52-160P

RT-40-145A

Tridem Models

RZ-166 RZ-186 RZ-188

2 Introduction

5 Meritor Maintenance Manual 5L (Revised 08-15)

Inter-Axle Main Differential (IAD)

The Meritor inter-axle differential (IAD) is a driver-controlled,

air-actuated traction device. The IAD allows for speed differences

between the forward and rear axles in a tandem while also providing

equal pulling power from each axle of the tandem. By activating the

IAD switch located in the vehicle dash, improved traction is provided

for each axle.

The inter-axle differential is also known as a power divider or third

differential.

Stall-Testing Can Damage a Drive Axle

Stall-testing is a procedure used to troubleshoot transmissions,

evaluate vehicle performance, and test the service and park brakes.

During stall-testing, or any similar procedure, the drive axle input

receives multiplied torque, which can exceed the specified torque

rating. Excessive torque can damage a drive axle, which will affect

axle performance and component life. A drive axle damaged by

stall-testing will void Meritor’s warranty.

Call the Meritor OnTrac™ Customer Call Center at 866-668-7221 if

you have questions regarding stall-testing.

Use of Traction Chains

Meritor recommends that if you are using traction chains, you

should install chains on both tires on each side of all drive axles on

the vehicle.

Identification

Model Number

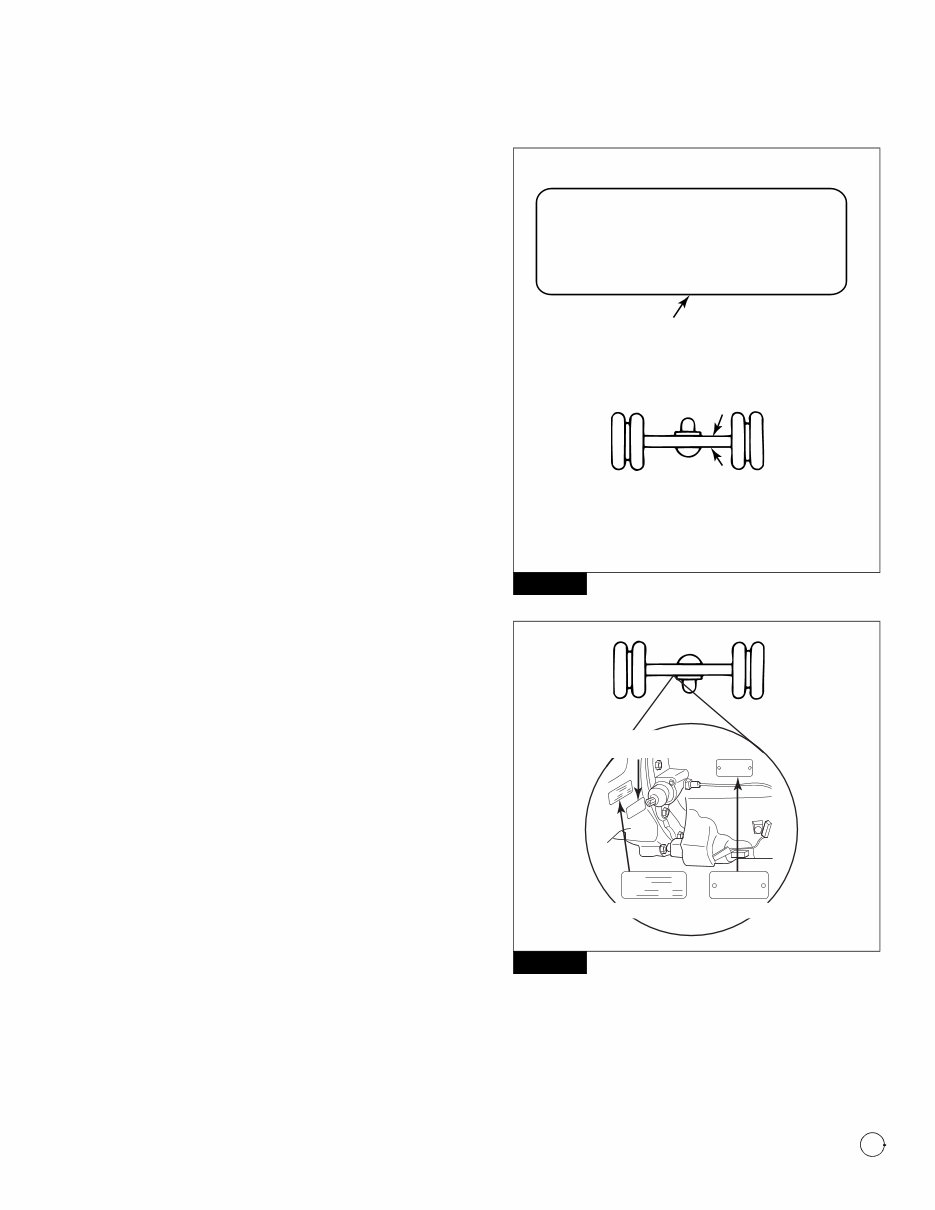

An identification tag is riveted on the axle housing or on the

differential carrier. Figure 2.3 and Figure 2.4. Use the model

number and the ratio number marked on the identification tag and

the number on the carrier to order replacement parts.

Figure 2.3

Figure 2.4

Refer to Figure 2.5 for an explanation of the model number.

Figure 2.3

Figure 2.4

Model No. . . . . . . . . . . . . . . . . . . .

Customer No. . . . . . . . . . . . . . . . .

Serial No. . . . . . . . . Plant . . . . . . . .

Ratio . . . . . . . . . . . .

IDENTIFICATION TAG

LOCATION OF THE IDENTIFICATION TAG, OR STAMP

NUMBER, FOR THE AXLES. LOCATION IS

DETERMINED FROM THE LEFT DRIVER SIDE

LOOKING TOWARD THE FRONT OF THE VEHICLE.

A — FRONT ENGINE DRIVE — RIGHT REAR, NEXT

TO COVER

B — REAR ENGINE DRIVE — LEFT OR RIGHT REAR,

NEXT TO DRIVE UNIT

A

B

1002704c

AXLE IDENTIFICATION TAG INFORMATION

CARRIER PART NO.

CUSTOMER NO.

SERIAL NO.

RATIO

Model No.

Customer No.

Serial No. Plant

Ratio Date

CARRIER PART NO.

CUSTOMER NO.

SERIAL NO.

RATIO

Model No.

Customer No.

Serial No. Plant

Ratio Date

AXLE

IDENTIFICATION TAG

CARRIER

IDENTIFICATION TAG

AXLE HOUSING

IDENTIFICATION TAG

4000625a

2 Introduction

6 Meritor Maintenance Manual 5L (Revised 08-15)

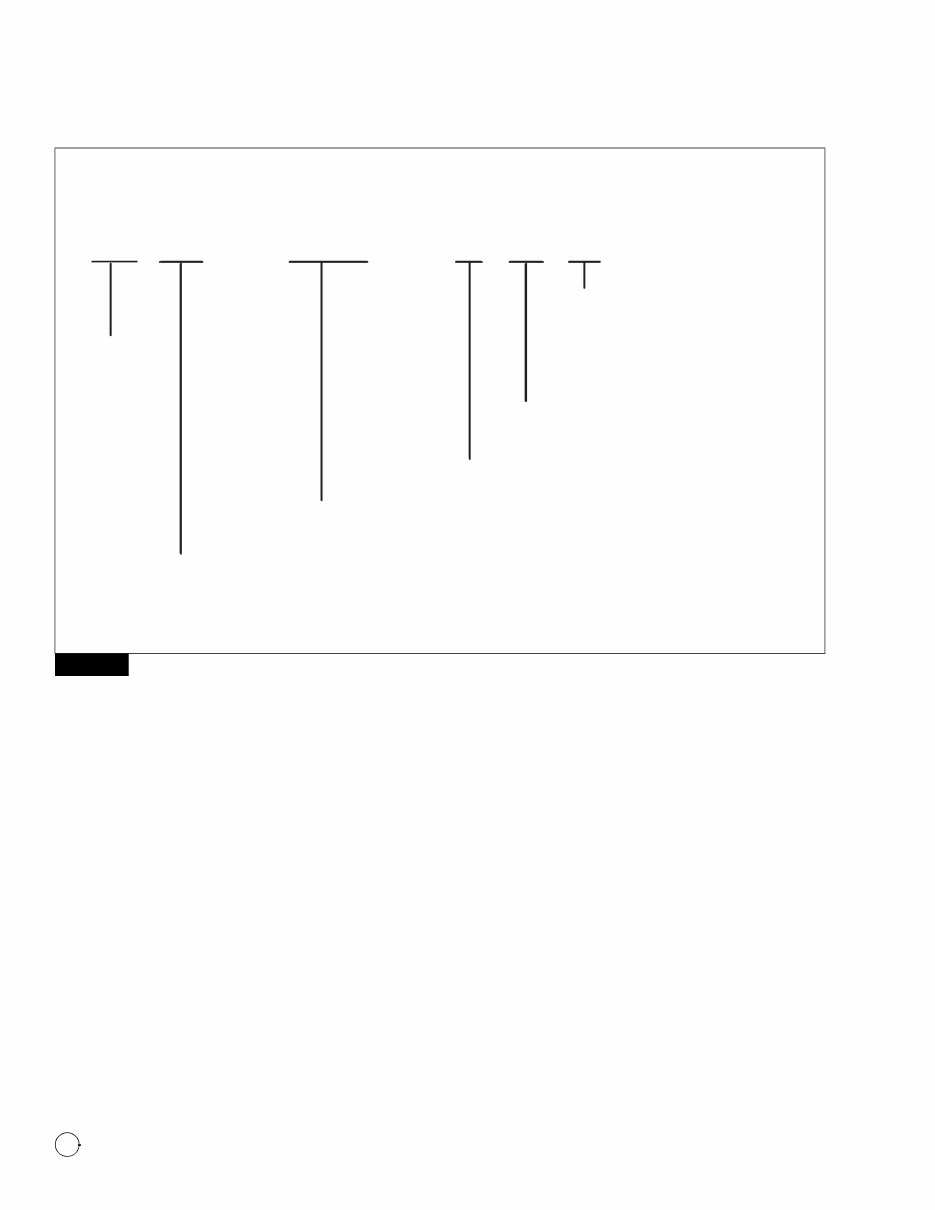

Figure 2.5

Figure 2.5

Axle Design V ariation: Indicates

axle design level or variation,

(e.g., RS-23-161 has a thicker

wall housing than RS-23-160).

For information, refer to the Bill

of Materials for that specific

axle model.

Carrier Type: Carrier size. Larger numbers

indicate a higher GCW rated Carrier; i.e.,

larger ring gear, etc.

Gearing Type:

1 = Single Speed

Nominal Axle Load Rating (GAWR): In thousands of pounds.

Individual forward and rear axles of a tandem set (D, N, P) are rated

as single axles. A tandem set (T) is rated as the combination of the

two axles.

Meritor

M T - - 1 4 X

Axle Type

D = Forward-Rear Axle of a Drive T andem with Inter-Axle Differential

N = Forward-Rear Axle of a Drive T andem without Inter-Axle Differential

P = Forward-Rear Axle of a Drive T andem with Inter-Axle Differential and Pump

T = T andem Drive Axle Set

40

CARRIER MODEL TAG NUMBER INFORMATION

1002705e

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$55.99

Viewed 12 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$55.99

This manual contains essential maintenance and service details for the Meritor forward tandem drive axles. It covers a range of models including the RT-140, -144, -145, -149, -160, -169, RZ-166, -186, and -188 Series models.