Engine SWAP GUIDE 1985-1992 GM TPI EFI system engine into a 1970 - 1981 Camaro - NOW

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

This guide is designed specifically to swap a 1985-1992 GM TPI EFI

system/engine into a 1970-81 Camaro. Though, for the most part, it can be used

to swap in a TBI or LT1/LT4 engine/EFI system as well. All three engines install

like a conventional engine on the existing motor mounts and they have the same

transmission bell housing flange. The newest LS1/LS6 is a completely different

animal altogether requiring extensive chassis modifications to install and will not

be covered in this article.

The first thing you need to take stock of is your vehicle and the system

you will be installing. You need to also consider the emissions regulations in

your state and how you will meet those requirements. I’ll touch on the emissions

system briefly, telling how to hook it up. The emissions control systems are not

essential to engine operation (save for maybe PCV and canister purge), but

again, the emissions regulations will dictate their necessity from a legal

standpoint. In California, there is a rolling 30 year exemption meaning that

currently 1973 and older cars are exempt from smog. As such, I am not using

EGR, AIR injection, or any of the other late model smog devices. However, I did

retain my 1971 charcoal canister purge and PCV system.

This article will cover two possible scenarios. The first is that you have

bought an entire engine/transmission assembly or just the engine. You may or

may not have the factory wiring harness and computer, you may or may not all of

the sensors, injectors, and relays, or have bought new sensors to replace old or

damaged ones. In this scenario, you have already taken out your old engine and

or transmission and installed the new one in its place. You now need to

reconfigure the rest of the vehicle to run the new power plant. If you are

installing an LT1, this is your only scenario since the intake manifold cannot be

bolted on to an older small block without extensive modifications. However, if

you’re bent on doing something like that, visit the www.thirdgen.org site and do a

search. Several people have adapted LT1 manifolds to work the TPI. I will touch

briefly on the installation of a TH700R4 and how to adapt it in to a 2

nd

gen since

this is what I did. However, I will not discuss converting to a later model stick

shift since I have no experience in that area.

The second scenario is that you are putting the TPI/TBI system onto an

older engine. In this scenario, you have already removed the old carbureted

intake manifold and bolted on the new manifold. If you have TPI, only bolt on the

base plate at this point. It’ll be easier to wire and plumb the system with the

upper manifold and runners off (and the distributor out). Again, you now need to

reconfigure the rest of the vehicle to run the system. I’m kind of glossing over the

TPI base plate or TBI manifold installation part because putting on an intake

manifold or installing an engine is pretty generic and can be found in any repair

manual. The only caveat I have for this scenario is putting TPI or TBI on a

seriously modified engine- that is, one that has a camshaft over 214° intake

duration, cylinder heads with 180cc or more intake ports, full length headers and

free flowing exhaust systems, etc. Stock TPI/TBI engines were extremely

restricted as far as heads, cams, and exhaust systems go. Putting a bone stock

EFI system onto a modified engine like this will result in poor, disappointing

performance if you do not get the EPROM recalibrated for the new combination.

This will either require you to have a professional tuning shop do it, or you can

learn to do it yourself.

One thing to note before you get started is that I highly recommend using

the 1990-1992 system. So much so, that I’m going to focus solely on installing

this type of system. For reasons that will become apparent later in the guide,

1990-92 MAP systems are much more practical for EFI swaps than earlier 1985-

1989 MAF ones (see sensor section for definitions of MAP and MAF). If you

have a 1989 or earlier MAF system, you can upgrade it to the 1990-92

configuration very easily. I’ll cover that later on.

Another thing is that I would HIGHLY, HIGHLY suggest is buying a good

automotive scanner! I use an AutoXray. It’s a very nice tool. It will read trouble

codes, allow you to view real time operational data from the ECM (Electronic

Control Module, aka, computer) as well as record it for future reference. You can

also download this data into your PC and export it into Microsoft Excel for

graphing and further analysis. This tool is invaluable for diagnosing malfunctions

as well as for tuning, if you decide to get into that later. Actron also has a nice

scanner, but it cannot record data.

The main objective in an EFI swap is properly configuring the vehicle to

work with the system. This involves two areas- fuel and electrical systems. Both

need to be brought up to date. We’ll start with the fuel system.

Vehicle Fuel System Preparation

TPI/LT1 engines require a constant pressure of upwards of 40 psi to run

properly as well as a return line to the tank. TBI’s operate on a much lower

pressure of about 15 psi, but even they require a return line. In both cases, it

means you will need an electric fuel pump. This presents you with two choices-

either an in-tank pump or an external pump.

At first glance, the external pump may appear to be the easier method, but

it has several draw backs. The most obvious and complained about one is noise.

Since you will be mounting the pump to the chassis, the humming of the pump

will be transmitted through the frame and will be audible inside the vehicle. While

only a mild annoyance, it takes away from the “factory-ness” of the swap. The

second drawback is the heat generation. Cooling is mainly by convection

(whereas an in-tank pump is submerged in a cooling medium, the fuel). Since

there’ll be a lot of rubber (thermally insulating) padding to keep the pump

mechanically isolated from the frame (to reduce vibration noise transmission) the

heat conduction away from the pump is significantly reduced. Therefore,

overheating the pump is a possibility. The third problem is fuel starvation.

Unless internal baffling is added to the tank, low fuel levels combined with hard

braking/acceleration and/or hard cornering can uncover the fuel pickup allowing

the pump to suck air. Electric fuel pumps do not like to suck air since it reduces

the life of the pump significantly.

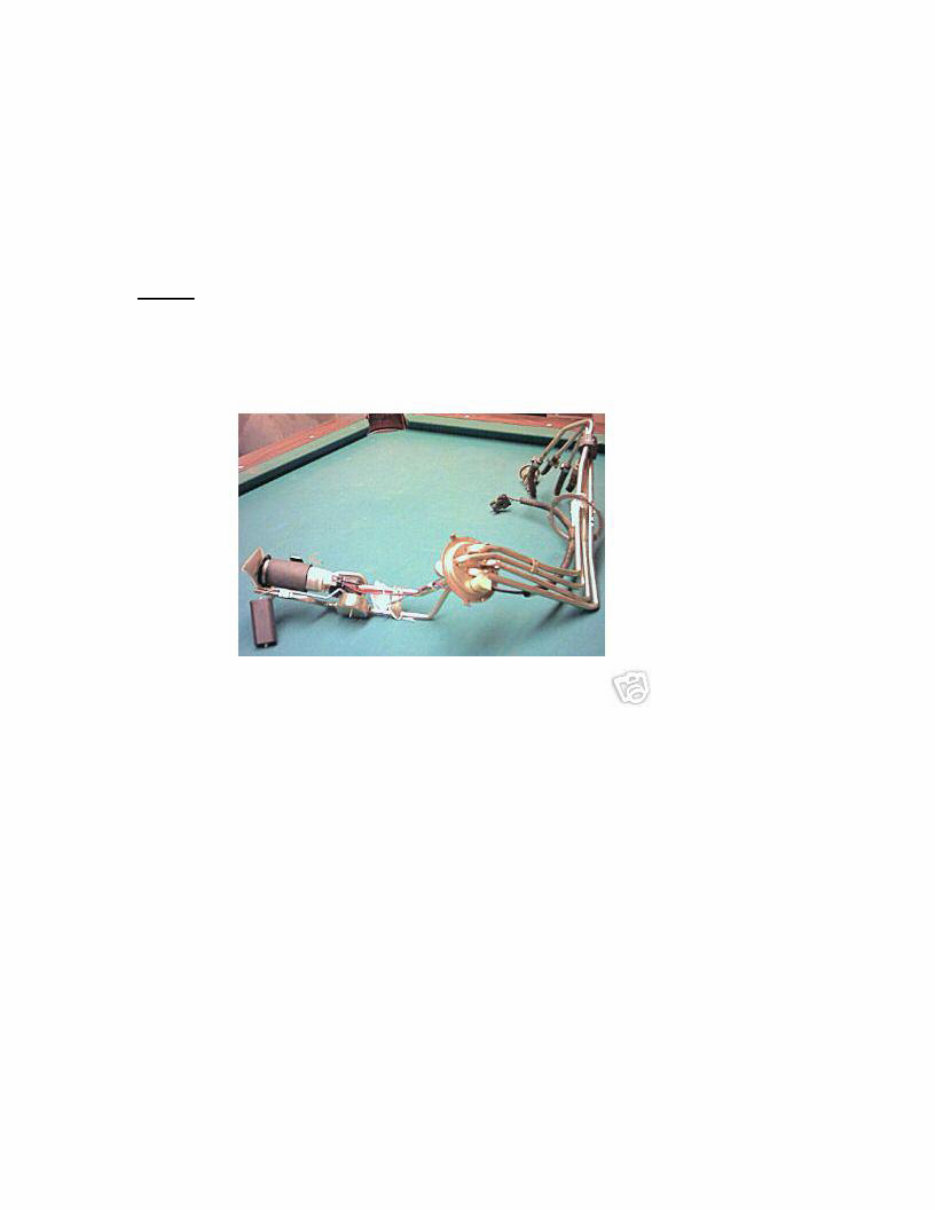

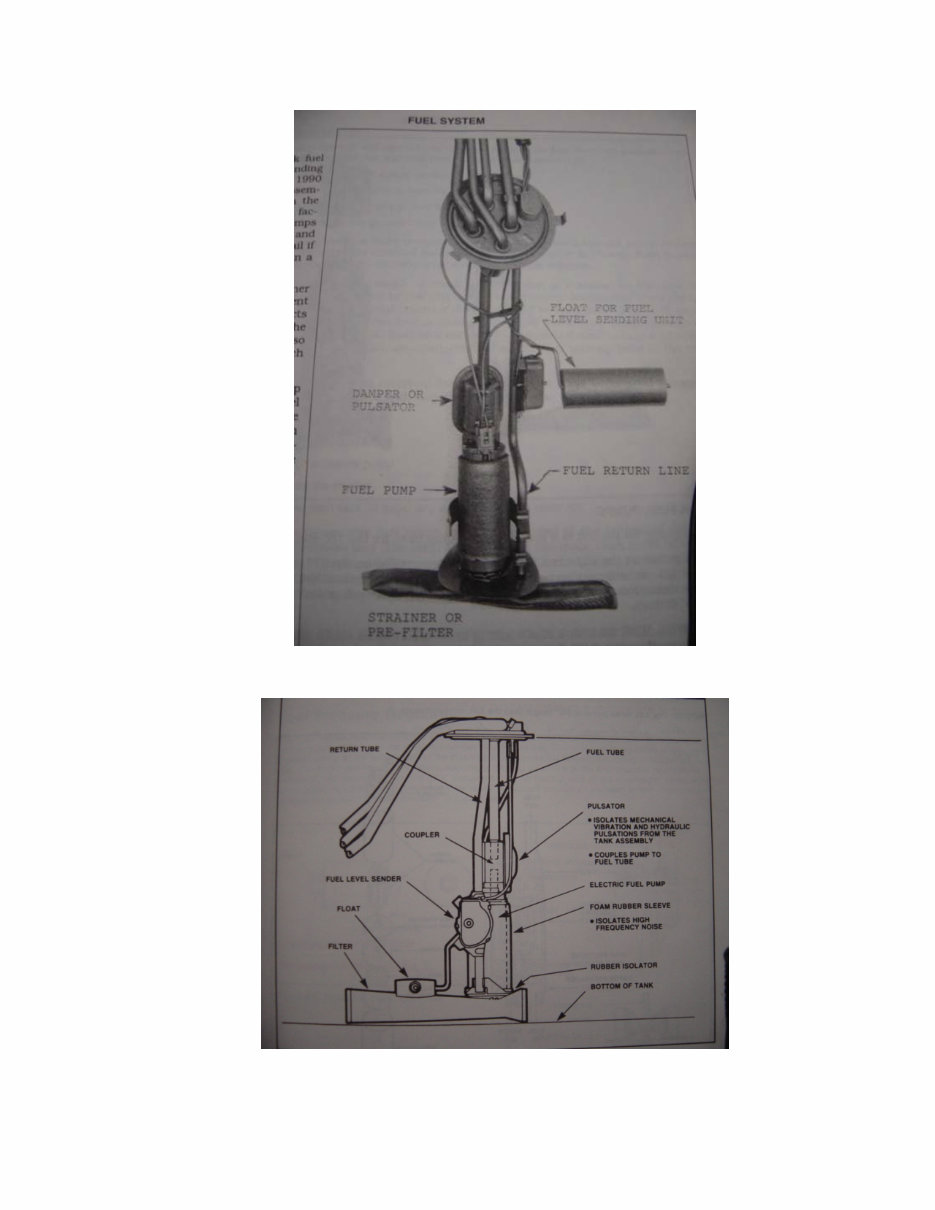

In my opinion, the best way to install an electric pump is to go in-tank. It’s

a lot easier than you may think and you eliminate all of the above problems. The

key to the installation is to find a V8 or V6 late-third generation fuel tank sender

like the one shown below.

NOTE: It was recently discovered that a third gen sender does not fit into late

second generation Camaro’s. It’s unknown the exact cut-off year. However, if

cannot verify if the opening for your sender is not the same as a 1970-73, then

this sender will not work with your fuel tank.

As you can see it has everything on it that you need and it’s a factory

setup! Now, the beauty of this is that it will fit into a second generation fuel tank

with minimal modifications. Namely:

1.) The depth of the fuel tanks between 2

nd

and 3

rd

gen tanks vary

with the model year. As such, minor bending of the lines

leading into the tank will probably be necessary. This can be

accomplished by hand (but be gentle and don’t kink the lines!).

Basically, measure the depth of your tank from the top flange of

the sending unit to the bottom of the tank and make sure that

the pump assembly is no more than 1/4” from the bottom.

2.) The fuel level electrical sender will operate the factory 2

nd

gen

fuel gauge perfectly (don’t you just love GM?). Both operate on

a 0-90 ohm potentiometer operated by a float arm. However

again, due to depth variations between tanks, you may need to

do some minor bending on the float arm such that it is calibrated

to the dimensions of your fuel tank. Just take the appropriate

measurements and you’re set.

3.) As you can see, this sending unit has a lot of fuel lines.

However on 2

nd

gens, you only need two of them. Find the

pressure line and the return line. The remaining two lines are

evaporative lines and can be deleted since the 2

nd

gen already

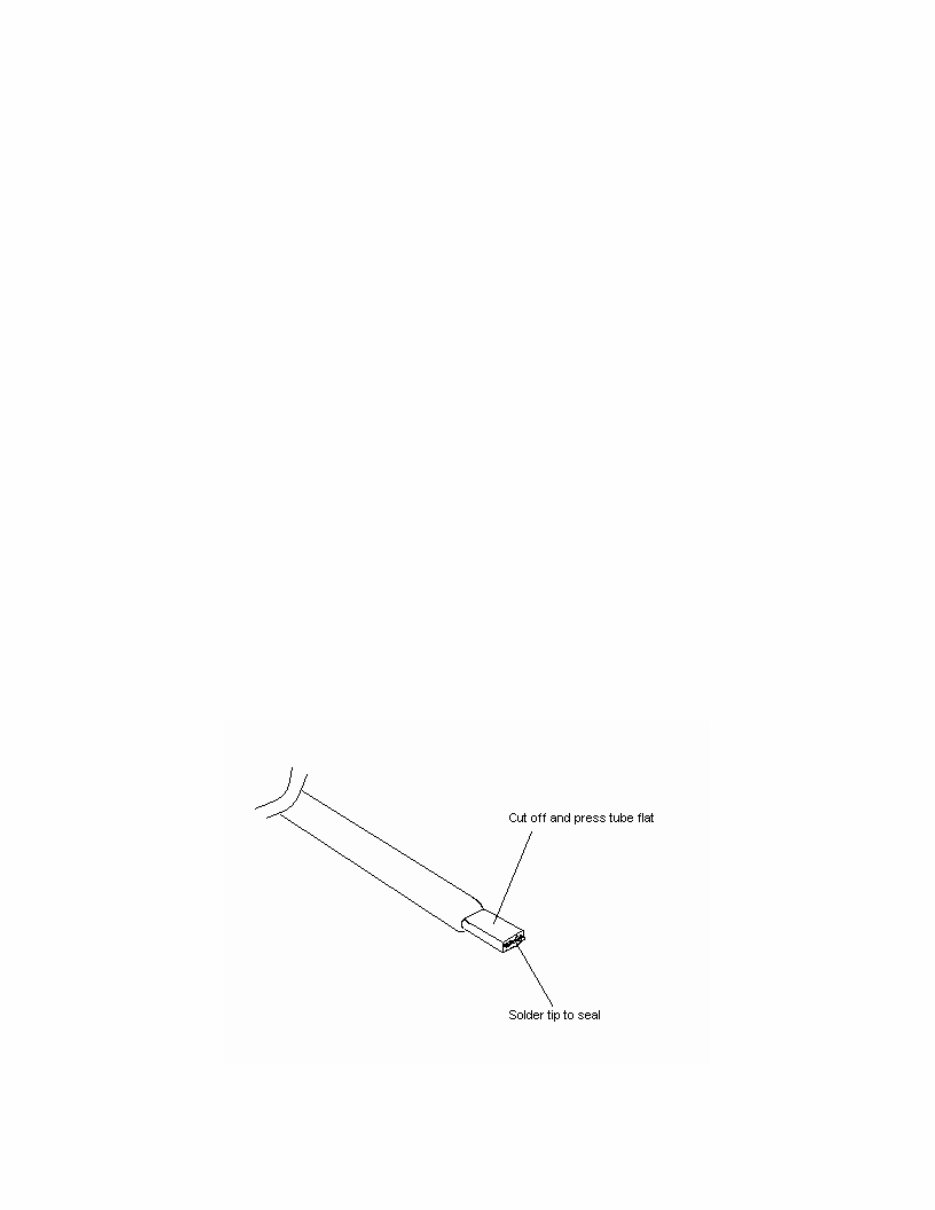

has evaporator lines integral on the tank. On mine, I simply cut

them a few inches from the root, pressed it flat about ½ inch

from the cut end, and soldered the tip shut with standard Sn63

solder to ensure a leak proof seal (see diagram below)

To plumb the lines to the tank you could use the stock 3/8 supply line that

runs the length of the car as the supply line for the EFI. However, you would

have to run high pressure rubber fuel injection hose from the supply line on the

sender to the line on the vehicle. You could also attempt to bend up some steel

line to run the length of the car for the return line as well or attempt to use the

vapor line as a return line. Some people have apparently done this successfully,

but I’d rather not do it in such a manner. Again, you’d have to have rubber hose

connections to mate up with the fuel sending unit. If you go this route, you NEED

to use high pressure fuel injection hose!!! There would also be the need to

plumb the steel lines into the fuel rail- calling for more adapters. I didn’t want to

deal with all of the rubber hose and adapters and such so I ditched the 1971

steel lines and went the Earl’s braided line route. Basically, I bought fittings that

allow you to hook up –AN braided steel hose to a steel fuel line. Today though,

Earl’s has tubing adapters that are specifically designed to allow you to hook up

braided steel line to the steel tubing. Simply call them up and as for fittings that

allow you to hook up -6 AN line to 3/8” steel tubing. They also have fittings that

utilize the factory fuel rail connections and allow you to plumb the braided hose

right to the fuel rail. This gives the benefit of running a one piece line from the

tank to the fuel rail (not counting the in-line high pressure fuel filter of course).

Not to mention that flexible braided steel hose is a lot easier to route than rigid

steel. One thing to keep in mind here, try to maintain as few connections as

possible since each additional connection is a potential source for leaks! Below

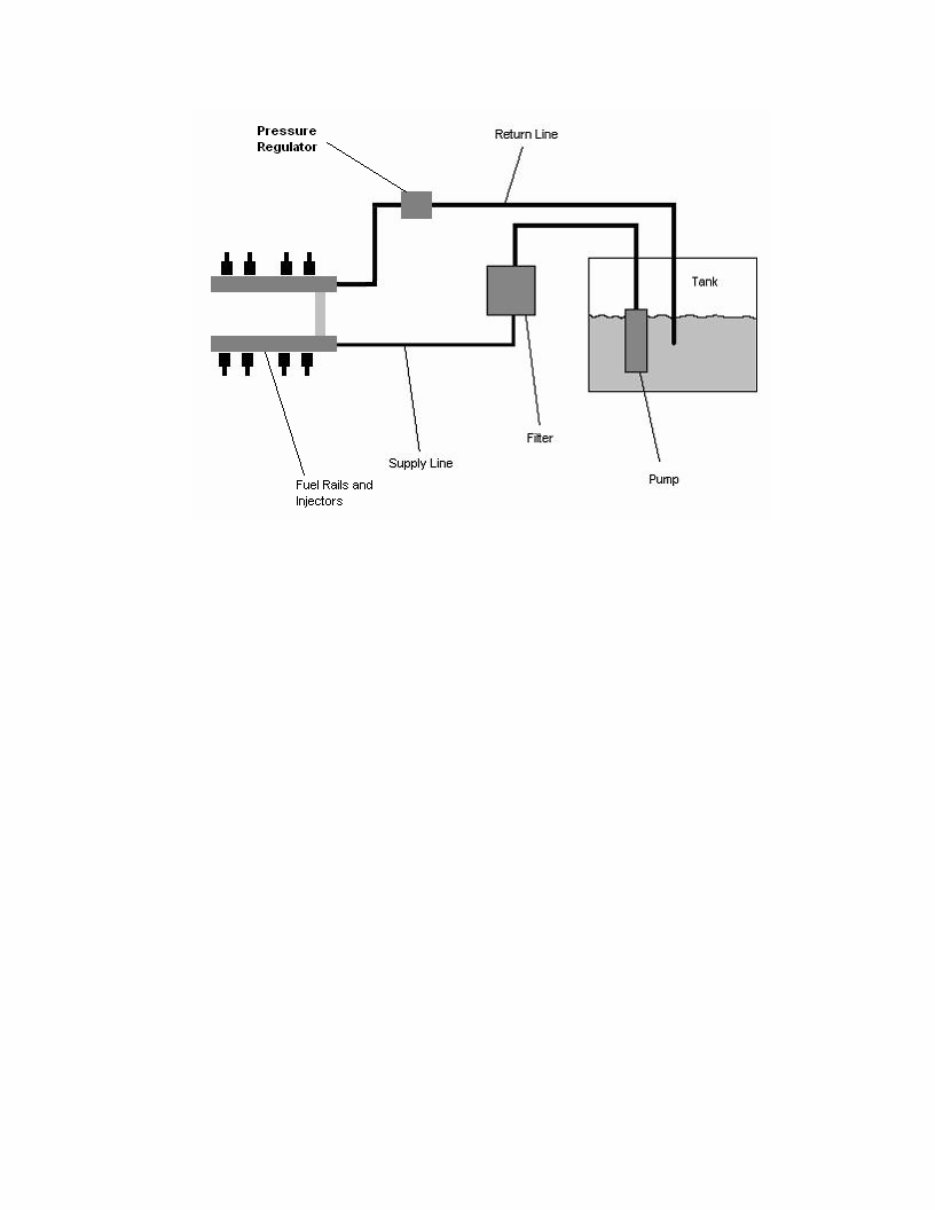

is a EFI fuel system block diagram:

NOTE : I recently discovered that gasoline can permeate through braided rubber

fuel line and result in a constant fuel odor, particularly when the vehicle is parked

inside a garage. This is most likely due to various fuel additives in certain parts

of the United States. One possible remedy, aside from hard steel lines, is to run

braided teflon lines. Teflon lines are available from a variety of sources. While I

did this option on my Camaro (which ridded me of the fuel smell), Aeroquip has

posted a disclaimer about running any type of braided line on EFI engines.

http://www.aeroquip.com/media/performance/A-SPPE-MC001-E-p54.pdf

The fuel recirculation can oxidize the fuel which can allow to attack and

deteriorate the hose. Therefore, I am not recommending running braided

hose , but merely presenting the option as many people are already doing this

rather than forming hard steel lines.

Lastly, the fuel starvation problem needs to be addressed. 2

nd

gen fuel

tanks were obviously not designed for EFI. Electric pumps meet an early demise

if starved for fuel too many times which is why late model fuel tanks have

complex baffle systems inside. This prevents starvation during high-g

maneuvers. On my tank, I did the best I could to mimic the baffle philosophy by

welding in a tray on the bottom of the tank. Basically, a gas tank shop cut out a

section of the tank floor, welded a tray to it and then welded the floor back in.

The tray looks like just that, a tray. It’s rectangular and a couple of inches tall. It

has four holes (one at each corner near the bottom of the tray walls) to allow fuel

to slowly enter in to the tray, but keep it from getting away from the pump. I

forget the exact dimensions (since I did this about 7 or 8 years ago) but I would

suggest a tray about one foot long by about one foot wide by about two to three

inches tall. Here’s a generic view of what I’m talking about. The pump doesn’t

necessarily have to sit in the tank like this though. In fact, with the third gen

sending unit, the pump will be pointing toward the back of the tank.

In any case, the then hangs down and sits in the of the tray. This is not a

sump. From the outside, the tank looks stock. This baffle tray is completely

inside the tank. What I would suggest is to fit your fuel tank sender in and then

take the tank and sender to a shop and describe what you’re doing. If they are at

all able to do some custom work they should be able to do this. That’s basically

how I did it.

For the pump itself, I’m running a Holley high-performance in-tank pump.

It feeds my modified ZZ4 (~400hp) just fine.

Another option for an EFI fuel tank is to contact Rock Valley

(www.rockvalleyantiqueautoparts.com/history.htm ). They can build a custom

stainless steel tank for your 2

nd

gen Camaro. The tank already has baffles in it

and is setup for EFI. It’s pretty pricey at about $1000, but it comes ready for use.

The above applies to all TPI/TBI/LT1 engines. Like I said, the only thing

that will vary is the type of pump used- TPI/LT1 vs. TBI. Obviously, the higher

the horsepower and displacement of the engine, the higher the pump output

you’ll need.

While I’m on the subject of the fuel systems, let’s talk injectors and fuel

pressure regulators. Since I don’t recommend putting TBI on a high performance

engine, I’m going to stick with the TPIs and LT1s. They use the same injectors.

305 TPIs came stock with 19 lb/hr injectors, on 350 TPIs that was increased to

22 lb/hr. When the LT1s came out, they received 24 lb/hr units. Rule of thumb, if

you’re aiming for over 350 hp (which is pretty easy these days), upgrade to 24

lb/hr injectors. Additionally, don’t try to run 305 injectors on a 350 (especially if

it’s a modified 350). They have insufficient capacity to feed that much

displacement. The cheapest place I’ve found that sells injectors is Summit

Racing. Matter of fact, I’m running Ford Motorsport 24 lb/hr injectors! I know…

“HERESY HERESY TRAITOR!!” Hey what can I say, they use the same

injectors that GM does, but they charge about half as much. At Summit, they

cost about $220. For the regulator, you can run the factory regulator, but you’ll

stuck with the factory fuel pressure. While not really a bad thing, but if you want

to up the pressure a little you’ll have to install an adjustable fuel pressure

regulator. There are a ton of them out there- Crane, TPI Specialties, Granatelli,

Holley, etc. They’re all pretty much the same, so whatever strikes your fancy.

Injector operation varies between TPIs and LT1s. All TPIs were batch fire

systems. That is, the computer alternately fires all four driver side injectors then

all four passenger side injectors. 1993 LT1s had the same style injector

operation. However in 1994, GM changed to sequential injection where each

injector is timed to fire per the engine firing order. Sequential injection has a little

bit of an advantage at low RPMs (usually showing up in idle quality). But in the

mid-range and high RPMs, the speed of the engine is high enough that the timing

of the injectors becomes less important.

Lastly, remember that you need a high pressure EFI fuel filter!!

And, it’s directional at that. Make sure you install it with the arrow (on the filter

housing) pointing in the right direction!!!

Well, this pretty much takes care of the fuel system.

Vehicle Electrical System Preparation

The electrical system of an EFI system is not as complicated as you might

think. Nonetheless, the vehicle must first be prepared to handle the demands of

a late model engine management system. Like I said previously, they call the

system “stand-alone” because of the system’s minimal interfacing with the rest of

the vehicle’s electrical system. On the EFI harness, the only places where the

system connects electrically to the vehicle are power and ground. There is one

hook up to the battery, one hookup to +12V switched power source, and a few

ground locations (typically engine and chassis). As such, the system basically

stands alone. I will take you through the electrical preparation, but also guiding

you through the engine schematic explaining the sensor operation. Again, this is

something most TPI swapping guides do not do. If you are unfamiliar with wiring

schematics, this will help you familiarize yourself with them. It’s important that

you do so that when problems arise with the installation (and they usually do the

first time through), you will be able to more successfully diagnose the situation.

First of all, you need to make sure that your vehicle’s electrical system is

up to the task of powering an EFI system! Remember, you’re going to be adding

eight fuel injectors, a computer, a fuel pump, electric fans (likely), sensors,

relays, etc. This is going to place a much heavier demand than your original

electrical system was designed to handle. First, examine your power wire going

from the battery to the alternator- make sure it is in good condition. In fact, I

would strongly suggest upgrading it to a heavier gauge wire since you’re going to

have to have a high output alternator. Also, ensure you have excellent (not just

good) grounds going from the battery to the engine, engine to chassis, and even

battery to chassis. It sounds redundant, but trust me, EFI systems do not like

electrical ground loops. All of your chassis grounds from the EFI harness must

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 94 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

This manual is specifically designed for swapping a 1985-1992 GM TPI EFI system/engine into a 1970-1981 Camaro. It can also be used for swapping in a TBI or LT1/LT4 engine/EFI system. All three engines install like a conventional engine on the existing motor mounts and they have the same transmission bell housing flange.

Please note that the newest LS1/LS6 requires extensive chassis modifications for installation and is not covered in this manual.