1966-1983 Chrysler Marine 3.5-140HP Engines Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

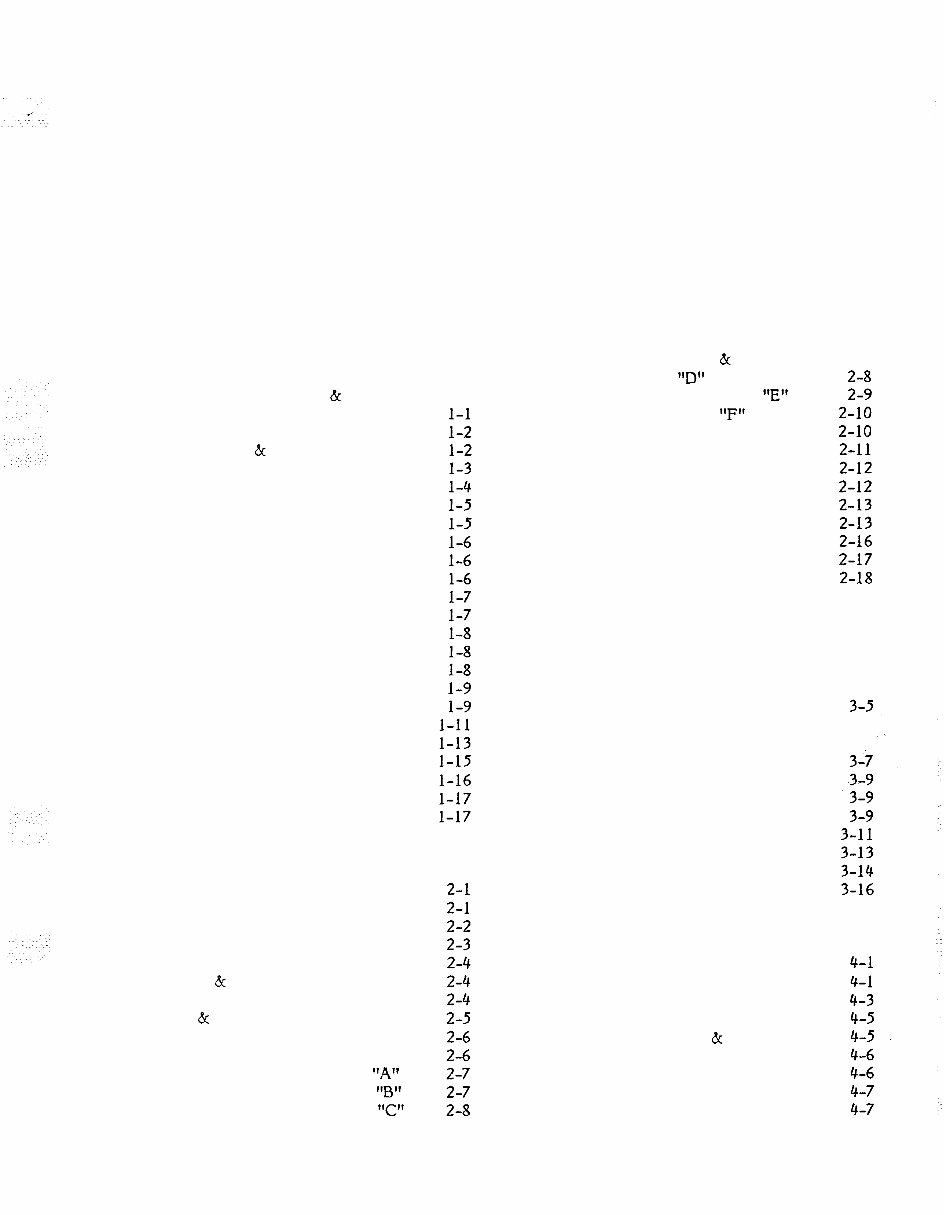

TABLE OF CONTENTS

1 SAFETY

INTRODUCTION 1-1

CLEANING, WAXING, & POLISHING 1-1

CONTROLLI NG CORROSION

PROPELLERS

Diameter & Pitch

Proper Selection

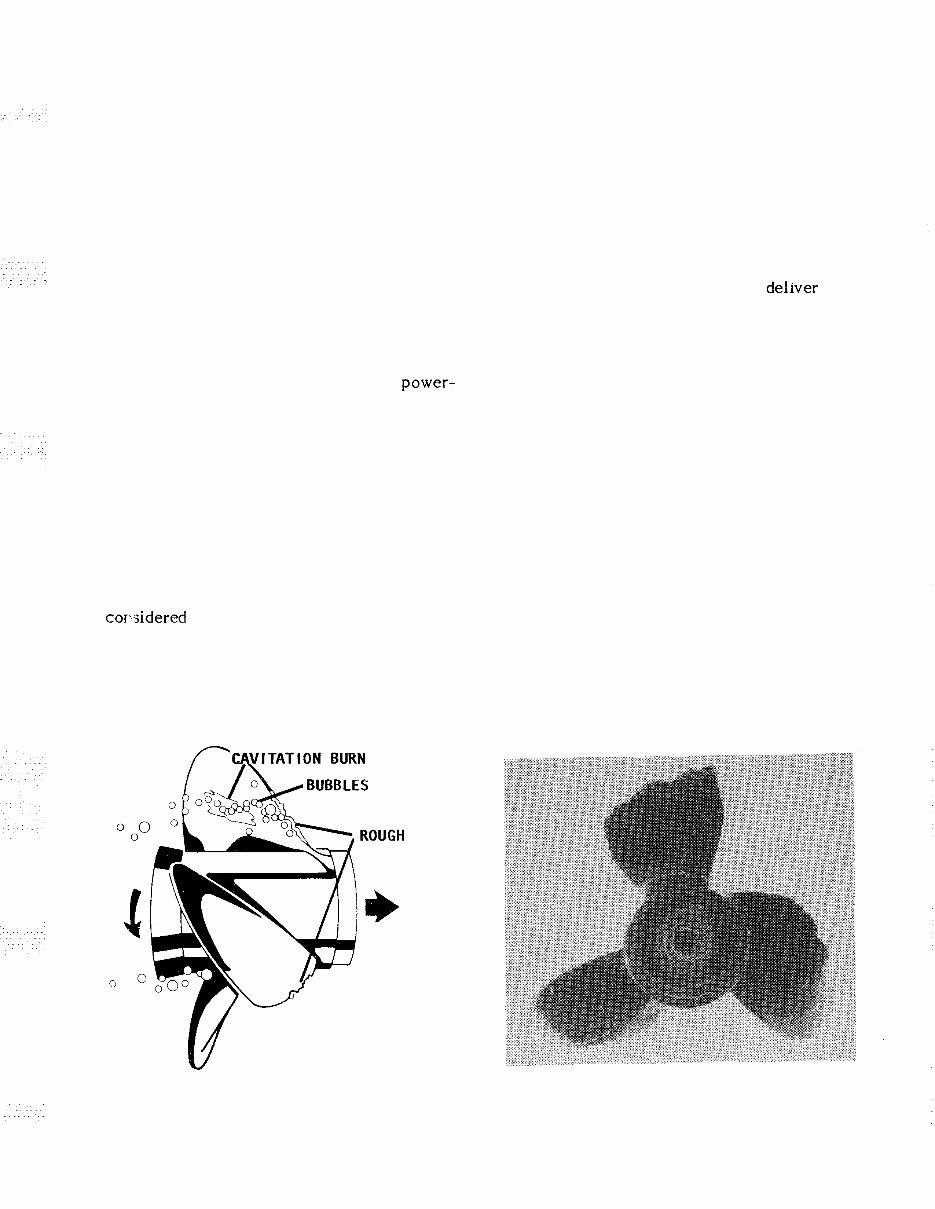

Cavitation

Vibration

Shock Absorbers

Propeller Rake

Progressive Pitch

Cupping

FUEL SYSTEM

Taking on Fuel

Static Electricity

Fuel Tank Grounding

LOADING

HORSEPOWER

FLOTATION

EMERGENCY EQUIPMENT

COMPASS

ANCHORS

MISCELLANEOUS EQUIPMENT

BOATING ACCIDENT REPORTS

NAVIGATION

2 N NING

INTRODUCTION

TUNE- UP SEQUENCE

COMPRESSION CHECK

SPARK PLUG INSPECTION

IGNITION SYSTEM

TIMING & SYNCHRONIZING

BATTERY CHECK

FUEL & FUEL TANKS

GENERAL CARBURETOR INFO.

SPECIFIC CARBURETOR INFO.

Walbro LMB, Carburetor "A"

Tillotson MT, Carburetor "B"

Tillotson MD, Carburetor "C"

Tillotson CO, TC, & WB --

Carburetor "D"

Walbro WE, Carburetor "E"

Amal, Carburetor "F"

TACHOMETER LESSON

FUEL SYSTEM

Fuel Pumps

CRANKING MOTOR

INTERNAL WIRING HARNESS

WATER PUMP CHECK

PROPELLER

LOWER UNIT

BOAT TESTING

3 MAINTENANCE

INTRODUCTION 3-1

OUTBOARD SERIAL NUMBERS 3-2

LUBRICATION - - COMPLETE UNIT 3-2

PRE-SEASON PREPARATION

SEALANTS, ADHESIVES, LUBRI-

CANTS, HYDRAULIC FLUID,

AND STABILIZERS

BELOW WATERLINE SERVICE

INSIDE THE BOAT

SUBMERGED ENGINE SERVICE

LOWER UNIT

PROPELLER SERVICE

WINTER STORAGE

Battery Storage

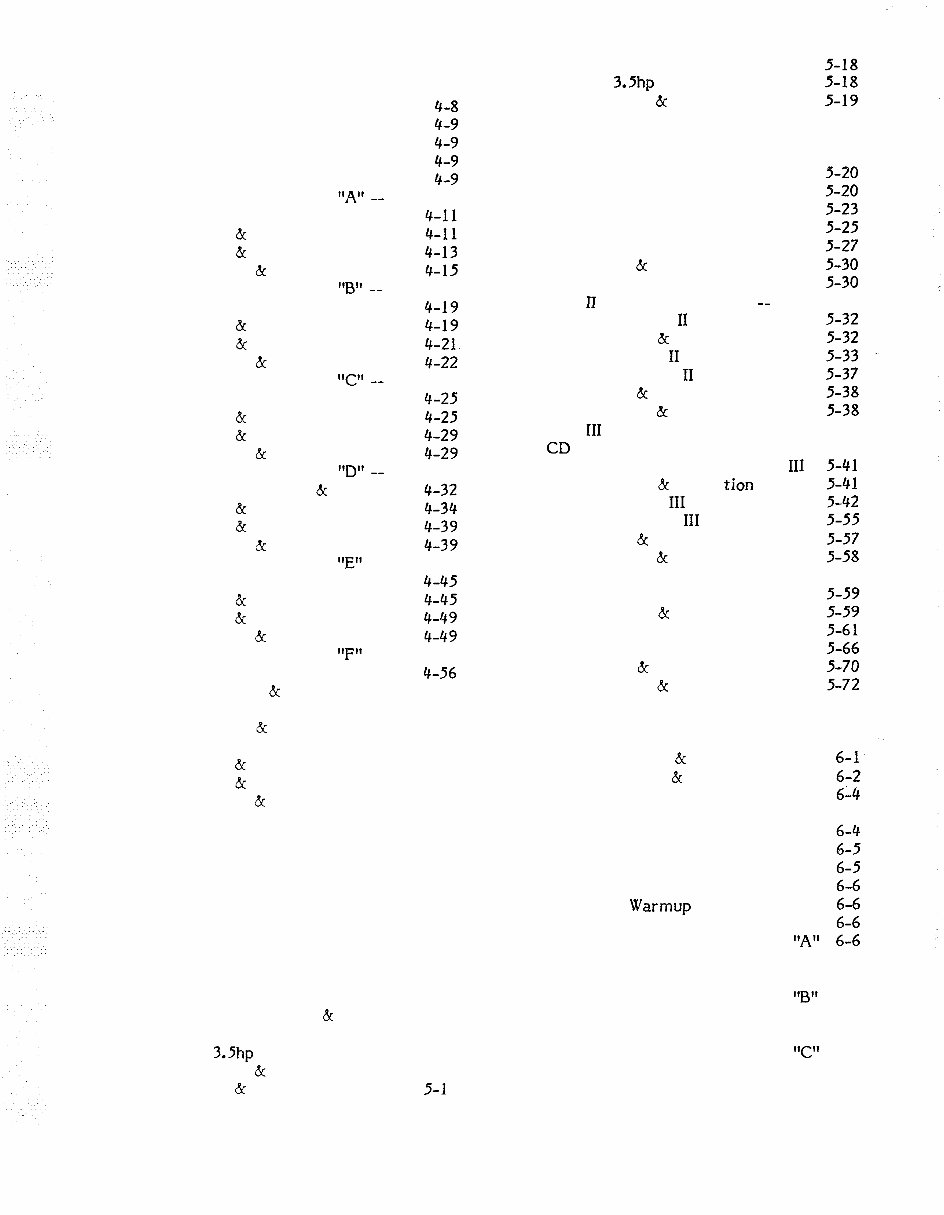

4 FUEL

INTRODUCTION

GENERAL CARBURETOR INFO.

CARBURETOR MODELS

FUEL SYSTEM

Leaded Gasoline & Gasohol

Removing Fuel From System

TROUBLESHOOTING

Fuel Problems

"Sour" Fuel

(c) PDF Manual Publisher

4 FUEL (CONTINUED)

TROUBLESHOOTING (CONT.)

Fuel Pump Test

Fuel Line Test

Rough Engine Idle

Excessive Fuel Consumption

Engine Surge

SERVICE CARBURETOR "A" --

WALBRO LMB

Removal & Disassembling

Cleaning & Inspecting

Assembling & Installation

SERVICE CARBURETOR "B" --

TILLOTSON MT

Removal & Disassembling

Cleaning & Inspecting

Assembling & Installation

SERVICE CARBURETOR "C" --

TILLOTSON MD

Removal & Disassembling

Cleaning & Inspecting

Assembling & Installation

SERVICE CARBURETOR "D" --

TILLOTSON CO, TC, & WB

Removal & Disassembling

Cleaning & Inspecting

Assembling & Installation

SERVICE CARBURETOR "El1 - -

WALBRO WE

Removal & Disassembling

Cleaning & Inspecting

Assembling & Installation

SERVICE CARBURETOR "F" - -

THE AMAL

TACHOMETERS & CONNECTIONS 4-56

FUEL PUMP 4-57

Description & Operation 4-57

Pressure Check 4-58

Removal & Disassembling 4-59

Cleaning & Inspecting 4-62

Assembling & Installation 4-62

5 IGNITION

INTRODUCTION 5- 1

SPARK PLUG EVALUATION 5-2

POLARITY CHECK 5-5

WIRING HARNESS 5-6

TROUBLESHOOTING BASIC COMPO-

NENTS 5-6

TESTING BASIC COMPONENTS 5-9

FLYWHEEL REMOVAL & INSTALLA-

TION 5-14

Model 3.5hp thru 30hp 5-14

Model 35hp & Larger 5-16

Cleaning & Inspecting 5-1 7

Flywheel Magnets

Model 3.5hp thru 30hp

Model 35hp & Larger

TYPE I IGNITION SYSTEM --

FLYWHEEL MAGNETO -

BATTERY TYPE --

MAGNAPOWER I

Component Function

Operation Description

Testing Type I

Servicing Type I

Cleaning & Inspecting

Installation

TYPE I1 IGNITION SYSTEM --

MAGNAPOWER I1

Description & Operation

Testing Type I1

Servicing Type I1

Cleaning & Inspecting

Assembling & Installation

TYPE I11 IGNITION SYSTEM --

CD (CAPACITOR DISCHARGE) -

PRESTOLITE MAGNAPOWER I11

Description & Opera tion

Testing Type I11

Servicing Type I11

Cleaning & Inspecting

Assembling & Installation

TYPE IV IGNITION SYSTEM

UNITS WITH DISTRIBUTOR

Description & Operation

Testing Type IV

Servicing Type IV

Cleaning & Inspecting

Assembling & Installation

6 TIMING AND SYNCHRONIZING

INTRODUCTION & PREPARATION

TACHOMETERS & CONNECTIONS

IGNITION TIMING

CARBURETOR SYNCHRONIZING -

GENERAL ADJUSTMENTS

Throttle Pickup Adjustment

Idle Mixture Adjustment

Idle Speed Adjustment

Neutral Warmup

Electric Choke Adjustment

SYNCHRONIZE CARBURETOR "A"

Static Adjustments 6-7

Dynamic Adjustments 6-8

SYNCHRONIZE CARBURETOR "B" 6- 9

Static Adjustments 6-10

Dynamic Adjustments 6-11

SYNCHRONIZE CARBURETOR "C" 6-12

Static Adjustments 6-13

Dynamic Adjustments 6-13

(c) PDF Manual Publisher

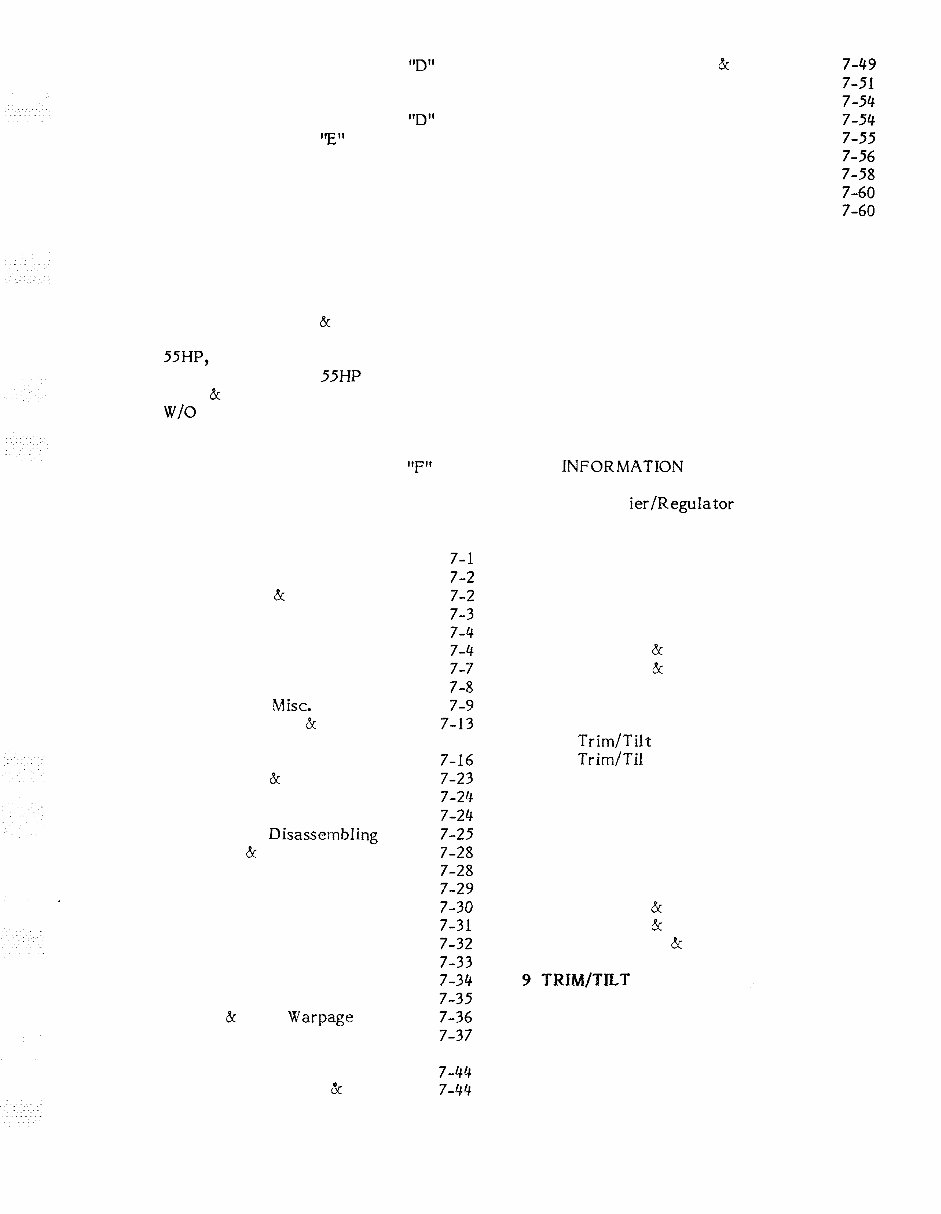

SYNCHRONIZE CARBURETOR "D" 6- 14

Static Adjustments 6 - 15

Dynamic Adjustments 6- 16

SYNCHRONIZE CARBURETOR "D"

OR CARBURETOR "E" 6- 18

Static Adjustments 6-1 9

Dynamic Adjustments 6- 24

IGNITION TIMING - - ALL MODELS

35HP AND LARGER

General Information 6- 26

Model 35hp -- 1976 - 79

and 1983- 84 6- 27

IGNITION TIMING AT WOT - - MODELS

WITH FLYWHEEL MARKS 6- 27

Establishing TDC & BTDC Marks 6 - 28

IGNITION TIMING - - 35HP THRU

55HP, SPECIFIC YEARS 6- 31

IGNITION TIMING -- 55HP THRU

65HP & ALL 4 - CYLINDER

W/O DISTRIBUTOR 6- 34

IGNITION TIMING --

WITH DISTRIBUTOR 6- 35

SYNCHRONIZE CARBURETOR "F" 6- 38

7 POWERHEAD

INTRODUCTION AND CHAPTER

ORGANIZATION

TWO- CYCLE POWERHEAD

Description & Operation

Physical Operation

Timing -- 2 - Stroke Unit

Cooling Lecture

Cylinder Drain System

PREPARATION FOR SERVICE

Removal -- Misc. Components

Intake Manifold & Reed Block

POWERHEAD REMOVAL

AND DISASSEMBLING

Crankshaft & Rod Removal

Main Bearings

Piston Removal

Crankshaft Disassembling

CLEANING & INSPECTING

Thermostat Service

Temperature Sender

Crankshaft Service

Rod Service

Piston Service

Ring End Gap

Cylinder Block

Hone Cylinder Walls

Block & Head Warpage

Crankcase Cover

POWERHEAD ASSEMBLING

AND INSTALLATION

Assembling Pistons & Rods

Installing Pistons & Rods

Crankcase Cover

Exhaust Cover

Upper Oil Seal Housing

Power head Installation

Closing Tasks

Sealing Service Words

Thermoswitch

Supporting Components

8 ELECTRICAL

INTRODUCTION 8- 1

BATTERIES 8- 1

Marine Batteries 8- 1

Construction 8- 2

Ratings 8 - 2

Service 8- 3

Jumper Cables 8- 6

Storage 8- 6

TACHOMETER 8- 7

GENERAL ELECTRICAL

INFOR MATION 8- 7

CHARGING CIRCUIT SERVICE 8- 8

Rectif ier/Regulator 8 - 8

Stator Service 8- 10

CRANKING MOTOR CIRCUIT 8- 11

Description 8- 1 1

Troubleshooting 8 - 13

Installation 8- 15

CRANKING MOTOR SERVICE 8- 16

Description 8- 16

Removal & Disassembling 8- 16

Cleaning & Inspecting 8 - 18

Testing Components 8- 20

Assembling 8- 23

TESTING OTHER COMPONENTS 8- 26

TrimITilt Switch 8- 26

Trim/Til t Motor 8- 27

Ignition Switch 8- 27

"Kill" Switch 8- 28

Shift Interlock Switch 8- 28

Overheat Warning Horn 8 - 29

Circuit Breaker 8- 29

AUTO ELECTRIC SYSTEM 8- 30

Description 8- 30

Removal & Disassembling 8- 30

Cleaning & Inspecting 8-31

Assembling 3c Installation 8- 33

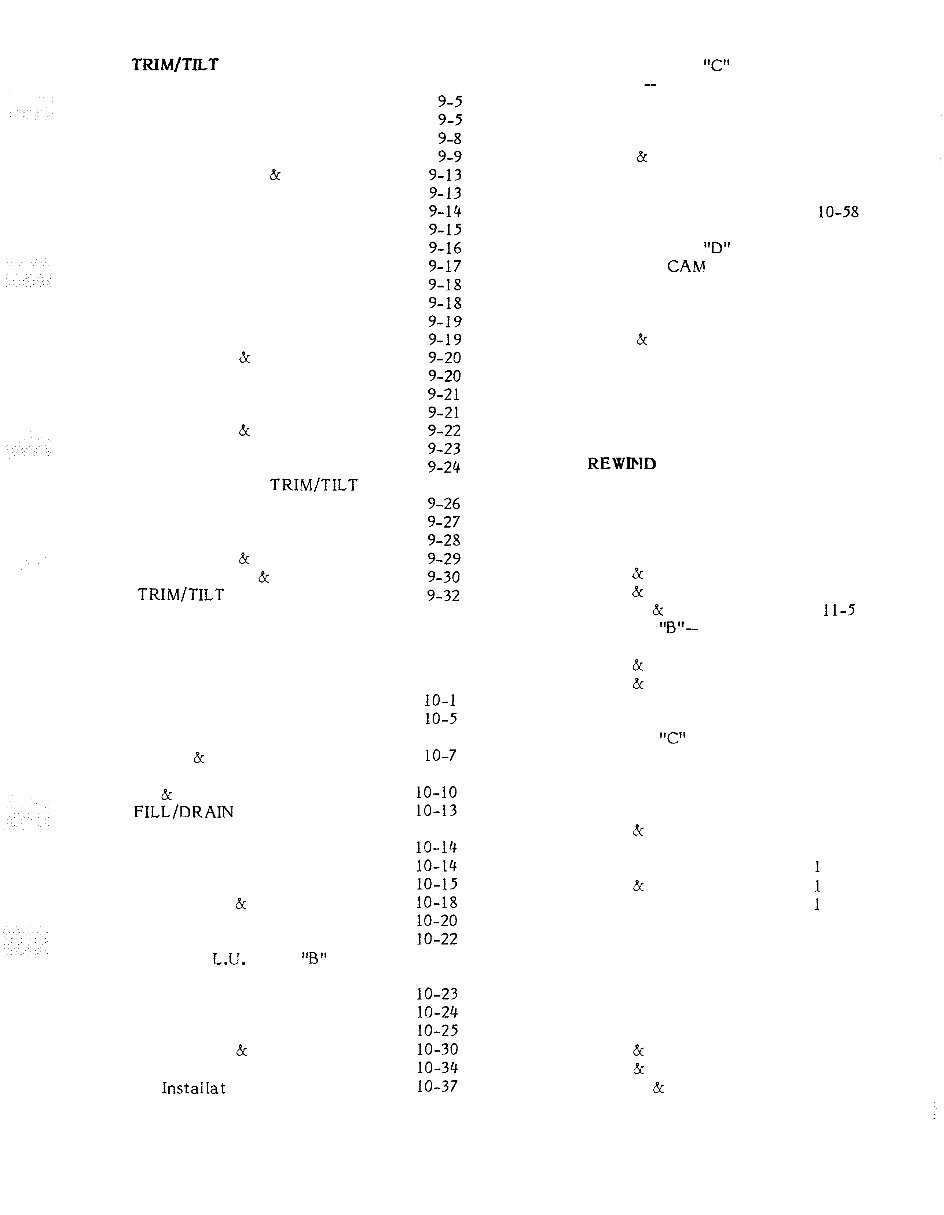

INTRODUCTION AND CHAPTER

ORGANIZATION 9- 1

SYSTEM OPERATION 9- 2

Electric Motor 9-2

Hydraulic Pump 9- 2

(c) PDF Manual Publisher

9 TRIM/TILT (CONTINUED)

PURGING AIR FROM SYSTEM

TROUBLESHOOTING

Hydraulic Test

Electrical Test

SERVICE PUMP & MOTOR

Removal

Disassembling

Testing Motor

Assembling

Installation

SERVICE CYLINDERS

Preliminary Tasks

TILT CYLINDER

Disassembling

Cleaning & Inspecting

Assembling

TRIM CYLINDER

Disassembling

Cleaning & Inspecting

Assembling

Installation

SYSTEM -- ONE TRIMITILT CYL.

TWO DESIGNS INCLUDED

Removal

Disassembling

Cleaning & Inspecting

Assembling & Installation

TRIMITILT SENDING UNIT

10 LOWER UNIT

CHAPTER ORGANIZATION

TROUBLESHOOTING

PROPELLER SERVICE

ONE- & TWO- CYLINDER UNITS

PROPELLER SERVICE

3- & 4 - CYLINDER UNITS

FILLIDRAIN ALL LOWER UNITS

SERVICE L.U. TYPE "A"

CONSTANT MESH -- NO SHIFT

Removal

Disassembling

Cleaning & Inspecting

Assembling

Installat ion

SERVICE L.lJ. TYPE "B"

ONE PIECE -- CAM SHIFT

F- N OR F- N- R

Removal

Disassembling

Cleaning & Inspecting

Assembling

Installat ion

SERVICE L.U. TYPE "C"

ONE PIECE - COUPLER SHIFT

F- N- R 10 - 39

Removal 10 - 39

Disassembling 10- 41

Cleaning & Inspecting 10- 47

Assembling 10- 51

Backlash 10- 53

Prop. Shaft End " Play" 10-58

Installation 10- 62

SERVICE L.U. TYPE "Dlt

TWO- PIECE -- CAM OR COUPLER

SHIFT - - F- N- R 10- 64

Removal 10- 64

Disassembling 10- 66

Cleaning & Inspecting 10 - 73

Assembling 10- 77

Prop. Shaft End Play 10- 85

Installation 10- 87

11 HAND REWIND STARTER

INTRODUCTION AND

CHAPTER COVERAGE 11- 1

SERVICE TYPE "A" --

MOUNTED ATOP FLYWHEEL 11- 2

Removal & Disassembling 11- 2

Cleaning & Inspecting 11- 4

Assembling & Installation 11-5

SERVICE TYPE "B"--

MOUNTED ATOP FLYWHEEL 11- 9

Removal & Disassembling 11- 10

Cleaning S( Inspecting 11 - 12

Assembling & Installation 11- 12

Check Interlock System 11- 16

SERVICE TYPE "C" --

SPOOL MOUNTED VERTICALLY

THREE MODELS INCLIJDED 11- 17

Replace Frayed or

Broken Rope 11- 17

Cleaning & Inspecting 11- 22

Installation 11 - 23

Replace Broken Spring 1 1- 26

Cleaning & Inspecting 1 1- 27

Installation 1 1- 28

Adjust Interlock System 11- 30

12 REMOTE CONTROL

INTRODUCTION 12- 1

OPERATION 12- 1

SERVICING 12- 1

Removal & Disassembling 12- 2

Cleaning & Inspecting 12- 5

Assembling & Installation 12-6

(c) PDF Manual Publisher

APPENDIX

METRIC CONVERSION TABLE

DRILL SIZE CONVERSION CHART

TORQUE SPECIFICATIONS

ENGINE SPECIFICATION AND

TUNE-UP ADJUSTMENTS

1962 thru 1966

1967 thru 1969

1970 and 1971

1972 and 1973

1974 and 1975

1976 and 1977

1978 and 1979

1980 and 1981

1982 and 1983

1984

POWERHEAD SPECIFICATIONS A-24

CYLINDER COMPRESSION A-26

LOWER UNIT OIL CAPACITY A-27

CARBURETOR JET SIZE/

ELEVATION CHART A-28

WIRING DIAGRAMS WITH

COLOR CODE

By Horsepower

& Ignition System A-29 thru A-53

(c) PDF Manual Publisher

SAFETY

1-1 INTRODUCTION

In order to protect the investment for

the boat and outboard, they must be cared

for properly while being used and when out

of the water. Always store the boat with

the bow higher than the stern and be sure to

remove the transom drain plug and the inner

hull drain plugs. If any type of cover is used

to protect the boat, be sure to allow for

some movement of air through the hull.

Proper ventilation will assure eiaporation of

any condensation that may form due to

changes in temperature and humidity.

1-2 CLEANING, WAXING, AND POLISHING

Any boat should be washed with clear

water after each use to remove surface dirt

and any salt deposits from use in salt water.

Regular rinsing will extend the time be -

tween waxing and polishing. It will also give

you " pride of ownership " , by having a sharp

looking piece of equipment. Elbow grease, a

mild detergent, and a brush will be required

to remove stubborn dirt, oil, and other un -

sightly deposits.

Stay away from harsh abrasives or strong

chemical cleaners. A white buffing com -

pound can be used to restore the original

gloss to a scratched, dull, or faded area.

The finish of your boat should be thoroughly

cleaned, buffed, and polished at least once

each season. Take care when buffing or

polishing with a marine cleaner not to over -

heat the surface you are working, because

you will burn it.

The first form was merely rot in the wood

and then it was rust, followed by other

forms of destructive corrosion in the more

modern materials. One defense against cor -

rosion is to use similar metals throughout

the boat. Even though this is difficult to do

in designing a new boat, particularly the

undersides, similar metals should be used

whenever and wherever possible.

A second defense against corrosion is to

insulate dissimilar metals. This can be done

1-3 CONTROLLING CORROSION A well kept unit, cleaned, serviced, tuned, and ready

to leave the service facility. Proper care reflects the

Since man first started out on the water, owner's "pride of ownership" and will be rewarded with

corrosion on his craft has been his enemy.

p zrf orm ance.

(c) PDF Manual Publisher

1 - 2 SAFETY

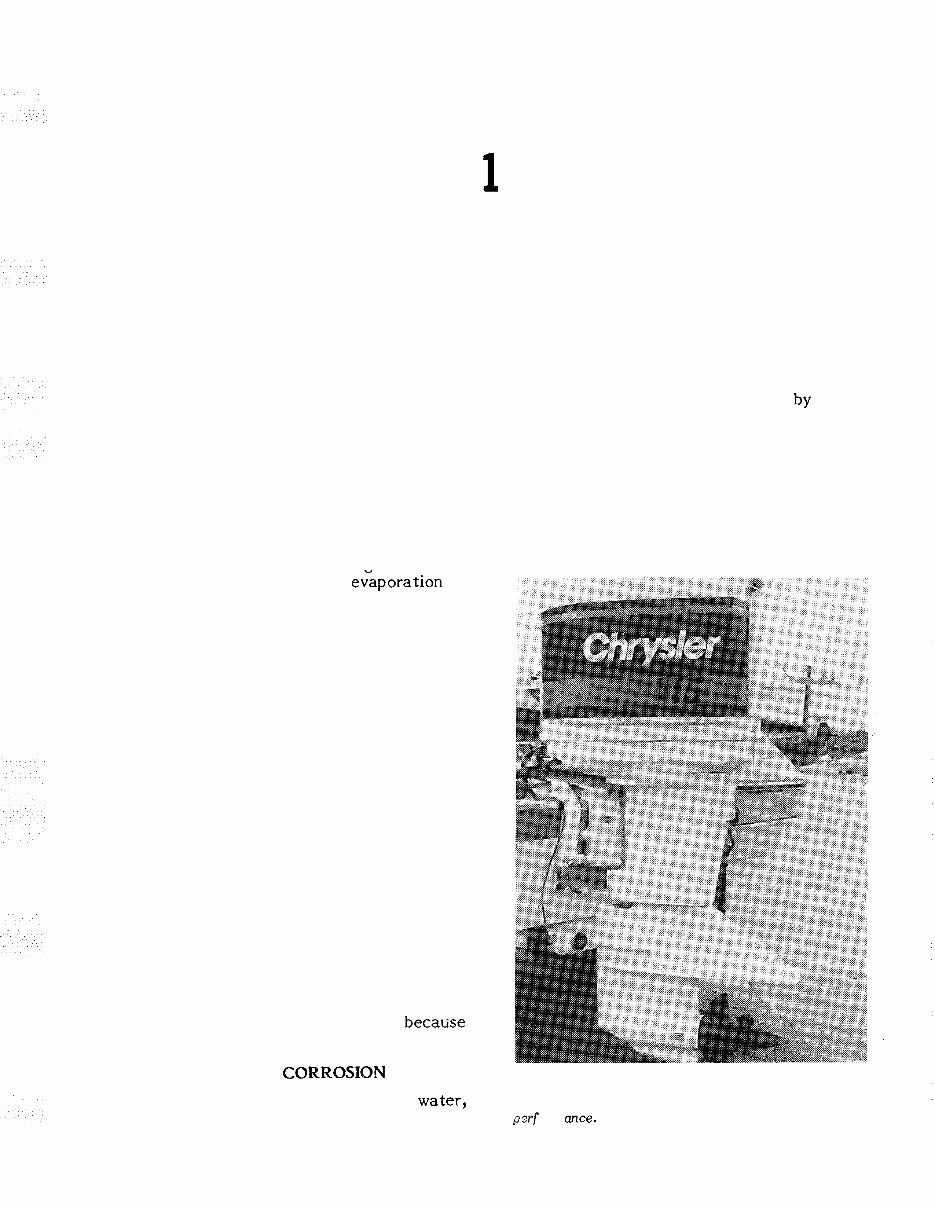

A new anode, left, compared with a slightly used

one, right. This type anode is attached to the bearing

carrier on larger hp units.

by using an exterior coating of Sea Skin or

by insulating them with plastic or rubber

gaskets.

Using Zinc

The proper amount of zinc attached to a

boat is extremely important. The use of too

much zinc can cause wood burning by plac -

ing the metals close together and they be -

come "hot". On the other hand, using too

small a zinc plate will cause more rapid

deterioration of the metal you are trying to

Mounting a large zinc on the transom to protect

more valuable parts.

protect. If in doubt, consider the fact that

it is far better to replace the zincs than to

replace planking or other expensive metal

parts from having an excess of zinc.

When installing zinc plates, there are

two routes available. One is to install many

different zincs on all metal parts and thus

run the risk of wood burning. Another

route, is to use one large zinc on the tran -

som of the boat and then connect this zinc

to every underwater metal part through

internal bonding. Of the two choices, the

one zinc on the transom is the better way to

go*

1- 4 PROPELLERS

As you know, the propeller is actually

what moves the boat through the water.

This is how it is done. The propeller oper -

ates in water in much the same manner as a

wood screw does in wood. The propeller

" bites " into the water as it rotates. Water

passes between the blades and out to the

rear in the shape of a cone. The propeller

" biting" through the water in much the same

manner as a wood auger is what propels the

boat.

All units covered in this manual are

equipped, from the factory, with a through

the propeller exhaust. With these units,

exhaust gas is forced out through the pro -

peller.

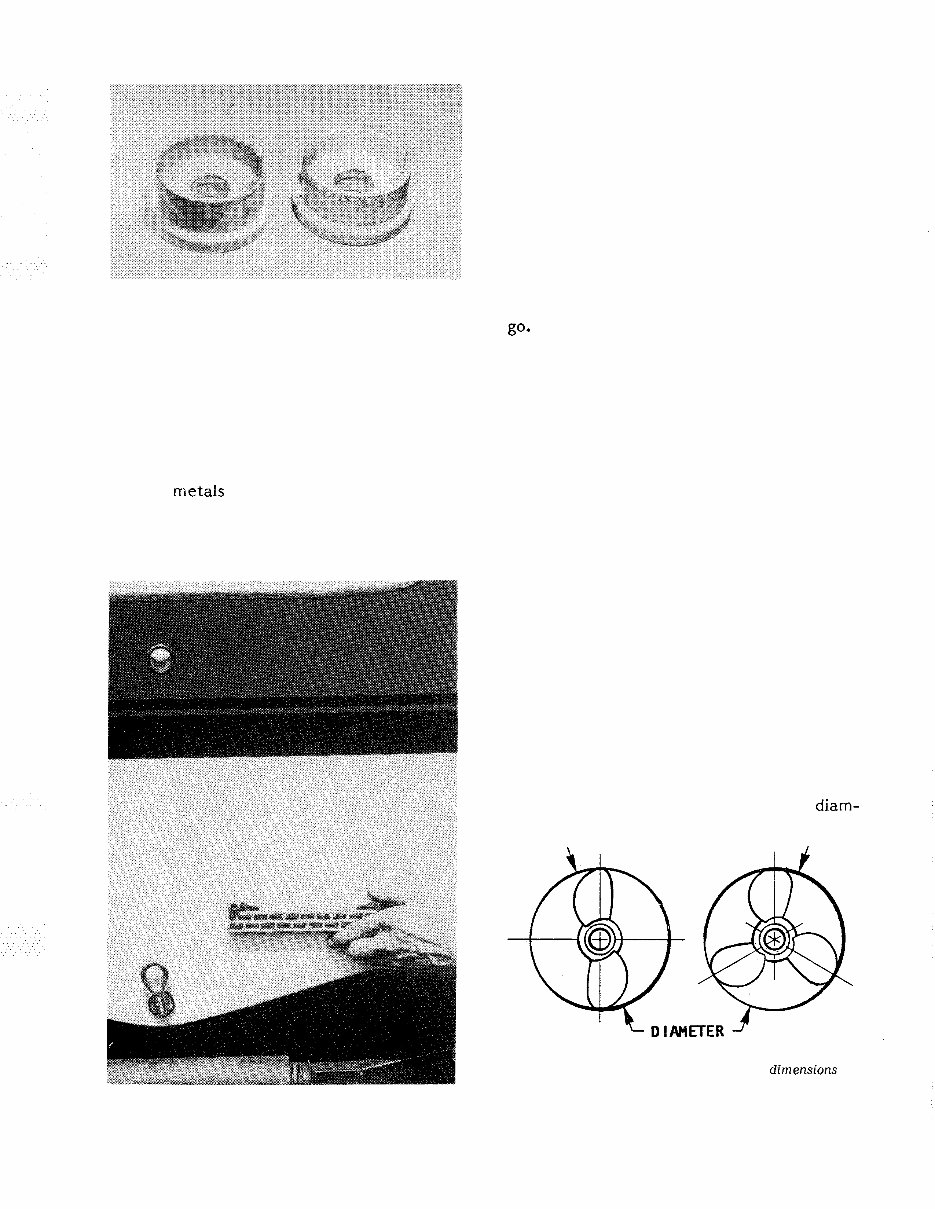

Diameter and Pitch

Only two dimensions of the propeller are

of real interest to the boat owner: the

diameter and the pitch. These two dimen -

sions are stamped on the propeller hub and

always appear in the same order: the diam-

Diameter and pitch are the two basic dimensions of

a propeller. The diameter is measured across the

circumference of a circle scribed by the propeller

blades, as shown.

(c) PDF Manual Publisher

PROPELLERS 1 - 3

eter first and then the pitch. Propellers

furnished with the outboard by the manufac -

turer for the units covered in this manual

have a letter designation following the pitch

size. This letter indicates the propeller

type. For instance, the numbers and letter

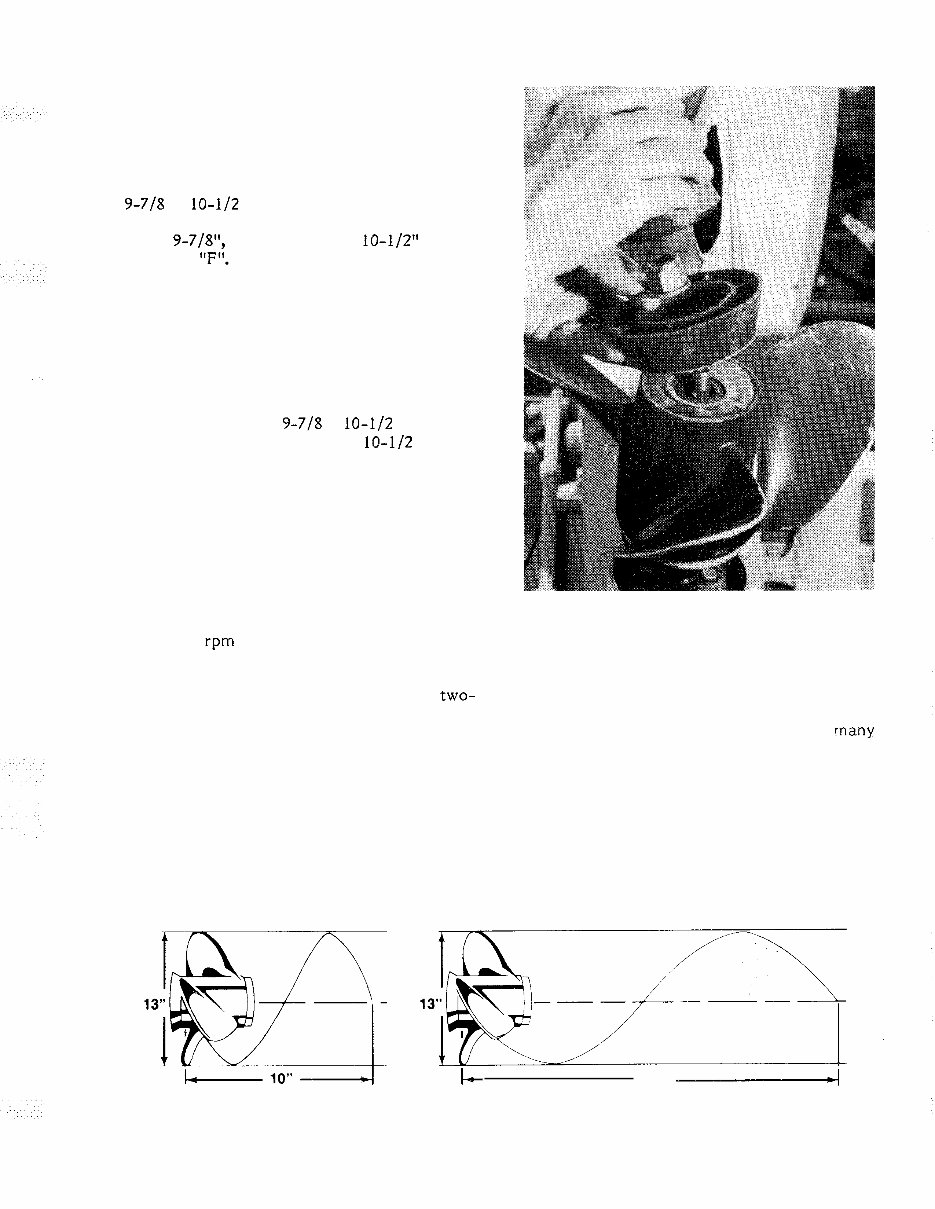

9-718 x 10-112 - F stamped on the back of

one blade indicates the propeller diameter

to be 9-7/8", with a pitch of 10-112" and it

is a Type "F".

The diameter is the measured distance

from the tip of one blade to the tip of the

other as shown in the accompanying illus -

tration.

The pitch of a propeller is the angle at

which the blades are attached to the hub.

This figure is expressed in inches of water

travel for each revolution of the propeller.

In our example of a 9-718 x 10-112 propeller,

the propeller should travel 10-112 inches

through the water each time it revolves. If

the propeller action was perfect and there

was no slippage, then the pitch multiplied by

the propeller rpms would be the boat speed.

Most outboard manufacturers equip their

units with a standard propeller having a di -

ameter and pitch they consider to be best

suited to the engine and the boat. Such a

propeller allows the engine to run as near to

the rated rpm and horsepower (at full throt -

tle) as possible for the boat design.

The blade area of the propeller deter -

mines its load - carrying capacity. A two-

blade propeller is used for high - speed run -

ning under very light loads.

A four - blade propeller is installed in

boats intended to operate at low speeds

under very heavy loads such as tugs, barges,

or large houseboats. The three - blade pro -

peller is the happy medium covering the

wide range between the high performance

units and the load carrying workhorses.

Diagram to explain the pitch dimension

through water if there were no friction.

Typical attaching hardware to secure the propeller

onto the propeller shaft.

Propeller Selection

There is no standard propeller that will

do the proper job in very many cases. The

list of sizes and weights of boats is almost

endless. This fact coupled with the many

boat - engine combinations makes the propel -

ler selection for a specific purpose a diffi -

cult task. Actually, in many cases the

propeller may be changed after a few test

runs. Proper selection is aided through the

use of charts set up for various engines and

boats. These charts should be studied and

C6 21" - 4

of a propeller. The pitch is the theoretical distance a propeller would travel

(c) PDF Manual Publisher

1 - 4 SAFETY

understood when buying a propeller. How-

ever, bear in mind, the charts are based on

average boats with average loads, therefore,

it may be necessary to make a change in

size or pitch, in order to obtain the desired

results for the hull design or load condition.

Propellers are available with a wide

range of pitch. Remember, a low pitch

takes a smaller bite of the water than the

high pitch propeller. This means the low

pitch propeller will travel less distance

through the water per revolution. The low

pitch will require less horsepower and will

allow the engine to run faster.

All engine manufacturers design their

units to operate with full throttle at, or

slightly above, the rated rpm. If t h e power-

head is operated at the rated rpm, several

positive advantages will be gained.

1 - Spark plug life will be increased.

2 - Better fuel economy will be realized.

3 - Easier steering qualities.

4- Best performance received from the

boat and power unit.

Therefore, take time to make the proper

propeller selection for the rated rpm of the

engine at full throttle with what might be

corsidered an " average " load. The boat will

then be correctly balanced between engine

and propeller throughout the entire speed

range.

A reliable tachometer must be used to

measure powerhead speed at full throttle to

EDGE

Cavitation (air bubbles) formed at the propeller.

Manufacturers are constantly fighting this problem, as

explained in the text.

ensure the engine will achieve full horse -

power and operate efficiently and safely.

To test for the correct propeller, make a

test run in a body of smooth water with the

lower unit in forward gear at full throttle.

If the reading is above the manufacturer's

recommended operating range, try propel -

lers of greater pitch, until one is found

allowing the powerhead to operate continu -

ally within the recommended full throttle

range.

If the engine is unable to del~ver top

performance and the powerhead is properly

tuned, then the propeller may not be to

blame. Operating conditions have a marked

effect on performance. For instance, an

engine will lose rpm when run in very cold

water. It will also lose rpm when run in salt

water as compared with fresh water. A hot,

low - barometer day will also cause the en -

gine to lose power.

Cavitation

Cavitation is the forming of voids in the

water just ahead of the propeller blades.

Marine propulsion designers are constantly

fighting the battle against the formation of

these voids due to excessive blade tip speed

and engine wear. The voids may be filled

with air or water vapor, or they may actual -

ly be a partial vacuum. Cavitation may be

caused by installing a piece of equipment

too close to the lower unit, such as the knot

indicator pickup, depth sounder, or bait tank

pickup.

Example of a damaged propeller. This unit should

have been replaced long before this amount of damage

was sustained.

(c) PDF Manual Publisher

PROPELLERS 1 - 5

Vibration

The propeller should be checked reg -

ularly to ensure all blades are in good condi -

tion. If any of the blades become bent or

nicked, this condition will set up vibrations

in the drive unit and the motor. If the

vibration becomes very serious it will cause

a loss of power, efficiency, and boat perfor -

mance. If the vibration is allowed to con -

tinue over a period of time it can have a

damaging effect on many of the operating

parts.

Vibration in boats can never be com -

pletely eliminated, but it can be reduced by

keeping all parts in good working condition

and through proper maintenance and lubri -

cation. Vibration can also be reduced in

some cases by increasing the number of

blades. For this reason, many racers use

two - blade props and luxury cruisers have

four - and five - blade props installed.

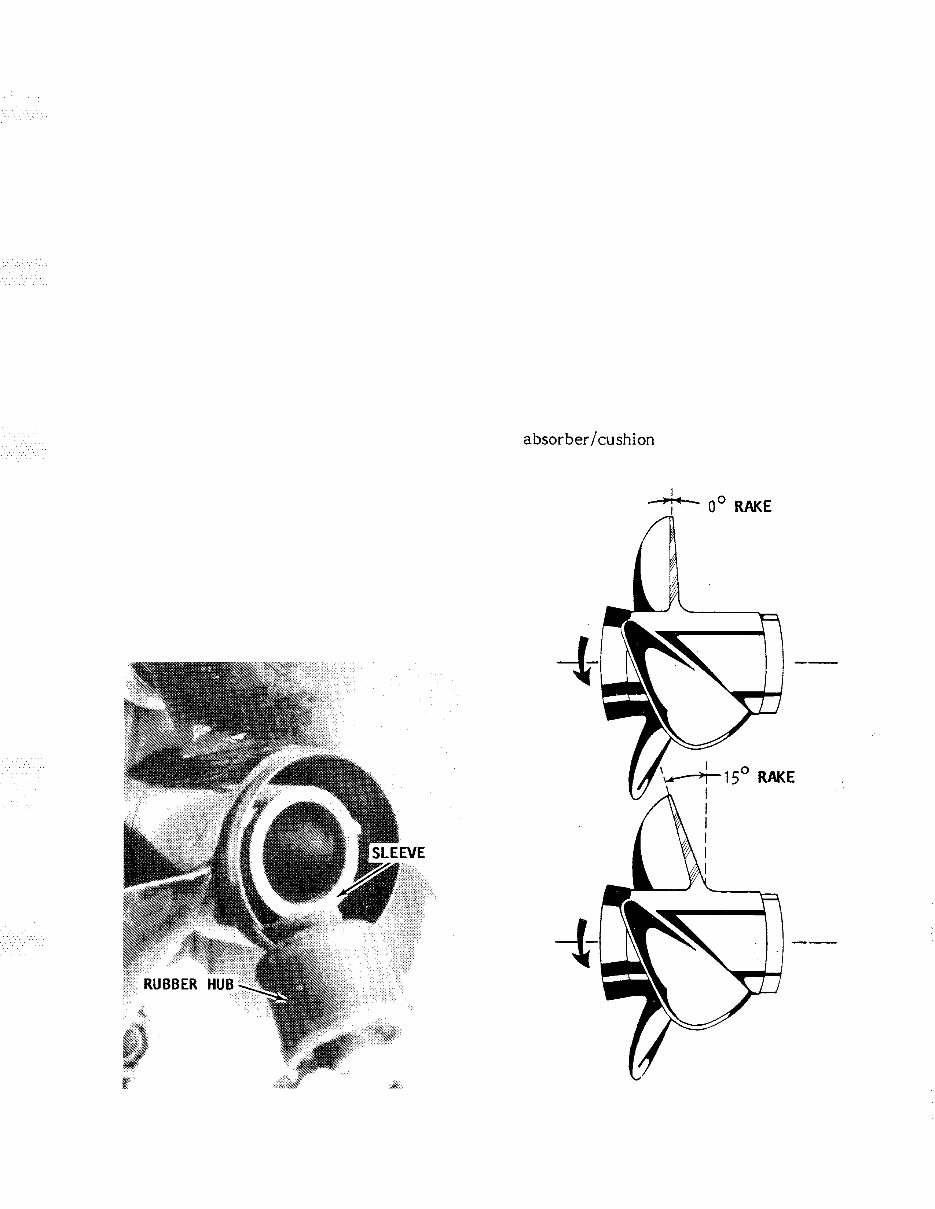

Shock Absorbers

The shock absorber in the propeller plays

a very important role in protecting the

shafting, gears, and engine against the shock

of a blow, should the propeller strike an

underwater object. The shock absorber al -

lows the propeller to stop rotating at the

instant of impact while the power train

continues turning.

Rubber hub removed from the propeller because the

hub was slipping in the propeller.

How much impact the propeller is able

to withstand, before causing the shock ab -

sorber to slip, is calculated to be more than

the force needed to propel the boat, but lets

than the amount that could damage any part

of the power train. Under normal propulsion

loads of moving the boat through the water,

the hub will not slip. However, it will slip if

the propeller strikes an object with a force

that would be great enough to stop any part

of the power train.

If the power train was to absorb an

impact great enough to stop rotation, even

for an instant, something would have to

give, resulting in severe damage. If a

propeller is subjected to repeated striking of

underwater objects, it would eventually slip

on its clutch hub under normal loads. If the

propeller should start to slip, a new shock

absorber/cushion hub would have to be in-

stalled.

Illustration depicting the rake of a propeller, as

explained in the text.

(c) PDF Manual Publisher

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

$44.99

Viewed 50 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

$44.99

- The 1966-1983 Chrysler Marine 3.5-140HP Engines Service & Repair Manual is a comprehensive technical manual designed for servicing, maintaining, troubleshooting, and replacing engine components.

- It includes step-by-step instructions, clear images, and exploded-view illustrations sourced from the manufacturer, making it suitable for both professional mechanics and DIY enthusiasts.

- This manual encompasses all troubleshooting and replacement procedures, torque specifications, and detailed images necessary for diagnosing, repairing, or overhauling the engine efficiently.

- It offers the convenience of easy access, searchability, and portability, making it more practical than traditional bound manuals. It is also printable for those who prefer physical copies.

- Printable: Yes

- Language: English

- Compatibility: Compatible with various electronic devices, including PC & Mac computers, Android and Apple smartphones & tablets, etc.

- Requirements: Adobe Reader (free)