CAR HAULER TRAILER PLANS FLAT BED

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

TABLE OF CONTENTS

TRAILERS

Athletic Trailer ..... ...... .... ... .... ........ .. .. .. ... .... . ........... .. .. .. . ... . .. ..... .. .... .. .... . ... ... ... . . .

Tandem Livestock Trailer .. . .. .... .. ..... . .. .. .... .. . ....... ... .... ..... .. ... . ... . ... .. ... .... . .. .. ... .. ... ... . .

The Design and Construction of a Tandem-Axle Automobile Transporter ....... .. .. .. .. ...... .... ... . ... . .

Design and Fabrication of Heavy-Duty Utilit y Trailer .. .. ..... .... .. ........ . ............ .. .. .. .... .... ..... .

Heavy-Duty Fifth Wheel Agricultural Trailer . .. . ... . ............. . .. ... .. .... ... .. .. .... . .. ..... .. ..... .. ... .

The Comb i nation Machiner y and Hay Trailer . .. .. ... ..... . .. . ... . ... .. ...... .. . ........ . ... .. .... . ..... ... .. .

Two Horse Trailer .. . .... . .. .. ..... . .... .. . ..... . ...... ..... ... . .. .. ... ..... .. ........... ... .. . .. . ....... .. .... . .

6 Ton Flat Bed Equipment Trailer .. .. .............. .. .. ...... . ......... ... ... ... ..... . ... ..... . .. . ..... .. .. .. .

Heavy Dut y Goo se-Neck Trailer .. .. .. . .. . .... .. ..... ... . .. . ..... .. ... . .. .. .. .. .. . ... ..... .. .. ... ....... ... .. . .

Building a Stock Trail er ... . .... .. . .... .. ... . .. ... .. ... .. ...... ....... .. .. .... .. .. . ..... . .... .. ... ... ........... .

A Trailer For Haulin g Carpentry Tools ... . ......... ........... . ........ . .. .. .... . ...... .. .. .. .. .. .... . ... ... . .

Double-Axle Flatbed Tr ailer . . .. .. .. .. .. . .... . .. . ... .. .. . ... .. . .. . ... .. .. .. ..... ... .. .. . ... ........ .. . ..... . . . . .

Tandem Axle, Boa t/ Utility Trailer .. ..... ... .. ... ..... . .. . .. . ............ . ... .. ...... ..... .. ........ . .. .. .. ... .

General Utility T·railer ................ .... .. . .. .. .. ..... .. . .... ... .. . .. . .. . .... . .. . ... . ............ . .. .. ....... .

Goo seneck Tr ailer ......... .... .... . .. .. ..... .. ... . ..... . ..... . ... .. .. ... . ...... ..... . .... . ... . .... . ... .. .. ... .. .

F abrication of a Tilt-Bed Tr ailer ....... ... ... .. . .. . ...... . ...... .. ..... . ...... . ... . .. .. .. . .. .. ..... . ... .. . ... . .

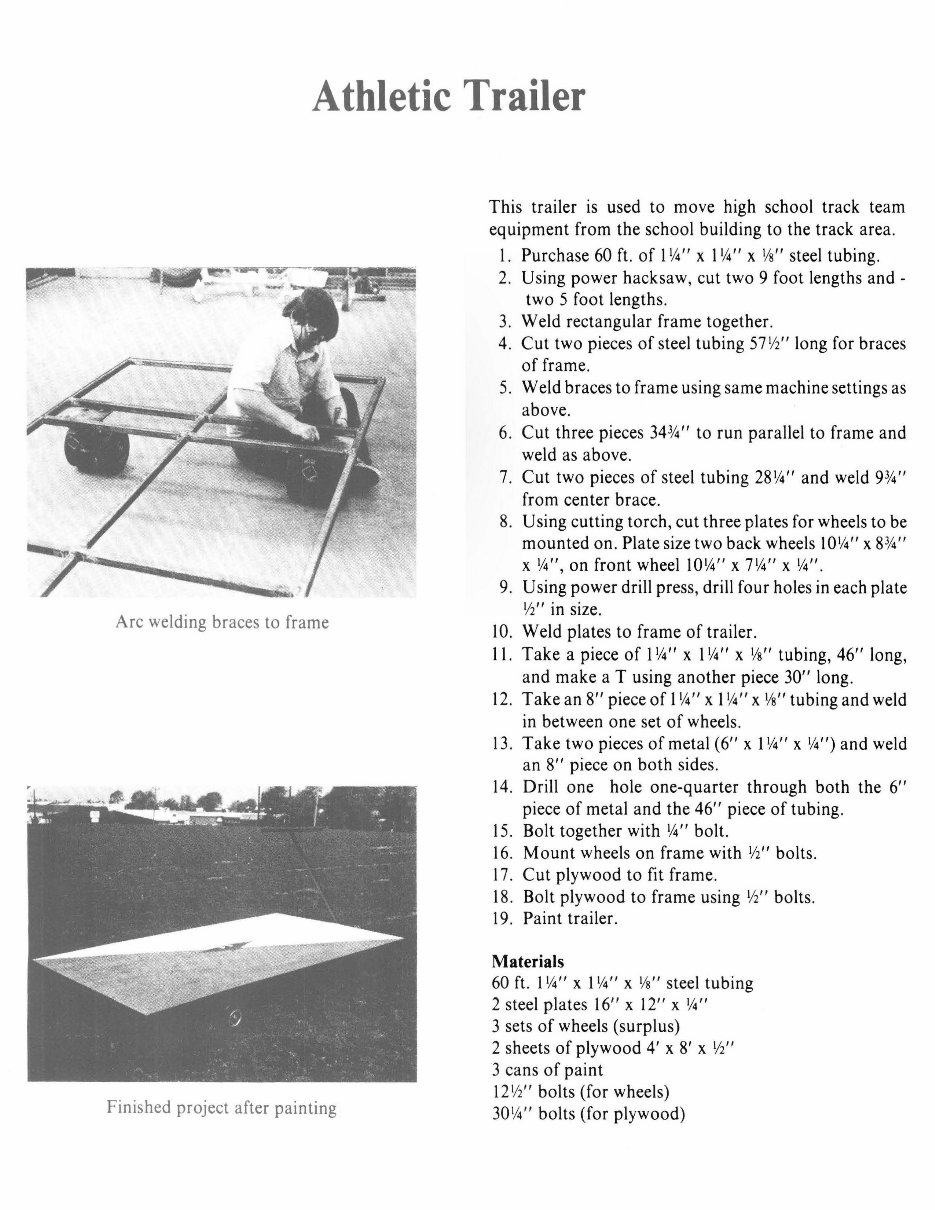

Athletic Trailer

Arc welding braces to frame

Finished project after painting

This trailer is used to move high school track team

equipment from the school building to the track area.

l . Purchase 60 ft. of 1

1

/4 " x l '14" x

1

/s" steel tubing.

2. Using power hacksaw, cut two 9 foot lengths and -

two 5 foot lengths.

3. Weld rectangular frame together.

4. Cut two pieces of steel tubing 57 1/i' ' long for braces

of frame.

5. Weld braces to frame using same machine settings as

above.

6. Cut three pieces 34 314' ' to run parallel to frame and

weld as above.

7. Cut two pieces of steel tubing 28'14" and weld 9314''

from center brace.

8. Using cutting torch, cut three plates for wheels to be

mounted on. Plate size two back wheels 10114'' x 8314' '

x 114'', on front wheel 10114'' x 7114'' x '14".

9. Using power drill press, drill four holes in each plate

1

12 " in size.

10. Weld plates to frame of trailer.

11 . Take a piece of 1114'' x l '14" x Ys" tubing, 46" long,

and make a T using another piece 30" long.

12 . Take an 8" piece of l '14 " x 1114'' x Ys " tubing and weld

in between one set of wheels.

13 . Take two pieces of metal (6" x l '14" x

1

/.i") and weld

an 8" piece on both sides.

14. Drill one hole one-quarter through both the 6"

piece of metal and the 46" piece of tubing.

15. Bolt together with 114'' bolt.

16. Mount wheels on frame with '12'' bolts.

17. Cut plywood to fit frame.

18 . Bolt plywood to frame using '12' ' bolts.

19. Paint trailer.

Materials

60 ft. 1114' ' x 1114'' x Ys " steel tubing

2 steel plates 16" x 12" x '14 "

3 sets of wheels (surplus)

2 sheets of plywood 4' x 8' x Yi''

3 cans of paint

12 1/i'' bolts (for wheels)

30 114'' bolts (for plywood)

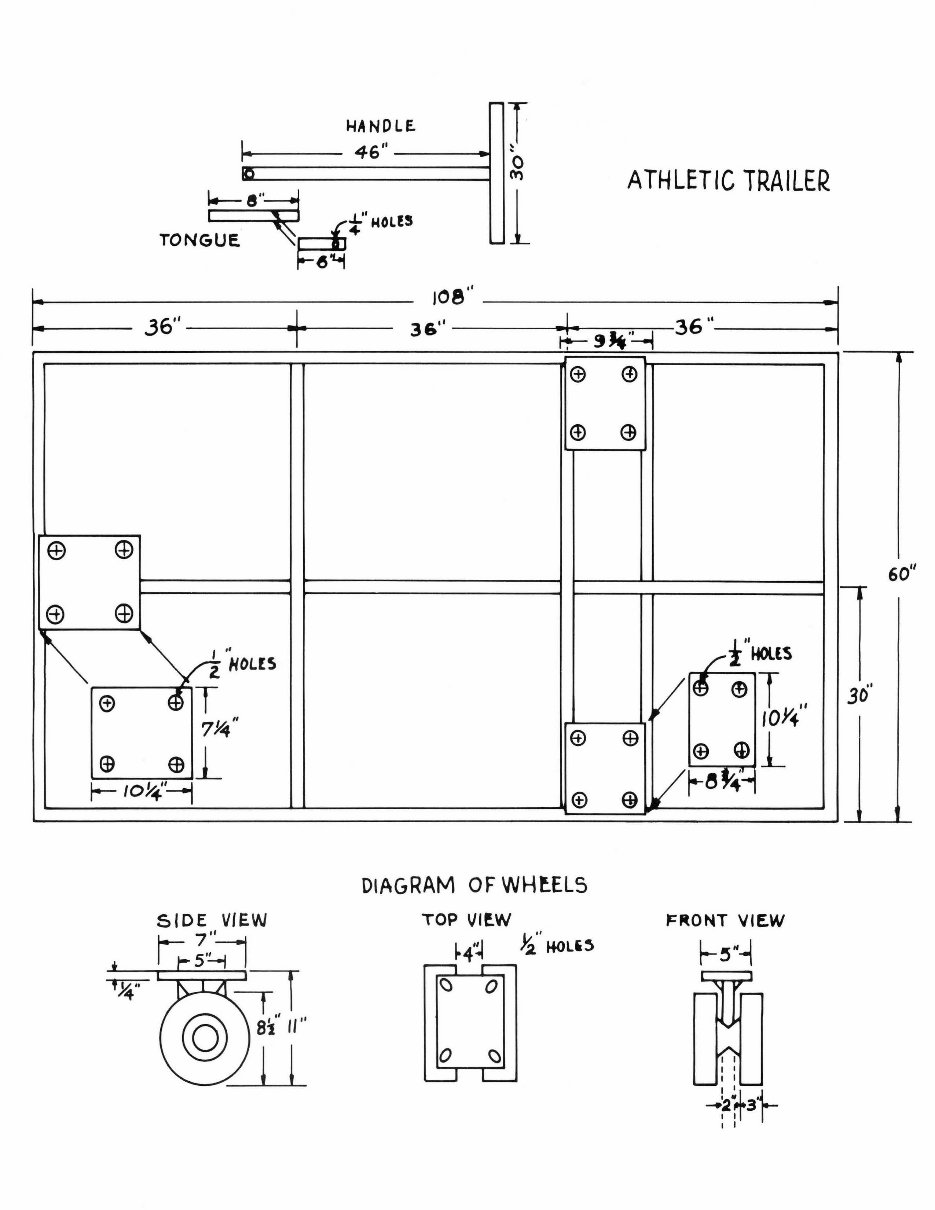

HA ND LE.

I·

46''

___ J

T

~

0

no,

~

TONG~~t" MOLE!

~

l

36''

---t--+-

I ,,

z HOLC5

T

DIAGRAM OF WH~EL5

TOP Vlf.W

~4·~ Ji" HOL'~

ATHLETIC TRAILER

~~ONT VIEW

~!5~-{

I I

I I

I I

I I

~2*3'1-

1 I

60"

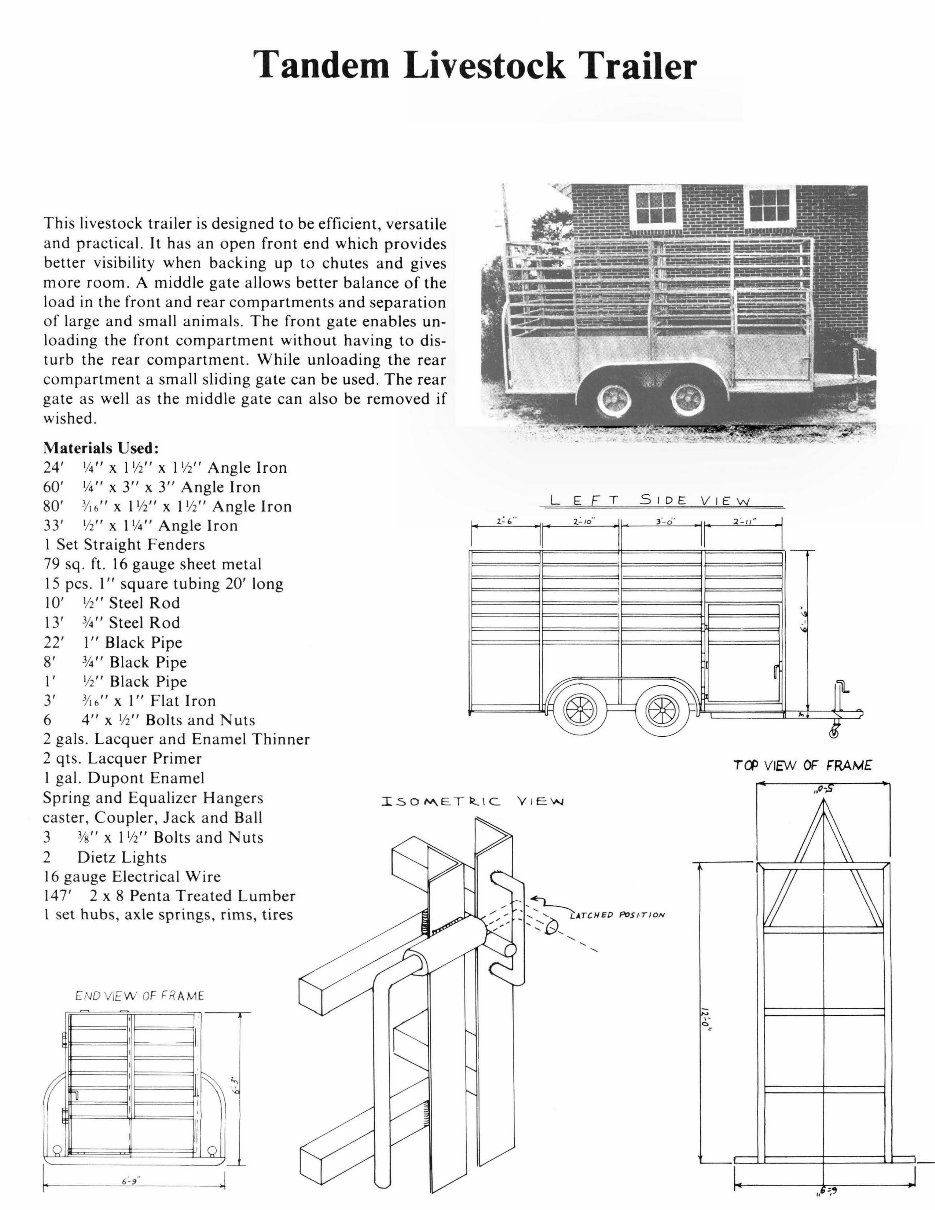

Tandem Livestock Trailer

This livestock trailer is designed to be efficient, versatile

and practical. It has an open front end which provides

better visibility when backing up to chutes and gives

more room . A middle gate allows better balance of the

load in the front and rear compartments and separation

of large and small animals. The front gate enables un-

loading the front compartment without having to dis-

turb the rear compartment. While unloading the rear

compartment a small sliding gate can be used. The rear

gate as well as the middle gate can also be removed if

wished.

Materials Used:

24'

1

/4 " x 1

1

/2

11

x 11/i' ' Angle Iron

60'

1

/4

11

x 3" x 3" Angle Iron

80' 3/ 16

11

x 1

1

/2

11

x I V2

11

Angle Iron

33' V2

11

x 1

1

/4

11

Angle Iron

I Set Straight Fenders

79 sq . ft. 16 gauge sheet metal

15 pcs . I" square tubing 20' long

IO' l/i' ' Steel Rod

13 ' 314'' Steel Rod

22' I" Black Pipe

8' 3/4

11

Black Pipe

l' l/i' ' Black Pipe

3' 3/16

11

x I" Flat Iron

6 4" x l/i' ' Bolts and Nut s

2 gals. Lacquer and Enamel Thinner

2 qt s. Lacquer Primer

I gal. Dupont Enamel

Spring and Equalizer Ha nger s

caster, Coupler , Jack and Ball

3 3/s " x 1

1

/2

11

Bolts a nd Nut s

2 Dietz Lights

16 gauge Electrical Wir e

147 ' 2 x 8 Penta Tre a ted Lumber

l set hubs , axle springs, rim s, tires

f

I

0

ENO VI EW OF FRAME

'

I

I

I

I

I

I

11

I

I

I

6-9

1;

,I

I

'

J

l

1

! 0 i

I

LE FT SIDE VI EW

1 ·

i-i."

II'

2.-10

..

I

: i-0'

I

2' 11"

--

I

I

~

~

I

· @!@

~

..

'

t

T (1) VIEW OF F'RAME

h ~'

The Design and Construction of

A Tandem-Axle Automobile Transporter

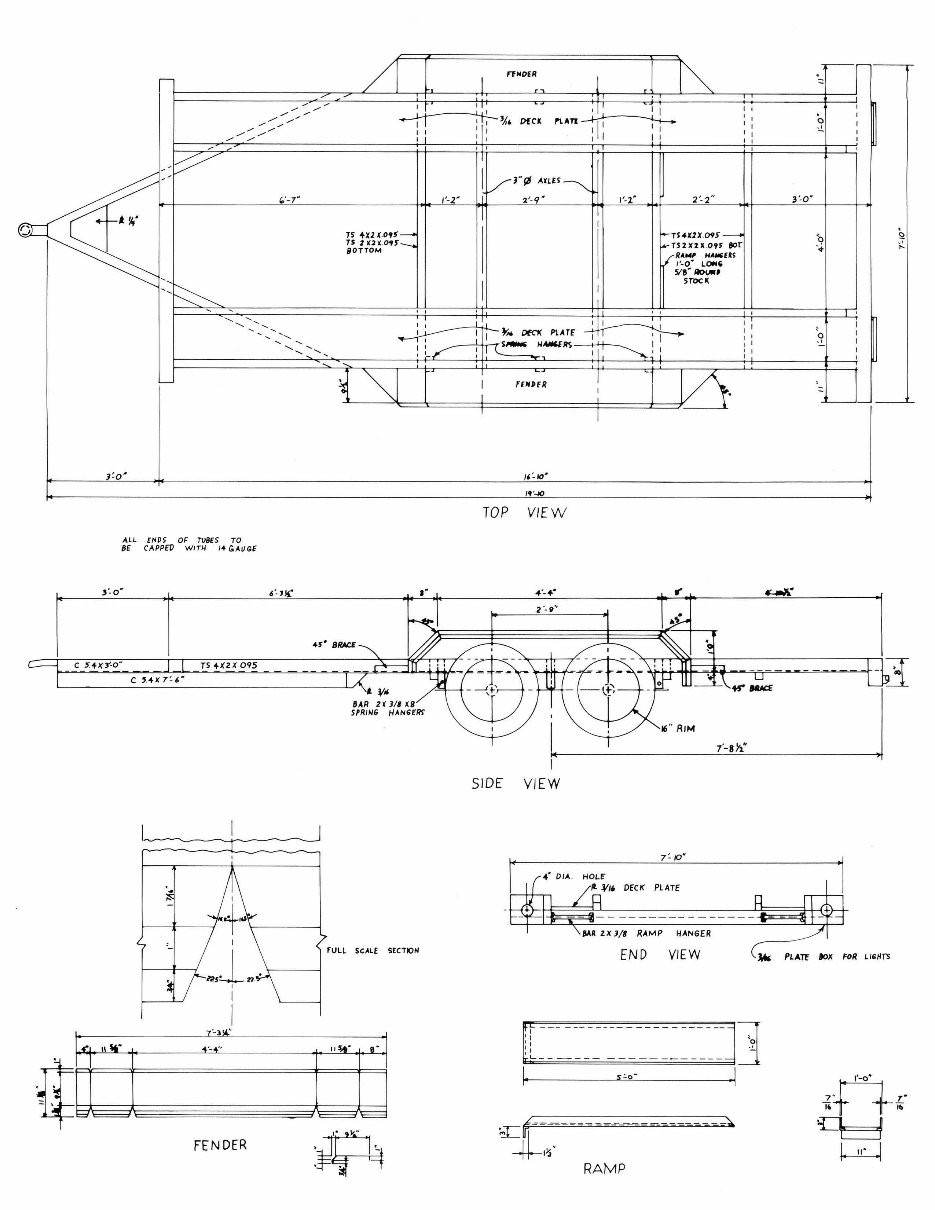

The tandem-axle assembly, complete with electric

brakes and leaf springs, was purchased from a house-

trailer manufacturer. The axles originally measured 77"

from center to center on the spring-hangers, and were

cut to 74" as specified on the prints.

The axles were shortened by removing a 3" section from

the center of each, fitting them with chill-rings, and tack-

ing them together in an angle-iron jig to maintain align-

ment. Wheel alignment was carefully checked with a

tape before the final welding.

The frame of the trailer was then cut, laid out, squared,

and tacked together. The 4 longitudinal sections were 2"

x 4" x .095 rectangular tub ing and the 2 end pieces were

4" x 4" x .250 square tubing.

12 spring hangers were made from 2" x 3/ s" flat bar,

measuring 8" in length overall, and 7" to the center of

the Ys" hole. This length allows 3" travel space for spr-

ings and axels. The bottom end of each hanger was

rounded off with a torch and ground smooth .

The blueprints specified that the center of the spring-axe!

assembly will be 6" back from the actual center of the

frame to insure proper balance when the trailer is

loaded.

The center pairs of hangers were welded to the frame at

this mid-point and the front and back pairs were welded

to align with spring mounting holes.

5

/s" bolts were used

to mount springs.

The cross-supports were placed directly in front of the

front hangers and directly behind the back hangers. The

top supports, made from 2" x 4" x .095 tubing fit

between the two inside longitudinal pieces and flush with

the frame. The bottom supports made from 2" x 2" x

.095 tubing, extend to the outside edge of the frame and

tie into the spring hangers to support the whole struc-

ture.

One additional 2" x 2" x .095 cross-support was welded

under the frame to help support the ramps and also the

rear wheels of the automobile .

The frame was then suspended and leveled on blocks for

the construction of the tongue.

The tongue was designed so that the distance from the

front edge of the 4" x 4" crossmember to the center of the

ball would be 3 feet. Since a standard pick-up bed is

about 6 feet wide, a diagonal measurement of slightly

over 3 feet was needed for clearance, so that the truck

could be turned in excess of 45°.

The tongue was constructed from 4" x 5.4 standard

channel with the two long sections welded to the under-

side of the frame and the two short sections welded flush

with the frame. The front of the tongue was cut and

beveled to fit the forged steel V-type coupler purchased

for the trailer. The hitch had a 2 inch ball and a 5,000

pound capacity.

3

/ 16

11

deck plate was then sheared to 1 foot widths and

notches for the spring hangars were flame-cut. The plate

was then leveled, tacked, and welded to the rectangular

tubing with #7018 in a staggered intermittent sequence

for minimum distortion.

A slight camber occured during welding of the underside

and was corrected by flame-heating the top of the curve

and allowing contraction to correct the camber.

The fenders, constructed of 14 gauge steel, were designed

to be functional as well as attractive.

The fender design was fairly complex, using triangula-

tion to determine angles and requiring a right and left

side. The back of each fender extends 4" below the frame

to eliminate the need for mud flaps. Triangular gussets

were attached front and back to reinforce the fenders

vertically and also horizontally.

The steel was sheared, notched, and the longitudinal

bends were made on a cornice brake. Fabrication of a 9"

male die for the press brake was necessary to make the

four lateral bends.

The back piece was spot-welded to the fenders and

micro-wire was used for finishing and to attach the

fenders to the frame.

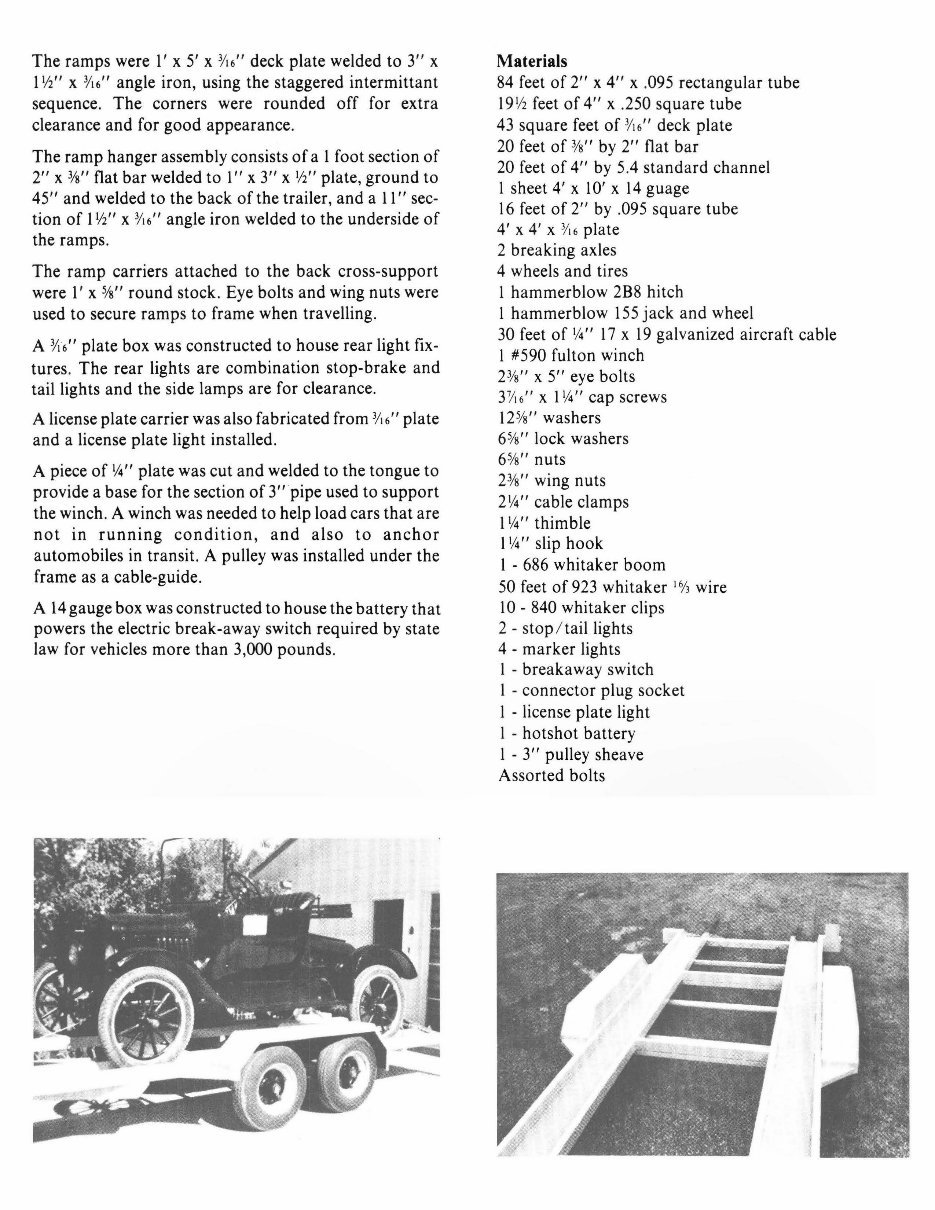

The ramps were 1' x 5' x 3/ 16" deck plate welded to 3" x

11/i' ' x

3

/ 16" angle iron, using the staggered intermittant

sequence. The corners were rounded off for extra

clearance and for good appearance.

The ramp hanger assembly consists of a 1 foot section of

2" x

3

/s" flat bar welded to l" x 3" x l/i'' plate, ground to

45" and welded to the back of the trailer, and a 11" sec-

tion of 1 V2" x :Y16" angle iron welded to the underside of

the ramps .

The ramp carriers attached to the back cross-support

were l' x

5

/s" round stock. Eye bolts and wing nuts were

used to secure ramps to frame when travelling.

A :Y 16" plate box was constructed to house rear light fix-

tures. The rear lights are combination stop-brake and

tail lights and the side lamps are for clearance.

A license plate carrier was also fabricated from

3

/ 16" plate

and a license plate light installed.

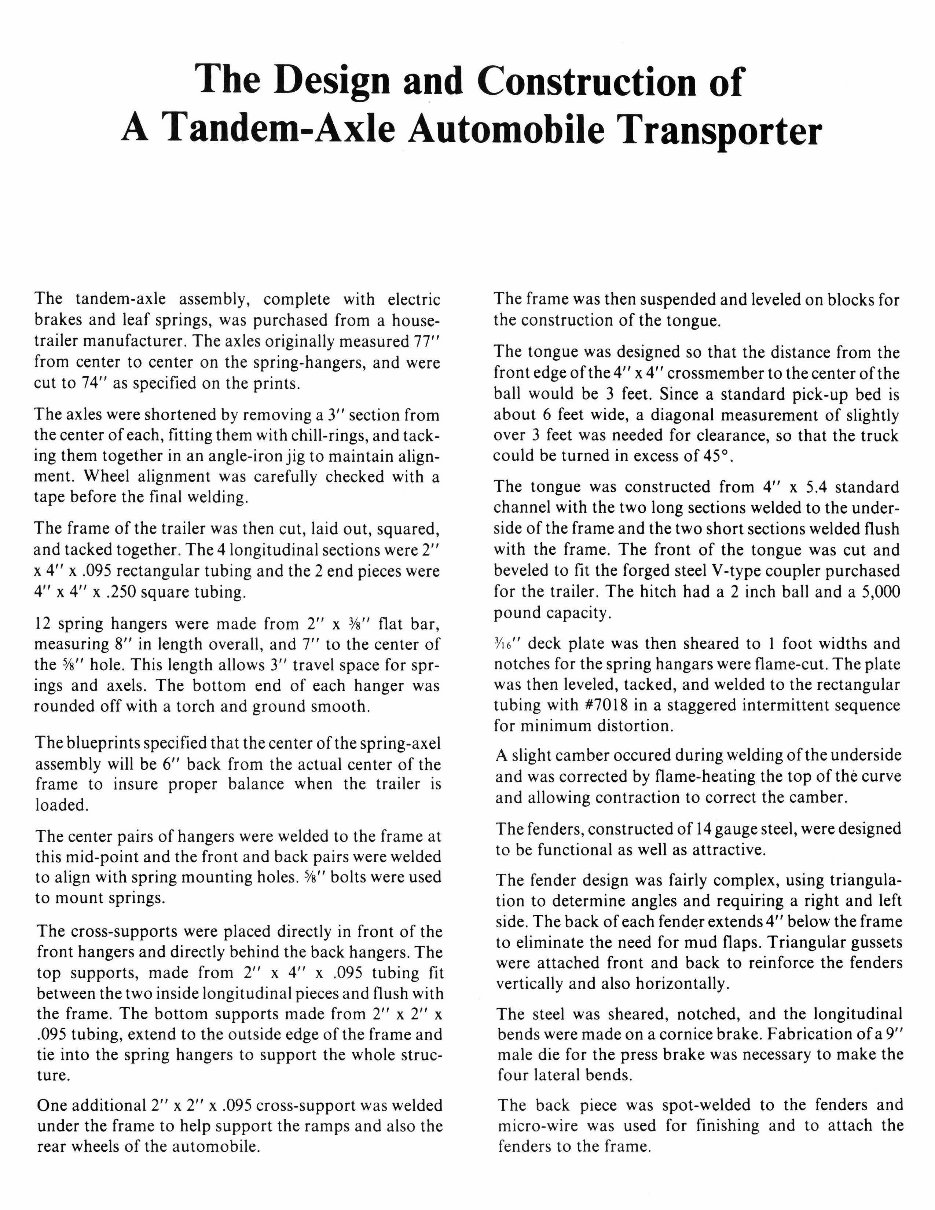

A piece of If.I'' plate was cut and welded to the tongue to

provide a base for the section of 3" pipe used to support

the winch. A winch was needed to help load cars that are

not in running condition, and also to anchor

automobiles in transit. A pulley was installed under the

frame as a cable-guide.

A 14 gauge box was constructed to house the battery that

powers the electric break-away switch required by state

law for vehicles more than 3,000 pounds .

Materials

84 feet of 2" x 4" x .095 rectangular tube

19

1

/2 feet of 4" x .250 square tube

43 square feet of

3

/ 16" deck plate

20 feet of 3/s' ' by 2" flat bar

20 feet of 4" by 5.4 standard channel

1 sheet 4' x 10' x 14 guage

16 feet of 2" by .095 square tube

4' x 4' x 3/ 16 plate

2 breaking axles

4 wheels and tires

1 hammerblow 2B8 hitch

l hammerblow 155 jack and wheel

30 feet of

1

/.i " 17 x 19 galvanized aircraft cable

l #590 fulton winch

23/s' ' x 5" eye bolts

31 1 16" x l If.I'' cap screws

12 5/s " washers

6 5/s' ' lock washers

6 5/s " nuts

23/s' ' wing nuts

21/.i'' cable clamps

l If.I'' thimble

l If.I'' slip hook

l - 686 whitaker boom

50 feet of 923 whitaker

1

6/3 wire

l 0 - 840 whitaker clips

2 - stop / tail lights

4 - marker lights

l - breakaway switch

l - connector plug socket

l - license plate light

l - hotshot battery

l - 3" pulley sheave

Assorted bolts

ALL ENO~ OF TU8£S TO

~E CAPPfD WITll 14 GoAUGE

C , .4K 7'. 6'

·•

I

f---.J------1 ·+~ >------ ---<

I

"2$1., . ,________.

I

I

I I

~'fi'•l>fCl

l I I I

TS +x2 (.OfS

rs z i2v: . 09r

BOTTOM

I I o

i' -2'

' I I

l'LATI~ I' I

I I

I I I I

TS·UZX.09.f

TS2X2l .095 901'.

RA.M' HA1115U~

1'-0" LON{;

5te·-,

STOCK

TOP VIEW

FULL SGALf SECTIOM

END VIEW

I

'

'

I

I

I

I I

I

i'-4''

E-- ~--- - __ ___ _______ ]]

Ef1

FEN DER

. ~-

.

.

q::::t-- -- = -~ --- ---~-- ---- __ ,.

~,~·

RAMP

-

0

·'

3·. o·

::

PLAT£ IOX FOR L IGHfS

Design and Fabrication of

Heavy-Duty Utility Trailer

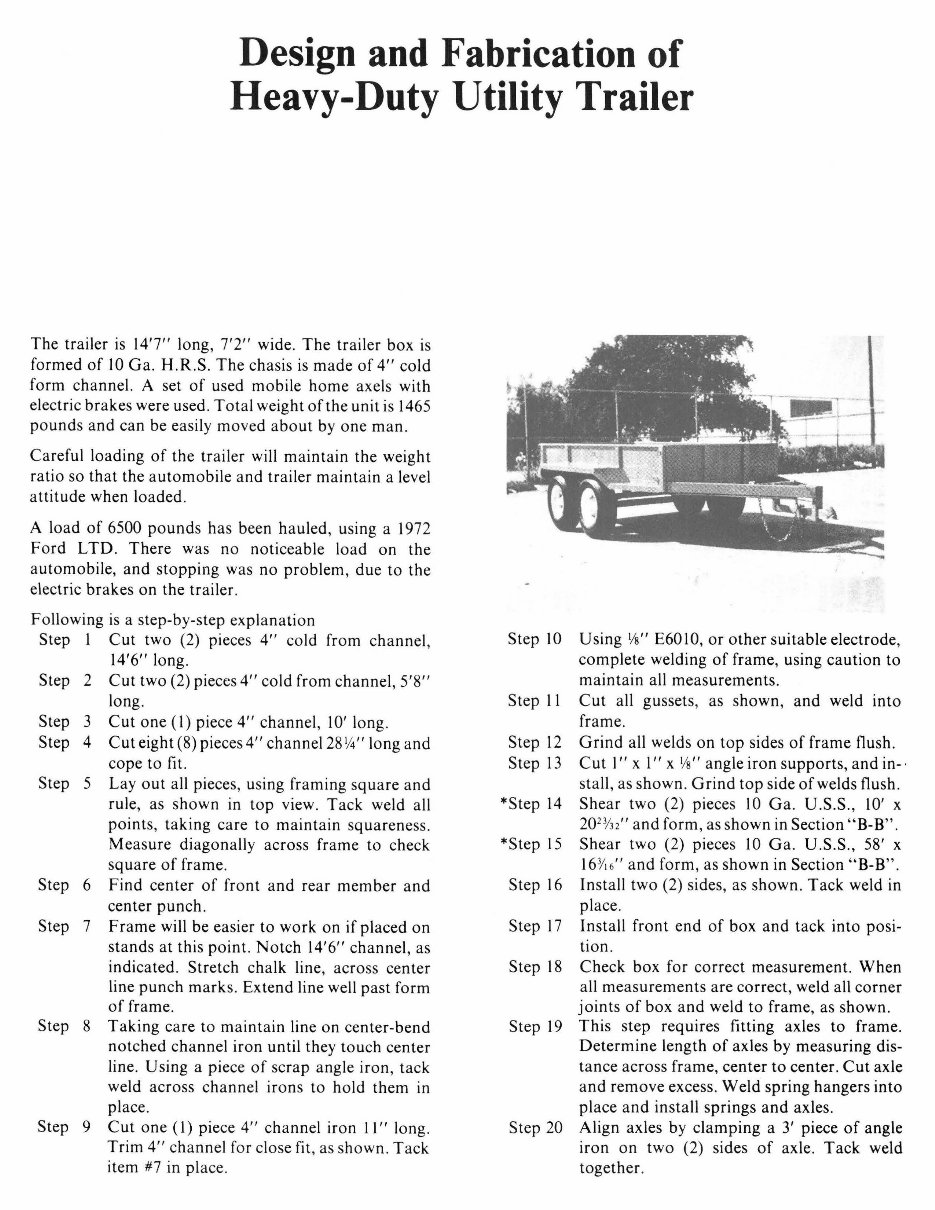

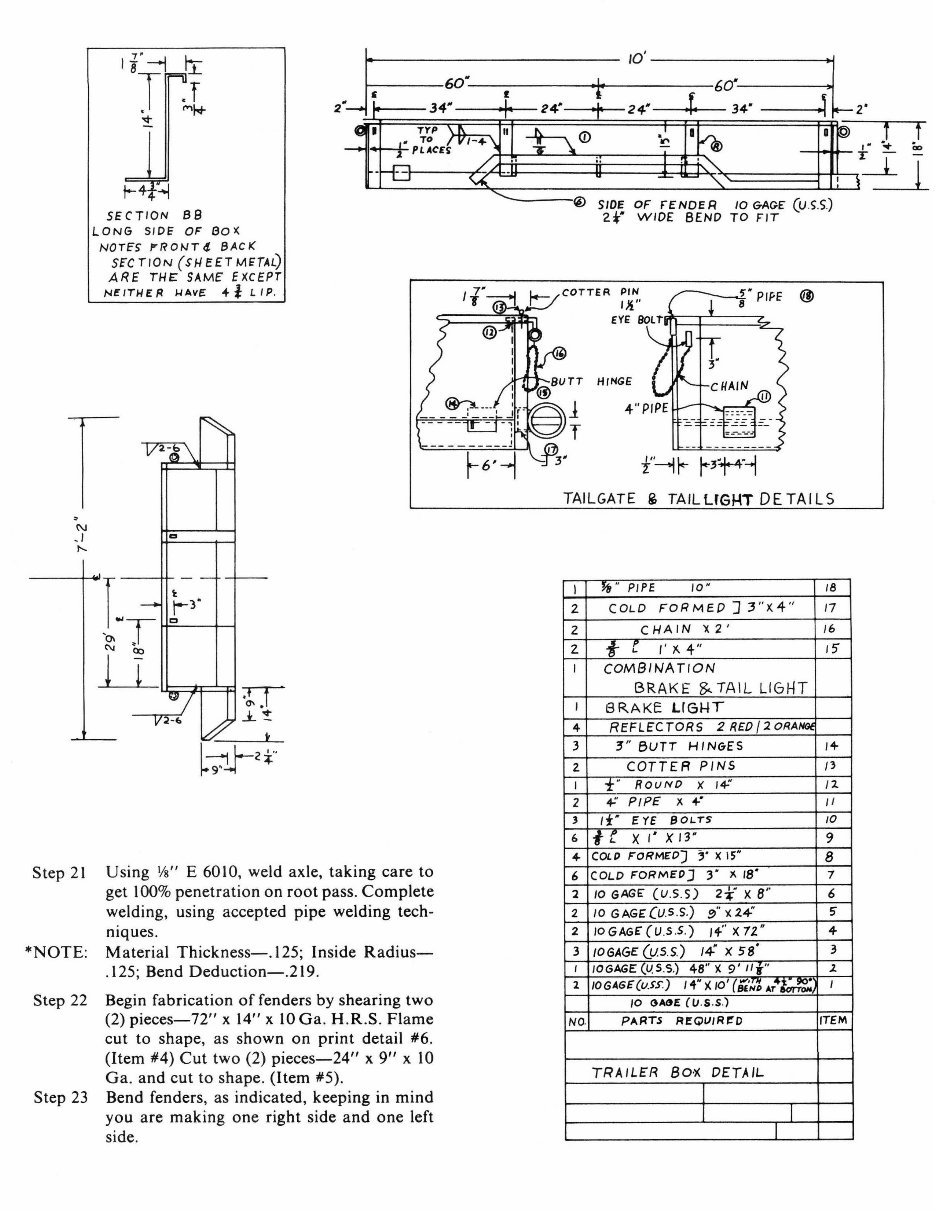

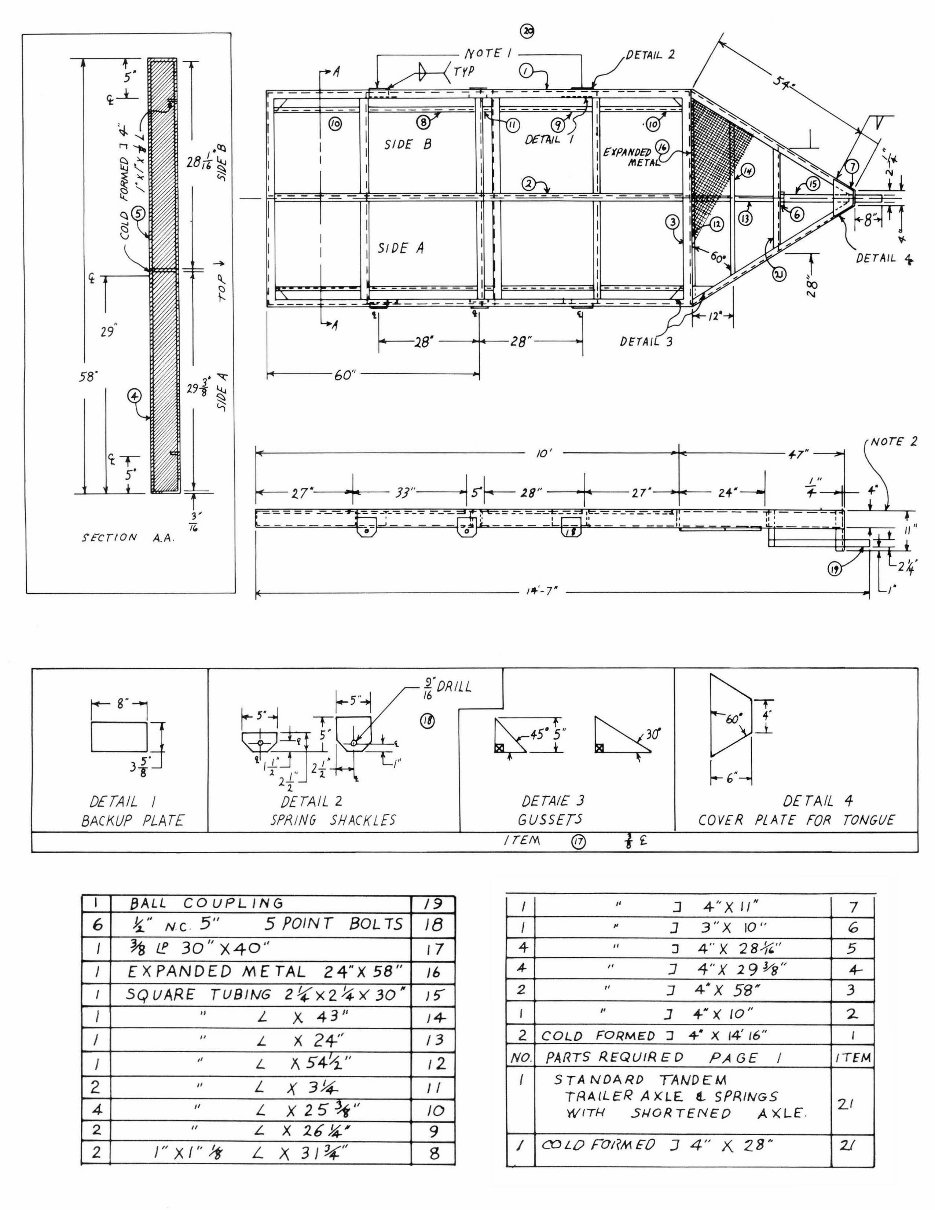

The trailer is 14'7" Jong, 7'2" wide. The trailer box is

formed of 10 Ga. H.R.S. The chasis is made of 4" cold

form channel. A set of used mobile home axels with

electric brakes were used . Total weight of the unit is 1465

pounds and can be easily moved about by one man.

Careful loading of the trailer will maintain the weight

ratio so that the automobile and trailer maintain a level

attitude when loaded .

A load of 6500 pounds has been hauled, using a 1972

Ford LTD. There was no noticeable load on the

automobile, and stopping was no problem, due to the

electric brakes on the trailer.

Following is a step-by-step explanation

Step 1 Cut two (2) pieces 4

11

cold from channel,

14

1

6

11

long.

Step 2 Cut two (2) pieces 4

11

cold from channel , 5'8"

long.

Step 3 Cut one ( 1) piece 4

11

channel, 10' long.

Step 4 Cut eight (8) pieces 4

11

channel 28

1

.4 " long and

cope to fit.

Step 5 Lay out all pieces, using framing square and

rule, as shown in top view . Tack weld all

points , taking care to maintain squareness .

Measure diagonally across frame to check

square of frame.

Step 6 Find center of front and rear member and

center punch.

Step 7 Frame will be easier to work on if placed on

stands at this point. Notch 14

1

6

11

channel, as

indicated. Stretch chalk line, across center

line punch marks. Extend line well past form

of frame.

Step 8 Taking care to maintain line on center-bend

notched channel iron until they touch center

line. Using a piece of scrap angle iron, tack

weld across channel irons to hold them in

place.

Step 9 Cut one (I) piece 4

11

channel iron 11

11

long.

Trim 4

11

channel for close fit, as shown. Tack

item #7 in place.

Step 10 Using Vs" E6010, or other suitable electrode,

complete welding of frame, using caution to

maintain all measurements.

Step 11 Cut all gussets, as shown, and weld into

frame.

Step 12 Grind all welds on top sides of frame flush.

Step 13 Cut 1

11

x 1

11

x Vs " angle iron supports, and in- ·

stall, as shown. Grind top side of welds flush .

*Step 14 Shear two (2) pieces 10 Ga. U .S.S ., 10' x

20

2

3/32

11

and form, as shown in Section "B-B" .

*Step 15 Shear two (2) pieces 10 Ga . U .S.S., 58' x

16

3

/ 16

11

and form, as shown in Section "B-B".

Step 16 Install two (2) sides, as shown. Tack weld in

place.

Step 17 Install front end of box and tack into posi-

tion .

Step 18 Check box for correct measurement. When

all measurements are correct, weld all corner

joints of box and weld to frame, as shown.

Step 19 This step requires fitting axles to frame.

Determine length of axles by measuring dis-

tance across frame, center to center. Cut axle

and remove excess. Weld spring hangers into

place and install springs and axles.

Step 20 Align axles by clamping a 3' piece of angle

iron on two (2) sides of axle. Tack weld

together.

1f-j

T

'It-

SECTION 88

LONG SIDE: OF aox

NOTE'S f'RONT4 BACI(

SE'C TION (HI EET METAL)

ARE THE SAME' EXCEPT

Nt:IT11ER "4AVE: fl LIP.

r

Step 21 Using Vs" E 6010, weld axle, taking care to

get l 00% penetration on root pass. Complete

welding, using accepted pipe welding tech-

niques.

*NOTE: Material Thickness-.125; Inside Radius-

.125; Bend Deduction-.219.

Step 22 Begin fabrication off enders by shearing two

(2) pieces-72" x 14" x 10 Ga . H.R.S . Flame

cut to shape, as shown on print detail #6.

(Item #4) Cut two (2) pieces-24" x 9" x 10

Ga. and cut to shape. (Item #5).

Step 23 Bend fenders, as indicated, keeping in mind

you are making one right side and one left

side.

SIDE OF FENDER IOGAG£ (U.S.S.)

2t• WIDE BEND TO FIT

f"--1 r- r-Jt-4"-1

TAILGATE i TAILUGHT DETAILS

I

W' PIPE 10 " 18

2 COLD FOR MEO] 3"X4 " 17

2 CHAIN 'X 2' 16

2. !- r

,. x. 4" 15'

I COMBINATION

BRAKE ~TAIL LIGHT

I

BRAKE LIGHT

4 REFLE'CTORS 2 REO / 2 ORANG#.

3 ~"BUTT HINGES I+

2. COTTER PINS /3

I t• ROUND x

,~

I l.

2 +· PIPE' x +· II

3 1t• EYE 80L"TS 10

6

tr

X 1• X13 " 9

4- COLP FORMED] ;• XIS"

8

6 COLD FORMEP J

3· x 1s· 7

2 10 GAGE' (U.5.S) 2¥ )( 8" 6

2 10 GAG£ (u.s.s.) !}" x2+ 5'

2 IOGAGE'(U .S .5 . ) 1+" x n· 4-

3 /06AGE (u.s .s.) 14 x sa· 3

I IOGAGE (U.5 .5 .) 48 " X 9' Ill'" .2.

2 JO GAGE (u.ss:) I 4• '/.. 10

1

( {E. ' /./'o AT.,.~ I

10 GME (lJ .s .s.)

NO. PAFITS REQUIR~O ITEM

TRAILFR 80·X DETAIL

I

I I

I

@

[}fTAIL 2

If

r- --

I

I

@

I

I

I , .<:fl

I

281[~

I

~

2

I

-- - - --------

I

I

I

51 DE A

I

I

-

I

If: Cl..

I

I

I_

1--------

~

- ------- - ---------

I

- -- -- - -----

"

L:o

l--w·

J

28"~

29

[)E'TAIL 3

58'

10 '

+ ]J"--1 s-f-- 28'' ------

-= = = =- ----=-

_______

S'FCrtON A.A.

9•

~1

1s· -,

r-5 "1

l6 OR/LL

r-

5

·1 T @

q.;t

~+

~~

~-w·

~·

t ,. q , •

L t

~ . .]

.38 IT /" 21

1-

2.

DETAIL I DETAIL 2 DETAIE J DETAIL 4

BACKUP PLAT£ SPP. I NG SHACKLES GUSSETS COVER PLATE FOR TONGUE

I TEM

@ £

I 8ALL COUPLING 19

I

,,

J 4" x 11"

7

6 ~ " NC 5" 5 POINT 80L TS 18

I

~

] 3"X 10" 6

I ~ l! 30" X40'' 17

4

"

J 4" x 2 8./(4 " 5

I £ X PAND£D M £ TAL 24"X 58" 16

~

,,

]

4"X 29~ " 4--

2

"

J 4•x 58" 3

I SQUARE TUBING 2 !( x 2 ~ >< 30 " ) 5'

I " L

x

4311

J~

I

,,

] +"X 10" 2

I " L x 24-'' /3

2 COLD FORMED J +· x 14' 16" I

I

,,

L x. 5 4-'.1. '' 12

NO. PARTS REQUIR £ D PA GE I ITEM

I 5 TA NOA RD TANDEM

TRA.tL£R AXLE 4.. SPRINGS

2..1

WITH 51-!0P.TENEO AXLE".

2 "

L x 3hf._ II

4-

,,

L x 25 ~" JO

2

"

L

x 261'.' 9

2 I" x / '' Jt L x 31 ~" 8

I O'.J LO FOt?M FO J 4" x. 28H 21

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 16 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Nice neatly made 45 paged book on trailer plans.

- Tilt-bed, gooseneck, sports utility, tandem axle

- Boat, double axle flatbed hauling carpentry tools

- Stock, heavy duty goose neck, 6 ton flatbed, two horse

- Combination machinery/hay, heavy duty fifth wheel agricultural

- Heavy duty utility, tandem axel automobile, livestock car hauler flat bed with ramps

Complete instructions, material lists, measured drawings and diagrams.

All pages can be printed out on your own computer. This is a high quality high resolution file.