International 6 Plus Transmission Manual SPICER 7 Speed

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

TRANSMISSION

TECHNOLOGIES

Corporation

Technology in Motion

®

MODELS

ES52-7B

ES56-7B

ES066-7B

7 SPEED

TRANSMISSION

Service Manual

Bulletin No. 2366

Revised August 2002

Tech Support 1-800-401-9866

TABLE OF CONTENTS

SECTION I — GENERAL INFORMATION

SPECIFICATIONS ......................................................................................................... 1

TORQUE SPECIFICATIONS ......................................................................................... 2

DRIVER INSTRUCTIONS ............................................................................................. 3

SECTION II — MAINTENANCE

LUBRICATION .............................................................................................................. 4

TOOL REFERENCE ..................................................................................................... 5

SECTION III — GENERAL DISASSEMBLY ............................................................................. 6

SECTION IV — SHIFT TOWER DISASSEMBLY ...................................................................... 8

SECTION V — REAR CASE DISASSEMBLY

REAR CASE EXPLODED DRAWING ........................................................................... 9

REAR CASE GEARS EXPLODED DRAWING ............................................................ 10

REAR CASE DISASSEMBLY ...................................................................................... 11

REAR CASE DISASSEMBLY (OPTI-RAIL) ................................................................. 16

SECTION VI — MAIN CASE DISASSEMBLY

MAIN CASE EXPLODED DRAWING .......................................................................... 21

CLUTCH HOUSING & SHIFT FORKS EXPLODED DRAWING ................................. 22

MAIN CASE DISASSEMBLY ....................................................................................... 23

MAIN CASE DISASSEMBLY (OPTI-RAIL) .................................................................. 26

SECTION VII — MAINSHAFT DISASSEMBLY

MAINSHAFT EXPLODED DRAWING ......................................................................... 29

MAINSHAFT DISASSEMBLY ...................................................................................... 30

SECTION VIII — COUNTERSHAFT DISASSEMBLY & REASSEMBLY ................................ 32

SECTION IX — CLEANING & INSPECTION PROCEDURES ............................................... 33

SECTION X — MAINSHAFT REASSEMBLY ......................................................................... 34

SECTION XI — MAIN CASE REASSEMBLY ......................................................................... 36

MAIN CASE REASSEMBLY (OPTI-RAIL) ................................................................... 38

SECTION XII — REAR CASE REASSEMBLY ....................................................................... 41

REAR CASE REASSEMBLY (OPTI-RAIL) .................................................................. 45

SECTION XIII — SHIFT TOWER REASSEMBLY ................................................................... 50

SECTION XIV — TROUBLESHOOTING ................................................................................ 51

Tech Support 1-800-401-9866

GENERAL

INFORMATION

SECTION I

1

Gear Ratios

ES52-7B ES066-7B

ES56-7B

Gear Ratio Ratio % Step

Rev. 8.99 6.66

1st 10.09 7.48

—69—

2nd 5.98 4.43

—61—

3rd 3.72 2.76

—45—

4th 2.56 1.90

—41—

5th 1.81 1.34

—34—

6th 1.35 1.00

—35—

7th 1.00 .074

Specifications

Torque Capacity ........................ ES52-7B - 520 lbs. ft. (704 nm)

ES56-7B - 560 lbs. ft. (758 nm)

ESO66-7B - 660 lbs. ft. (894 nm)

Ratio Coverage .......................... 10:1

Synchronized ............................. Gears 2-7

Length ....................................... 35” (clutch housing mounting face to washer seat face)

Weight ....................................... 454 lbs. (206 kg)

Clutch Housing .......................... SAE No. 2

Clutch ........................................ 13” or 14” single or 2-plate push or pull

Input Shaft ................................. 1 3/4” - 10-spline or 1 1/2” - 10-spline

Lube Capacity ........................... 22 pints (10.4 liters)

Speedometer ............................. Provision for mechanical and electronic

Power Take-Off .......................... 6-bolt right & left, countershaft rear

34 tooth 18° right-hand helix

17.50° pressure angle

PTO Speeds: ............................. % of engine RPM ES52-7B, 48.8%

ES56-7B, 48.8%

ES066-7B, 65.8%

General Application Guidelines

On-Highway Use

ES56-7B

ES52-7B ES066-7B

GVW: 50,000 lbs. 65,000 lbs.

HP Range: 155 - 210 HP 185 - 250 HP

RPM Range: 1,800 - 3,000

Engine Types: 5 - 9 Liter Diesel

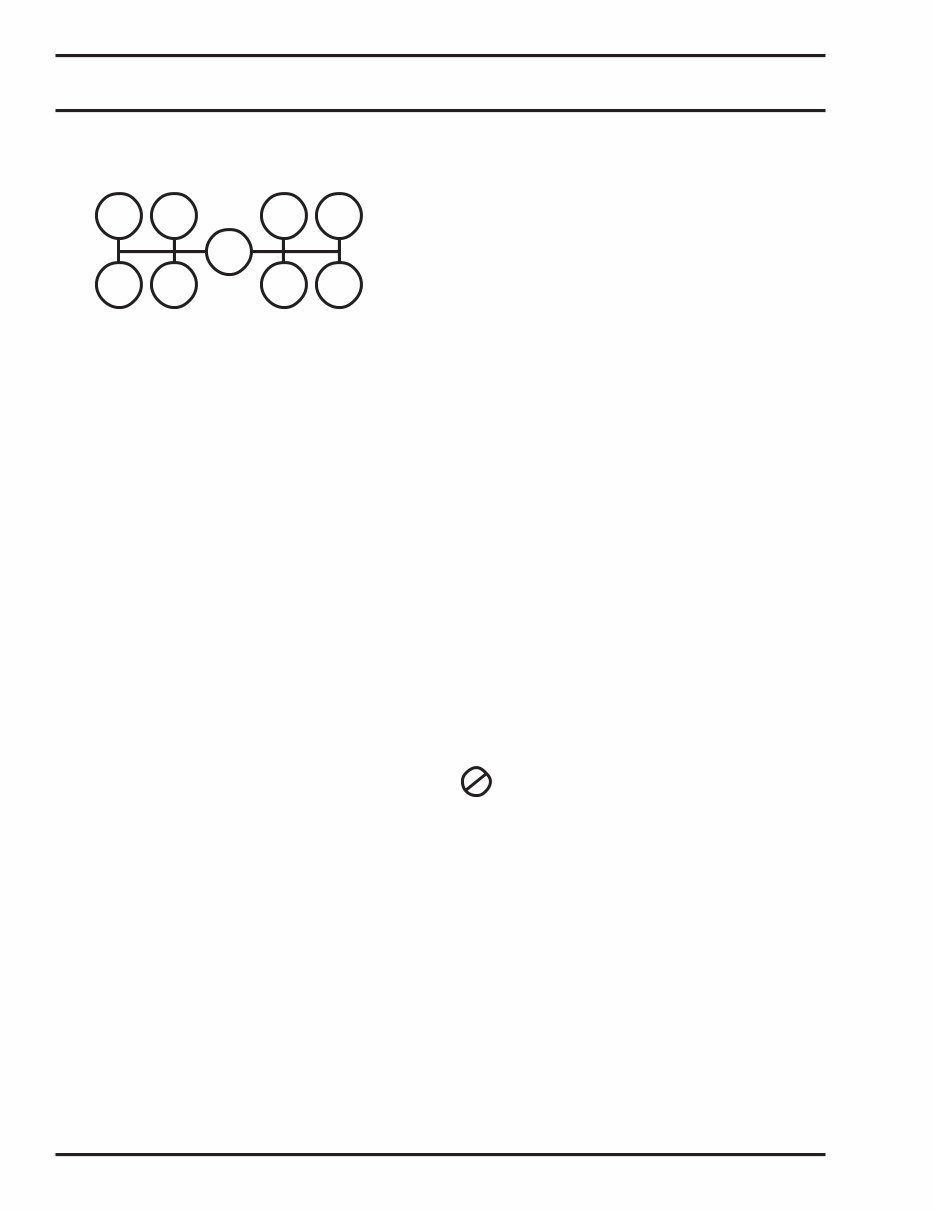

Simple Shift Pattern

R 2 4 6

1 3

N

5 7

Tech Support 1-800-401-9866

GENERAL

INFORMATION

SECTION I

2

TORQUE SPECIFICATIONS FOR NUTS AND CAP SCREWS

Nom. Size (Dia.) Wrench Torque (ft. lbs.)

Part Name

Inches mm Min. Max.

.375 10 Oil trough (16 x .750) 25 41

.375 10 Intermediate shift bar support

(16 x 1.00) 25 41

.375 10 Front mainshaft bearing cap

(16 x 1.00) 25 41

.375 10 Overdrive linkage (16 x 1.00) 25 41

.375 10 Rear mainshaft bearing cap

(16 x 1.125) 25 41

.375 10 Rear countershaft bearing cap

(16 x 1.125) 25 41

.375 10 Clutch housing to main case

(16 x 1.25) 25 41

.375 10 Front shift bar support

(16 x 2.250) 25 41

.438 11 Rear mainshaft brake cap

(14 x 1.25) 40 56

1.062 27 Shift tower trunnion 100 125

.375 10 6-bolt PTO aperture cover 25 41

1.250 32 Mainshaft output nut 300 325

2.548 65 Intermediate mainshaft (spanner) nut 300 325

.875 23 Backup light switch 40 40

Tech Support 1-800-401-9866

GENERAL

INFORMATION

SECTION I

3

How to Shift the Spicer Easy-Shift

7-Speed Transmissions

Synchronizer Information

The purpose of a synchronizer is to simplify shifting and help

deliver clash-free shifts. Only 1st and reverse gears aren’t

synchronized.

To shift, the driver depresses the clutch and moves the lever

toward the desired gear. When the synchronizer ring makes

contact with the desired gear, “blockers” automatically prevent

the shift collar from completing the shift until the gear and

mainshaft speeds are matched. When the speeds are matched,

the synchronizer allows the shift to be completed without

clashing.

Steady pressure on the shift lever helps the synchronizer do

its job. When speeds are synchronized, the lever moves into

gear smoothly and easily. If the driver jabs or “teases” the

synchronizer, the synchronizer can’t do its job. It is possible to

override a blocker if the lever is forced into gear. However, this

defeats the purpose of the synchronizer and can shorten the

life of the transmission.

Driver Instructions

Upshifting

To drive a vehicle containing this transmission, first depress

the clutch and wait for complete release. Next, move the shift

lever into 1st gear and engage the clutch. Accelerate to an

RPM that will allow enough momentum to select the next

higher gear and still have vehicle acceleration after complet-

ing the shift into 2nd gear. This is known as the progressive shift

technique. Using this shift technique saves fuel. There is usually

no reason to go all the way to the governor before you shift to

1

R 2

3

N

4

5

6

7

2nd gear. This method can vary depending on the GVW of the

vehicle, road conditions, and type of service.

When 2nd gear is desired, declutch and move the shift lever

toward that gear. The synchronizer will pick up 2nd gear and

synchronize its speed to the mainshaft speed. When synchro-

nized, the lever moves easily into 2nd gear.

Continue in the same manner to top road speed. Notice that as

you approach top road speed you must accelerate close to

the governed speed before allowing the engine to drop to the

next gear shift point. This is because air resistance at higher

speeds requires more of the available horsepower to get

adequate performance. Maximum performance and horse-

power are achieved at governed speed.

Downshifting

To begin downshifting form top gear, declutch and move the

shift lever steadily toward 6th gear and speed it up to the vehicle

speed. This will allow a clash-free shift from 7th to 6th gear. After

the shift, reengage the clutch while accelerating the engine to

keep the vehicle moving at the desired speed. If further

downshifts are required, continue in a similar manner.

Remember that 1st gear isn’t synchronized. Therefore, shift-

ing into gear will require a double clutch operation to complete

a clash-free shift.

Towing

Do not tow vehicles without first pulling the axles

or disconnecting the driveshaft. If you tow the

vehicle without doing this, you can damage drive train

components because the system lubrication is inad-

equate when the vehicle is towed.

Tech Support 1-800-401-9866

4

MAINTENANCE

SECTION II

Lubrication

To insure proper lubrication and operating tem-

peratures in this unit, the proper lubricants

must be used. Correct oil levels must be main-

tained. TTC recommends using only lubricants produced by

reputable, well-known suppliers. If you want to use a lubricant

not specified below, please contact your local truck dealer to

determine whether the lubricant is suitable for your purposes.

Recommended Lubricants

The lubricants listed below are recommended for use in all Spicer

mechanical transmissions, auxiliaries, and transfer cases.

Oil Changes

For off highway use, TTC recommends that the oil be changed

after the first 24 hours of service, but before 100 hours of service

have been completed.

Many factors influence the following oil change periods. There-

fore, a definite mileage interval is not specified here. In general,

a drain and flush should be scheduled at 50,000 miles,

or one-year intervals. If synthetic oil is used, a drain and flush

should be scheduled at 500,000 miles, or 5 year intervals. Off-

highway uses usually require an oil change every 1,000 hours.

The oil level in the transmission should be checked every 5,000

miles (8045 km) on-highway, or every 40 hours in off-highway

operation. When it is necessary to add oil, TTC recommends

that types and brands of oil not be mixed. The correct oil level in

this transmission is established by the filler plug opening.

Refill

First, remove all dirt around the filler plug. Then refill the

transmission with now oil. Use the grade recommended for the

existing season and prevailing service. The lubricant should be

level with the oil fill plug located on the right side of the

transmission case.

Overfilling

Do not overfill the transmission. This usually results in oil

breakdown due to excessive heat and aeration form

the churning action of the gears.

Early breakdown of the oil will result in heavy varnish

and sludge deposits that plug up oil ports and build up on splines

and bearings.

!

TEMPERATURE GRADE TYPE

Above 0°F (-18°C) SAE 30 or 40 Heavy duty engine oil meeting MIL-L-2104 D or

Below 0°F (-18°C) SAE 30 MIL-L-46152 B, API-SF, or API-CD

(MIL-L-2104 B & C, or 46152 are also acceptable)

Above 0°F (-18°C) SAE 90 Straight mineral gear oil

Below 0°F (-18°C) SAE 80 R & O type API-GL-1

All CD SAE 50 Synthetic engine oil meeting

CD SAE 30 MIL-L-2104 D or MIL-L-46152 B,

API-SF or API-CD

Do not use extreme pressure additive such as those found in multi-purpose or rear axle type lubricants. These

additives are not required for this unit and my, in some cases, create transmission problems. Multi-purpose oils, as a

group, have relatively poor oxidation stability, a high rate of sludge formation, and a greater tendency to react on or

corrode the bronze parts in this transmission.

Tech Support 1-800-401-9866

5

MAINTENANCE

SECTION II

Tool Reference

This Spicer transmission can be repaired with ordinary

mechanic’s tools. However, if your transmission has a mainshaft

intermediate nut rather than a snap ring, vehicle downtime can

be minimized with the use of this special socket. It is available

through Sealed Power Corporation, part number OEM6599

To order, contact:

OTC Division

Sealed Power Corporation

O.E.M. Sales

655 Eisenhower Drive

Owatonna, MN 55060

Phone: (800) 533-6127

Fax: (800) 283-8665

Tech Support 1-800-401-9866

GENERAL

DISASSEMBLY

SECTION III

6

Important Procedure

To locate and correct unit power or auxiliary transmission

troubles, a systematic procedure should be followed.

Road test whenever possible. Mechanics usually get second-

or third-hand reports of trouble experienced with the unit. These

reports do not always accurately describe the actual

conditions. Sometimes symptoms seem to indicate trouble in

the transmission, while actually the problem is with the axle,

driveshaft, universal joints, engine or clutch. This is especially

true of noise complaints. Therefore, before removing the

transmission or related components to locate trouble, road

test to check the possibility of trouble in other closely associ-

ated units. Road testing is most effective when the mechanic

drives the vehicle. However, riding with the driver can be very

informative.

Check Functioning

Prior to Disassembly

If a remote control is used, a careful check of the remote and

connecting linkages (and their adjustment) must be made. The

remote unit must be in good working order if the transmis-

sion is expected to shift satisfactorily.

Many times, the answer to the trouble is apparent when the unit

is inspected prior to disassembly. But this evidence is often lost

when the parts are separated. If possible, check the

unit prior to disassembly. Bear in mind that a careful inspection

of the unit should be made as each disassembly step is

performed.

Inspect Thoroughly

During Disassembly

It is poor practice to disassemble a unit or the complete

transmission as quickly as possible without examining the

parts. The mechanic may completely dissemble a unit and fail

to find the cause of the trouble, unless he examines the parts.

After the transmission is disassembled, check the lubricant

for foreign particles, This is a source of trouble often overlooked

during the disassembly.

Repair or Replace Worn Parts

Many times the parts or critical adjustments causing the trouble

are not replace or corrected because the mechanic only

inspects and replaced parts that have failed completely. All

pieces should be carefully examined because broken parts

are often just the result—not the cause—of the problem. All

parts that are broken or worn and no longer meet specifications

should be replaced.

Also, parts that are worn to the extent that they do not have a

long service life remaining should be replace. Replacing

these parts now will avoid another teardown on the unit in the

near future. Also at this time, make the recommended changes

or modifications to bring the transmission up to date and

increase the service life of the unit.

Tech Support 1-800-401-9866

GENERAL

DISASSEMBLY

SECTION III

7

Read this section before starting the

detailed disassembly proce-dures.

Follow each procedure closely in

each section, making use of both text and

pictures.

Rebuild Facilities

A suitable holding fixture or overhaul stand with a hole for the

input shaft is desirable.

For easier working conditions, table height should be 28 - 30

inches. A light chain hoist should be used to handle the

mainshaft and countershaft during removal and reassembly

procedures.

Cleanliness

Transmissions should be steam cleaned prior to disassembly.

Seal all openings before steam cleaning to prevent entry of dirt

and water which can damage serviceable parts.

Dirt is abrasive and will cause premature wear of bearings and

other parts. TTC suggests that mechanics have a wash tank

available to clean parts just prior to reassembly.

Bearings

When a transmission is removed at relatively low mileage,

bearings should be removed with pullers designed for this

purpose. Wrap the bearings to keep out dirt. Clean, inspect,

and lubricate all bearings just prior to reassembly. If accumu-

lated mileage is over 150,000 miles, we suggest that all

bearings be replaced. If bearings are worn or damaged,

always replace them regardless of mileage.

!

End Yokes and Flanges

Do not hammer on end yokes and flanges to

remove or install them. It is not only destructive to

the yoke or the flange itself, but can also cause

serious internal damage. Hammering destroys or

mutilates the pilot diameters and warps or bends the flange.

Hammering on end yokes will close-in the bearing bores or

misalign yoke lugs. This will result in early failures of journal

needle bearings.

Serious damage can be done internally to bearings, thrust

faces and washers, pilot bearings, etc., by hammering on

external parts. In most designs, when the yoke/flange locknuts

are tightened and secure, the internal bearings and gears are

in proper location. When the yoke/flange is driven on the shaft,

however, two conditions can exist.

(a) If the bearing fit is tight on the shaft, usually the bear-

ings will brinell as they must absorb the pounding force.

(b) If the bearing fit is loose, the shaft will keep moving

inward until it is stopped by the internal parts such as

the pilot bearing thrust washers.

Power Take-Offs

Refer to your owner’s manual and installation procedures

when installing any PTO on your transmission.

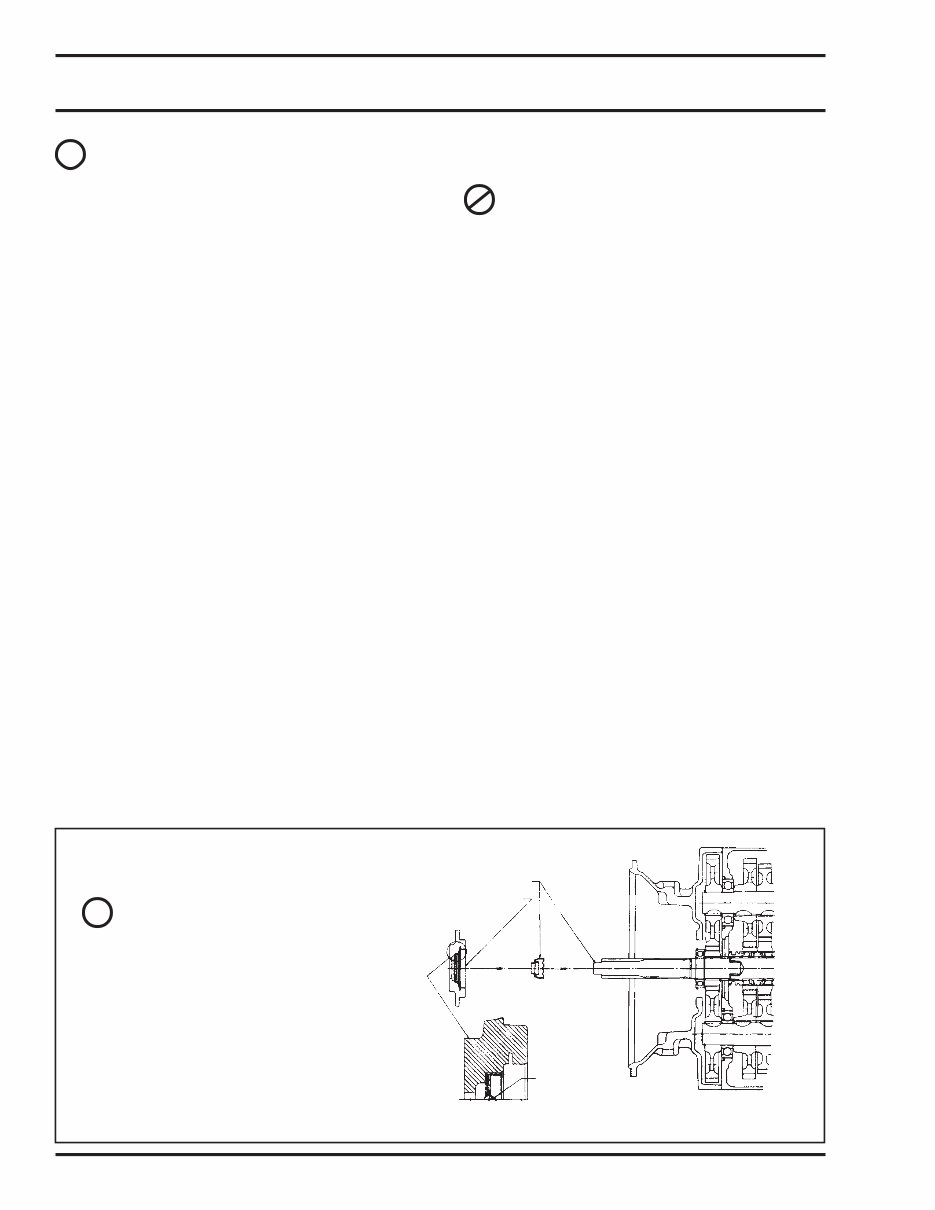

Front Bearing Retainer & Seal

When installing the front bearing

retainer and seal in the transmis-

sion, use the red plastic sleeve to

prevent serious damage to the oil

seal. Failure to use the seal sleeve

will void the seal warranty.

!

PUSH SLEEVE OVER END OF SHAFT

INSTALL BEARING CAP ASSEMBLY

AFTER RED SLEEVE IS IN PLACE

INSTALL SEAL DRY

HYDRODYNAMIC LIP

SEAL MUST BE INSTALLED SO THAT HYDRODYNAMIC

LIP FACES TOWARD INSIDE OF TRANSMISSION

REMOVE SEAL CARDBOARD SHIPPING TUBE OR

PLASTIC INSTALLATION SLEEVE JUST PRIOR TO

INSTALLING BEARING CAP ASSEMBLY TO

TRANSMISSION

Tech Support 1-800-401-9866

SHIFT TOWER

DISASSEMBLY

SECTION IV

8

Shift Tower Disassembly

1. Begin disassembly by cutting the two tie cables which

secure the boot.

2. Slide the boot off the shift lever.

3. Remove the two trunnion screws.

4. Lift the lever from the tower.

5. To remove the shift yoke from the lever, simply press out

the pivot pin.

6. Wash all parts. Inspect them thoroughly for damage.

Replace parts as necessary.

HANDLE

UPPER TIE CABLE

BOOT

LOWER TIE CABLE

SHIFT LEVER

PIVOT PIN

YOKE

BOSS

SHIFT TOWER SCREW

SHIFT TOWER

TRUNNION SCREW

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$32.99

Viewed 99 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$32.99

The International ES52-7B, ES56-7B, and ES066-7B 7-speed transmission repair manual provides comprehensive guidance for the complete teardown and rebuild of these transmissions. Whether you are a professional mechanic or a DIY enthusiast, this manual equips you with the technical information needed to effectively repair and maintain these transmissions.