DANA SPICER TE27 & TE32 Transmission Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SPICER OFF-HIGHWAY PRODUCTS DIVISION

Maintenance and Service manual

TE27 / 32

POWERSHIFT TRANSMISSION

Manual: 8100102

CD-ROM: 8100101

4 SPEED

SHORT DROP

TE27/32 4 SD 12/2002

Table of Contents

TOWING OR PUSHING

FOREWORD

1 SAFETY PRECAUTIONS .................................................................................................... 1

2 CLEANING AND INSPECTION ........................................................................................... 1

2.1 CLEANING ...................................................................................................................................... 2

2.1.1 BEARINGS ............................................................................................................................ 2

2.1.2 HOUSINGS ............................................................................................................................ 2

2.2 INSPECTION .................................................................................................................................... 2

2.2.1 BEARINGS ............................................................................................................................ 2

2.2.2 OIL SEALS, GASKETS, etc. ................................................................................................. 3

2.2.3 GEARS & SHAFTS................................................................................................................ 3

2.2.4 HOUSINGS, COVERS, etc. ................................................................................................... 3

2.3 LEGEND SYMBOLS ........................................................................................................................ 3

3 TECHNICAL SPECIFICATIONS .......................................................................................... 1

3.1. IDENTIFICATION OF THE UNIT ...................................................................................................... 2

3.2. WEIGHT, DIMENSIONS, OIL CAPACITY......................................................................................... 2

3.3 TIGHTENING TORQUES.................................................................................................................. 3

3.4 PRESSURE & TEMPERATURE SPECIFICATIONS ........................................................................ 5

3.5 ELECTRICAL SPECIFICATIONS .................................................................................................... 6

3.6 HYDRAULIC COOLER LINES SPECIFICATIONS .......................................................................... 6

4 MAINTENANCE ............................................................................................................... 1

4.1. OIL SPECIFICATION........................................................................................................................ 2

4.1.1 RECOMMENDED LUBRICANTS .......................................................................................... 2

4.2 MAINTENANCE INTERVALS........................................................................................................... 2

4.2.1 DAILY ..................................................................................................................................... 2

4.2.2 NORMAL DRAIN PERIOD ..................................................................................................... 2

4.3 SERVICING MACHINE AFTER COMPONENTS OVERHAUL ......................................................... 3

5 INSTALLATION DETAILS .................................................................................................... 1

5.1 CONVERTER DRIVE COUPLING ................................................................................................. 2

5.2 TRANSMISSION TO ENGINE INSTALLATION PROCEDURE........................................................ 3

5.3 EXTERNAL PLUMBING................................................................................................................... 4

5.3.1 COOLER & FILTER LINES SPECIFICATIONS ...................................................................... 4

5.4 SPEED SENSOR INSTALLATION ................................................................................................... 5

TE27/32 4 SD 12/2002

6 TRANSMISSION OPERATION ............................................................................................ 1

6.1 THE TRANSMISSION ASSEMBLY .................................................................................................. 2

6.1.1 THE CONVERTER, PUMP DRIVE SECTION AND PRESSURE REGULATING VALVE ...... 3

6.1.2 THE INPUT SHAFT AND DIRECTIONAL CLUTCHES ........................................................ 4

6.1.3 THE RANGE CLUTCHES ..................................................................................................... 5

6.1.4 THE OUTPUT SECTION ....................................................................................................... 5

6.2 THE TRANSMISSION CONTROLS (REFER TO HYDRAULIC DIAGRAM) .................................... 6

6.3 ELECTRIC SOLENOID CONTROLS ............................................................................................... 6

6.4 POWERFLOWS, ACTIVATED SOLENOIDS AND HYDRAULIC CIRCUIT...................................... 7

6.4.1 NEUTRAL SELECTED........................................................................................................... 7

6.4.2 FORWARD 1ST SPEED ........................................................................................................ 9

6.4.3 FORWARD 2ND SPEED...................................................................................................... 11

6.4.4 FORWARD 3RD SPEED...................................................................................................... 13

6.4.5 FORWARD 4TH SPEED ...................................................................................................... 15

6.4.6 REVERSE 1ST SPEED ....................................................................................................... 17

6.4.7 REVERSE 2ND SPEED ....................................................................................................... 19

6.4.8 REVERSE 3RD SPEED ....................................................................................................... 21

6.4.9 REVERSE 4TH SPEED ....................................................................................................... 23

6.5 GEAR AND CLUTCH LAYOUT ....................................................................................................... 25

7 TROUBLESHOOTING GUIDE ............................................................................................. 1

7.1 THE TRANSMISSION....................................................................................................................... 2

7.2 THE INPUT SHAFT AND DIRECTIONAL CLUTCHES .................................................................... 2

7.2.1 STALL TEST .......................................................................................................................... 2

7.2.2 TRANSMISSION PRESSURE CHECK ................................................................................. 3

7.2.3 MECHANICAL AND ELECTRICAL CHECKS ........................................................................ 3

7.2.4 HYDRAULIC CHECKS ........................................................................................................... 3

7.3 TROUBLESHOOTING GUIDE......................................................................................................... 4

7.3.1 LOW CLUTCH PRESSURE................................................................................................... 4

7.3.2 LOW CHARGING PUMP OUTPUT FLOW ............................................................................ 4

7.3.3 OVERHEATING...................................................................................................................... 4

7.3.4 NOISE CONVERTER............................................................................................................. 4

7.3.5 LACK OF POWER ................................................................................................................. 4

7.4 CHECK POINTS ............................................................................................................................... 5

7.5 SPEED SENSOR - STATIC STANDALONE TEST ........................................................................... 8

8 SECTIONAL VIEWS & PARTS IDENTIFICATION............................................................... 1

TE 27/32 TORQUE CONVERTER GROUP................................................................................................. 2

TE 27/32 TORQUE CONVERTER GROUP................................................................................................. 3

TE 27/32 TRANSMISSION CASE & REAR COVER GROUP .................................................................... 4

TE 27/32 TRANSMISSION CASE & REAR COVER GROUP .................................................................... 5

TE 27/32 TURBINE SHAFT GROUP .......................................................................................................... 6

TE 27/32 TURBINE SHAFT GROUP .......................................................................................................... 7

TE 27/32 PUMP DRIVE GROUP................................................................................................................. 8

TE 27/32 PUMP DRIVE GROUP................................................................................................................. 9

TE 27/32 ADAPTOR SLEEVE GROUP .................................................................................................... 10

TE 27/32 ADAPTOR SLEEVE GROUP .................................................................................................... 11

TE 27/32 WHEEL GROUP ........................................................................................................................ 12

TE 27/32 WHEEL GROUP ........................................................................................................................ 13

TE27/32 4 SD 12/2002

TE 27/32 DRIVE PLATE GROUP ............................................................................................................. 14

TE 27/32 DRIVE PLATE GROUP ............................................................................................................. 15

TE 27/32 FWD & REV/2ND AND 3TH OR 4TH CLUTCH SHAFT ASSY ................................................ 16

TE 27/32 FWD & REV/2ND AND 3TH OR 4TH CLUTCH SHAFT ASSY ................................................ 17

TE 27/32 forward clutch shaft GROUP ................................................................................................... 18

TE 27/32 forward clutch shaft GROUP ................................................................................................... 19

TE 27/32 3rd speed clucth shaft GROUP ............................................................................................... 20

TE 27/32 3rd speed clucth shaft GROUP ............................................................................................... 21

TE 27/32 3rd speed gear.......................................................................................................................... 22

TE 27/32 3rd speed gear.......................................................................................................................... 23

TE 27/32 REV / 2nd schaft GROUP......................................................................................................... 24

TE 27/32 REV / 2nd schaft GROUP......................................................................................................... 25

TE 27/32 1st speed clutch shaft GROUP ............................................................................................... 26

TE 27/32 1st speed clutch shaft GROUP ............................................................................................... 27

TE 27/32 4th speed clutch shaft GROUP ............................................................................................... 28

TE 27/32 4th speed clutch shaft GROUP ............................................................................................... 29

TE 27/32 1st shaft gear GROUP.............................................................................................................. 30

TE 27/32 1st shaft gear GROUP.............................................................................................................. 31

TE 27/32 Output shaft GROUP................................................................................................................ 32

TE 27/32 output shaft group ................................................................................................................... 33

TE 27/32 Regulator valve group ............................................................................................................. 34

TE 27/32 Regulator valve group ............................................................................................................. 35

TE 27/32 control valve GROUP ............................................................................................................... 36

TE 27/32 control valve GROUP ............................................................................................................... 37

TE 27/32 control valve GROUP (cont.) ................................................................................................... 38

TE 27/32 control valve GROUP (cont.) ................................................................................................... 39

TE 27/32 remote filter adapter GROUP .................................................................................................. 40

TE 27/32 remote filter adaptor GROUP .................................................................................................. 41

9 ASSEMBLY INSTRUCTIONS .............................................................................................. 1

10 DISASSEMBLY AND REASSEMBLY OF THE TRANSMISSION...................................... 1

11 SPECIAL TOOLS ............................................................................................................... 1

TE27/32-4-SD 12/02 I

TOWING OR PUSHING

Before towing the vehicle, be sure to lift the rear wheels off the ground or disconnect the driveline to avoid dam-

age to the transmission during towing.

NOTE:

Because of the design of the hydraulic system, the engine cannot be started by pushing or towing.

©Copyright Dana Spicer Off-Higwhay Products Division

Unpublished Material - All rights reserved

Limited Distribution

No part of this work may be reproduced in any form under any means without direct written permission of the

Dana Spicer Off-Highway Products Division

TE27/32-4-SD 12/02 II

FOREWORD

This manual has been prepared to provide the customer and the maintenance personnel with information and

instructions on the maintenance and repair of the SPICER OFF-HIGWAY PRODUCTS product.

Extreme care has been exercised in the design, selection of materials, and manufacturing of these units. The

slight outlay in personal attention and cost required to provide regular and proper lubrication, inspection at stated

intervals, and such adjustments as may be indicated, will be reimbursed many times in low cost operation and

trouble-free service.

In order to become familiar with the various parts of the product, its principle of operation, troubleshooting and

adjustments, it is urged that the mechanic studies the instructions in this manual carefully and uses it as a refer-

ence when performing maintenance and repair operations.

Whenever repair or replacement of component parts is required, only SPICER OFF-HIGHWAY PRODUCTS ap-

proved parts as listed in the applicable parts manual should be used. Use of “will-fit” or non-approved parts may

endanger proper operation and performance of the equipment. SPICER OFF-HIGHWAY PRODUCTS does not

warrant repair or replacement parts, nor failures resulting from the use of parts which are not supplied or ap-

proved by SPICER OFF-HIGHWAY PRODUCTS.

IMPORTANT

ALWAYS FURNISH THE DISTRIBUTOR WITH THE SERIAL AND MODEL NUMBER WHEN ORDERING PARTS.

TE27/32-4-SD 12/02 III

FWD

2ND

3RD

1ST REV

4TH

TE27/32-4-SD 12/02 1-1

1. SAFETY PRECAUTIONS

To reduce the chance of personal injury and/or property damage, the following instructions must be carefully

observed.

Proper service and repair are important to the safety of the service technician and the safe reliable operation of

the machine. If replacement parts are required the part must be replaced by a spare part which has the same

part number or with an equivalent part. DO NOT USE A SPARE PART OF LESSER QUALITY.

The service procedures recommended in this manual are effective methods for performing service and

repair. Some of these procedures require the use of tools specifically designed for the purpose.

Accordingly, anyone who intends to use a spare parts, service procedure or tool, which is not recommended by

SPICER OFF-HIGHWAY PRODUCTS, must first determine that neither his safety nor the safe operation of the

machine will be jeopardized by the spare part, service procedure or tool selected.

IMPORTANT

It is important to note that this manual contains various ’CAUTIONS’ and ‘NOTES’ that must be carefully observed in

order to reduce the risk of personal injury during service or repair, or the possibility that improper service or repair

may damage the unit or render it unsafe.

It is also important to understand that these ‘CAUTIONS” and ‘NOTES’ are not exhaustive, because it is impossible

to warn about all the possible hazardous consequences that might result from failure to follow these instructions.

TE27/32-4-SD 12/02 2-1

2. CLEANING, INSPECTION AND LEGEND SYMBOLS

2.1 CLEANING

Clean all parts thoroughly using solvent type cleaning fluid. It is recommended that parts be immersed in

cleaning fluid and moved up and down slowly until all old lubricant and foreign material is dissolved and parts are

thoroughly cleaned.

CAUTION

Care should be exercised to avoid skin rashes, fire hazards, and inhalation of vapors when using solvent type clean-

ers.

2.1.1 Bearings

Remove bearings from cleaning fluid and strike flat against a block of wood to dislodge solidified particles

of lubricant. Immerse again in cleaning fluid to flush out particles. Repeat above operation until bearings are

thoroughly clean. Dry bearings using moisture-free compressed air. Be careful to direct air stream across bearing

to avoid spinning. Do not spin bearings when drying. Bearings may be rotated slowly by hand to facilitate drying

process.

2.1.2 Housings

Clean interior and exterior of housings, bearing caps, etc…, thoroughly. Cast parts may be cleaned in hot solution

tanks with mild alkali solutions providing these parts do not have ground or polished surfaces.

Parts should remain in solution long enough to be thoroughly cleaned and heated. This will aid the evaporation of

the cleaning solution and rinse water. Parts cleaned in solution tanks must be thoroughly rinsed with clean water

to remove all traces of alkali. Cast parts may also be cleaned with steam cleaner.

CAUTION

Care should be exercised to avoid inhalation of vapors and skin rashes when using alkali cleaners.

All parts cleaned must be thoroughly dried immediately by using moisture-free compressed air or soft, lintless

absorbent wiping rags free of abrasive materials such as metal fillings, contaminated oil, or lapping compound.

2.2 INSPECTION

The importance of careful and thorough inspection of all parts cannot be overstressed. Replacement of all parts

showing indication of wear or stress will eliminate costly and avoidable failures at a later date.

2.2.1 Bearings

Carefully inspect all rollers: cages and cups for wear, chipping, or nicks to determine fitness of bearings for

further use. Do not replace a bearing cone or cup individually without replacing the mating cup or cone at the

same time. After inspection, dip bearings in Automatic Transmission Fluid and wrap in clean lintless cloth or

paper to protect them until installed.

TE27/32-4-SD 12/02 2-2

2.2.2 Oil Seals, Gaskets, Etc.

Replacement of spring load oil seals, “O” rings, metal sealing rings, gaskets, and snap rings is more economical

when unit is disassembled than premature overhaul to replace these parts at a future time.

Further loss of lubricant through a worn seal may result in failure of other more expensive parts of the assembly.

Sealing members should be handled carefully, particularly when being installed. Cutting, scratching, or curling

under of lip of seal seriously impairs its efficiency. When assembling new metal type sealing rings, these should

be lubricated with coat of chassis grease to stabilize rings in their grooves for ease of assembly of mating

members. Lubricate all “O” rings and seals with recommended type Automatic Transmission Fluid before

assembly.

2.2.3 Gears and Shafts

If magna-flux process is available, use process to check parts. Examine teeth on all gears carefully for wear,

pitting, chipping, nicks, cracks, or scores. If gear teeth show spots where case hardening is worn through or

cracked, replace with new gear. Small nicks may be removed with suitable hone. Inspect shafts and quills to

make certain they are not sprung, bent, or splines twisted, and that shafts are true.

2.2.4 Housing, Covers, etc.

Inspect housings, covers and bearing caps to ensure that they are thoroughly clean and that mating surfaces,

bearing bores, etc…, are free from nicks or burrs. Check all parts carefully for evidence of cracks or conditions

which would cause subsequent oil leaks or failures.

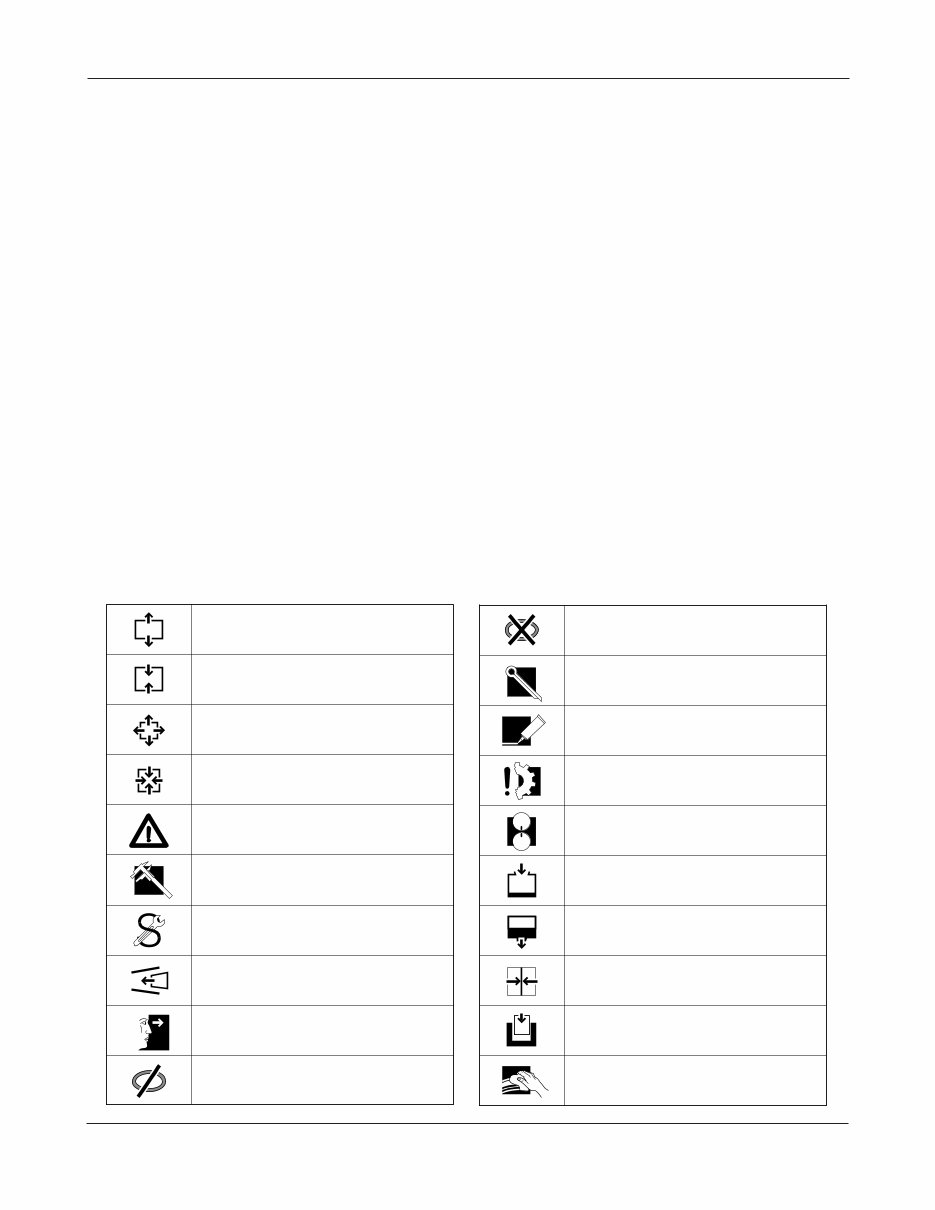

2.3 LEGEND SYMBOLS

Cleaning, inspection and legend symbols

Smontaggio di sottogruppi

Montaggio di sottogruppi

Smontaggio di particollari ingombranti

Montaggio di particollari ingombranti

Attenzione, indicazione importante

Controllare regolare p.e. coppie, misure, pressione etc.

T = Attrezzature speciali P = Pagina

Rispettare direzione di montaggio

Controllare esaminare controllo visuale

Eventualimente riutilizzable (sostituire se necessario)

Sostituire con ogni montaggio

Togliere - mettere la sicura

Mettere la sicura, incollare (mastice liquido)

Evitare danni ai materiali, danni ai pezzi

Marchiari prima dello smontaggio (per il montaggio)

Carricare riempire (olio - lubrificante)

Scarricare olio, lubrificante

Tendere

Insere pressione nel circuito idraulico

Pulire

Disassembly of assembly groups

Reassemble to from assembly group

Remove obstruction parts

Reinstall - remount parts which had obstructed disassembly

Attention! important notice

Check - adjust e.g. torque, dimensions, pressures etc.

T = Special tool P = Page

Note direction of installation

Visual inspection

Possibly still serviceable, renew if necessary

Renew at each reassembly

Unlock - lock e.g. split pin, locking plate, etc.

Lock - adhere (liquid sealant)

Guard against material damage, damage to parts

Mark before disassembly, observe marks when reasembl.

Filling - topping up - refilling e.g. oil, cooling water, etc.

Drain off oil, lubricant

Tighten - clamp ; tightening a clamping device

Apply pressure into hydraulic circuit

To clean

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

Viewed 61 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

Dive into the comprehensive DANA SPICER TE27 & TE32 Transmission Service Repair Manual, spanning 121 pages. This Maintenance & Service Manual covers the TE27 / TE32 Powershift Transmission, featuring a 4-speed configuration with a short drop. Whether you're a professional mechanic or a DIY enthusiast, this manual equips you with the essential knowledge to effectively service and repair these transmissions.