ISUZU AW03-72LE Automatic Transmission AUTO Gearbox Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

FOR SERVICE TRAINING

AUTOMATIC TRANSMISSION

(AW03-72LE)

ISUZU MOTORS LIMITED

AW03-72LE Automatic Transmission-1

MAIN DATA & SPECIFICATION

Model AW03-72LE

Torque Converter Type Three Elements, One Stage & Two Phase Type with Lock-up Function

Name ATF DEXRON II or III

Quantity Approximately 6.5L

ATF

Cooling System Water Cooled Type (Radiator)

1

st

2.826

2

nd

1.493

3

rd

1.000

4

th

(Over Drive) 0.688

Gear Ratio

Reverse 2.703

One-way Clutch No. 1 F-1 18

One-way Clutch No. 2 F-2 26

Clutch

Over Drive One-way Clutch F-0 20

Number of Sprag

Forward Clutch C-1 4

Direct Clutch C-2 3

Over Drive Direct Clutch C-0 2

Second Coast Brake B-1 2

Second Brake B-2 3

First & Reverse Brake B-3 5

Friction Element

Over Drive Brake B-0 3

Number of Disc

AW03-72LE Automatic Transmission-2

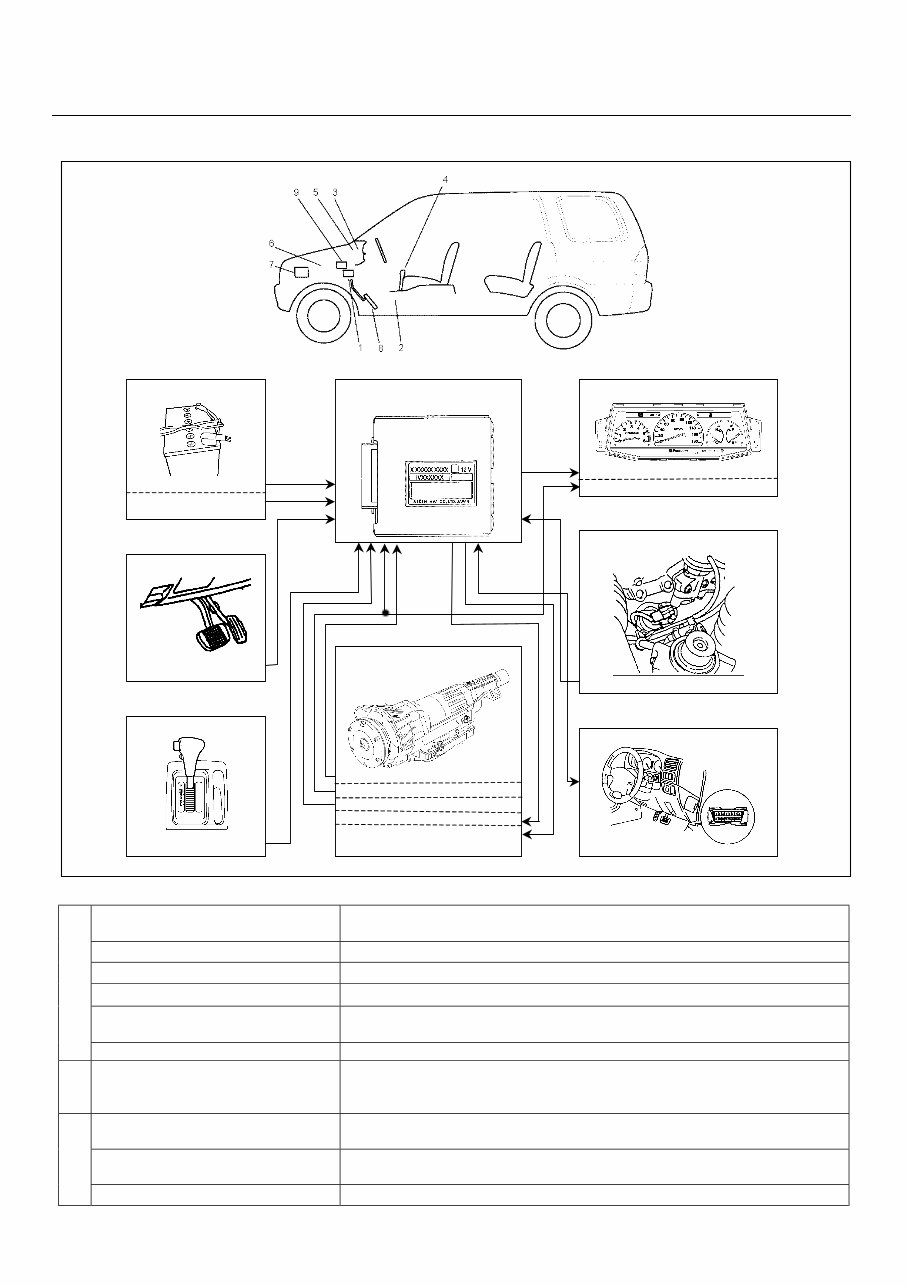

SYSTEM DIAGRAM

Vehicle Speed Sensor (SP1) Detects output shaft revolution seed and send signal to TCM and

speedometer.

Vehicle Speed Sensor (SP2) Detects output shaft revolution seed and send signal to TCM.

Throttle Position Sensor Detects injection pump lever operating angle and send signal to TCM.

Inhibitor Switch Detects select lever position and send signal to TCM.

Over Drive Switch Detects overdrive request switch selected by driver and send signal to

TCM.

Input

Brake Switch Detects brake pedal operated by driver and send signal to TCM.

TCM Judges necessary line pressure, gear shifting point and lock-up operation

based on electrical signals from switches and sensors and send

appropriate signals to solenoids.

Shift Solenoid (S1 & S2) Selects appropriate gear shifting position for current driving condition

based on signal from TCM.

Lock-up Solenoid (S3) Regulates lock-up pressure for current driving condition based on signal

from TCM.

Output

CHECK TRANS Indicator Lamp Indicates CHECK TRANS indicator lamp in case of malfunction.

8. Brake Pedal

-Brake Switch

3. 5. Meter

-CHECK TRANS Indicator Lamp

-Speedometer

1. Transmission Control Module

(TCM)

4. Select Lever

-Over Drive Switch

9. Data Link Connector (DLC)

6. Engine

-Throttle Position Sensor

2. Transmission

-Inhibitor Switch

-Vehicle Speed Sensor (SP1)

-Vehicle Speed Sensor (SP2)

-Shift Solenoid (S1 & S2)

-Lock-up Solenoid (S3)

7. Electrical Source

-Ignition Voltage

-Battery

AW03-72LE Automatic Transmission-3

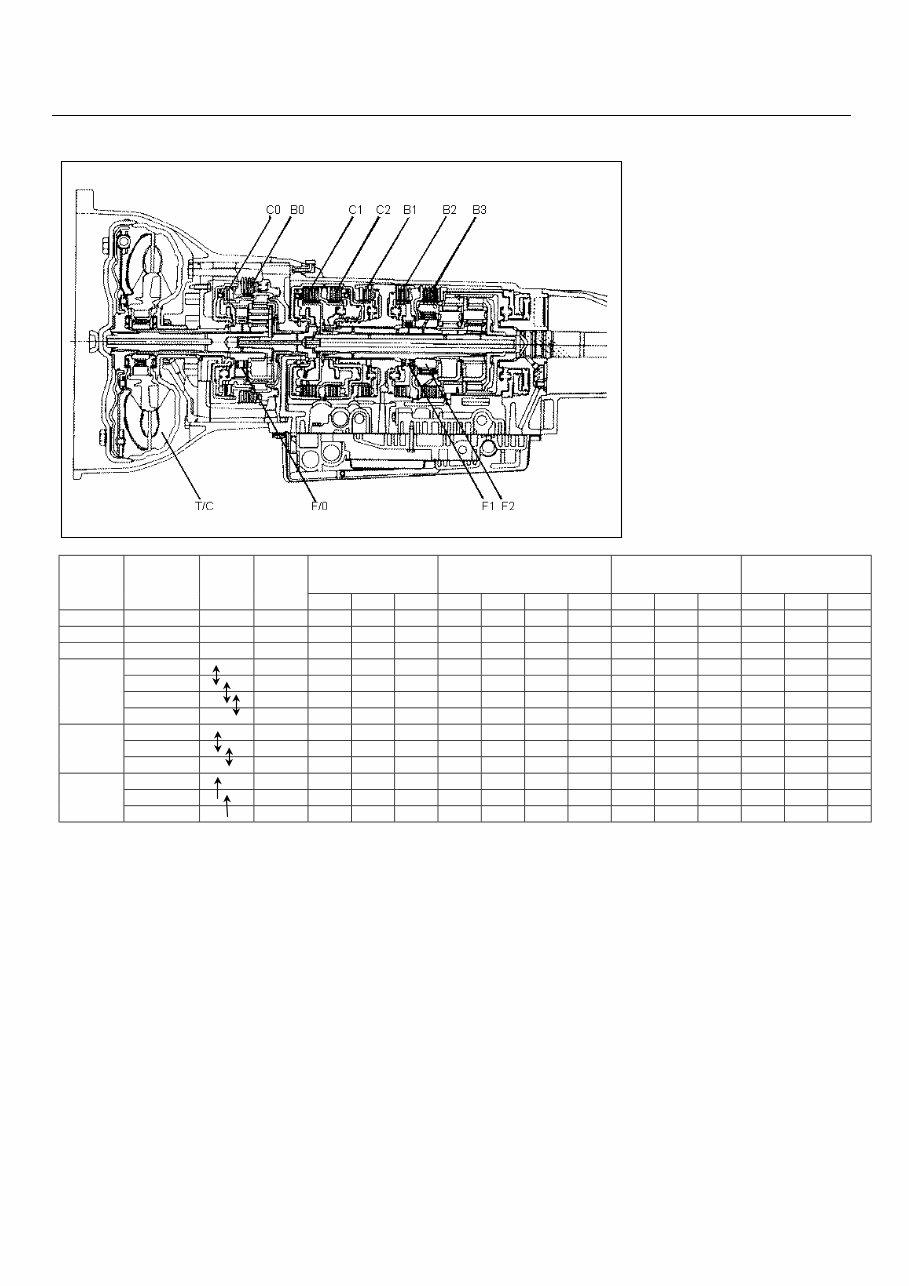

LOCATION & OPERATION OF CLIUTCH, BRAKE, ONE-WAY CLUTCH AND SOLENOID

C0: Over Drive Direct Clutch

C1: Forward Clutch

C2: Direct Clutch

B0: Over Drive Brake

B1: Second Coast Brake

B2: Second Brake

B3: First & Reverse Brake

F0: Over Drive One-way Clutch

F1: One-way Clutch (No. 1)

F2: One-way Clutch (No. 2)

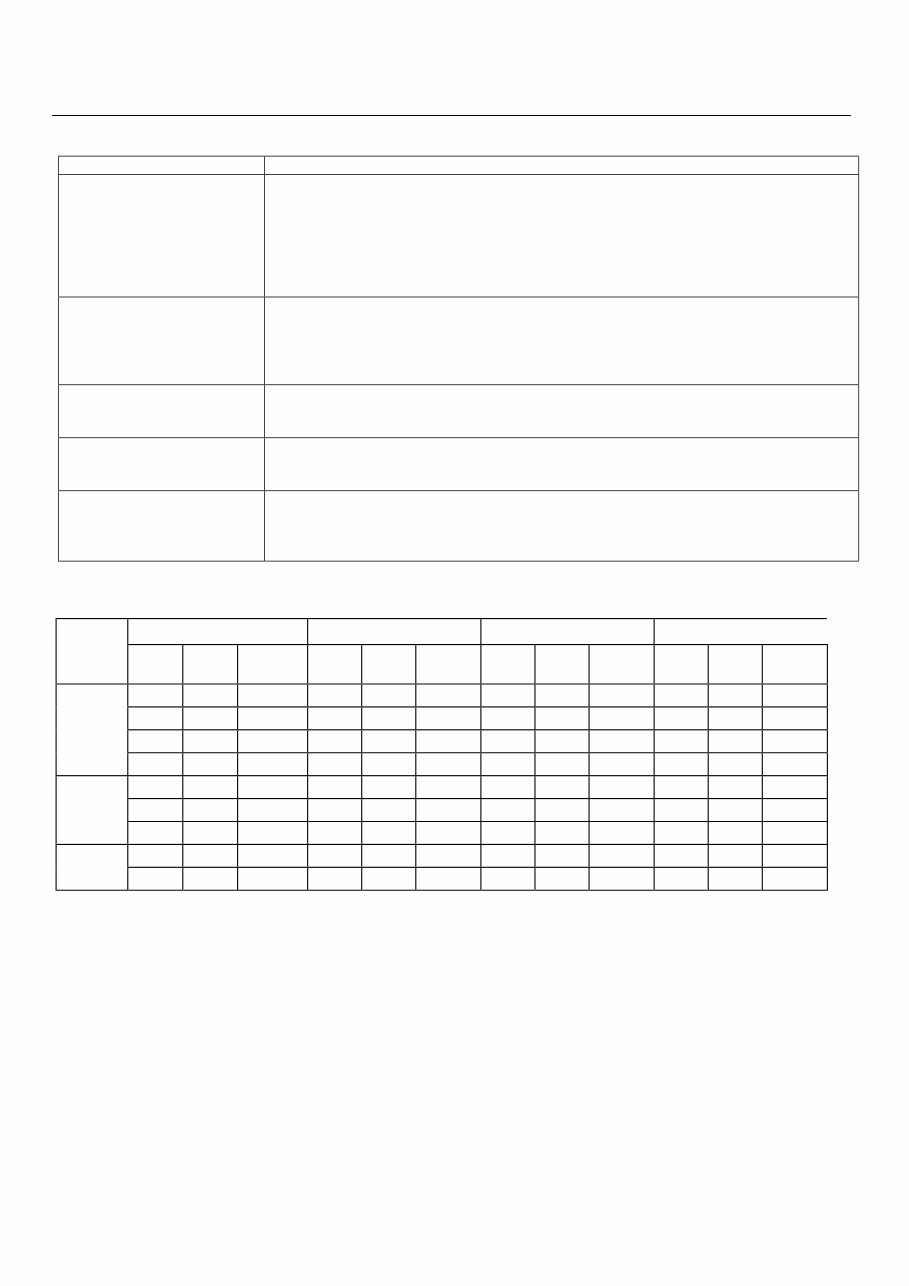

Clutch Brake One-way Clutch Solenoid Select

Lever

Position

Gear

Position

Gear

Shift

Lock-

up

C-0 C-1 C-2 B-0 B-1 B-2 B-3 F-0 F-1 F-2 S1 S2 S3

P - O O

R - O O O O O

N - O O

1

st

O O O O O

2

nd

O O O O O O O

3

rd

O O O O O O O O

D

4

th

(O/D) O O O O O O

1

st

O O O O O

2

nd

O O O O O O O O

2

3

rd

O O O O O O

1

st

O O O O O O

2

nd

O O O O O O O O

L

3

rd

O O O O O O

AW03-72LE Automatic Transmission-4

CONTENTS OF FUNCTION & CONTROL

Item Description

Gear Shift Control The TCM issues a shift solenoid drive signal based on the inhibitor switch, vehicle

speed and throttle opening. And, the TCM control shift schedule according to the

preset shift map.

In order to prevent engine over running, the TCM achieves up shift control 3

rd

to 4

th

when the vehicle speed is more than 110km/h even over drive (O/D) is tuned off. It

will return 4

th

to 3

rd

when the vehicle speed is less than 100km/h.

Lock-up Control The lock-up solenoid adjusts the pressure based on the signal from the TCM

according to the vehicle speed, throttle opening, select lever position based on the

preset lock-up point to control the lock-up.

The lock-up is disengaged when the throttle is closed or brake pedal is depressed.

Squat Control At garage shift, shift to the 1

st

gear sequentially after shifting into the 3

rd

gear first to

improve the garage shift shock.

Fail-safe Function In case of malfunction of sensors, solenoid, TCM automatically begins fail-safe control

to minimize effects on driving.

Self-diagnosis Function Parts required for controlling the automatic transmission are provided with a self-

diagnosis function. When any trouble occurs, the CHECK TRANS indicator lamp

blinks to warm the driver. The trouble code is memorized into the TCM.

SHIFT SOLENOID FAIL-SAFE FUNCTION

Normal Solenoid S1 Malfunction Solenoid S2 Malfunction S1& S2 Malfunction Select

Lever

Position

S1 S2 Gear

Position

S1 S2 Gear

Position

S1 S2 Gear

Position

S1 S2 Gear

Position

O 1

st

X O 3

rd

O X 1

st

X X 4

th

(O/D)

O O 2

nd

X O 3

rd

X 4

th

(O/D) X X 4

th

(O/D)

O 3

rd

X O 3

rd

X 4

th

(O/D) X X 4

th

(O/D)

D

4

th

(O/D) X 4

th

(O/D) X 4

th

(O/D) X X 4

th

(O/D)

O 1

st

X O 3

rd

O X 1

st

X X 3

rd

O O 2

nd

X O 3

rd

X 3

rd

X X 3

rd

2

O 3

rd

X O 3

rd

X 3

rd

X X 3

rd

O 1

st

X 3

rd

O X 1

st

X X 3

rd

L

O O 2

nd

X 3

rd

O X 1

st

X X 3

rd

AW03-72LE Automatic Transmission-5

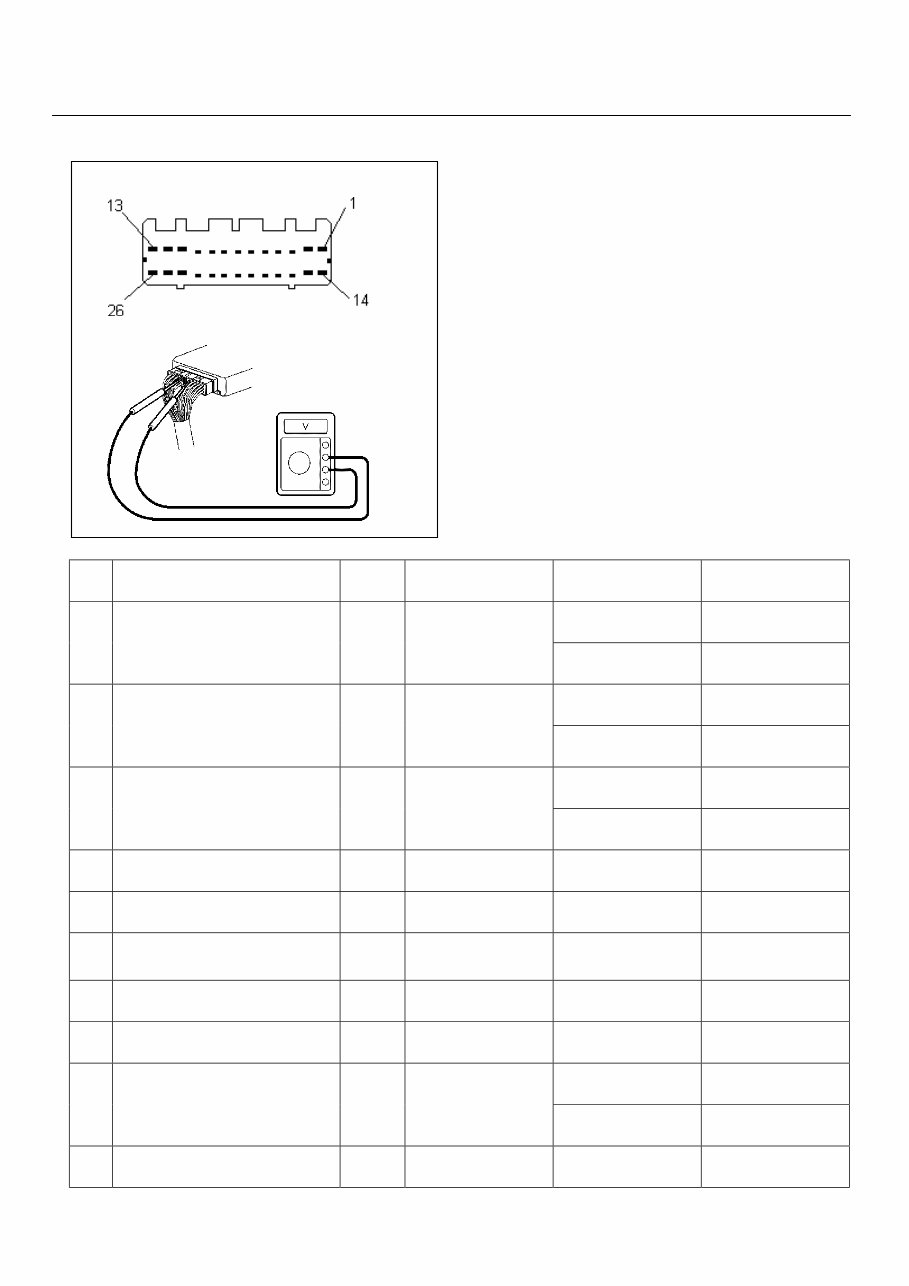

TCM PIN ASSIGNMENT

TCM voltage check is done to check for transmission

and TCM problems which cannot be detected by self-

diagnosis. Additionally, it severs as a back-up check

for self-diagnosis.

Measure the voltage drop and make a continuity test

for each of sensors, solenoids and switches. If the

voltage is within the specified range and continuity

exists, that particular area of the TCM and

transmission assembly is normal. If voltage deviation

or lack of continuity is discovered, disconnect the

applicable parts and check of them individually.

Pin Pin Name Input /

Output

Connected to Measurement

Condition

Standard

At L range 10 – 15 volts 1 L Range Switch Input Inhibitor Switch

Other than L range Less than 1 volt

At 2 Range 10 – 15 Volts 2 2 Range Switch Input Inhibitor Switch

Other than 2 range Less than 1 volt

At N Range 10 – 15 volts 3 N Range Switch Input Inhibitor Switch

Other than N range Less than 1 volt

4 Not Used - - - -

5 Not Used - - - -

6 Vehicle Speed Sensor (SP1) Input Vehicle Speed

Sensor (SP1)

At run in L range in

1

st

gear 20km/h

Pulse generated

(Approximately 5.6

volts by AC range)

7 Not Used - - - -

8 Throttle Position Sensor Ground - Throttle Position

Sensor

- Continuity with

ground

Switch depressed

(Over Drive ON)

10 – 15 volts 9 Over Drive Off Switch Input O/D Off Switch

Switch not depressed

(Over Drive OFF)

Less than 1 volt

10 Keyword 2000 Serial Data

Communication

Input /

Output

Data Link Connector

No. 7

- -

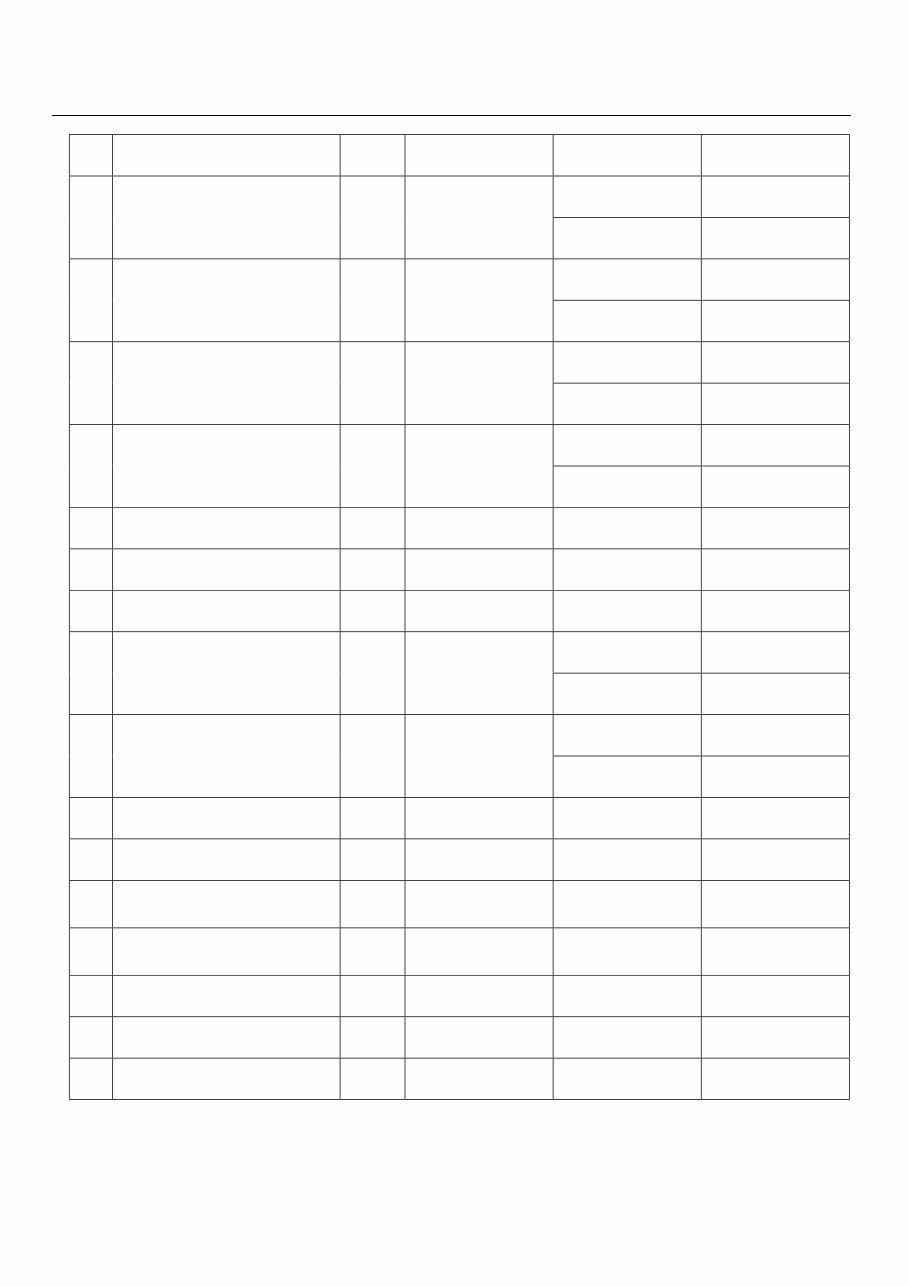

AW03-72LE Automatic Transmission-6

Pin Pin Name Input /

Output

Connected to Measurement

Condition

Standard

At lock-up 10 – 15 volts 11 Lock-up Solenoid Output Lock-up Solenoid

Other than lock-up Less than 1 volt

At 2

nd

, 3

rd

gear 10 – 15 volts 12 Shift Solenoid S2 Output Shift Solenoid S2

At 1

st

, 4

th

gear Less than 1 volt

At 1

st

, 2

nd

gear 10 – 15 volts 13 Shift Solenoid S1 Output Shift Solenoid S1

At 3

rd

, 4

th

gear Less than 1 volt

Pedal depressed 10 – 15 volts 14 Brake Switch Input Brake Switch

Pedal released Less than 1 volt

15 Not Used - - - -

16 Not Used - - - -

17 Not Used - - - -

Pedal released (Idle

position)

Approximately 0.45

volts

18 Throttle Position Sensor Signal Input Throttle Position

Sensor

Pedal fully depressed

(WOT)

Approximately 3.50

volts

Lamp turned ON Less than 1 volt 19 Check Trans Indicator Lamp Output CHECK TRANS

Indicator Lamp

Lamp turned OFF 10 – 15 volts

20 Throttle Position Sensor Voltage

Supply

Output Throttle Position

Sensor

Ignition switch ON Approximately 5 volts

21 Diagnosis Request Switch Input Data Link Connector

No. 11

- -

22 Vehicle Speed Sensor (SP2) High Input Vehicle Speed

Sensor (SP2)

At run in L range in

1

st

gear 20km/h

Pulse generated

(Approximately 0.48

by AC range)

23 Vehicle Speed Sensor (SP2) Low Input Vehicle Speed

Sensor (SP2)

Ignition switch OFF

and measure pins 22

and 23

Approximately 370

ohms

24 Ground - Body Ground - Continuity with

ground

25 Battery Voltage Supply Input Battery All time 10 – 15 volts

26 Ignition Voltage Supply Input Ignition Switch Ignition Switch ON 10 – 15 volts

AW03-72LE Automatic Transmission-7

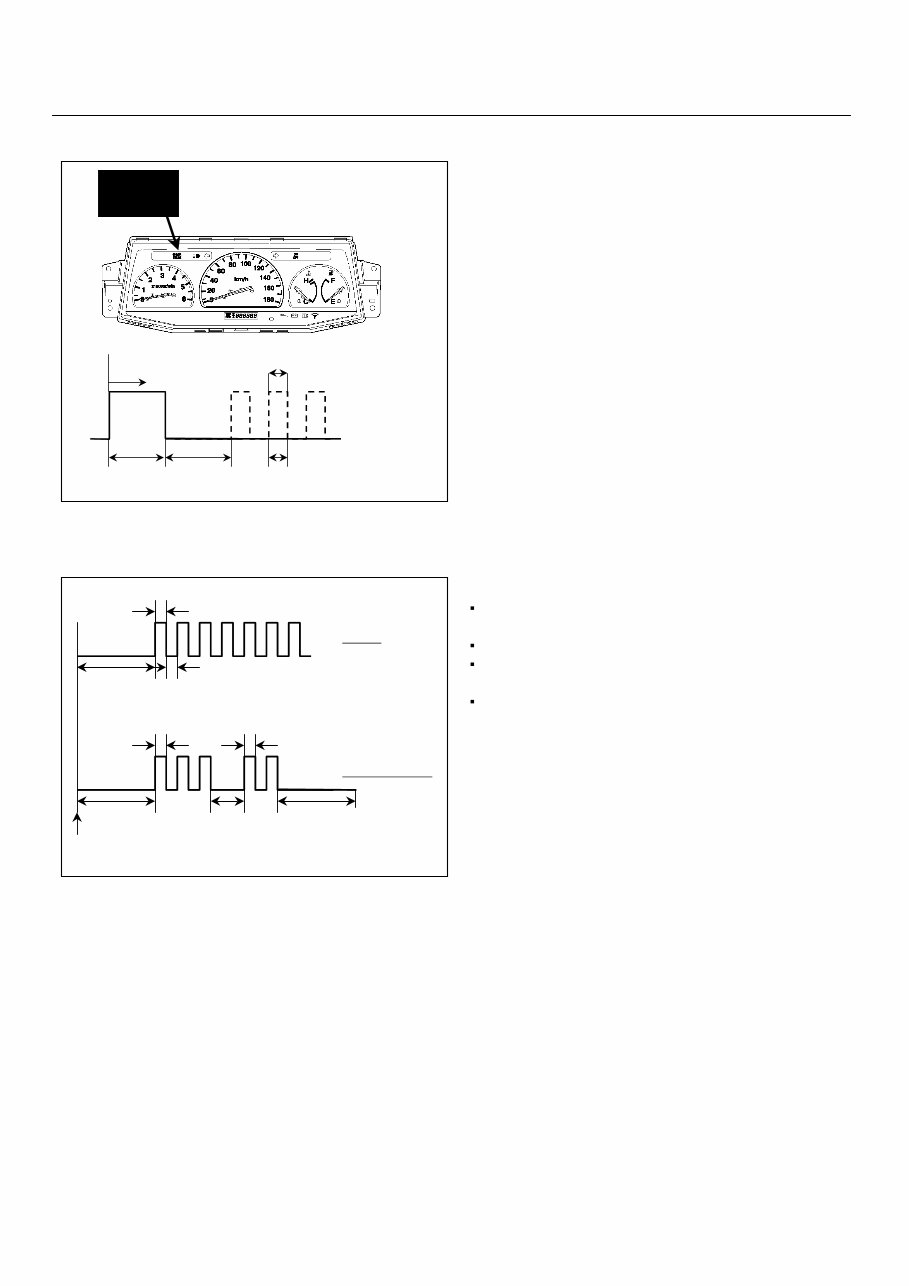

CHECK TRANS INDICATOR LAMP

"CHECK TRANS" is ON during 3 seconds at key

switch ON position. When trouble has occurred to

electrical components, "CHECK TRANS" lamp is

blinked (1.25 Hz) even during driving to warn the

driver. The trouble is recorded by trouble code in

TCM. When temporary trouble code has been

canceled, the "CHECK TRANS" lamp stops blinking.

This blinking can be stopped by setting the key off.

But the trouble code remains memorized in TCM.

SELF-DIAGNOSIS CODE (FLASH CODE) DISPLAY

Indication Method:

Terminal No. 11 and No. 4 or 5 (ground) of data

link connector are short circuited.

Turn the key switch to the ON position.

In case no trouble code existence, "CHECK

TRANS" lamp is blinked (1.25 Hz).

In case the plural trouble codes have occurred at

a time, each code are indicated three times in

numerical order.

Trouble Code Clear Method:

If you have Tech 2:

Follow the procedure instructed on the Tech 2.

Note:

If you clear the DTC you will not be able to read any

codes recorded during the last occurrence. To use

the DTC again to identify a problem, you will need to

reproduce the fault or the problem. This may require

a new test drive or just turning the key switch on (this

depends on the nature of the fault).

Key SW ON

OFF

ON

3 sec.

(Lamp Check)

Normal

Abnormal (DTC Stored)

3.2 sec.

0.4 sec.

0.4 sec.

CHECK

TRANS

Normal

Trouble Code (32)

Self-diagnosis Start

0.4Sec.

0.4Sec. 3.2Sec.

0.4Sec. 0.4Sec.

3.2Sec. 1.2Sec. 3.2Sec.

AW03-72LE Automatic Transmission-8

DIAGNOSIS WITH TECH 2

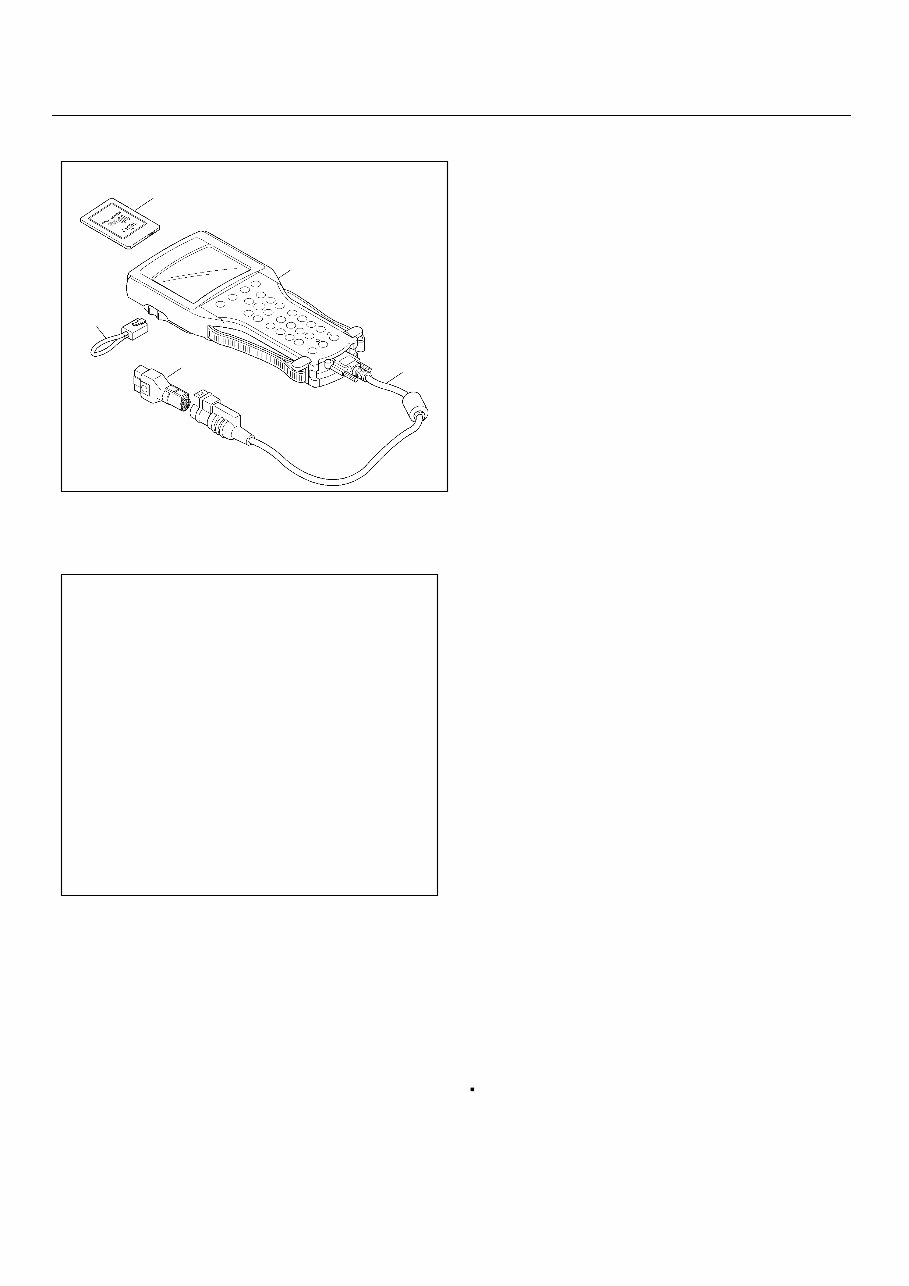

Getting Started

Before operating the Isuzu PCMCIA card with the

Tech 2, the following steps must be performed:

1. The PCMCIA card (1) inserts into the Tech 2 (5).

2. Connect the SAE 16/19 adapter (3) to the DLC

cable (4).

3. Connect the DLC cable to the Tech 2 (5).

4. Make sure the ignition switch is OFF.

5. Connect the Tech 2 SAE 16/19 (3) adapter to the

vehicle data link connector (DLC).

6. Turn the ignition ON and press the “PWR” key of

the Tech 2.

7. Verify the Tech 2 power up display.

Operating Procedure

1. Press Enter at start screen.

2. Select “F0 Diagnostic” then press Enter.

3. Select the appropriate vehicle identification.

4. Select “F0 Powertrain” then press Enter.

5. Select “AW03-72LE”.

The following table shows, which functions are used

the available equipment version.

F0: Diagnostic Trouble Codes

The purpose of the "Diagnostic Trouble Codes"

mode is to display stored trouble code in the TCM.

When "Clear DTC Information" is selected, a "Clear

DTC Information", warning screen appears. This

screen informs you that by cleaning DTC's "all stored

DTC information in the TCM will be erased".

F1: Data Display

The purpose of the "Data Display" mode is to

continuously monitor data parameters.

The current actual values of all important sensors

and signals in the system are display through F1

mode.

F2: Snapshot

"Snapshot" allows you to focus on making the

condition occur, rather than trying to view all of the

data in anticipation of the fault.

The snapshot will collect parameter information

around a trigger point that you select.

F3: Miscellaneous Test

The purpose of "Miscellaneous Test" mode is to

check for correct operation of electronic system

actuators.

Check Light Test

The purpose of this test is for checking whether

the CHECK TRANS indicator lamp is operated

when it commanded ON. Faulty circuit(s) or

opened bulb could be considered when not

operating with commanded ON.

F0: Diagnostic Trouble Codes

F0: Read DTC Info By Priority

F1: Read DTC Info As Stored By ECU

F2: Clear DTC Information

F1: Data Display

F2: Snapshot

F3: Miscellaneous Tests

F0: Lamps

F0: Check Light Test

F1: Solenoids

F0: Solenoid 2-3 Test

F1: Solenoid 1-2/3-4 Test

F2: TCC Solenoid Test

1

2

4 3

5

AW03-72LE Automatic Transmission-9

Solenoid 2-3 Test

The purpose of this test for checking whether the

shift solenoid S1 is operated when it commanded

ON/OFF. Faulty shift solenoid S1 could be

considered that does not create clicking noise

(solenoid operating noise), interrupted noise or

abnormal noise when commanded ON.

Solenoid 1-2/3-4 Test

The purpose of this test for checking whether the

shift solenoid S2 is operated when it commanded

ON/OFF. Faulty shift solenoid S2 could be

considered that does not create clicking noise

(solenoid operating noise), interrupted noise or

abnormal noise when commanded ON.

TCC Solenoid Test

The purpose of this test for checking whether the

lock-up solenoid S3 is operated when it

commanded ON/OFF. Faulty lock-up solenoid S3

could be considered that does not create clicking

noise (solenoid operating noise), interrupted noise

or abnormal noise when commanded ON.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Viewed 82 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Our Isuzu AW03-72LE Automatic Transmission Auto Gearbox Manual is an essential resource for both professional mechanics and DIY enthusiasts. This comprehensive manual provides detailed technical information to assist in the repair and maintenance of the Isuzu AW03-72LE automatic transmission. Whether you're tackling a complete overhaul or a simple repair, this manual offers step-by-step instructions and diagrams to guide you through the process. With its clear and concise format, this manual is a valuable tool for anyone working on the Isuzu AW03-72LE automatic transmission.