4L80E 4L80 Transmission Gearbox REBUILD PROCEDURE Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

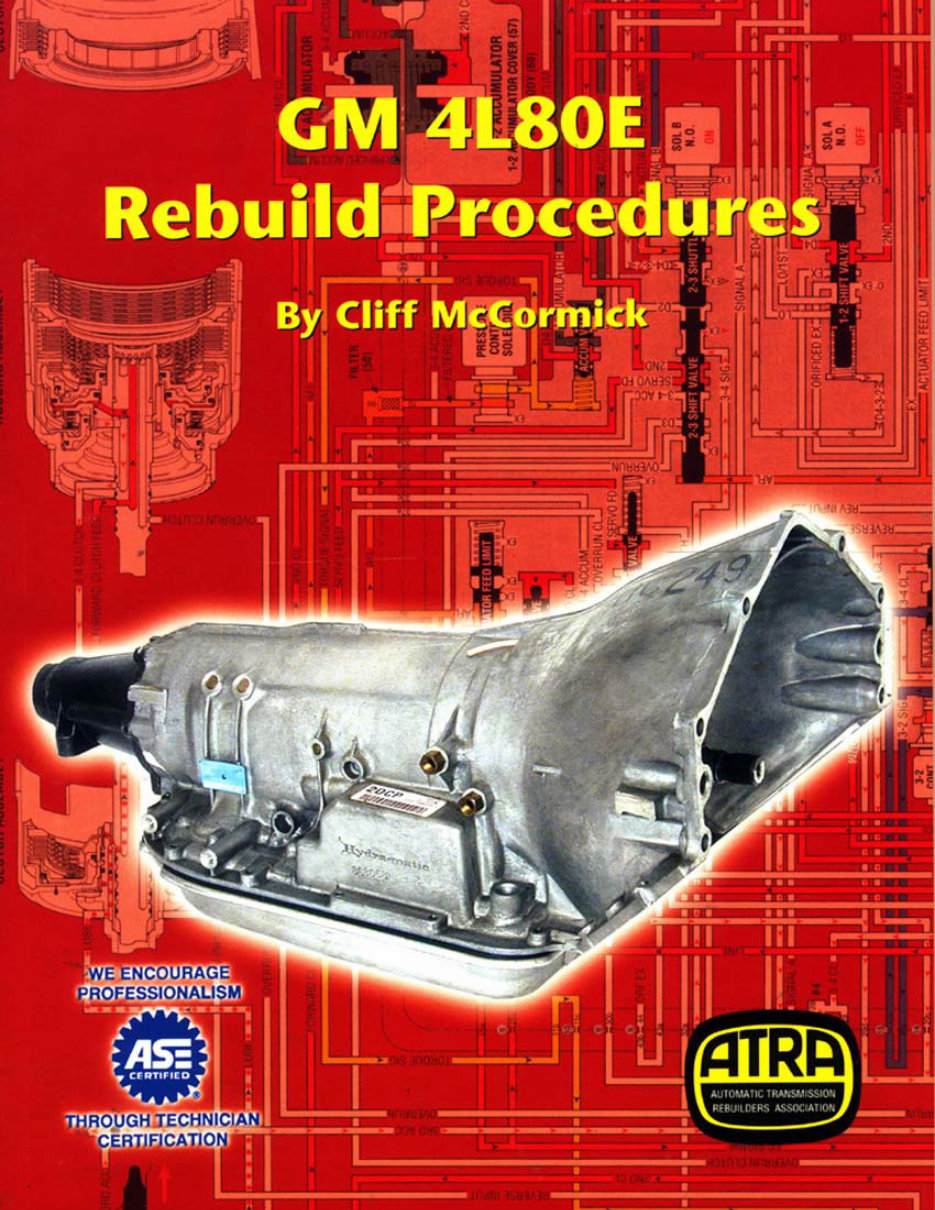

GM 4L80E

Rebuild Procedures

Written by Clifford McCormick

©2003 ATRA. All Rights Reserved. Printed in U. S. A.

iii 4L80E Rebuild Procedures

Program Introduction…

The General Motors 4L80E, in production since 1991, has become the workhorse

of GM’s light truck series. This unit has also surfaced in some rather exotic and

unexpected vehicles simply because those manufacturers wanted one of the best, most

reliable units available at the time. Based on the bulletproof THM 400, which could take

just about anything a car or truck could dish out without breaking a sweat, the 4L80E was

the natural evolution of the 400, updating the design with a beefy overdrive section built

into the case in front of the venerable tried-and-true three speed. No longer does the old

governor/modulator debate tell the transmission what to do, when and how much to do it.

Fully computerized control of the shift points, torque converter clutch engagement and

line pressure control ensure that the 4L80E will be with us for quite some time to come,

easily interfacing with the newest powertrain control and diagnostic computer systems.

There may be parts of the rebuild process that you are not very familiar with, or

you may be new to this particular type of transmission. In either case, you need some

point of reference- something that will show you how to proceed when you are not sure

(or have no idea whatsoever), and that is exactly what this book is designed to do.

You will not find a photocopied section out of a factory manual between these

covers. In fact, you will notice a substantial difference between the book you are holding

and any other books written on the subject. This is because, as this book was being

written, the author was rebuilding a 4L80E step by step as he was writing this book. This

helps assure that there would be no missing steps (and it was also quite handy for taking

pictures along the way…). This book was written for transmission rebuilders by a

transmission rebuilder, in plain English rather than complex ‘factoreze’ terminology, or

instructions that have been partially ‘transrated’ from some other language.

So, whether you’ve already done a few of the 4L80E units or are about to tackle

your first one, this book will show you how to get through the sticky parts of a rebuild, as

well as the most thorough way to get through the job, start to finish. Thank you for your

attention, your efforts and your trust.

©2003 ATRA. All Rights Reserved. Printed in U. S. A.

iv 4L80E Rebuild Procedures

©2003 ATRA. All Rights Reserved. Printed in U. S. A.

v 4L80E Rebuild Procedures

Table Of Contents

Unit Disassembly

Pump

Fourth Clutch Assembly

Overrun clutch/OD Planet

Forward Clutch Drum

Direct Clutch Drum

Geartrain

Case Preparation

Valve Body

Unit Assembly

Page 1

Page 12

Page 23

Page 28

Page 36

Page 42

Page 49

Page 61

Page 65

Page 74

This program has been designed by the Automatic Transmission Rebuilders Association (ATRA) to be used by qualified automotive

transmission technicians. Since the circumstance of its use is beyond ATRA’s control, ATRA assumes no liability for the use of such

information or any damages incurred through its use and application. Nothing contained in this program is to be considered

contractual or providing some form of warranty on the part of ATRA. No part of this program should be construed as recommending

any procedure which is contrary to the vehicle manufacturer’s procedures. ATRA recommends that only certified automotive

technicians with experience in transmission diagnosis and repair perform the procedures in this program.

This program contains copyrighted material belonging to ATRA. No part of this program may be reproduced or used in any form by

any means- graphic, electronic or mechanical, including photocopying, recording, electronic, or information storage-and-retrieval

systems- without the express written permission from ATRA.

ATRA® and the ATRA® logo are registered trademarks of the Automatic Transmission Rebuilders Association.

Public exhibition or use of this material for group training or as part of a school curriculum, without the express written permission of

ATRA, is prohibited by law. For information on using this material for independent training programs, contact ATRA at (805) 604-

2000.

©2003 ATRA. All rights reserved. Printed in U.S.A.

©2003 ATRA. All Rights Reserved. Printed in U. S. A.

1 4L80E Rebuild Procedures

Unit Disassembly

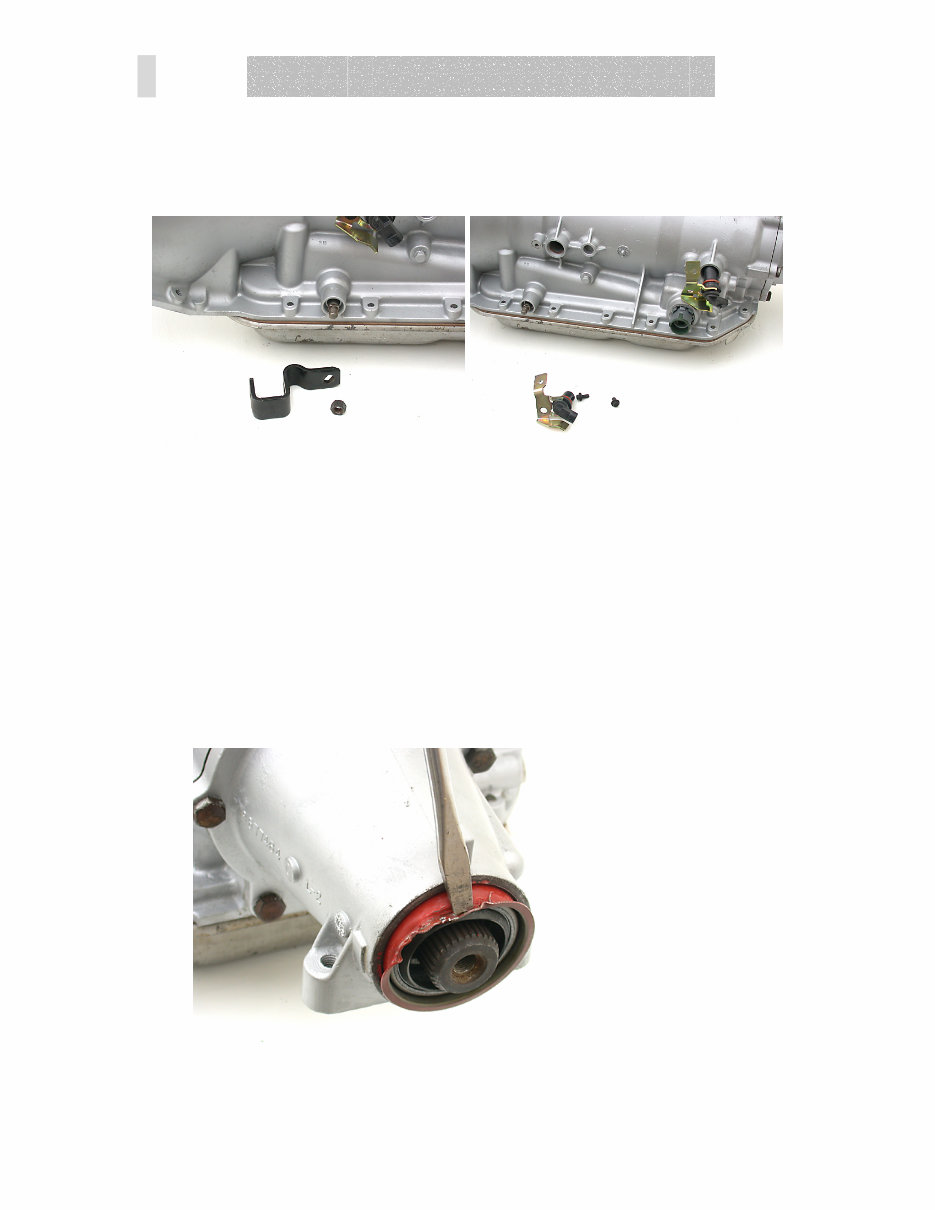

Step 1: Unbolt the shift lever and speed sensors, remove them from the case, then use a

pick to remove the o-rings from the sensors.

Note: The next two steps only apply to 2-wheel drive units.

Step 2: The rear seal usually needs to get repeatedly bashed with a hammer and

screwdriver or chisel to remove it from the extension housing as shown. This will

definitely be easier to do while the housing is still bolted to a big, heavy transmission,

rather than chasing the extension housing with your tools all over your bench and the

shop floor after it’s been removed from the unit. Save yourself the embarrassment of

somebody else seeing this clown act by removing the seal now in a dignified manner.

©2003 ATRA. All Rights Reserved. Printed in U. S. A.

2 4L80E Rebuild Procedures

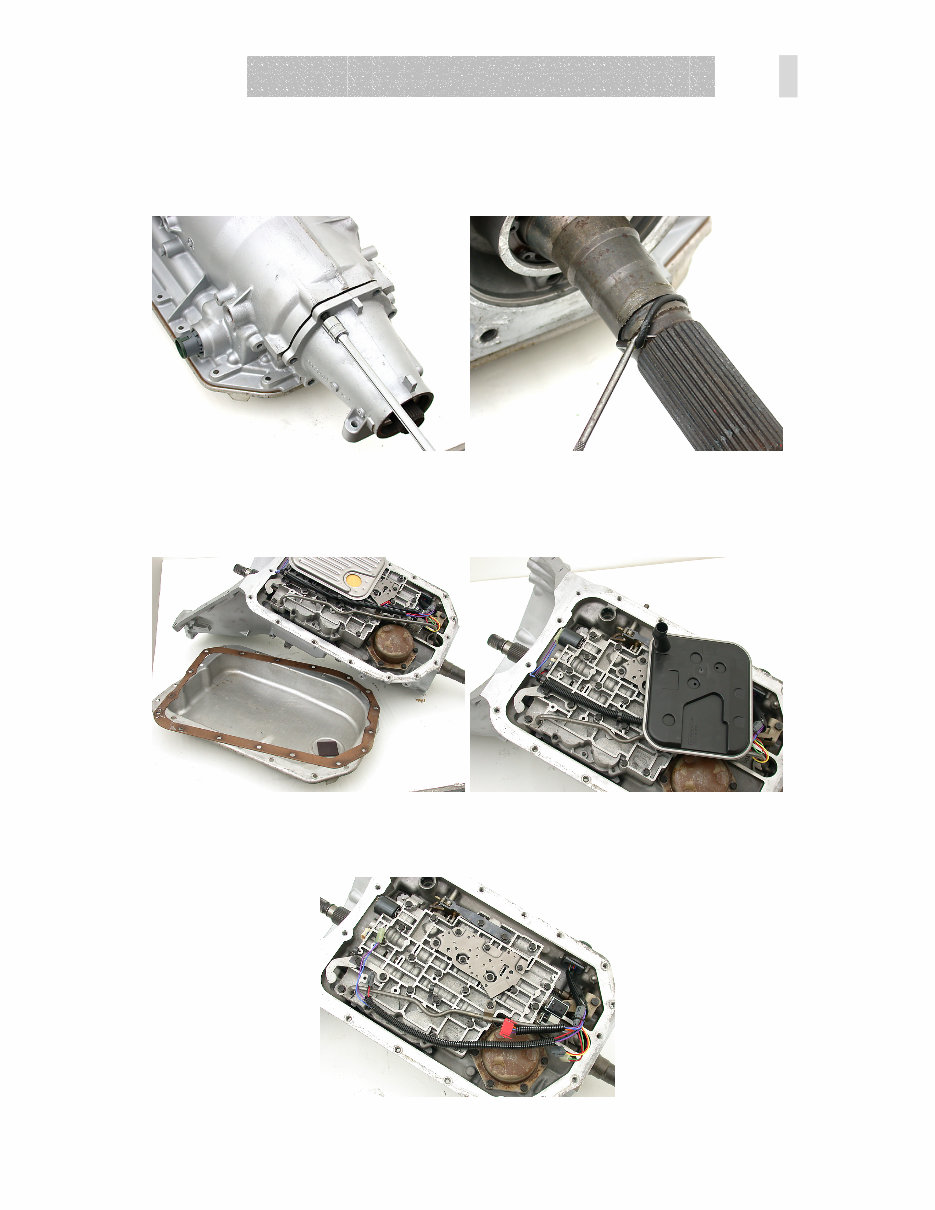

Step 3: Remove the extension housing bolts, and slide the extension housing off of the

case. Remove the o-ring from the shaft groove, paying careful attention to any thrust

washers, bearings or seals on the shaft; the exact configuration depends on the unit you're

working on.

Step 4: Unbolt the transmission oil pan, and remove the pan, gasket and oil filter from

the unit. Be careful with the pan gasket if it’s rubber and has metal bolt holes— it's

reusable as long as it’s still soft and isn’t nicked or cut anywhere. Discard the filter.

Step 5: Carefully disconnect the transmission wiring harness connectors from the

solenoids and switches on the valve body.

©2003 ATRA. All Rights Reserved. Printed in U. S. A.

3 4L80E Rebuild Procedures

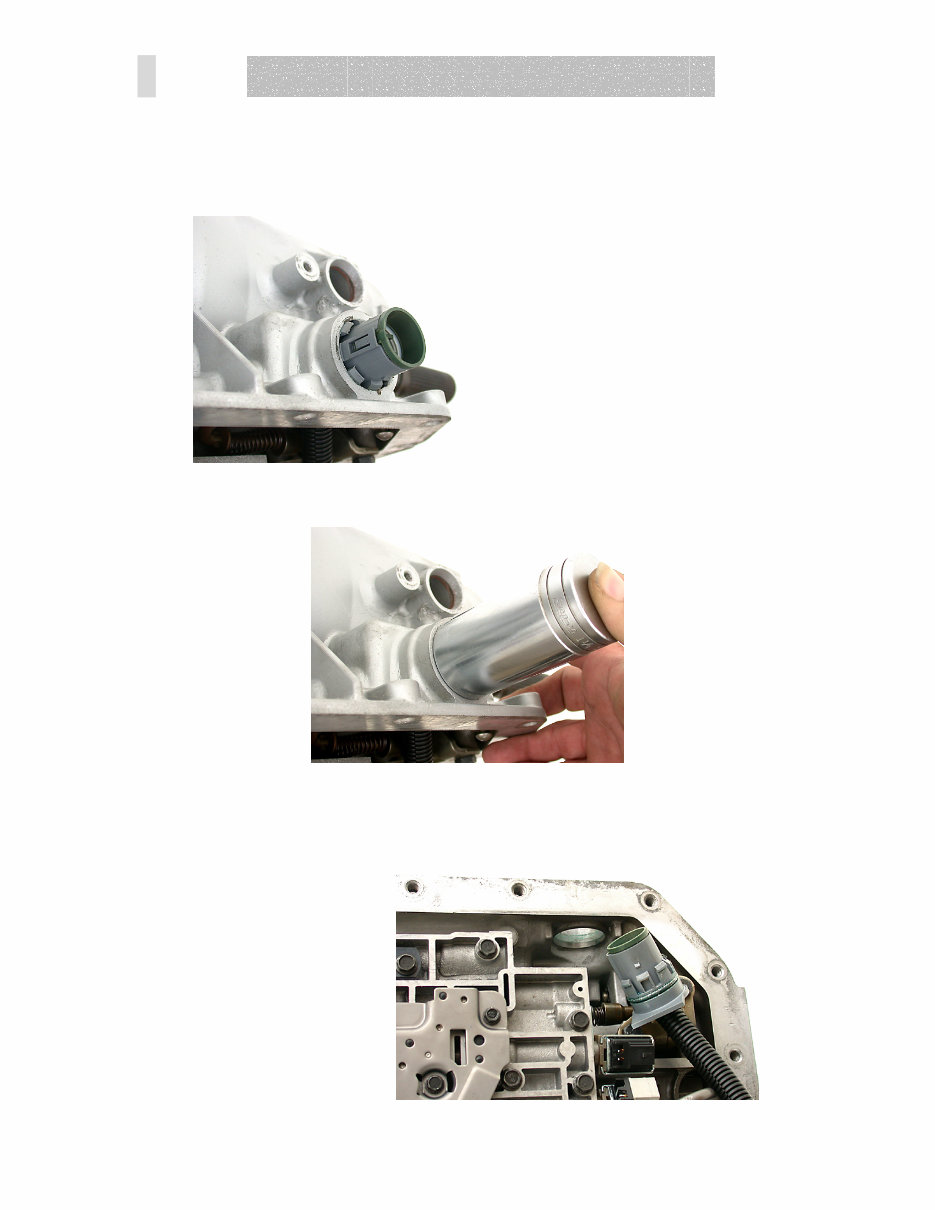

Step 6: Push a 1-1/4", 12-point socket or box wrench over the transmission case

connector to compress the retaining clips, and carefully push the case connector into the

case to remove it. Don't pull on the wires; they can break internally, and cause electrical

problems later.

©2003 ATRA. All Rights Reserved. Printed in U. S. A.

4 4L80E Rebuild Procedures

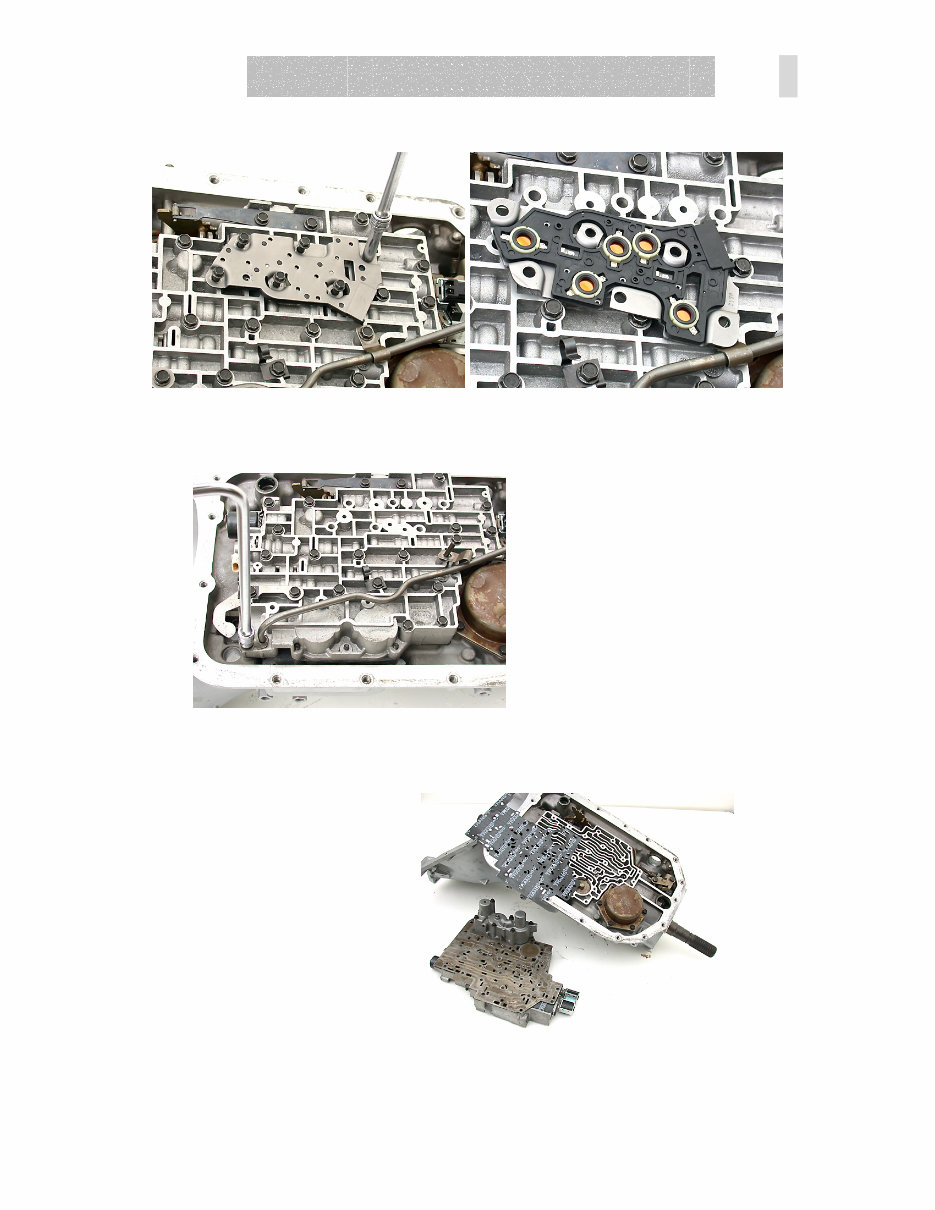

Step 7: Remove the Pressure Switch Manifold (PSM) bolts, and remove the switch.

Step 8: Remove the bracket holding the lube oil pipe in place, and carefully remove the

pipe from the unit.

Step 9: Unbolt the valve body and accumulator assembly. Remove the valve body and

accumulator assembly, separator plate and gaskets from the transmission.

©2003 ATRA. All Rights Reserved. Printed in U. S. A.

5 4L80E Rebuild Procedures

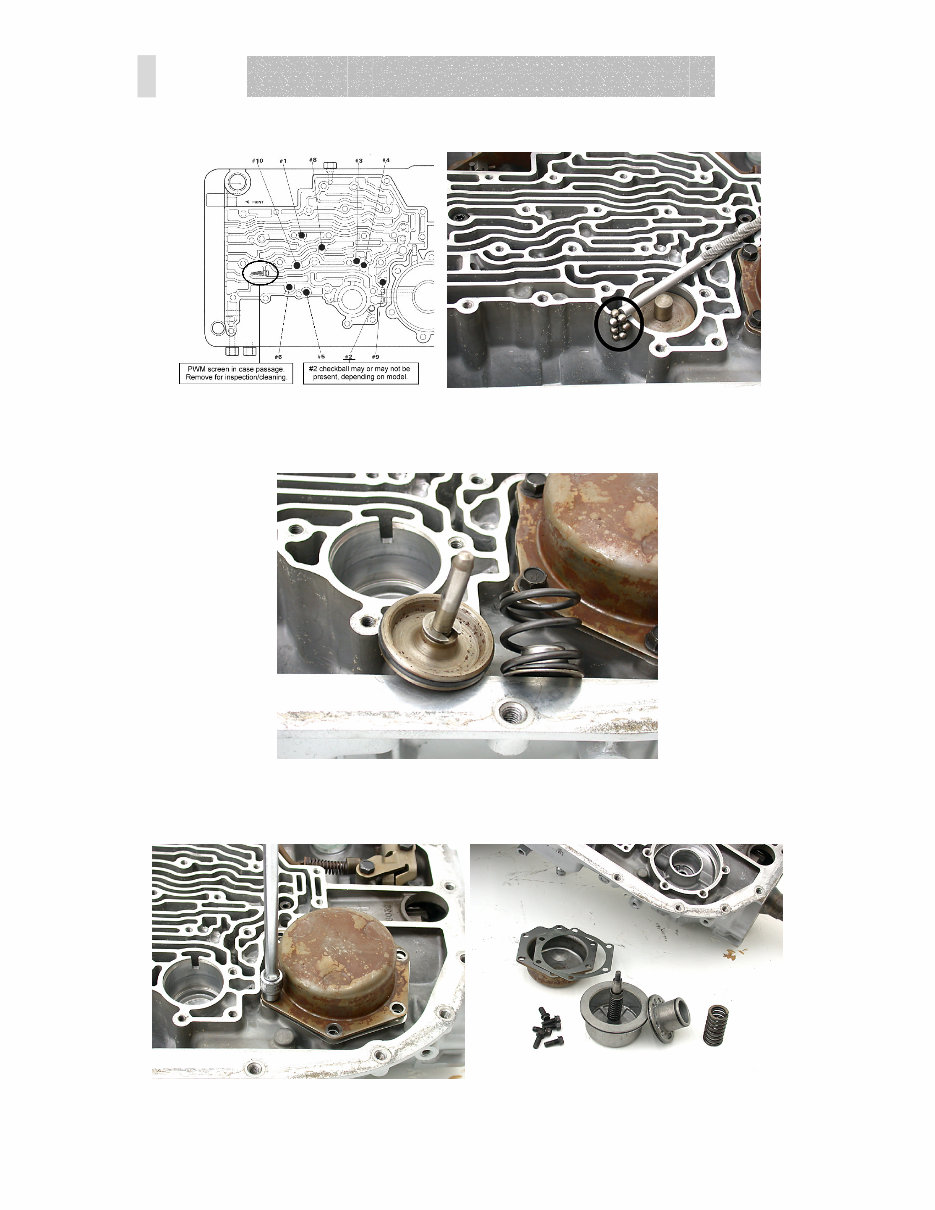

Step 10: Remove the case filter and checkballs from the case.

Step 11: Remove the Manual 2 brake band servo and spring, located directly in front of

the low/reverse servo cover.

Step 12: Unbolt the low/reverse servo cover. Remove the cover, gasket, servo and return

spring from the case. Discard the gasket.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

Viewed 24 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

Get access to the comprehensive 4L80 4L80E Transmission Gearbox Rebuild Procedure Manual. This manual is an essential resource for professional mechanics and DIY enthusiasts alike. It is bookmarked for quick navigation, allowing you to find the specific section you need with ease.