Ford 4R100 4-Speed Automatic Transmission Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

INTRODUCTION

FORD 4R100

AUTOMATIC TRANSMISSION SERVICE GROUP

9200 S. DADELAND BLVD. SUITE 720

MIAMI, FLORIDA 33156

(305) 670-4161

DALE ENGLAND

FIELD SERVICE CONSULTANT

ED KRUSE

TECHNICAL CONSULTANT

WAYNE COLONNA

TECHNICAL SUPERVISOR

PETER LUBAN

TECHNICAL CONSULTANT

JIM DIAL

TECHNICAL CONSULTANT

GREGORY LIPNICK

TECHNICAL CONSULTANT

JERRY GOTT

TECHNICAL CONSULTANT

JON GLATSTEIN

TECHNICAL CONSULTANT

DAVID CHALKER

TECHNICAL CONSULTANT

STANTON ANDERSON

TECHNICAL CONSULTANT

ROLAND ALVAREZ

TECHNICAL CONSULTANT

MIKE SOUZA

TECHNICAL CONSULTANT

GERALD CAMPBELL

TECHNICAL CONSULTANT

1

No part of any ATSG publication may be reproduced, stored in any retrieval system or transmitted in any form or

by any means, including but not limited to electronic, mechanical, photocopying, recording or otherwise,

without written permission of Automatic Transmission Service Group. This includes all text illustrations,

tables and charts.

The information and part numbers contained in this booklet have

been carefully compiled from industry sources known for their

reliability, but ATSG does not guarantee its accuracy.

Copyright © ATSG 2003

Updated

October, 2003

The Ford 4R100 transmission is an updated version of the E4OD and was first introduced in the 1999 model

year, and is currently found in the F250, F350, F450 and F550 Super Duty trucks, E150, E250, E350, E450 vans

and the Expedition/Navigator/Excursion vehicles equipped with the 5.4L, 6.8L, and 7.3L engines. Some of the

4R100 units are equipped with a Power-Take-Off (PTO) window on the left hand side of the transmission case.

The revisions in the 4R100 have created many new engineering changes that have affected many of the internal

and external parts that will affect the servicing, repairing and overhaul of these units.

We wish to thank Ford Motor Company

for the information and illustrations

that have made this booklet possible.

INDEX

Copyright © ATSG 2003

FORD 4R100

2

AUTOMATIC TRANSMISSION SERVICE GROUP

9200 S. DADELAND BLVD. SUITE 720

MIAMI, FLORIDA 33156

(305) 670-4161

IDENTIFICATION TAG LOCATION AND INFORMATION ............................................................... 3

GENERAL DESCRIPTION AND OPERATION ..................................................................................... 4

COMPONENT AND SOLENOID APPLICATION CHART ................................................................... 5

"PTO" GENERAL REQUIREMENTS .................................................................................................... 6

ELECTRICAL COMPONENT DIAGNOSIS ........................................................................................... 8

FLUID REQUIREMENTS ....................................................................................................................... 12

SOLENOID PACK TESTING .................................................................................................................. 12

ABBREVIATION DESCRIPTION .......................................................................................................... 14

DIAGNOSTIC TROUBLE CODE CHART AND DESCRIPTION ........................................................ 15

LINE PRESSURE TEST .......................................................................................................................... 21

NON-PTO AND PTO HYDRAULIC DIFFERENCES ........................................................................... 22

PWM AND NON-PWM OIL PUMPDIFFERENCES ........................................................................... 34

CASE CHECKBALL LOCATIONS ......................................................................................................... 38

VALVE BODY CHECKBALL LOCATIONS ........................................................................................... 39

AIR PRESSURE CHECKS ...................................................................................................................... 40

TRANSMISSION DISASSEMBLY ......................................................................................................... 41

COMPONENT REBUILD SECTION

TRANSMISSION CASE ASSEMBLY ................................................................................................ 55

FRONT AND REAR PLANETARYCARRIERS ............................................................................... 64

FORWARD CLUTCH HOUSING ...................................................................................................... 66

DIRECT CLUTCH HOUSING ........................................................................................................... 69

FORWARD, DIRECT, SUN SHELL SUB-ASSEMBLY .................................................................... 76

CENTER SUPPORT ASSEMBLY ...................................................................................................... 80

INTERMEDIATE/OVERDRIVE CYLINDER ASSEMBLY ............................................................. 82

OVERDRIVE GEARSET ASSEMBLY ............................................................................................... 84

COAST CLUTCH HOUSING DIFFERENCES ................................................................................ 88

COAST CLUTCH HOUSING ASSEMBLY ........................................................................................ 90

OIL PUMP ASSEMBLY ...................................................................................................................... 94

VALVE BODY ASSEMBLY ............................................................................................................... 100

TRANSMISSION FINAL ASSEMBLY ................................................................................................. 102

MANUAL VALVE CHECK .................................................................................................................... 111

MANUAL SHIFT LEVER DIFFERENCES ........................................................................................ 112

TORQUE SPECIFICATIONS ............................................................................................................... 115

VALVE BODY BOLT CHART AND IDENTIFICATION .................................................................... 116

BOLT CHART AND IDENTIFICATION ............................................................................................. 117

SPECIAL SERVICE TOOLS ................................................................................................................. 118

3

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

Copyright © 2003 ATSG

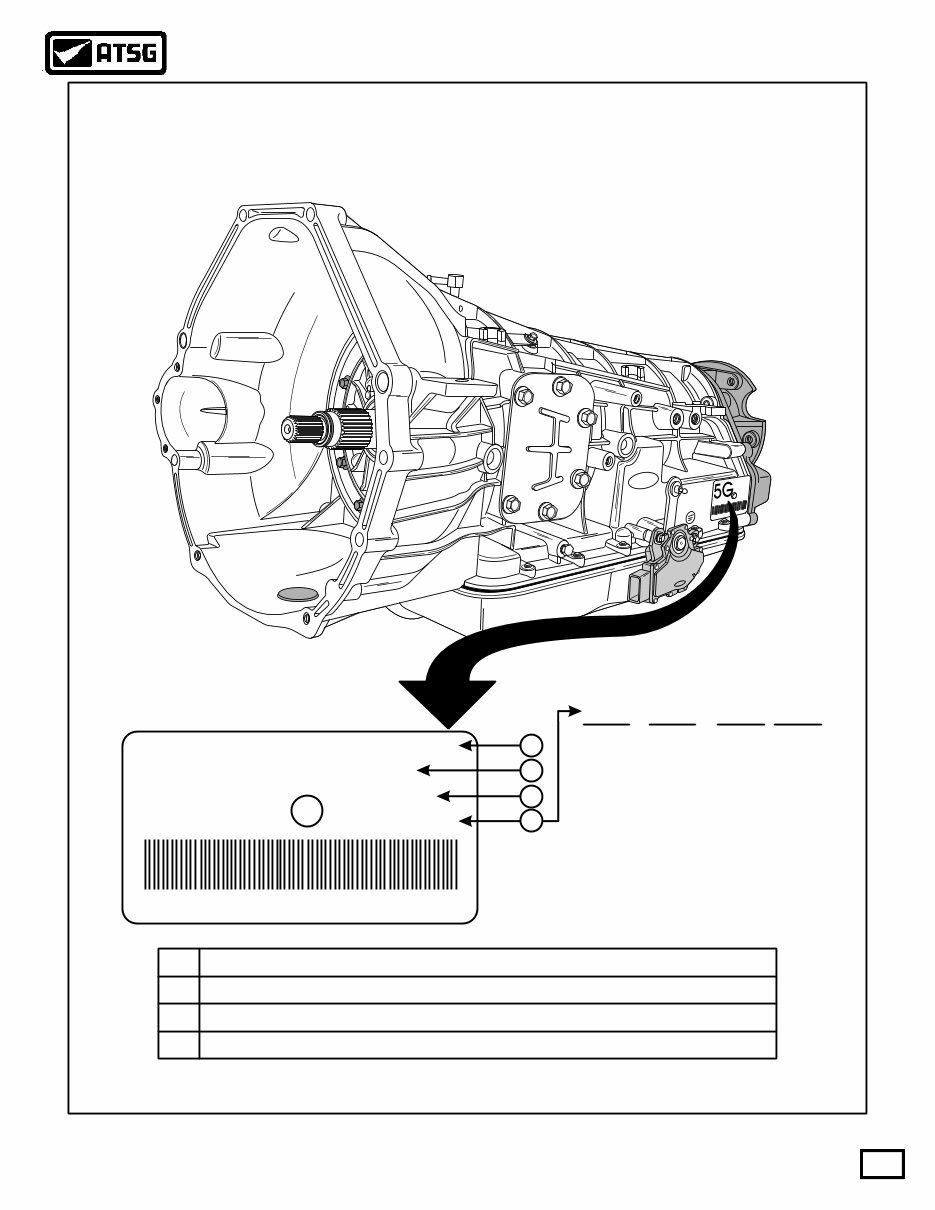

RFF81P-7006-BA

Ford

Ford Ford

98

XW4P-AC

RJL-B

004361

BD-9C17

17 C 9 BD-

Build

Date

Year Month Day

9=1999

0=2000

1=2001

2=2002

3=2003

A=Jan

B=Feb

C=Mar

D=Apr

E=May

F=Jun

G=Jul

H=Aug

J=Sep

K=Oct

L=Nov

M=Dec

XW4P-AC

5G

RJL-B

BD-9C17

004361

004361 6520

4 X 4 4 X 4

1

2

3

4

Build Date (Year, Month, Day)

Serial Number

Transmission Model

Assembly Part Number, Prefix And Suffix 1

2

3

4

TRANSMISSION IDENTIFICATION

WITH POWER TAKE OFF OPTION

PTO is available as an option on 8500 GVW or above, Super Duty

F-Series trucks with 6.8L gasoline and 7.3L Diesel engines.

Ford 4R100 transmissions on other models are not PTO capable.

Note:

Figure 1

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

4

Copyright © 2003 ATSG

TRANSMISSION

DESCRIPTION AND OPERATION

General Description

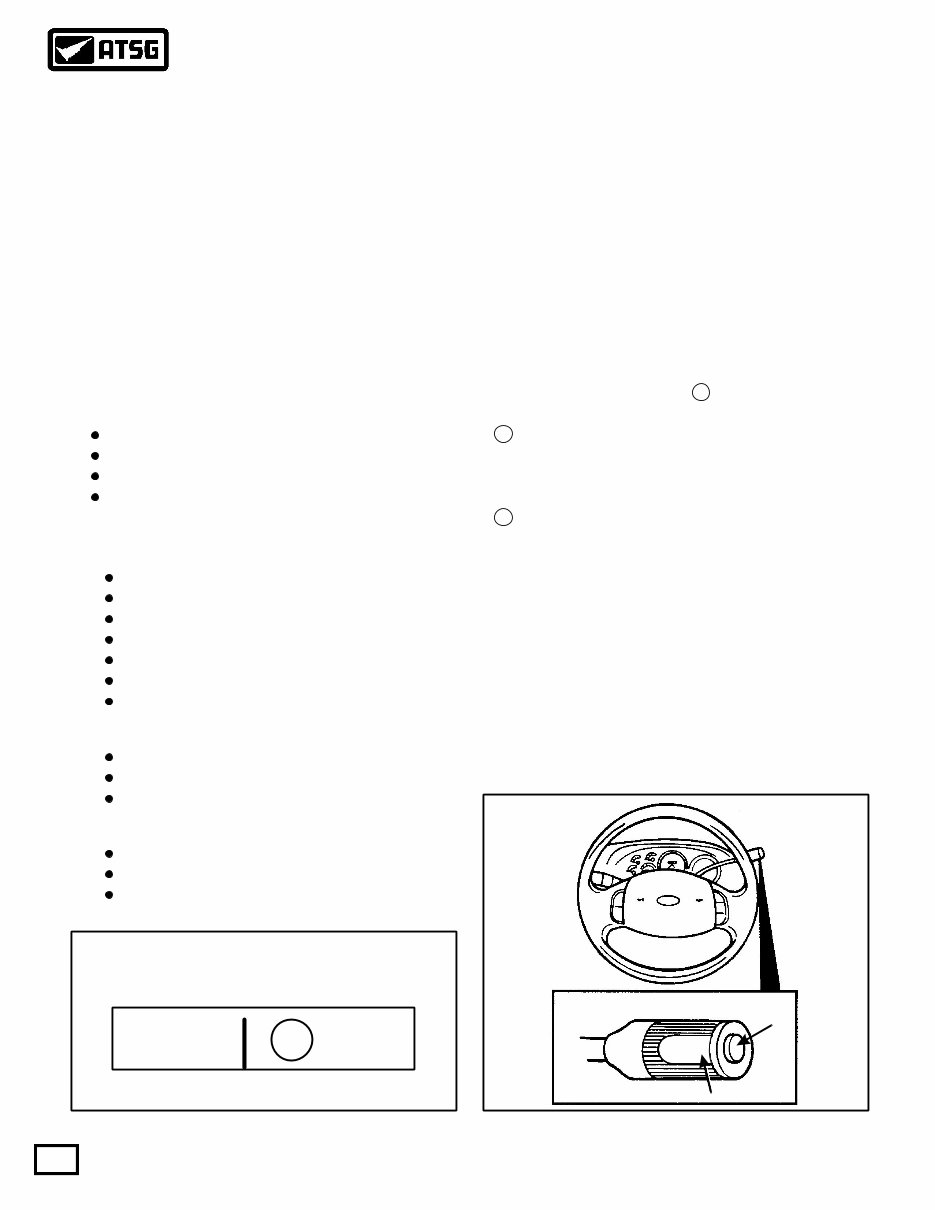

Shift Quadrant Indicator

Major Internal Components

"Seven Friction Apply Elements"

"Three One-Way Clutches"

"Three Simple Planetary Gearsets"

"Typical" Shift Quadrant Indicator

The Ford 4R100 automatic transmission is a four

forward speed unit with electronic shift control. It is

designed for longitudinal powertrains for rear wheel

drive vehicles.

The 4R100 transmission features a four element

torque converter design that includes Torque

Converter Clutch (TCC) and a gear train that includes

three planetary gearsets.

Some models provide for Power Take Off (PTO)

operation in all transmission shift lever positions.

During PTO operation in OD, 4th gear is disabled.

The hydraulic control system of the 4R100 unit has

five electronically controlled solenoids for:

Shift feel, through line pressure control.

Shift scheduling, through shift valve position.

Engine braking during coast conditions.

TCC apply (On/Off or Modulating).

Intermediate Band

Coast Clutch, Multi-disc

Overdrive Clutch, Multi-disc

Intermediate Clutch, Multi-disc

Direct Clutch, Multi-disc

Forward Clutch, Multi-disc

Low/Reverse Clutch, Multi-disc

Overdrive Roller Clutch

Intermediate Sprag

Low Roller Clutch

Overdrive

Forward

Reverse

PRND21

Figure 2 Figure 3

Vehicles equipped with the 4R100 transmission have

a Transmission Control Switch (TCS), also referred to

as "Overdrive Cancel Switch", and a Transmission

Control Indicator Lamp (TCIL), located on the end of

the manual gear shift lever, as shown in Figure 3. The

TCS is a momentary contact switch. When this

switch is pressed, a signal is sent to the PCM to allow

automatic shifts from 1st to 4th gear or from 1st to 3rd

gear. After the TCS has been pressed the PCM turns

on the TCIL lamp ("OFF"), to indicate that overdrive

has been canceled, as shown in Figure 3.

OVERDRIVE OFF OVERDRIVE OFF

TCS

SWITCH

TCIL LAMP

The shift quadrant has the following positions, as

shown in Figure 2: P, R, N, D , 2 and 1.

D position (TCS OFF) provides 1-2-3-4 automatic

upshifts and downshifts. Coast braking occurs in 4th

gear. (TCIL Not Illuminated)

D position (TCS ON) provides 1-2-3 automatic

upshifts and downshifts. Coast braking occurs in 3rd

gear. (TCIL Illuminated)

2 position provides a pull-in shift to 3rd gear with

coast braking. After an automatic downshift, a 2nd

gear hold occurs with coast braking.

1 position provides a pull-in shift to 2nd gear with

coast braking. After an automatic downshift, a 1st

gear hold occurs with coast braking.

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

5

Copyright © 2003 ATSG

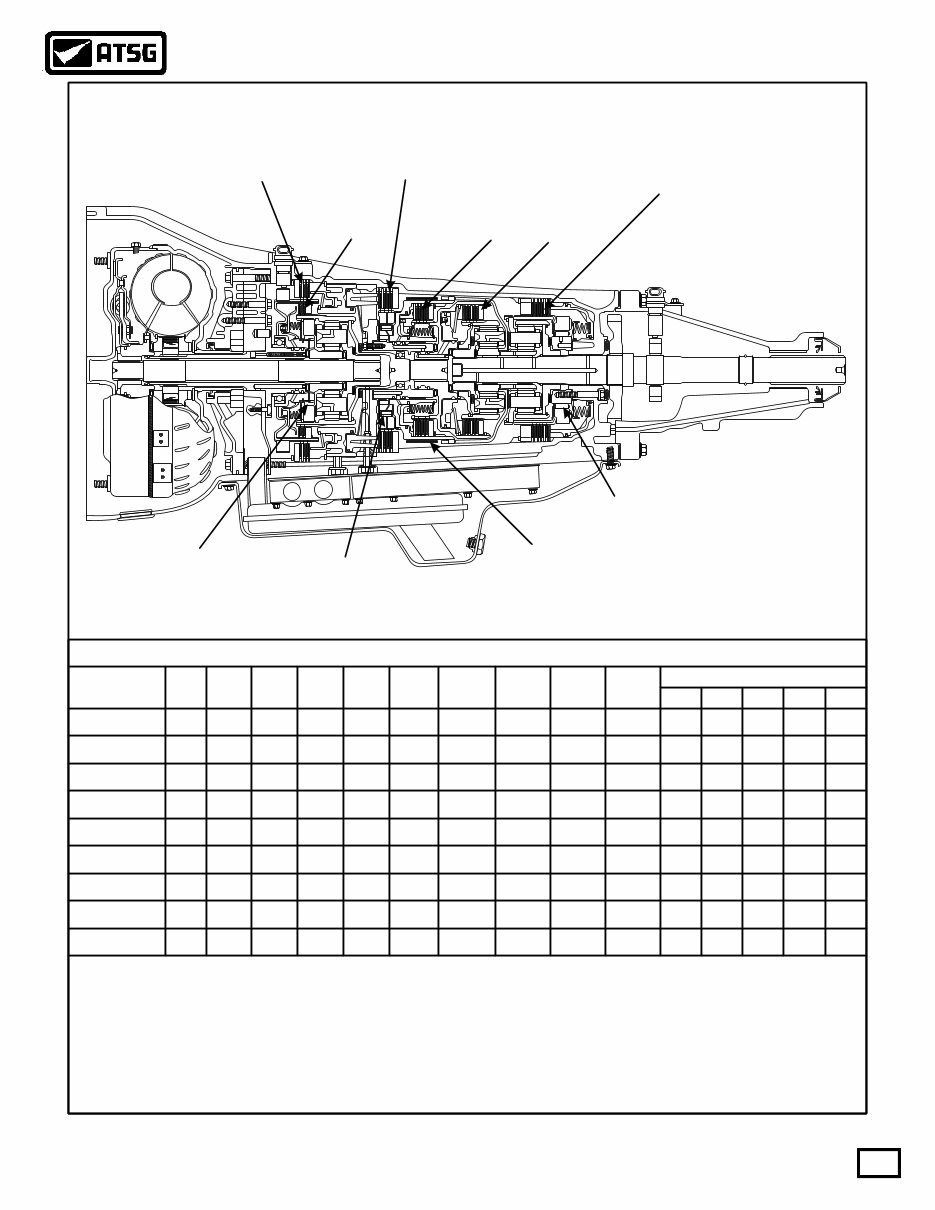

FORD MOTOR COMPANY

4R100 ("PTO" Version Illustrated)

Reverse - 2.18

GEAR RATIOS

Overdrive

Clutch

Overdrive

Roller Clutch

Intermediate

Clutch

Intermediate

Band

Intermediate

Sprag

Coast

Clutch

Forward

Clutch

Direct

Clutch

Low/Reverse

Clutch

Low

Roller Clutch

1st Gear - 2.71

2nd Gear - 1.54

3rd Gear - 1.00

4th Gear - 0.71

Fwd

Clut

ON Hold

Hold

Hold

Hold

Hold Hold

Hold

Hold

Hold

Hold

Hold

ON ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON ON

On

On

On *On

*On

*On

*On

*On

*On

On

On

On

On

On

On On

On

Mod

Mod

Mod

Mod

Mod

Mod

Mod

Mod

Mod On

On

Off Off

Off Off Off

Off

Off

Off

*Off

*Off

*Off

Off

Off

Off

Off

Off

Off

ON

ON ON

ON

ON ON

ON

ON

ON

ON

Int

Clut

Int

Band

O.D.

Roller

Low

Roller SS1 SS2 CCS

SOLENOIDS

TCC EPC

Int

Sprag

Dir

Clut

O.D.

Clut

Cst

Clut

L/R

Clut

Park/Neut

Reverse

OD-2nd

OD-3rd

OD-3rd**

OD-3rd** = TCS "On" with TCIL illuminated showing "Off"

OD-4th

M-2nd

M-1st

OD-1st

GEAR

COMPONENT AND SOLENOID APPLICATION CHART

*On = If the PCM determines that powertrain operating conditions exist for TCC apply, the TCC solenoid may

be On (Modulating with PWM TCC units) in any forward gear except Manual 1st.

*Off = Will be "On", if the TCS switch is pushed.

Mod = Modulating at all times by the PCM and line pressure will be regulated based on throttle position,

engine load and vehicle speed.

Figure 4

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

6

Copyright © 2003 ATSG

PTO "GENERAL" REQUIREMENTS:

RFF81P-7006-BA

Ford

Ford Ford

98

XW4P-AC

RJL-B

004361

BD-9C17

PTO

Window

Figure 5

(1) Obviously the case must be PTO capable with

the cast-in window in the transmission where the

PTO unit mounts to the transmission, as shown in

Figure 5.

(2) Designed for use during Mobile (Some Models)

or Stationary conditions.

Shift Solenoid 2 and the Coast Clutch Solenoid

must be energized when the PTO is turned ON.

(3) PTO is available as an option only on 8500 GVW

or above, Super Duty F-Series trucks with 6.8L

Gasoline and 7.3L Diesel engines. Ford 4R100

transmissions on other models are not PTO

capable.

(4)

(5)

Battery voltage must be supplied to the

Powertrain Control Module (PCM) input pin 4

on gasoline models, or pin 66 on diesel models,

when the PTO is engaged. The processor uses

this information to raise EPC pressure to

approximately 55 PSI so that you do not burn the

coast clutch. This voltage must be provided by

the PTO installer.

"GENERAL" CONDITIONS FOR OPERATION

(1)

(2)

(3)

(4)

(5)

The vehicle is not in the crank or start mode.

The transmission range selector must be in the P,

R, O.D, 2 or 1 position. The PTO will not operate

when selector is in the neutral position.

PTO operation is inhibited when in cranking

mode, neutral, or 4th gear.

Transmission only operates 1st through 3rd

gears. Computer strategy does not allow 4th

gear to engage, under any conditions.

Transmission Fluid Temperature Sensor (TFT)

reading must be up to operating temperature.

Specific Operation For Diesel, See Page 7.

GASOLINE ENGINE PTO OPERATION:

(1)

(2)

(3)

(4)

PTO installer must obtain a "High Idle Throttle

Control" from an aftermarket source.

Auxiliary Powertrain Control Module seen on

Page seven, does not work on the gasoline engine

models. APCM module works only on the 7.3L

diesel engine.

For stationary PTO operation an engine idle

speed of 1300 RPM is required.

The Torque Converter Clutch (TCC) engages

once the engine reaches 1300 RPM.

TRANSMISSION FUNCTIONS

DURING PTO OPERATION:

(1)

(2)

(3)

(4)

(6)

(5)

Shift Solenoid 2 and Coast Clutch Solenoids are

turned on, the coast clutch activates and does not

allow 4th gear operation during PTO operation.

Electronic Pressure Control (EPC) pressure is

raised to approximately 55 PSI. This is why the

coast clutch will be smoked in a short period of

time if a battery voltage wire is not supplied to

EEC input pin 4 (gasoline) or pin 66 (diesel)

when the PTO is engaged, as this rise in pressure

would not occur.

The Transmission Control Indicator Lamp

(TCIL) illuminates.

When the PTO is turned ON, the transmission

operates only in 1st through 3rd gears.

Overdrive 4th gear is not allowed by the PCM

strategy.

PTO operation can cause transmission fluid

temperature to exceed the recommended

maximum limit of 250 degrees F. Failure mode

logic within PCM strategy prevents transmission

damage by disabling the PTO above this

temperature limit.

The transmission shift schedule is early and shift

feel is very firm.

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

7

Copyright © 2003 ATSG

Ford Ford

Ford Ford

RPM

CONTROL

RPM

CONTROL

CHARGE

PROTECT

CHARGE

PROTECT

POWER POWER

2500

AUXILIARY POWERTRAIN CONTROL MODULE AUXILIARY POWERTRAIN CONTROL MODULE

CHARGE PROTECTION APPLICATION

KITS INCLUDE

RPM CONTROL

Charge Protection is used for maintaining battery charge.

In Charge Protection mode, the battery voltage is monitored and the

engine idle speed is increased as necessary, so the battery charge is

maintained as required.

Charge Protection can be activated from in-cab and can be

programmed to activate automatically on engine start-up.

Exclusively for light trucks with the 7.3L Diesel Engine.

Intended for Stationary Use Only.

Order Guide Option Code 961.

Aux. Powertrain Control Module.

Mounting Hardware and Bracket.

Wiring Harness.

Instruction Booklet.

Operators Card.

LCD screen displays the current

engine speed or battery voltage.

Each Single Arrow key contains a

preset speed allowing for four

programmable RPM settings.

The Double Arrow keys can also be

used to manually raise or lower the

engine speed at a faster or slower

rate.

RPM Control is used for

This is the recommended

method of elevating idle

speed for PTO operations.

RPM Control mode can be

activated from in-cab and

can be programmed to

activate automatically on

engine start-up.

The programmable speed

presets range from 1300 to

"AUXILIARY" POWERTRAIN CONTROL MODULE

7.3L DIESEL ENGINE (ONLY)

The Auxiliary Powertrain Control Module (APCM) commands the Electronic Engine Control

(EEC) module to increase the idle speed during PTO operation. The APCM controls engine

speed from 1300 to 2500 RPM.

The Auxiliary Powertrain Control Module is a seperate option, it does not come standard with a

PTO capable transmission, and is for 7.3L diesel applications only.

Intended for stationary use only, and in stationary operation the PTO requires an engine idle speed

of 1300 RPM. During stationary PTO operation on the 7.3L diesel, the EEC increases the idle to

1300 RPM automatically.

During stationary PTO operation, the Torque Converter Clutch (TCC) engages once the RPM

reaches 1200-1300 RPM.

The following conditions must be met before the idle speed is increased:

1. Parking brake must be engaged for all applications.

2. No hydraulic brake actuation.

3. Accelerator pedal must be in the idle position.

4. Vehicle speed must be zero MPH.

5. Brake lights must be functional.

DIESEL ENGINE PTO OPERATION:

Figure 6

DIAGNOSTIC CONCERNS WITH PTO

EQUIPPED VEHICLES:

ELECTRICAL COMPONENT DIAGNOSIS

(1)

(2)

(3)

(4)

Always ensure that PTO is turned OFF, before

any diagnostic procedures begin.

Never perform any transmission special tests

(i.e. pressure test, stall test etc.) when the PTO is

turned ON.

If a transmission concern or symptom goes

away with the PTO turned OFF, it is most likely

not a transmission concern.

On Board Diagnostics operate normally during

PTO operation with the exception of the engine

misfire monitor. The circuit checks made by the

PCM and Failure Mode Effect Management

(FMEM) capability will continue. The PTO

must be turned OFF to access Diagnostic

Trouble Codes (DTC's) and perform OBD tests.

Caution: If the batteries are disconnected for any

reason, the PCM "must" have a 7 mile drive cycle at

speeds above 50 MPH, before it remembers that it is

capable of running a PTO

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

8

Copyright © 2003 ATSG

Accelerator Pedal Position Sensor (Diesel Only)

4X4 Low Switch

The Accelerator Pedal (AP) position sensor is

mounted on the accelerator pedal inside the vehicle

and detects the position of the accelerator pedal and

sends this information as a varying voltage signal to

the PCM. The PCM then uses the monitored voltage

level of the AP sensor for control of EPC pressure and

shift scheduling.

The Idle Validation Switch is fed voltage through

fuse number 19, as well as the Transmission Control

Switch, as shown in Figure 7.

If the Idle Validation Switch feed voltage is lost for

any reason, the engine will immediately return to

idle and stay there until feed voltage is restored.

FUSE 19

Red/Yellow

Transmission Control Switch (TCS)

Clutch Pedal Position (CPP) (Std Trans Only)

Idle Validation Switch (IVS) (Diesel Only)

Overhead Trip Computer Module

Generic Electronic Module (GEM)

Instrument Cluster Terminal A12

Instrument Cluster Terminal B11

CENTRAL JUNCTION BOX

Figure 7

Figure 8

The 4X4 Low Switch is used to the PCM that the

transfer case system is operating in LOW range. The

PCM receives the 4X4 Low Switch input signal and

modifies shift scheduling for the lower gear ratio

(See Figure 8).

If the 4X4 LOW indicator fuse is blown, the

transmission will shift according to the 4X4 LOW

shift schedule, regardless of transfer case lever

position.

PCM PIN 14

Lt. Blue/Black

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

9

Copyright © 2003 ATSG

Copyright © 2003 ATSG

Turbine Shaft Speed Sensor

PTO Models Only = 496-1244 Ohms Resistance

Part Number F81Z-7M101-BA

Non PTO Models Only = 781-1979 Ohms Resistance

Part Number F81Z-7M101-AA

Copyright © 2003 ATSG

Output Shaft Speed Sensor

All Models = 781-1979 Ohms Resistance

Part Number F81Z-7M101-AA

Turbine Shaft Speed Sensor Output Shaft Speed Sensor

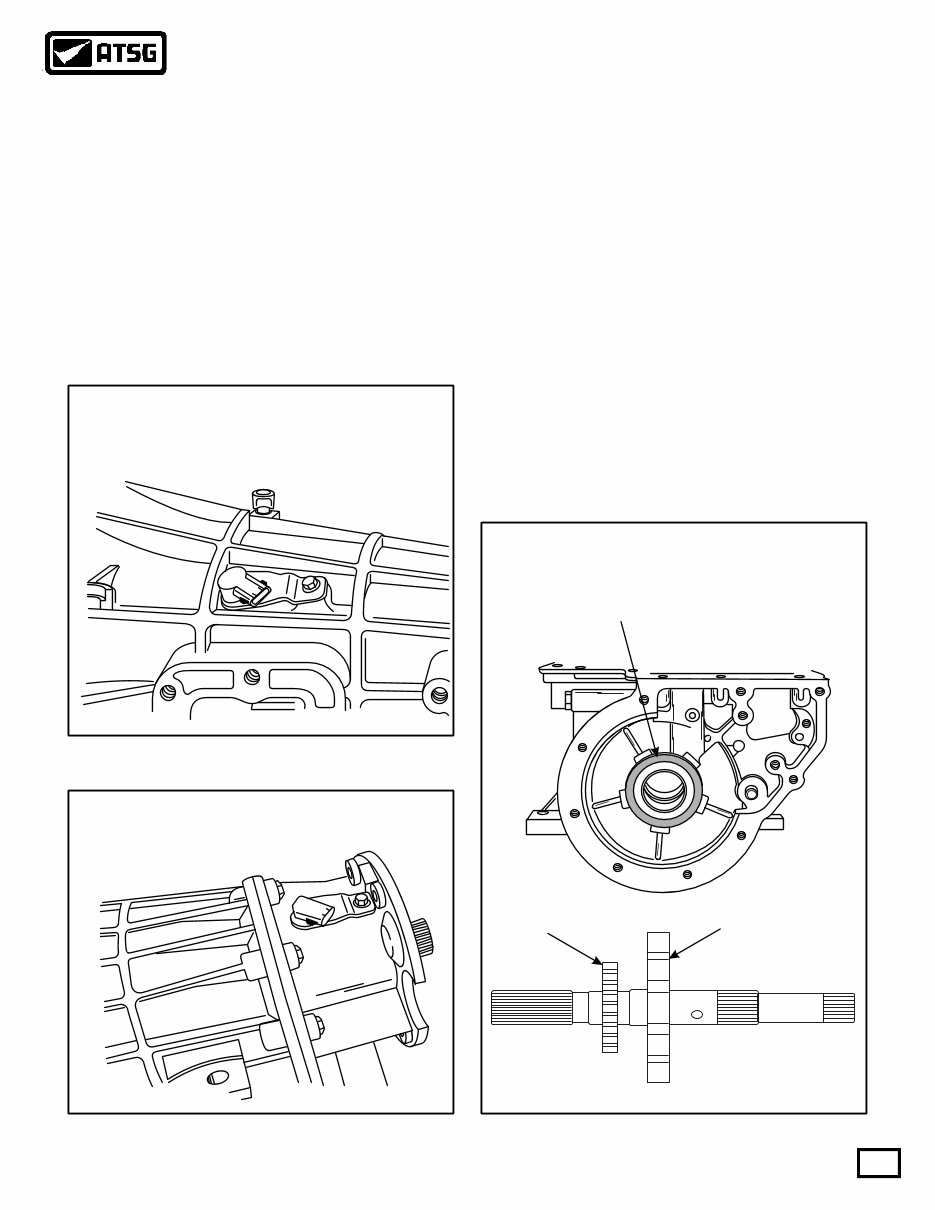

The Output Shaft Speed (OSS) sensor is a magnetic

pickup that sends the PCM a frequency signal related

to the rotating speed of the transmission output shaft.

The OSS sensor was added to the top of extension

housing, as shown in Figure 10. The OSS is triggered

by an added rotor pressed onto the output shaft. The

park gear is also now pressed onto the output shaft,

and the number 13 thrust washer has changed to a

thrust bearing, as shown in Figure 11. We have

provided you with the resistance reading and the

OEM part number for the output shaft speed sensor.

Refer to Figure 10 for output shaft speed sensor

information.

The PCM uses the OSS sensor signal to control EPC

pressure, shift scheduling and TCC strategy.

The Turbine Shaft Speed (TSS) sensor is a magnetic

pickup that sends the PCM a frequency signal related

to the rotating speed of the transmission input shaft.

The TSS mounts on the top front of the case on some

models, as shown in Figure 9. We have also provided

you with the resistance readings and OEM part

numbers on both Turbine Speed Sensors, as the PTO

and Non-PTO models use different sensors, as shown

in Figure 9.

The PCM uses the TSS sensor signal to control EPC

pressure and TCC strategy.

Figure 9

Figure 10 Figure 11

The Park Gear is also a press fit to the output

shaft, and the number 13 thrust washer, between

the case and the park gear has been replaced

with a needle bearing.

OSS Rotor Park Gear

(Press Fit) (Press Fit)

ELECTRICAL COMPONENT DIAGNOSIS DTR TESTING PROCEDURE

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

10

Copyright © 2003 ATSG

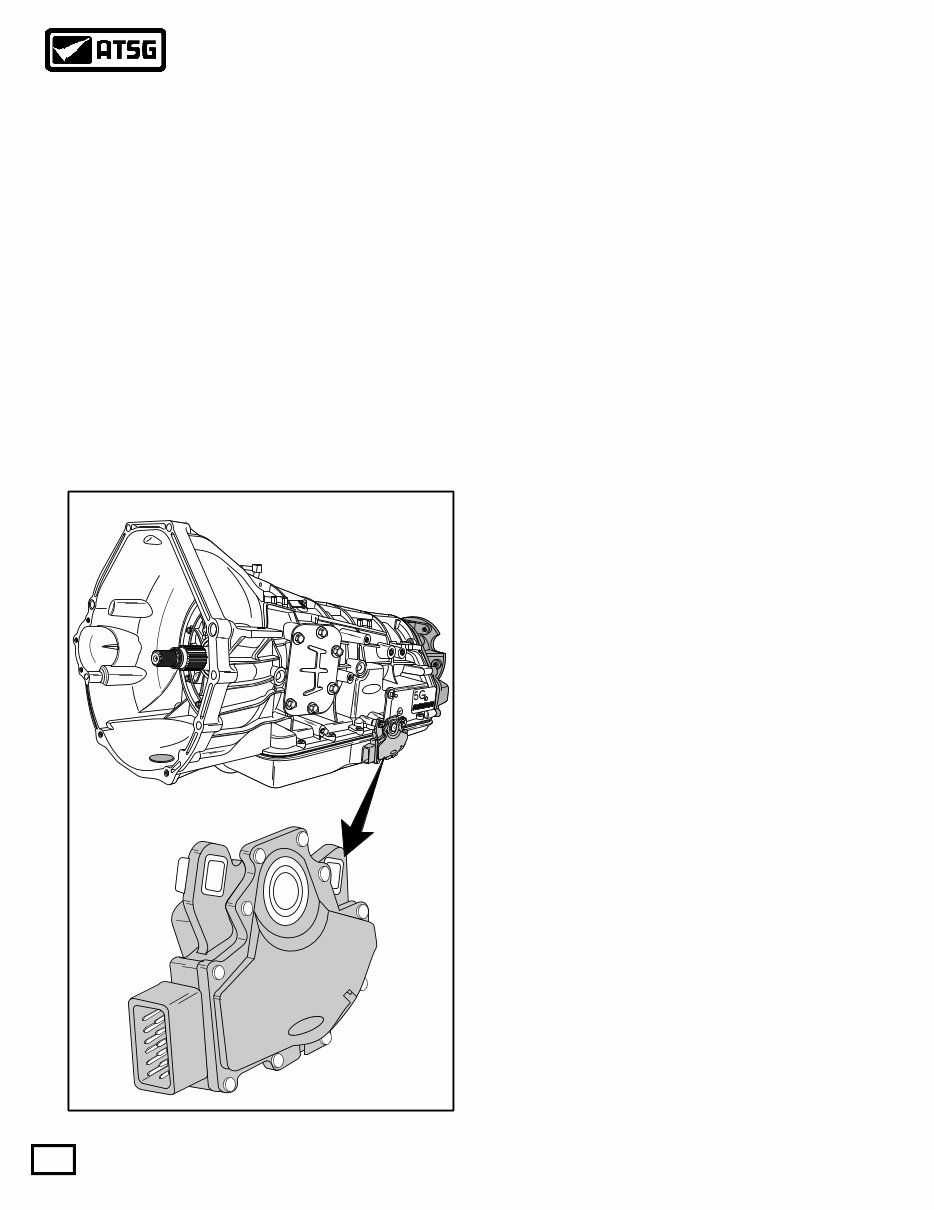

Digital Transmission Range Sensor

The Digital Transmission Range (DTR) sensor has a

twelve pin electrical connector and is located on the

outside of the transmission at the manual lever, as

shown in Figure 12.

The DTR sensor completes the start circuit in Park

and Neutral, the backup lamp circuit in Reverse, and

the neutral sense circuit (4WD Only) when in Neutral.

The DTR sensor also opens or closes a set of four

different switches that are monitored by the

Powertrain Control Module (PCM) to determine the

position of the transmission manual lever. Refer to

Figure 13.

Figure 12

Ford

F7TP-7F293-AA

NEUTRAL

L

C

RFF81P-7006-BA

Ford

Ford Ford

98

XW4P-AC

RJL-B

004361

BD-9C17

In Figure 13 we have provided you with pin number

identification for both the transmission range sensor

and the vehicle harness. We have also provided a

chart that will give you the open/closed state of each

internal switch, dependent on selector position, and

notice that three positions read a 270Ω resistor, that is

also internal.

Note: All testing that we have provided for you is

done with a DVOM, set to the ohms position, and all

tests are performed with the ignition switch in the

"OFF" position.

(1) Testing the transmission range 3A switch, and

the 270Ω internal resistor is done across pins 2

and 3 of the DTR sensor, and must be checked in

each selector position to determine the switch

and resistor integrity. Refer to Figure 13.

(2) Testing the transmission range 1 switch is done

across pins 2 and 4 of the DTR sensor, and must

be checked in each selector position to

determine switch integrity. Refer to Figure 13.

(3)

(4)

(5)

(6)

Testing the transmission range 2 switch is done

across pins 2 and 5 of the DTR sensor, and must

be checked in each selector position to

determine switch integrity. Refer to Figure 13.

Testing the transmission range 4 switch is done

across pins 2 and 6 of the DTR sensor, and must

be checked in each selector position to

determine switch integrity. Refer to Figure 13.

Testing the reverse lamp circuit is done across

pins 9 and 11 of the DTR sensor, and must be

checked in each selector position to determine

switch integrity. Refer to Figure 13.

Testing the neutral start circuit is done across

pins 10 and 12 of the DTR sensor, and must be

checked in each selector position to determine

switch integrity. Refer to Figure 13.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 54 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

The Ford 4R100 4-Speed Automatic Transmission Service & Repair Manual is an indispensable tool for any automotive professional or enthusiast servicing and maintaining Ford vehicles equipped with the 4R100 transmission. This detailed manual covers all aspects of service, repair, and maintenance:

- Comprehensive Service Instructions: Detailed procedures for servicing the 4R100 transmission, including fluid changes, filter replacement, and system diagnostics.

- Troubleshooting Guidelines: Diagnostic strategies and troubleshooting steps to help quickly resolve problems and restore transmission performance.

- Repair Procedures: Step-by-step repair instructions to tackle complex transmission issues, from minor adjustments to major rebuilds.

- Technical Specifications: Complete technical specs of the transmission, including torque specifications, capacities, and detailed assembly diagrams.

- Preventative Maintenance: Recommended maintenance schedules to extend the life of the transmission and avoid costly repairs down the line.

This manual is a must-have for maintaining the integrity and performance of Ford 4R100 transmissions. It provides the knowledge needed to ensure reliable operation, making it an invaluable resource for achieving professional-quality results in any setting.