Delphi DP210 Fuel Injection Pump OEM Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

WORKSHOP MANUAL

DP210 FUEL INJECTION PUMP DDNX184(EN)

2003

(D) Schutzbrille/Gesichtsschutz tragen.

(E) Úsese protección para los ojos/la cara.

(EN) Wear eye/face protection.

(F) Porter un appareil de protection des yeux / du visage.

(IT) Proteggersi gli occhi/la faccia.

(NL) Veiligheidsbril/-masker gebruiken.

(P) Use protecção da face/olhos.

(D) Von Zündquellen fernhalten - Nicht rauchen.

(E) Conservar alejado de toda llama o fuente de chispas -No fumar.

(EN) Keep away from sources of ignition - No smoking.

(F) Conserver à l'écart de toute flamme ou source d'étincelles - Ne pas fumer.

(IT) Conservare lontano da fiamme e scintille - Non fumare.

(NL) Ver van open vuur en ontstekingsbronnen houden – Niet roken.

(P) Mantenha afastado de fontes de ignição – Proibido fumar.

(D) Geeignete Schutzhandschuhe tragen.

(E) Usen guantes adecuados.

(EN) Wear suitable gloves.

(F) Porter des gants appropriés.

(IT) Usare guanti adatti.

(NL) Aangepaste veiligheidshandschoenen dragen.

(P) Use luvas apropriadas.

(D) Kommen Sie nicht mit dem Hochdruckstrahl in Verbindung! Besonders nicht, wenn

Druckrohrleitung oder Dichtung geprüft werden! Hochdruckflüssigkeiten können tödli-

che Verletzungen verursachen! Im Falle einer Berührung mit der Haut, kontaktieren Sie

sofort einen Arzt. Bitte beachten Sie die Gesundheits-/und Sicherheitsunterlagen.

(E) Mantenga las manos y el cuerpo lejos del rociado del líquido, especialmente inyecto-

res, tuberías y juntas de alta presión con fugas. La inyección de alta presión puede per-

forar la piel humana y producir una lesión fatal. En caso de que la inyección atraviese

la piel, consiga atención médica inmediatamente. Vea la hoja de Datos de Sanidad y

Seguridad.

(EN) Do not put your skin into the fuel jets under pressure, especially those due to pressure

pipe or seal leaks. High pressure liquids can cause deadly injuries. In case of an injec-

tion under the skin, contact a doctor immediately. Please refer to the health and secu-

rity fuel documents.

(F) Ne pas approcher les mains ni le corps des jets de liquides, particulièrement ceux pro-

venant des fuites de tuyaux et des joint soumis a la haute pression. Le liquide sous

haute pression injecté sous la peau peut causer des blessures mortelles. En cas d’in-

jection sous la peau, consulter immédiatement un médecin. Se reporter a la fiche de

santé et de sécurité du gazole.

(IT) Non esporre le mani o altre parti del corpo a getti di gasolio ad alta pressione, spe-

cialmente a quelli provenienti da tubi o paraolii. I getti di liquidi ad alta pressione pos-

sono causare ferite anche mortali. In caso di iniezione sotto pelle contattare immedia-

tamente un medico. Fare riferimento alle schede di sicurezza del gasolio.

(NL) Zorg dat uw handen of andere lichaamsdelen niet in contact komen met vloeistofstra-

len onder hoge druk, met name bij een lek aan een leiding of dichting. Als de vloeistof

onder hoge druk onder de huid terechtkomt, kan dit zelfs tot dodelijke verwondingen

leiden. Als de vloeistof onder de huid terechtkomt, onmiddellijk een arts raadplegen.

Lees de gezondheids- en veiligheidsfiche met betrekking tot de brandstof.

(P) Não exponha a pele a jactos de combustível sob pressão, especialmente os devidos a

fugas de tubos de pressão ou vedantes. Líquidos a alta pressão podem causar ferimen-

tos mortais. No caso de injecção subcutânea, consulte imediatamente um médico.

Consulte por favor a documentação respeitante a saúde e segurança de combustíveis.

CONTENTS

© Delphi Diesel Systems UK Ltd

Publication N°: DDNX184(EN) 2K/03.03/FOLIUM i

INTRODUCTION 1

DISMANTLING 2

COMPONENT INSPECTION AND RENEWAL 3

REASSEMBLY 4

TEST PROCEDURE 5

TOOLING, TORQUES & EVDS 6

BC - Boost Control

CA - Cold Advance

CP - Zero Backlash Drive

CPS - Carriage Position Sensor

DCU - Diesel Control Unit

ESOS - Electric Shut-Off Solenoid

EVD - Exploded View Diagram

FIE - Fuel injection Equipment

HP - High Pressure

LLA - Light Load Advance

OEM - Original Equipment Manufacturer

SIN - Service Instruction Note

TP - Transfer Pressure

NOTATIONAL CONVENTIONS AND ABBREVIATIONS

ii

Produced by:

Delphi Diesel Aftermarket Operations

Stratford Road

Shirley, Solihull Tel.: (44) (0)121 746 6000

B90 4DT, UK Fax: (44) (0)121 746 6001

1 INTRODUCTION

1.1 The Pump .........................................................................................................................................................................7

1.2 General ........................................................................................................................................................................7 - 8

1.3 This Manual ......................................................................................................................................................................8

1.4 Equipment ........................................................................................................................................................................8

1.5 Replacement of Parts.......................................................................................................................................................8

1.6 Pump Name Plate .......................................................................................................................................................8 - 9

2 DISMANTLING

2.1 Preparation .....................................................................................................................................................................11

2.1.1 Cleaning and draining ........................................................................................................................................11

2.1.2 Mounting the pump ...........................................................................................................................................11

2.1.3 Sealing caps and drive shaft lock bolt..............................................................................................................11

2.1.4 Drive hub (if fitted) .............................................................................................................................................12

2.1.5 Measuring drive shaft end float ........................................................................................................................12

2.1.6 Measuring drive shaft radial play .....................................................................................................................12

2.2 Drive Shaft ......................................................................................................................................................................13

2.3 High Pressure Outlets and End Plate Assembly .........................................................................................................13

2.3.1 High pressure outlets ........................................................................................................................................13

2.3.2 Endplate assembly .....................................................................................................................................13 - 14

2.4 Electric Shut-off Solenoid (ESOS) ................................................................................................................................14

2.5 Transfer Pump ................................................................................................................................................................14

2.6 Governor Cover External Components .......................................................................................................................15

2.6.1 Fuel return connections ....................................................................................................................................15

2.6.2 Throttle lever stop screws, maximum fuel adjuster blanking plug and torque control screw ..................15

2.6.3 Throttle lever ......................................................................................................................................................16

2.7 Governor Cover .............................................................................................................................................................16

2.7.1 Governor cover with torque control only ................................................................................................16 - 17

2.7.2 Governor cover fitted with boost control ................................................................................................17 - 19

2.8 All Speed Governor ......................................................................................................................................................19

2.9 Governor Control Bracket and Arm Assembly ..........................................................................................................19

2.9.1 Scroll link plate return spring ...................................................................................................................19 - 20

2.9.2 Governor control bracket assembly ................................................................................................................20

2.9.3 Governor control arm assembly ......................................................................................................................20

2.10 Slackening the Transfer Pump Rotor ..........................................................................................................................20

2.11 Advance Device .....................................................................................................................................................20 - 21

2.11.1 Cam screw...........................................................................................................................................................22

2.12. Head Locating Fittings and Hydraulic Head ................................................................................................................22

2.12.1 Head locking screws...........................................................................................................................................22

2.12.2 Light load advance (LLA) ...................................................................................................................................22

2.12.3 Latch valve ..........................................................................................................................................................22

2.12.4 Releasing the hydraulic head ............................................................................................................................23

2.12.5 Drive assembly ...........................................................................................................................................23 - 24

2.13 Drive Shaft Seal(s) ........................................................................................................................................................24

3 COMPONENT INSPECTION AND RENEWAL

3.1 Cleaning ..........................................................................................................................................................................25

3.2 General............................................................................................................................................................................25

3.2.1 Mated and matched assemblies .......................................................................................................................25

3.2.2 Examination and replacement ..........................................................................................................................25

CONTENTS

iii

3.2.3 Seals ....................................................................................................................................................................25

3.3 Details .............................................................................................................................................................................25

3.3.1 Hydraulic head rotor ..........................................................................................................................................25

3.3.2 Hydraulic head plungers ....................................................................................................................................25

3.3.3 Cam ring and scroll plates .................................................................................................................................25

3.3.4 Rollers and shoes ...............................................................................................................................................25

3.3.5 Transfer pump .............................................................................................................................................25 - 26

3.3.6 Endplate...............................................................................................................................................................26

3.3.7 Control valves .....................................................................................................................................................26

3.3.8 Delivery valves and cambox pressurising valves ...........................................................................................26

3.3.9 Springs ................................................................................................................................................................26

3.3.10 Fittings and threads............................................................................................................................................26

3.3.11 Linkages...............................................................................................................................................................26

3.3.12 Throttle shaft .......................................................................................................................................................26

3.3.13 Drive shafts and associated components ........................................................................................................26

3.3.14 Advance device...................................................................................................................................................26

3.3.15 External controls.................................................................................................................................................26

3.3.16 Pump housing.....................................................................................................................................................26

3.3.17 Governor control cover ......................................................................................................................................26

3.3.18 Orifices.................................................................................................................................................................26

3.3.19 Electric shut-off solenoid ...................................................................................................................................26

3.4 Storage ..........................................................................................................................................................................26

3.4.1 New pumps ........................................................................................................................................................26

3.4.2 Overhaul pumps ................................................................................................................................................26

3.4.3 Storage conditions ............................................................................................................................................27

4 REASSEMBLY

4.1 Preparation .....................................................................................................................................................................29

4.1.1 Hydraulic head ....................................................................................................................................................29

4.2 Drive Shaft ......................................................................................................................................................................29

4.2.1 Catch and support plates ...................................................................................................................................29

4.2.2 Rollers and shoes ...............................................................................................................................................29

4.2.3 Governor weight cage ......................................................................................................................................30

4.2.4 Fitting the governor weight assembly to the drive shaft ..............................................................................30

4.2.5 O-ring and rear scroll plate ..............................................................................................................................30

4.2.6 Cam ring, front scroll plate and inner bearing ........................................................................................30 - 31

4.2.7 Drive shaft assembly .........................................................................................................................................31

4.2.8 Fitting the pump housing .................................................................................................................................31

4.3 Drive Shaft Seals, End Float and Radial Play .............................................................................................................31

4.3.1 Drive shaft seals ................................................................................................................................................32

4.3.2 Securing the drive shaft ....................................................................................................................................32

4.3.3 Measuring drive shaft end float ........................................................................................................................32

4.3.4 Measuring drive shaft radial play .....................................................................................................................33

4.4 Hydraulic Head, Cam Screw and Head Locating Fittings ..........................................................................................33

4.4.1 Aligning the hydraulic head ..............................................................................................................................33

4.4.2 Cam advance screw ...........................................................................................................................................33

4.4.3 Head locating fittings .........................................................................................................................................34

4.5 Advance Device ......................................................................................................................................................34 - 35

CONTENTS

iv

CONTENTS

v

4.5.1 Fitting the advance device assembly to the pump housing...........................................................................35

4.5.2 Tightening the head fittings and advance end plates .....................................................................................36

4.6 Governor Control Bracket and Arm Assembly ..................................................................................................................36

4.6.1 Governor control arm assembly .............................................................................................................................36

4.6.2 Fitting the governor control bracket assembly......................................................................................................37

4.6.3 Scroll link plate return spring ..................................................................................................................................37

4.6.4 Setting the governor link length..............................................................................................................................37

4.7 Governor Cover ..............................................................................................................................................................38

4.7.1 Governor covers fitted with boost control .....................................................................................................38 - 39

4.7.2 Governor cover fitted with torque control only.....................................................................................................39

4.7.3 Assembling the torque trimmer ......................................................................................................................39 - 40

4.7.4 Throttle shaft and governor main spring ..............................................................................................................40

4.7.5 Fitting the governor cover .......................................................................................................................................40

4.8 Governor Cover External Components ..............................................................................................................................41

4.8.1 Throttle levers ............................................................................................................................................................41

4.8.2 Throttle lever stop screws, maximum fuel screw and torque control screw.............................................41 - 42

4.8.3 Fuel return connections ............................................................................................................................................42

4.9 Drive Hub, Transfer Pump and Endplate Assembly ........................................................................................................42

4.9.1 Drive hub ...................................................................................................................................................................42

4.9.2 Transfer pump rotor .................................................................................................................................................42

4.9.3 Internal recirculation (if fitted) ................................................................................................................................43

4.9.4 Assembling the transfer pump ...............................................................................................................................43

4.9.5 Endplate assembly ...........................................................................................................................................43 - 44

4.10 ESOS and High Pressure Outlets ........................................................................................................................................44

4.10.1 ESOS ..................................................................................................................................................................44 - 45

4.10.2 High pressure outlets and clamp plate ..................................................................................................................45

4.11 Drive Shaft Lock Bolt, Drain Plug and Cam Advance Screw ...........................................................................................45

4.11.1 Drive shaft lock bolt .................................................................................................................................................45

4.11.2 Drain plug ..................................................................................................................................................................46

4.11.3 Cam advance reading screw ...................................................................................................................................46

4.12 Leak Testing ...........................................................................................................................................................................46

5 TEST PROCEDURE

5.1 Pump Specification ........................................................................................................................................................47

5.1.1 Rotation ...............................................................................................................................................................47

5.1.2 Gov. link length ...................................................................................................................................................47

5.1.3 Plunger diameter ................................................................................................................................................47

5.1.4 Drive type ............................................................................................................................................................47

5.1.5 Pump features.....................................................................................................................................................47

5.1.6 OEM code ............................................................................................................................................................47

5.2 Test Conditions...............................................................................................................................................................48

5.2.1 Test fluid ..............................................................................................................................................................48

5.2.2 Inlet feed pressure ..............................................................................................................................................48

5.2.3 Nozzles.................................................................................................................................................................48

5.2.4 Nozzle opening pressure ...................................................................................................................................48

5.2.5 Nozzle holder ......................................................................................................................................................48

5.2.6 H.P. pipes .............................................................................................................................................................48

5.3 Pre-Test Notes ................................................................................................................................................................49

5.3.1 Introduction .........................................................................................................................................................49

5.3.2 Leak testing .........................................................................................................................................................49

CONTENTS

vi

5.3.3 Test machine drive .............................................................................................................................................49

5.3.4 Pre set notes ................................................................................................................................................49 - 50

5.4 Test Procedure................................................................................................................................................................50

5.4.1 Introduction .........................................................................................................................................................50

5.4.2 Warm-up and stabilisation.................................................................................................................................50

5.4.3 Initial settings .....................................................................................................................................................51

5.4.4 Transfer pressure ........................................................................................................................................51 - 52

5.4.5 Cambox pressure ...............................................................................................................................................52

5.4.6 Speed advance ............................................................................................................................................53 - 54

5.4.7 Cold advance ..............................................................................................................................................54 - 55

5.4.8 Light load advance ......................................................................................................................................55 - 56

5.4.9 Maximum fuel .....................................................................................................................................................56

5.4.10 Torque trimmer ...........................................................................................................................................57 - 58

5.4.11 Boost control .......................................................................................................................................................59

5.4.12 Latch Valve ..........................................................................................................................................................60

5.4.13 Maximum fuel adjustment ................................................................................................................................61

5.4.14 Torque screw ...............................................................................................................................................61 - 62

5.4.15 Governor ......................................................................................................................................................62 - 63

5.4.16 Light Load Valve .................................................................................................................................................63

5.4.17 Idle setting...........................................................................................................................................................64

5.4.18 ESOS ....................................................................................................................................................................65

5.4.19 Timing ..................................................................................................................................................................65

5.5 Overcheck Procedure ....................................................................................................................................................66

5.5.1 Introduction .........................................................................................................................................................66

5.5.2 Pump preparation...............................................................................................................................................66

5.5.3 Test machine drive .............................................................................................................................................66

5.5.4 Overcheck pre-set notes .............................................................................................................................66 - 67

5.5.5 Overcheck test procedure ..................................................................................................................................67

6 TOOLING, TORQUES & EVD’s

6.1 Tooling..........................................................................................................................................................69 - 70

6.2 Torque values......................................................................................................................................................71

6.3 EVD ..............................................................................................................................................................72 - 76

INTRODUCTION

1 - 7

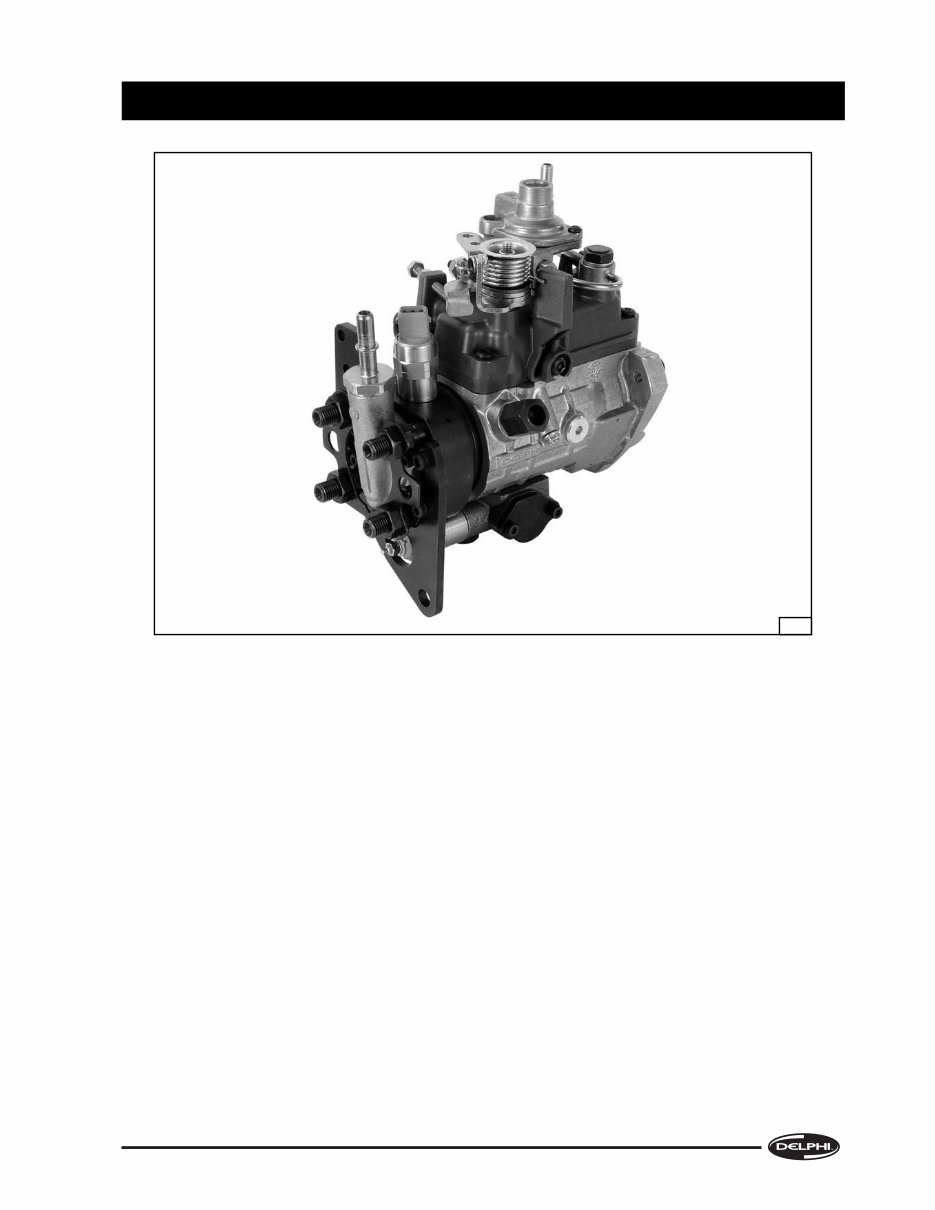

1.1 THE PUMP

The DP210 distributor-type fuel injection pump is a

compact, self-contained unit that is suitable for

direct injection engines of up to 33 BHP per cylinder

and with three, four or six cylinders with either

clockwise or anticlockwise gear drives. It is primarily

intended for diesel engines which have to meet the

Tier 2 off-highway exhaust emissions legislation for

the industrial and agricultural markets in Europe

and USA.

All internal working parts are lubricated by fuel oil

and the pump housing is maintained at an internal

pressure that prevents the ingress of external dirt or

other foreign matter.

Standard features include improved shaft locked

orientation timing, servo controlled light load

advance and speed advance with solenoid switched

cold advance, torque trimmer control of maximum

fuel delivery including excess fuel for starting,

transfer pressure curve slope adjustment with

viscosity compensation.

It can also be fitted with a range of options to suit

particular customer and engine rating

requirements, including boost-pressure control for

turbocharged engines, high strength camrings,

quick fit low pressure connections and throttle

levers with combined break-back and throttle return

spring features.

Due to the complexity of this product, the need for

highly trained personnel, and a high level of

investment in equipment and workshop resources,

together with the need for up-to-date Technical

Information, it can only be tested or serviced by a

Delphi authorised distributor.

It has been developed from the well-known range of

DPA, DPS and DP200 injection pumps and is the

result of the Delphi policy of continued

improvement of products to meet the demands of

new legislation and operational requirements.

1.2 GENERAL

Fuel pumps may require off-engine workshop

attention for two main reasons:

(a) Investigation of a specific fault in engine

performance, which may only require partial

dismantling.

(b) A complete overhaul e.g. at the same time as a

major engine overhaul.

3433

INTRODUCTION

1 - 8

A full performance test is recommended, both

before and after any level of attention, as many

aspects of pump performance are interrelated.

1.3 THIS MANUAL

The Dismantling, Reassembly and Testing Sections

are laid out on a “step-by-step” basis, with each

action accompanied by an illustration showing the

component(s) involved and where applicable,

its/their positions on the pump. The Manual is not

based on any one specification, but covers pump

features which have been included up to the time of

publication. For the purposes of illustration, more

than one pump specification has been used.

The pumps illustrated are for clockwise rotation

(when viewed from the drive end). Any component

used for anticlockwise pumps that is different, is

individually described.

1.4 EQUIPMENT

Any tools, both standard and special-purpose, used

for the servicing or repair of fuel injection equipment

(FIE) must be reserved solely for use on FIE. Worn or

damaged tools can cause damage to critical

components, as well as being a safety hazard.

The working area must be scrupulously clean and

should be in a room separated from any other

activity; the ingress of dust and dirt, airborne or

otherwise, must be prevented.

The minimum facilities required are:

1. A bench covered in non-rusting metal or industrial-

grade linoleum and fitted with an engineer’s vice

with a jaw size of 100 mm (4 in). The vice jaws must

be faced with either soft metal or fibre pads.

2. An adjustable pump-mounting device such as the

“Hydraclamp”, fitted with an appropriate adaptor

plate.

3. Easily cleaned compartmented trays for separate

storage of dismantled pumps are available from

Delphi Aftermarket Operations, Service Operations

Department.

4. All the necessary tools are listed in Section 6 of this

manual.

5. A low-pressure washing facility using a suitable,

approved, cleaning fluid (not water or water-based)

to clean pumps externally prior to dismantling.

Cleaning must be carried out in a place separated

from the “clean area”.

6. A tank large enough to accommodate a complete

pump and filled with clean test oil, near to a source

of clean, dry, variable pressure compressed air for

carrying out leakage tests.

7. Supplies of clean, lint-free (non-fluffy) cloths for

cleaning and drying components. Cotton waste must

never be used.

8. A pump test machine that conforms to ISO 4008.

9. Adequate storage facilities for pumps, tools and test

equipment, with separate areas for pumps before

and after repair.

Note: All cleaning tanks, workshop and test facilities

and fluids must conform to any Fire Prevention or

Health and Safety Regulations in force at the time of

use.

1.5 REPLACEMENT OF PARTS

All gaskets and seals must be replaced during

reassembly. However, in the event of partial

dismantling, only those seals that have been

disturbed need replacement, unless leaks from

elsewhere are detected during testing prior to

dismantling.

If any part of a “mated” assembly is worn or

damaged, the whole assembly must be replaced.

Any component showing signs of corrosion or water

ingress, cracks or distortion must be replaced.

Only service parts supplied by Delphi Aftermarket

Operations may be used as replacements. Parts

supplied from alternative sources may appear to be

externally similar and may carry the same part

numbers as the genuine item but may be inferior in

material specification or finish and lead to

malfunction or premature failure.

1.6 PUMP NAME PLATE

The number stamped on the type-plate attached to

the pump housing identifies the type and model of

the pump. Pumps with identical build but with

different settings, dependent upon engine

application, are further identified by the setting code

stamped beneath the serial number.

A typical Despatch Number could be as shown in Fig.

1.

Note 1: The pumps shown in the illustrations do not

necessarily represent any one specification, but

are used to show particular features.

Note 2: As components are removed, inspect them and

put those considered unfit for further service to

one side for replacement; place those which

are fit for further service into a clean

compartmented tray. (Trays available through

Delphi Diesel Systems Aftermarket Operations,

Service Operations Department.) A guide to

areas of possible wear or damage appears in

Section 3 (Component Inspection & Renewal).

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$40.99

Viewed 66 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$40.99

This Delphi DP210 Fuel Injection Pump OEM Service & Repair Manual is ideal for first-time owners, amateur enthusiasts, and professional technicians alike. Its easy-to-read format provides comprehensive and model-specific technical information for accurate diagnosis, procedure execution, and routine maintenance. Keeping this manual accessible and referring to it regularly will help prevent premature failure and unnecessary repairs, ensuring optimal performance of the Delphi DP210 fuel injection pump.

- INTRODUCTION

- DISMANTLING

- COMPONENT INSPECTION AND RENEWAL

- REASSEMBLY

- TEST PROCEDURE

- TOOLING, TORQUES & EVDS

File Format: PDF

Compatible: All Versions of Windows & Mac

Language: English

Requirements: Adobe Reader