Bosch Fuel Injection RQV - RQUV - EP - RSV Equipment

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Fuel Injection Equipment

for Diesel Engines

Governors

for In-Line Pumps

© 1975 Robert Bosch GmbH

Postfach 50, D-7000 Stuttgart 1

Automotive Equipment Division

Department for Technical Publications KH/VDT

Editor in chief: Ulrich Adler

Editor: Erich Kaufmann

Translation 1977): John T. Warner, Michael J. Scott

Composition, graphics, layout: Dept. KH/VDT

In consultation with the technical departments of our

organisation. Reproduction, duplication and translation of

this publication, even in abridged form, is only to ensue

with our previous written consent and with particulars of

source. Illustrations, descriptions, diagrams and other

particulars only serve for elucidation and presentation of

the text. They are not binding as regards details of

construction, installation or delivery.

We undertake no liability for conformity of the text with

national or local regulations.

Subject to revision.

Printed in the Federal Republic of Germany.

Imprime en Republique Féderale d'Allemagne.

1st edition

30th September 1975

Table of Contents

6 Introduction

6 General

6 Why is a governor required with a diesel engine?

8 Speed Droop

8 Functions of the Governor

10 Torque Control

12 Types of Governor

13 Maximum-Speed Governors

13 Minimum-Maximum-Speed Governors

14 Variable-Speed Governors

14 Combination Governors

15 Mechanical Governors

15 Metering Units

16 Minimum-Maximum-Speed Governor RQ

20 Minimum-Maximum-Speed Governor RQU

20 Maximum-Speed Governors RQ and RQU

21 Variable-Speed Governor RQV

24 Variable-Speed Governor RQUV

25 Variable-Speed Governor ROy.. K

28 Combination Governors ROy and RQUV

28 Variable-Speed Governor EP/RSV

32 Variable-Speed Governor EPRSUV

33 Minimum-Maximum-Speed Governor EP RS

36 Control-Lever and Control-Rod Stops for

Mechanical Governors

36 Control-Lever Stops

36 Spring-Loaded Idle-Speed Stop

36 Reduced-Delivery Stop

37 Control-Rod Stops

37 Rigid Excess-Fuel Stop for Starting

37 Spring-Loaded Control-Rod Stop for RQ Governors

38 Automatic Full-Load Control-Rod Stop

38 Control-Rod Stop with Torque-Control Mechanism

40 Manifold-Pressure Compensator (LOA)

41 Altitude- Pressure Compensator (ADA)

43 Electric Speed-Control Device

43 Use

43 Design

44 Pneumatic Governor

44 Variable-Speed Governor EP/M..

44 Operating Principle

45 Operating Characteristics

47 Special Designs

49 Maintenance

50 Testing and Repair

52 Glossary of Technical Terms

55 Test Page

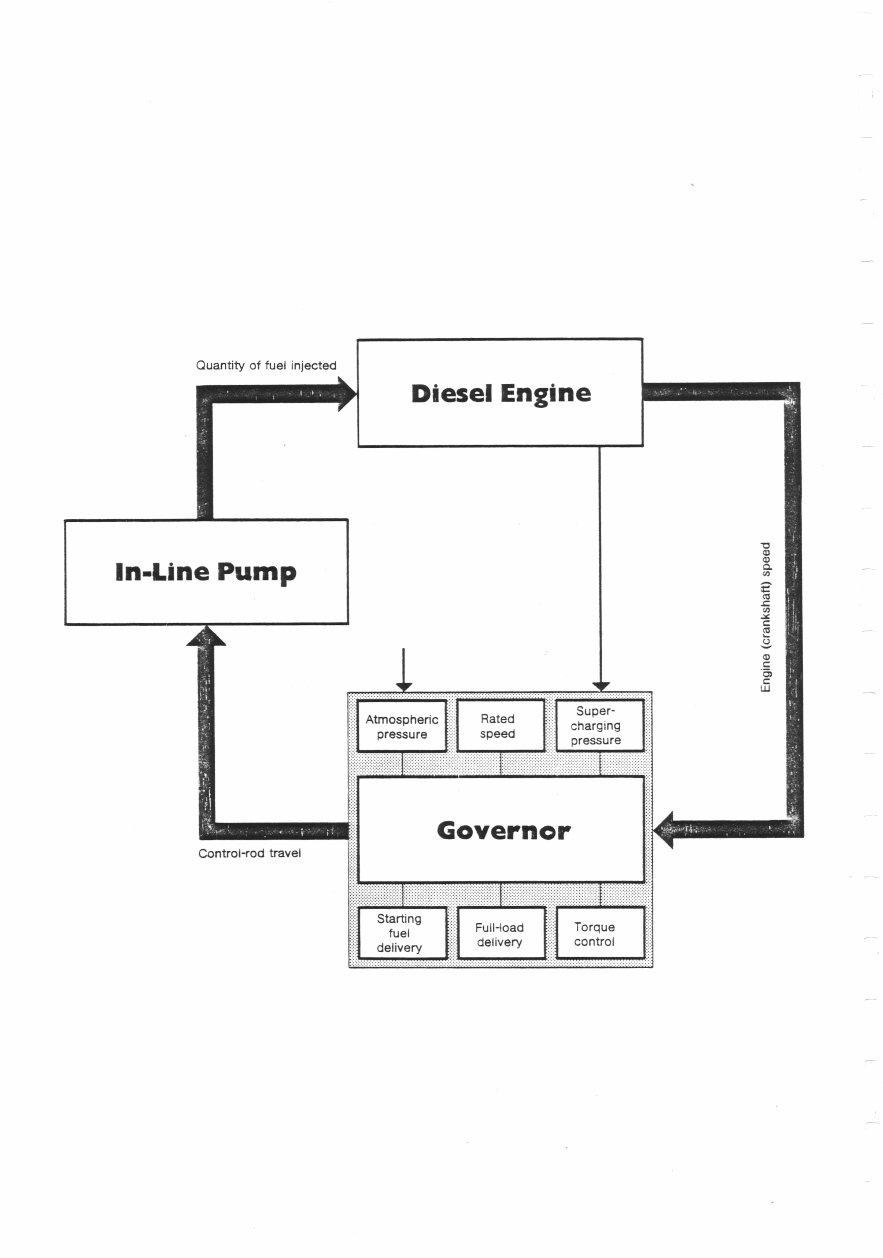

Quantity of fuel injected

Diesel Engine

In-Line Pump

CL

(I)

C

Q

C

C

LU

Governor

Control-rod travel

Starting j;

fuel

Full-load Torque

delivery

delivery control

We provided information on in-

line pumps for you in the booklet

in this series entitled "Diesel

Fuel-Injection Pumps Types

PE and PF". The in-line pump,

however, is only one part of the

fuel injection system. Equally

important is the governor. This

device is responsible for

ensuring that the engine

maintains a certain speed under

various load conditions, that the

engine speed does not exceed a

certain level as protection

• against self-destruction, and

that the engine does not stop

during pauses in loaded

operation, i.e. during idling. The

governor accomplishes all this

by controlling the amount of fuel

injected into the engine. How

the governor performs these as

well as a number of other

functions is described in this

booklet.

Introduction

General

The diesel engine draws only air in during the suction

stroke. During the compression stroke this air is heated to

such a high temperature that the diesel fuel injected into

the engine toward the end of the compression stroke

ignites of its own accord. The fuel is metered by the fuel

injection pump and is injected under high pressure through

the injection nozzle into the combustion chamber.

Fuel injection must take place:

• in an accurately metered quantity corresponding to the

engine load.

• at the correct instant in time.

• for a precisely determined period of time, and

• in a manner suited to the particular combustion process

concerned.

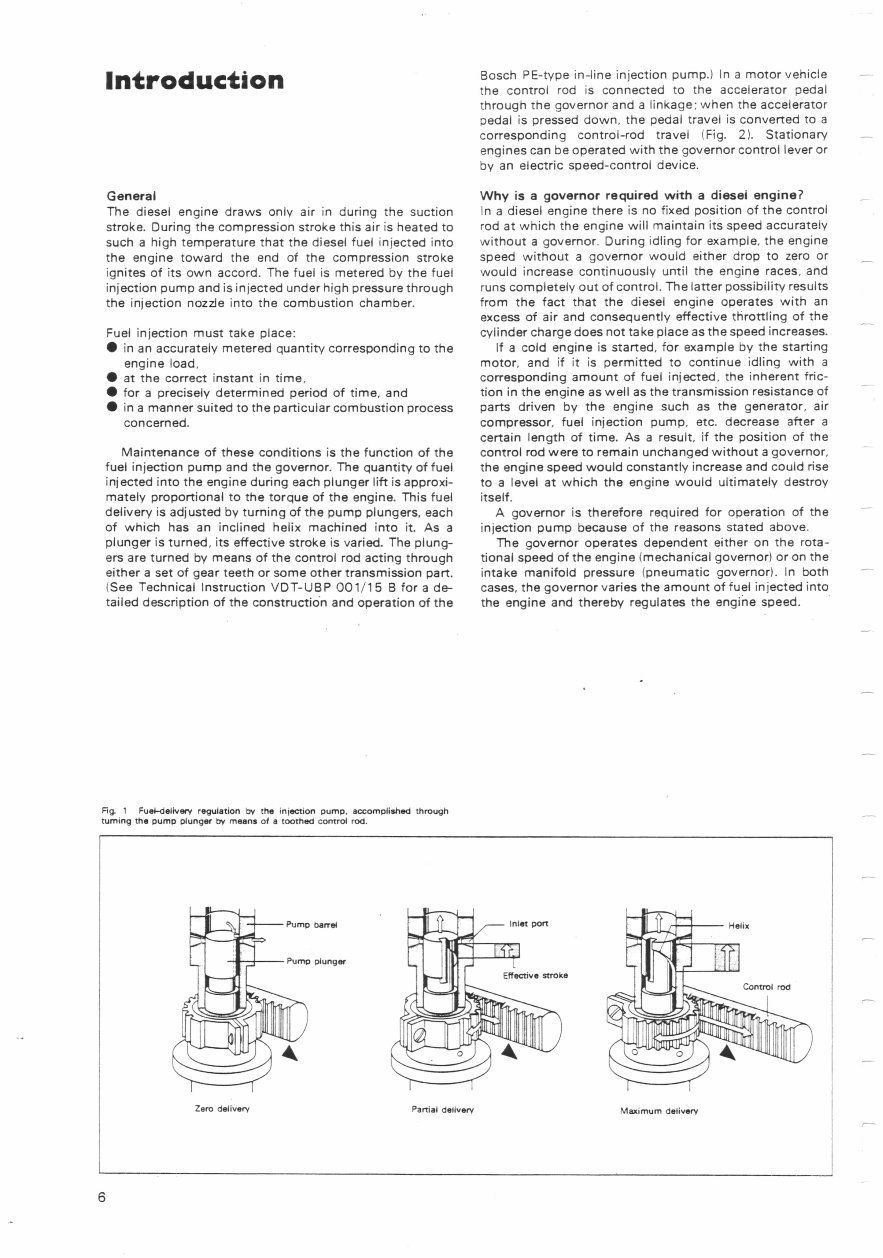

Maintenance of these conditions is the function of the

fuel injection pump and the governor. The quantity of fuel

injected into the engine during each plunger lift is approxi-

mately proportional to the torque of the engine. This fuel

delivery is adjusted by turning of the pump plungers, each

of which has an inclined helix machined into it. As a

plunger is turned, its effective stroke is varied. The plung-

ers are turned by means of the control rod acting through

either a Set of gear teeth or some other transmission part.

(See Technical Instruction VDT-UBP 001/15 B for a de-

tailed description of the construction and operation of the

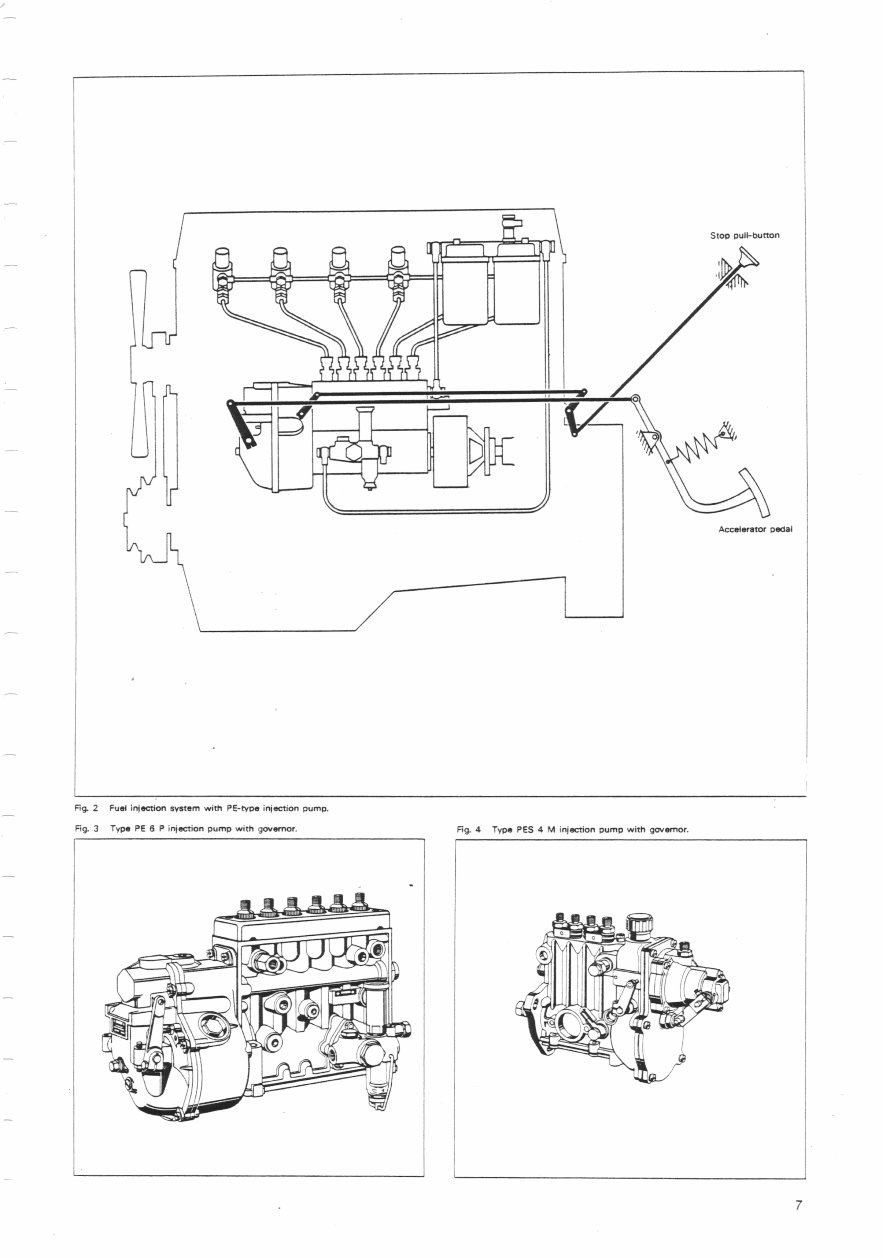

Bosch PE-type in-line injection pump.) In a motor vehicle

the control rod is connected to the accelerator pedal

through the governor and a linkage: when the accelerator

pedal is pressed down, the pedal travel is converted to a

corresponding control-rod travel (Fig. 2). Stationary

engines can be operated with the governor control lever or

by an electric speed-control device.

Why is a governor required with a diesel engine?

In a diesel engine there is no fixed position of the control

rod at which the engine will maintain its speed accurately

without a governor. During idling for example, the engine

speed without a governor would either drop to zero or

would increase continuously until the engine races, and

runs completely out of control. The latter possibility results

from the fact that the diesel engine operates with an

excess of air and consequently effective throttling of the

cylinder charge does not take place as the speed increases.

If a cold engine is started, for example by the starting

motor, and if it is permitted to continue idling with a

corresponding amount of fuel injected, the inherent fric-

tion in the engine as well as the transmission resistance of

parts driven by the engine such as the generator, air

compressor, fuel injection pump, etc. decrease after a

certain length of time. As a result, if the position of the

control rod were to remain unchanged without a governor,

the engine speed would constantly increase and could rise

to a level at which the engine would ultimately destroy

itself.

A governor is therefore required for operation of the

injection pump because of the reasons stated above.

The governor operates dependent either on the rota-

tional speed of the engine (mechanical governor) or on the

intake manifold pressure (pneumatic governor). In both

cases, the governor varies the amount of fuel injected into

the engine and thereby regulates the engine speed.

Fig. 1 Fuel-delivery regulation by the injection pump. accomplished through

turning the pump plunger by means of a toothed control rod.

Pump Helix

4 COnV-01 rrod

ve5e

p

Zero delivery Partial delivery Maximum delivery

I

.rcl__ i I::Ittr

\

Stop MI-button

fL

,

Acceiwaor -

Fig. 2 Fuel injection system with PE-type injection pump.

Fig. 3 Type PE S P injection pomp with governor. Fig. 4 Type PES 4 M injection Dump with governor.

7

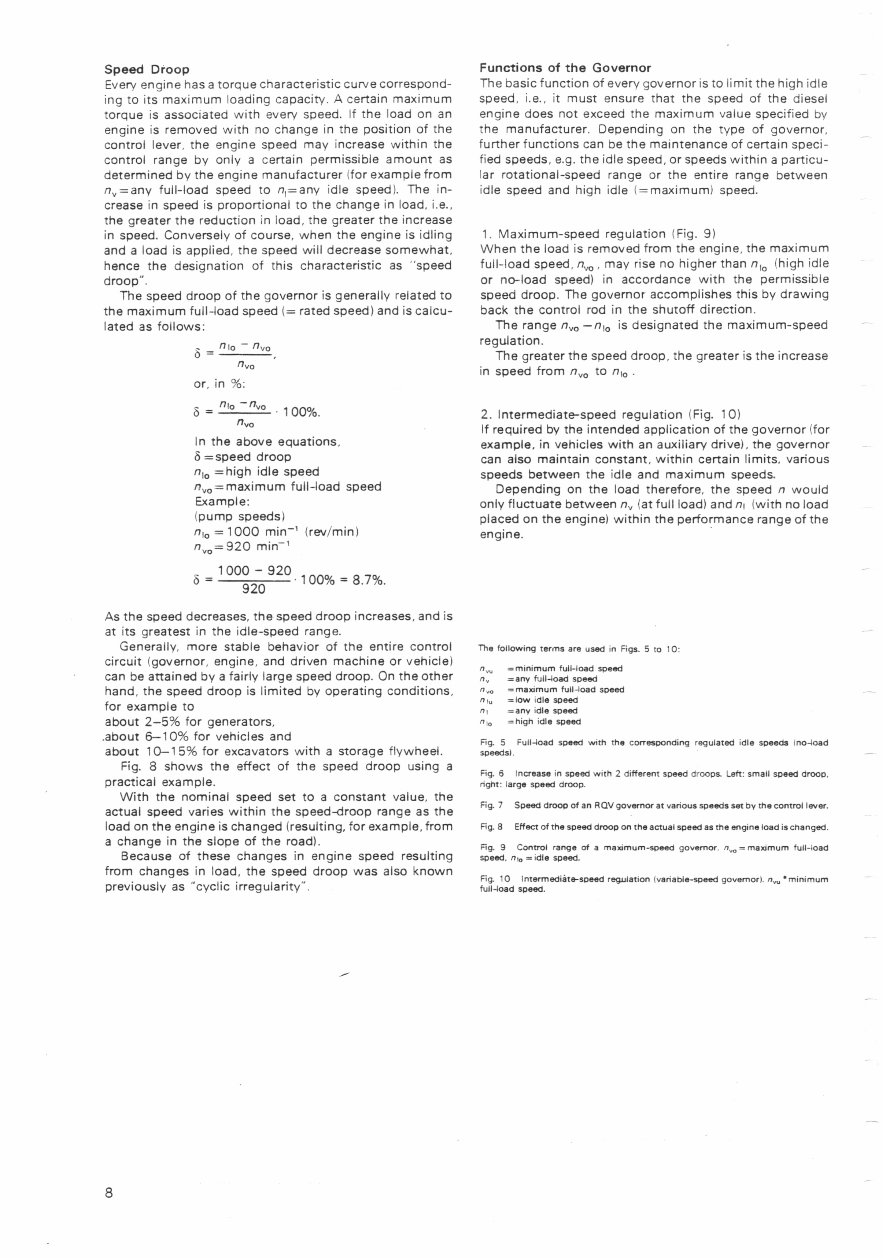

Speed Droop

Every engine has a torque characteristic curve correspond-

ing to its maximum loading capacity. A certain maximum

torque is associated with every speed. If the load on an

engine is removed with no change in the position of the

control lever, the engine speed may increase within the

control range by only a certain permissible amount as

determined by the engine manufacturer (for example from

n=any full-load speed to 1 1 =any idle speed). The in-

crease in speed is proportional to the change in load, i.e.,

the greater the reduction in load, the greater the increase

in speed. Conversely of course, when the engine is idling

and a load is applied, the speed will decrease somewhat,

hence the designation of this characteristic as "speed

droop".

The speed droop of the governor is generally related to

the maximum full-load speed 1= rated speed) and is calcu-

lated as follows:

= f7io -

n', 0

or, in %:

= nio

-nvo , 100%,

"Va

In the above equations,

=speed droop

n jo =high idle speed

n ' , 0 =maximum full-load speed

Example:

(pump speeds)

= 1000 min (rev/min)

n. 0 =920 min- '

= 100% = 8.7%.

As the speed decreases, the speed droop increases, and is

at its greatest in the idle-speed range.

Generally, more stable behavior of the entire control

circuit (governor, engine, and driven machine or vehicle)

can be attained by a fairly large speed droop. On the other

hand, the speed droop is limited by operating conditions,

for example to

about 2-5% for generators,

about 6-10% for vehicles and

about 10-15% for excavators with a storage flywheel.

Fig. 8 shows the effect of the speed droop using a

practical example.

With the nominal speed set to a constant value, the

actual speed varies within the speed-droop range as the

load on the engine is changed (resulting, for example, from

a change in the slope of the road).

Because of these changes in engine speed resulting

from changes in load, the speed droop was also known

previously as "cyclic irregularity".

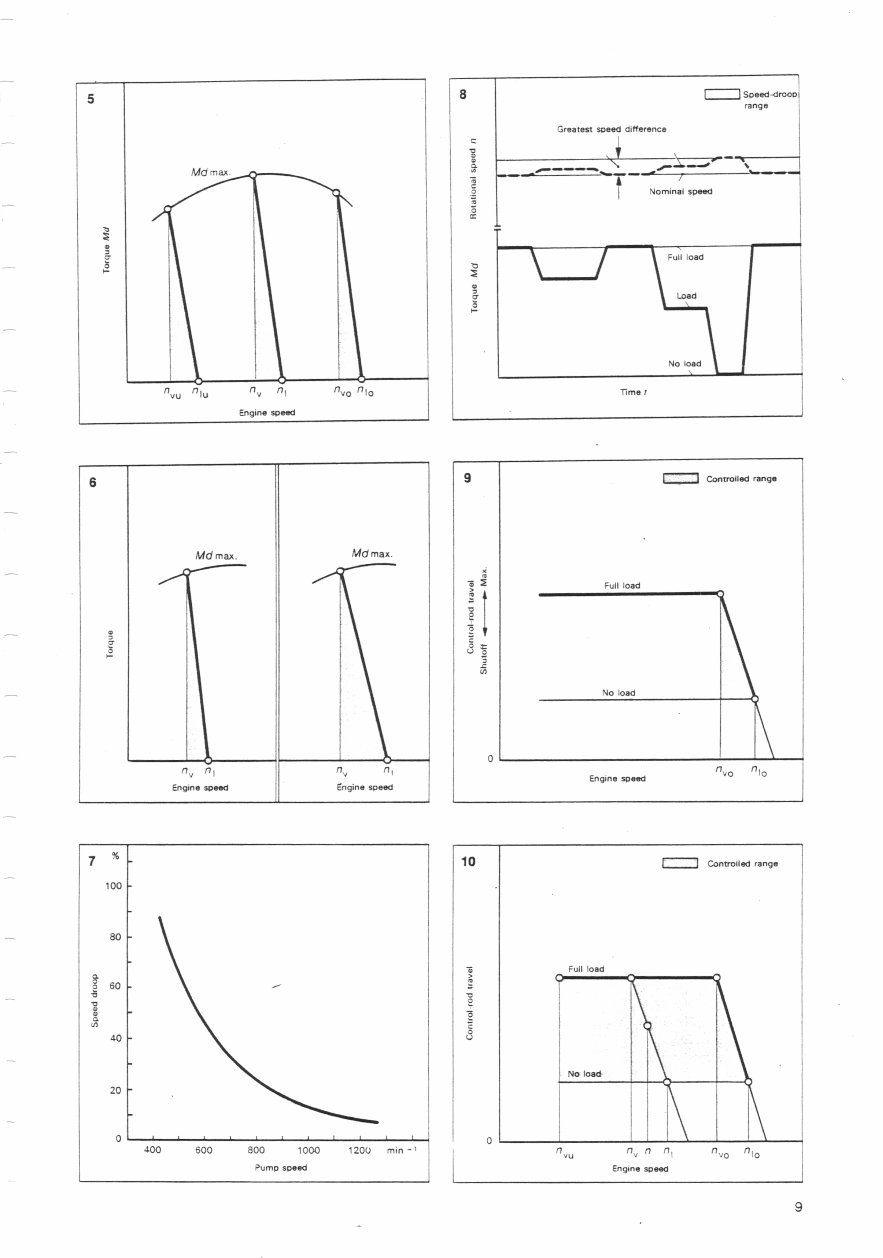

Functions of the Governor

The basic function of every governor is to limit the high idle

speed, i.e., it must ensure that the speed of the diesel

engine does not exceed the maximum value specified by

the manufacturer. Depending on the type of governor,

further functions can be the maintenance of certain speci-

fied speeds, e.g. the idle speed, or speeds within a particu-

lar rotational-speed range or the entire range between

idle speed and high idle (=maximum) speed.

1. Maximum-speed regulation (Fig. 9)

When the load is removed from the engine, the maximum

full-load speed, n' ,, may rise no higher than

n'

(high idle

or no-load speed) in accordance with the permissible

speed droop. The governor accomplishes this by drawing

back the control rod in the shutoff direction.

The range n ' , 0 -n 10 is designated the maximum-speed

regulation.

The greater the speed droop, the greater is the increase

in speed from

r'

to ri 0 .

2. Intermediate-speed regulation (Fig. 10)

If required by the intended application of the governor (for

example, in vehicles with an auxiliary drive), the governor

can also maintain constant, within certain limits, various

speeds between the idle and maximum speeds.

Depending on the load therefore, the speed ii would

only fluctuate between ri ' , (at full load) and ni (with no load

placed on the engine) within the performance range of the

engine.

The following terms are used in Figs. 5 to 10:

=minimum full-load speed

,7 =any full-load speed

,, =maomum full-load speed

n,, =low idle soeed

ti =any idle speed

0 10 =high idle speed

Fig. 5 Full-load speed with the corresponding regulated idle speeds tno4oad

speeds).

Fig. 6 Increase in speed with 2 different speed droops. Left: small speed droop.

right: large speed droop.

Fig. 7 Speed droop of an Ray governor at various speeds set by the control lever.

Fig, 8 Effect of the speed droop on the actual speed as the engine load is changed.

Fig. 9 Control range of a rna,amurn-speed governor. 'r,,, = maximum full-load

speed, n, =idle speed.

Fig. 10 Intermediéte-speed regulation variable-speed governor). n,,. minimum

full-load speed.

M rna.

3

Ii _

[I

vu 0 1u fl y 0vo

0l

Engine speed

5

8 r1

range

Greatest speed difference

.,- -'-

S

T f

-

Nominal speed

cc

\Fulo.d

Load !

a

\ I

No.d\I

Time I

8

Mdmax.

Mdmax.

S

a

8

I-

fl y ('V

I

Engine spied Engine speed

9 1 Controlled range

Full load

I I

a

No load

0

Engine speed

('VO ('10

7 % .

100

so

so

i

400 600 800 1000 1200 mm-'

Pump speed

10 Controlled range

S Full load

a

0

0

C

No load

0

"

('i vo 'lo

Engine speed

9

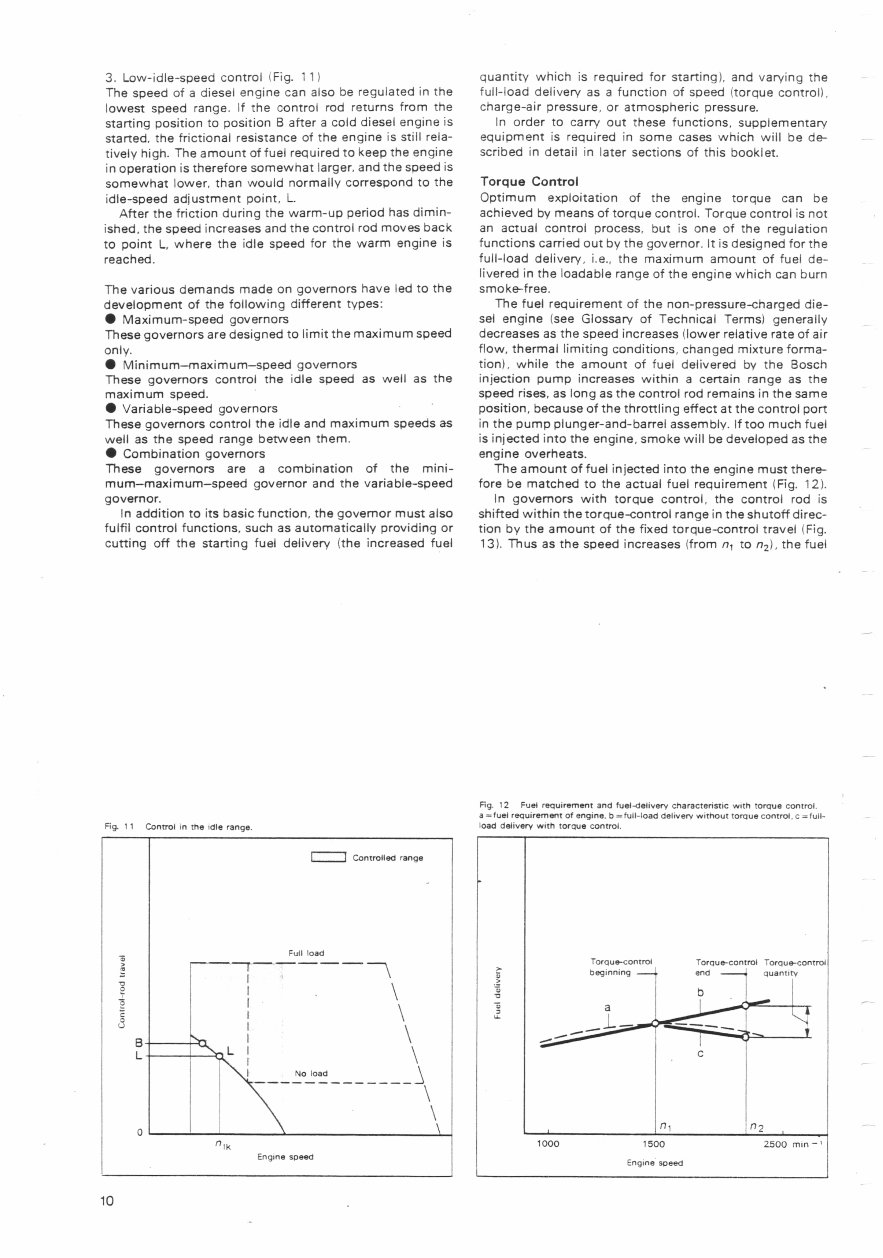

3. Low-idle-speed control Fig. 11)

The speed of a diesel engine can also be regulated in the

lowest speed range. If the control rod returns from the

starting position to position B after a cold diesel engine is

started, the frictional resistance of the engine is still rela-

tively high. The amount of fuel required to keep the engine

in operation is therefore somewhat larger, and the speed is

somewhat lower, than would normally correspond to the

idle-speed adjustment point, L

After the friction during the warm-up period has dimin-

ished, the speed increases and the control rod moves back

to point L, where the idle speed for the warm engine is

reached.

The various demands made on governors have led to the

development of the following different types:

• Maximum-speed governors

These governors are designed to limit the maximum speed

only.

• Minimum—maximum--speed governors

These governors control the idle speed as well as the

maximum speed.

• Variable-speed governors

These governors control the idle and maximum speeds as

well as the speed range between them.

• Combination governors

These governors are a combination of the mini-

mum—maximum—speed governor and the variable-speed

governor.

In addition to its basic function, the governor must also

fulfil control functions, such as automatically providing or

cutting off the starting fuel delivery (the increased fuel

quantity which is required for starting), and varying the

full-load delivery as a function of speed (torque control),

charge-air pressure, or atmospheric pressure.

In order to carry out these functions, supplementary

equipment is required in some cases which will be de-

scribed in detail in later sections of this booklet.

Torque Control

Optimum exploitation of the engine torque can be

achieved by means of torque control. Torque control is not

an actual control process, but is one of the regulation

functions carried out by the governor. It is designed for the

full-load delivery, i.e., the maximum amount of fuel de-

livered in the loadable range of the engine which can burn

smoke-free.

The fuel requirement of the non-pressure-charged die-

sel engine (See Glossary of Technical Terms) generally

decreases as the speed increases (lower relative rate of air

flow, thermal limiting conditions, changed mixture forma-

tion), while the amount of fuel delivered by the Bosch

injection pump increases within a certain range as the

speed rises, as long as the control rod remains in the same

position, because of the throttling effect at the control port

in the pump plunger-and-barrel assembly. If too much fuel

is injected into the engine, smoke will be developed as the

engine overheats.

The amount of fuel injected into the engine must there-

fore be matched to the actual fuel requirement (Fig. 12).

In governors with torque control, the control rod is

shifted within the torque-control range in the shutoff direc-

tion by the amount of the fixed torque-control travel (Fig.

13). Thus as the speed increases (from n 1 to n 2 ), the fuel

Fig. 12 Fuel requirement and fuel-delivery characteristic with torque control.

a =fuel requirement of engine. b = full-load delivery without torque control. c =full-

Fig. ii Control in the idle range. load delivery with torque control.

Controlled range

lk

Full load

\

I

\

\

No load

Engine speed

Torque-control Torque-control Torque-control

beginning end

a

2

.5

a

quantity

1000 1500 2500 min'

Engine speed

0

0

B

L

10

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 44 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Bosch Fuel Injection RQV - RQUV - EP - RSV Equipment

- Introduction

- General

- Why is a governor required with a diesel engine?

- Speed Droop

- Functions of the Governor

- Torque Control

- Types of Governor

- Maximum-Speed Governors

- Minimum-Maximum-Speed Governors

- Variable-Speed Governors

- Combination Governors

- Mechanical Governors

- Metering Units

- Minimum-Maximum-Speed Governor RQ

- Minimum-Maximum-Speed Governor RQU

- Maximum-Speed Governors RQ and RQU

- Variable-Speed Governor RQV

- Variable-Speed Governor RQUV

- Variable-Speed Governor ROy.. K

- Combination Governors ROy and RQUV

- Variable-Speed Governor EP/RSV

- Variable-Speed Governor EPRSUV

- Minimum-Maximum-Speed Governor EP RS

- Control-Lever and Control-Rod Stops for Mechanical Governors

- Control-Lever Stops

- Spring-Loaded Idle-Speed Stop

- Reduced-Delivery Stop

- Control-Rod Stops

- Rigid Excess-Fuel Stop for Starting

- Spring-Loaded Control-Rod Stop for RQ Governors

- Automatic Full-Load Control-Rod Stop

- Control-Rod Stop with Torque-Control Mechanism

- Manifold-Pressure Compensator (LOA)

- Altitude- Pressure Compensator (ADA)

- Electric Speed-Control Device

- Use

- Design

- Pneumatic Governor

- Variable-Speed Governor EP/M..

- Operating Principle

- Operating Characteristics

- Special Designs

- Maintenance

- Testing and Repair

- Glossary of Technical