HYSTER MAZDA Engine Workshop Service Repair Manual Forklift Lift Truck

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

STEERING AXLE

S30FT, S35FT, S40FTS [E010]; H1.6FT, H1.8FT, H2.0FTS

(H30FT, H35FT, H40FTS) [F001]; S2.0-3.5FT (S40-70FT, S55FTS

) [F187]; H2.0-3.5FT (H40-70FT) [L177]; S4.0, 4.5, 5.5FT, S5.5FTS (S80,

100, 120FT; S80, 100FTBCS; S120FTS; S120FTPRS) [G004];

H4.0FT5/FT6; H4.5FTS5, H4.5FT6; H5.0-5.5FT (H80, 90, 100, 110,

120FT) [N005, P005]; S6.0FT, S7.0FT, (S135FT, S155FT) [D024,

E024]; H6.0FT, H7.0FT (H135FT, H155FT) [H006, J006]

PART NO. 1580512 1600 SRM 1133

Steering Axle Table of Contents

TABLE OF CONTENTS

General ............................................................................................................................................................... 1

Steering Axle Assembly Repair ......................................................................................................................... 2

Remove ........................................................................................................................................................... 2

Disassemble ................................................................................................................................................... 3

Clean .............................................................................................................................................................. 3

Inspect ............................................................................................................................................................ 3

Assemble ........................................................................................................................................................ 10

Install ............................................................................................................................................................. 15

Spindles, Bearings, and Tie Rods Repair ......................................................................................................... 16

Spindles and Bearings ................................................................................................................................... 16

S2.0-3.5FT (S40-70FT, S55FTS) (F187), S4.0, 4.5, 5.5FT, S5.5FTS, (S80, 100, 120FT; S80,

100FTBCS; S120FTS; S120FTPRS) (G004), H4.0FT5/FT6; H4.5FTS5, H4.5FT6; H5.0-5.5FT

(H80, 90, 100, 110, 120FT) (N005, P005), S6.0FT, S7.0FT, (S135FT,S155FT) (D024, E024), and

H6.0FT, H7.0FT (H135FT, H155FT) (H006, J006).................................................................................. 16

Remove .................................................................................................................................................. 16

Disassemble ........................................................................................................................................... 17

Clean ...................................................................................................................................................... 18

Inspect ................................................................................................................................................... 18

Assemble ................................................................................................................................................ 18

Install..................................................................................................................................................... 19

Spindles and Bearings ................................................................................................................................... 22

S30FT, S35FT, S40FTS (E010), H1.6FT, H1.8FT, H2.0FTS (H30FT, H35FT, H40FTS) (F001),

and H2.0-3.5FT (H40-70FT) (L177) ......................................................................................................... 22

Remove and Disassemble ..................................................................................................................... 22

Assemble and Install ............................................................................................................................ 22

Tie Rods .......................................................................................................................................................... 23

S2.0-3.5FT (S40-70FT, S55FTS) (F187), and S4.0, 4.5, 5.5FT, S5.5FTS, (S80, 100, 120FT; S80,

100FTBCS; S120FTS; S120FTPRS) (G004)............................................................................................. 23

Remove .................................................................................................................................................. 23

Install..................................................................................................................................................... 24

Tie Rods .......................................................................................................................................................... 25

S30FT, S35FT, S40FTS (E010), H1.6FT, H1.8FT, H2.0FTS (H30FT, H35FT, H40FTS) (F001),

H2.0-3.5FT (H40-70FT) (L177), H4.0FT5/FT6; H4.5FTS5, H4.5FT6; H5.0-5.5FT (H80, 90,

100, 110, 120FT) (N005, P005), S6.0FT, S7.0FT, (S135FT,S155FT) (D024, E024) and H6.0FT,

H7.0FT (H135FT, H155FT) (H006, J006) ................................................................................................ 25

Remove .................................................................................................................................................. 25

Install..................................................................................................................................................... 25

Steering Cylinder Repair ................................................................................................................................... 28

Remove and Disassemble .............................................................................................................................. 28

Clean and Inspect .......................................................................................................................................... 29

Assemble and Install ..................................................................................................................................... 29

Torque Specifications ......................................................................................................................................... 30

©2008 HYSTER COMPANY i

Table of Contents Steering Axle

TABLE OF CONTENTS (Continued)

This section is for the following models:

S30FT, S35FT, S40FTS [E010];

H1.6FT, H1.8FT, H2.0FTS (H30FT, H35FT, H40FTS) [F001];

S2.0-3.5FT (S40-70FT, S55FTS ) [F187];

H2.0-3.5FT (H40-70FT) [L177];

S4.0, 4.5, 5.5FT, S5.5FTS (S80, 100, 120FT; S80, 100FTBCS;

S120FTS; S120FTPRS) [G004];

H4.0FT5/FT6; H4.5FTS5, H4.5FT6; H5.0-5.5FT (H80, 90, 100,

110, 120FT) [N005, P005];

S6.0FT, S7.0FT, (S135FT, S155FT) [D024, E024];

H6.0FT, H7.0FT (H135FT, H155FT) [H006, J006]

ii

1600 SRM 1133 General

General

This section has the description and repair proce-

dures for the steering axle.

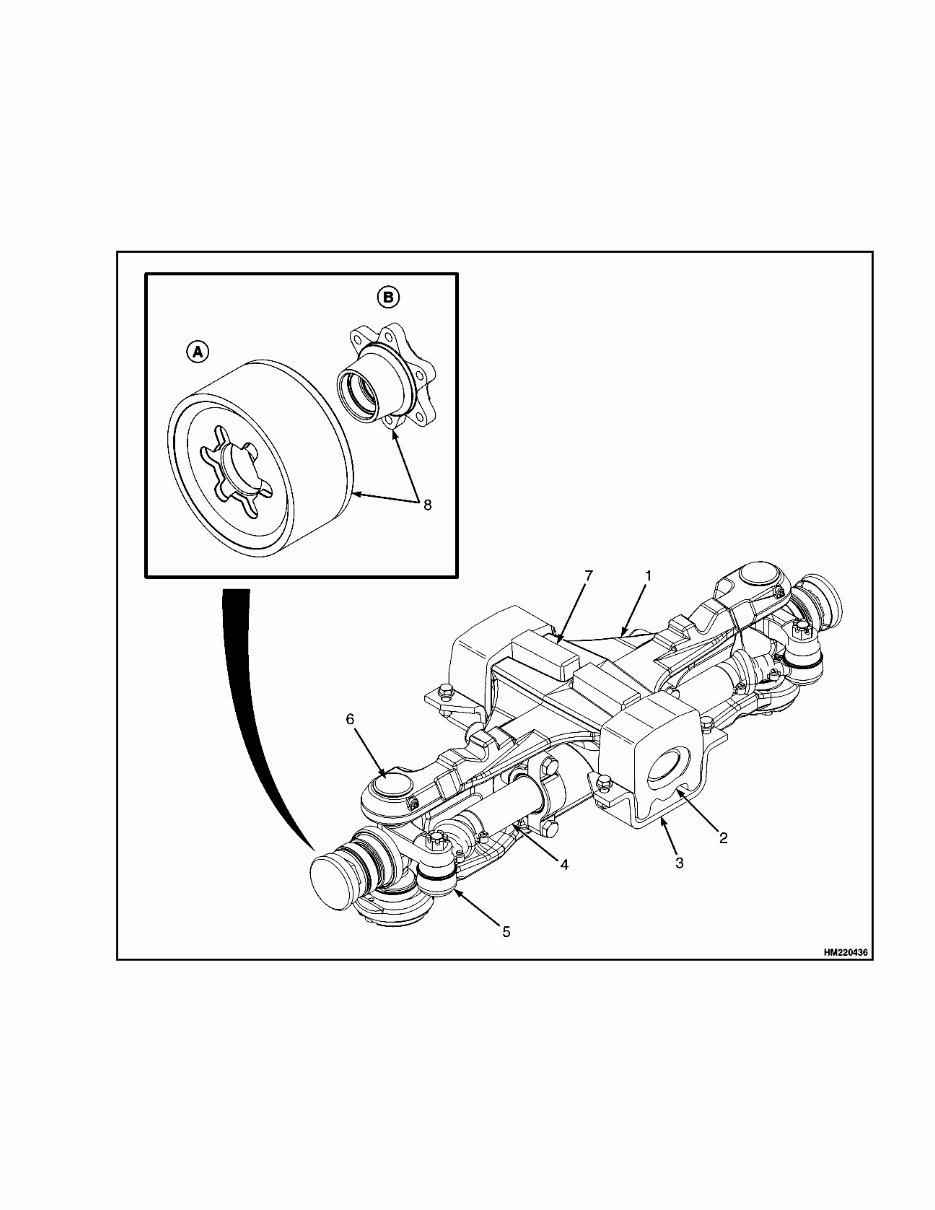

The steering axle assembly includes an axle

frame, steering cylinder, and two spindle and

hub assemblies. See Figure 1. The steering axle is

articulated and is connected to the frame by center

pivot mounts. The center pivot mounts permit the

steering axle to move in the frame mount when the

lift truck travels over rough surfaces.

A. CUSHION TRUCKS ONLY B. PNEUMATIC TRUCKS ONLY

1. AXLE FRAME

2. MOUNT

3. BRACKET

4. STEERING CYLINDER

5. TIE ROD

6. SPINDLE

7. MOUNT

8. HUB ASSEMBLIES

Figure 1. Steering Axle

1

Steering Axle Assembly Repair 1600 SRM 1133

The end caps of the steering cylinder are also the

mounts for the cylinder and are held to the shell by

the mount capscrews. There are O-rings, seals, and

wipers in the end caps to seal the caps to the shell

and rod. The ends of the piston rod extend from both

ends of the cylinder. A single piston and the seal are

at the center of the rod. Oil pressure on one side of

the piston moves the piston in the bore. The piston

pushes an equal amount of oil from the opposite side

of the cylinder.

When the piston reaches the end of the stroke, a re-

lief valve in the steering circuit controls the oil pres-

sure. The tie rods that connect the spindle arms to

the cylinder are not adjustable.

Each spindle turns on two tapered roller bearings in

mounts in the axle frame. The preload on the bear-

ings is controlled by shims at the lower bearing cap.

The wheels rotate on two tapered roller bearings and

are held on the spindles by a castle nut. The bearing

preload of the wheels is adjusted by the castle nut.

The grease seals protect the bearings from dirt and

water. Wear sleeves protect the hub from wear by the

seals.

Steering Axle Assembly Repair

REMOVE

WARNING

PUTTING THE LIFT TRUCK ON BLOCKS

The lift truck must be put on blocks for some

types of maintenance and repair. The removal

of the mast, drive axle, battery, or counter-

weight assemblies will cause large changes

in the center of gravity. When the lift truck

is put on blocks, put additional blocks in the

following positions:

• If the mast and drive axle are removed, put

blocks under the counterweight so the lift

truck cannot fall backward.

• If the counterweight is removed, put blocks

under the mast so that the lift truck cannot

fall forward.

Put the lift truck on blocks on a solid, even, and

level surface. Verify the blocks or stands have

enough capacity to hold the lift truck. Use ad-

ditional blocks next to the tires as necessary to

prevent movement of the lift truck. Verify the

lifting devices used during repairs can lift the

weight of the parts and assemblies.

See the Operating Manual or Periodic Mainte-

nance section for your lift truck model, for the

procedures to put the lift truck on blocks.

The steering axle can be removed without removing

the counterweight.

1. Verify wheels are set for straight travel. Put lift

truck on blocks so the steering axle will have

enough clearance to be removed. The top of the

axle frame must have clearance under the bot-

tom of the frame at the rear of the lift truck.

2. Disconnect hydraulic lines at steering cylinder.

Install plug fittings in cylinder and put caps on

hydraulic lines. Plug fittings will prevent spin-

dles from turning as axle is removed from under

the lift truck.

NOTE: Steering Axle Assembly may be mounted to

the frame with brackets or plates.

3. Slide floor jack or forks of another lift truck under

steering axle. Raise lifting device until it holds

the weight of the axle assembly.

a. To remove bracket type mounts, remove four

capscrews and nuts that fasten two brackets

under rubber mounts. For lift truck mod-

els S2.0-3.5FT (S40-70FT, S55FTS) (F187),

see Figure 2, for lift truck modelsH2.0-3.5FT

(H40-70FT) (L177), see Figure 3, for lift truck

models S4.0, 4.5, 5.5FT, S5.5FTS, (S80, 100,

120FT; S80, 100FTBCS; S120FTS; S120FT-

PRS) (G004), see Figure 5, and for H4.0FT5/

FT6; H4.5FTS5, H4.5FT6; H5.0-5.5FT (H80,

90, 100, 110, 120FT) (N005, P005), see Fig-

ure 6. Remove brackets and slowly lower

axle assembly onto wheels. Carefully roll

steering axle assembly away from lift truck.

2

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$55.99

$72.99

Viewed 11 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$55.99

$72.99

Get access to comprehensive repair and maintenance information for Mazda engines with displacement options of 2.0L and 2.2L. This manual covers a range of engine models including S30FT, S35FT, S40FTS, H1.6FT, H1.8FT, H2.0FTS, S2.0-3.5FT, S40-70FT, S55FTS, H2.0-3.5FT, and H40-70FT. Whether you are a professional mechanic or a DIY enthusiast, this manual provides valuable insights and detailed procedures to keep your Mazda engine in top condition.