CLARK Forklift FACTORY Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Service

Manual

SM 591

GPH/DPH 50/60/70/75

Group 20

Drive Axle

Group 32

lilt Cylinders

Group 21

Prop Shaft

Group 06

Transmlsslon

Group 00

Group26/26

-!I

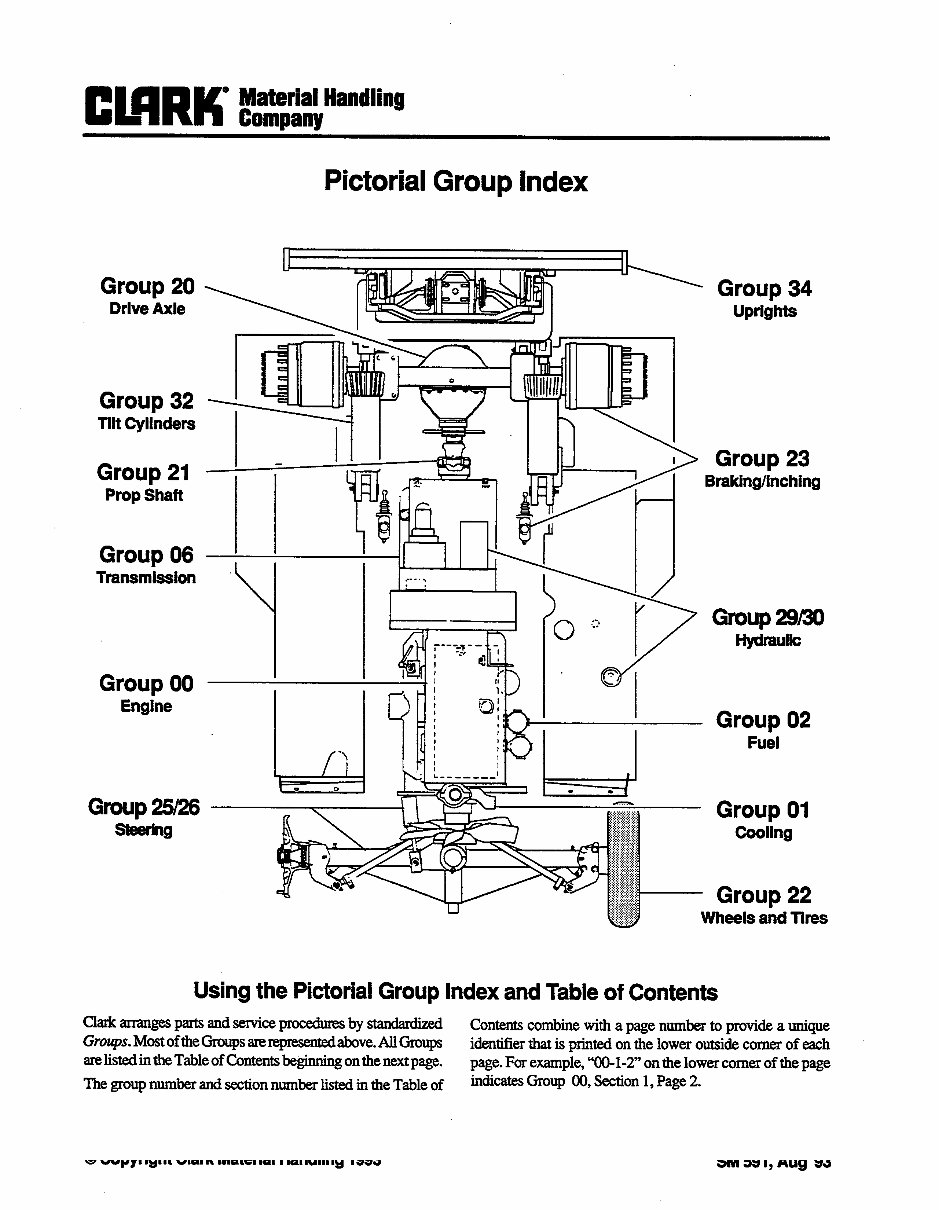

Pictorial Group Index

a_

Group 34

uprights

Group 23

Braklng/lnchlng

Group 29/30

Hydraulic

Group 02

Fuel

- Group 01

Cooling

- Group 22

Wheels and Tires

Using the PictorialGroup Index and Table of Contents

Clakinangespartsandserviceproceduresby~~

Contents combine with a page number to provide a unique

Gro~~~s.MostoftheGroupsarereprewWabove.AllGmups

identifierthat is printed on the lower outside comer of each

are listedin the Table of Contentsbeginningon the nextpage. page. For example,“00-1-2” on the lower comer of the page

The group number and section number listed in the Table of

indicatesGroup 00, Section 1, Page 2.

0 CopyrightClark Materlal Handling1993

SM 591, Aug ‘93

CONTENTS

Group#

00

00

al

00

00

00

01

01

01

01

01

02

02

02

02

02

06

06

06

06

06

06

14

14

14

14

14

20

20

20

20

20

20

20

20

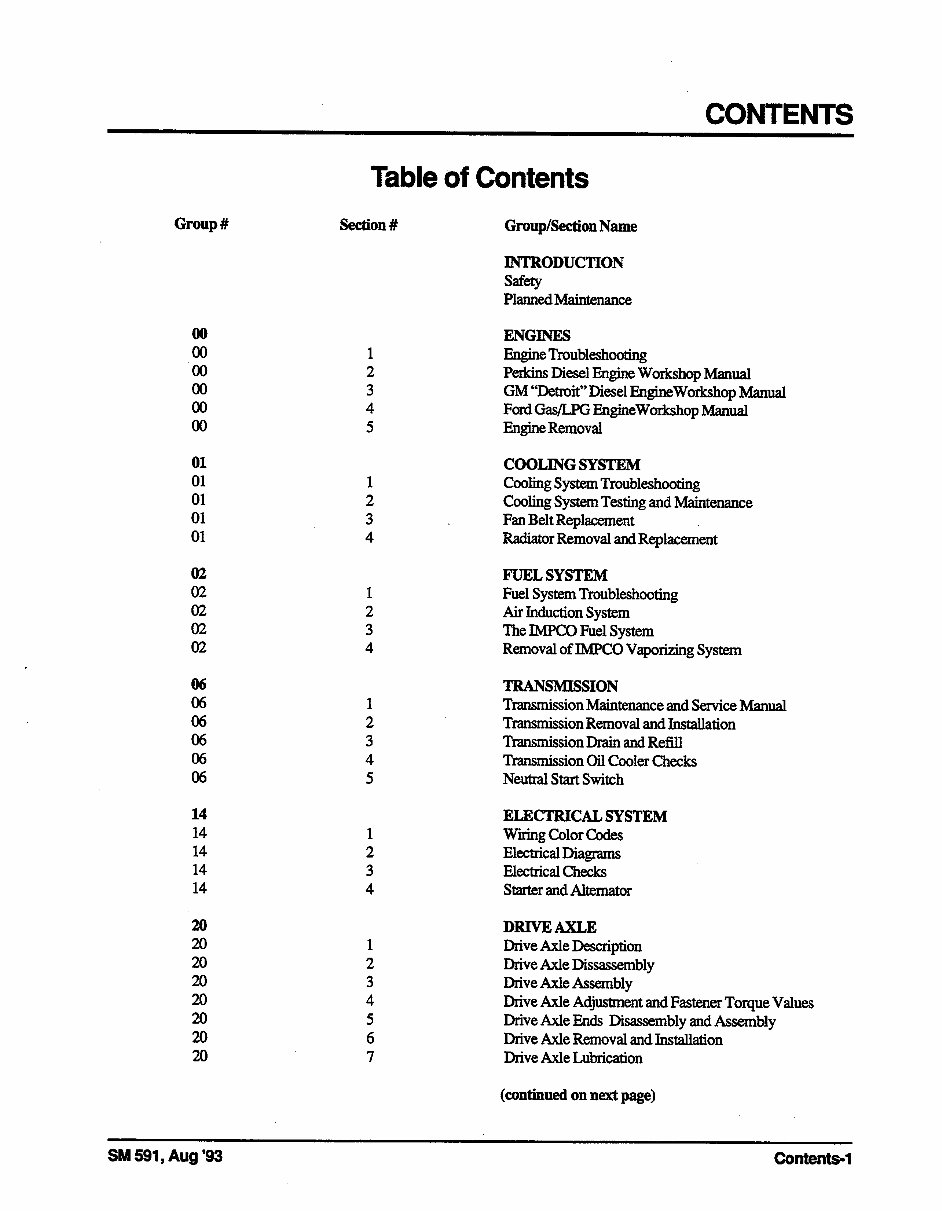

Table of Contents

Section# Group/Section Name

INTRODUCTION

Safety

PlannedMaintenance

ENGINES

Engine Troubleshooting

Perkins Diesel Engine Workshop Manual

GM “Detroit” Diesel EngineWorkshop Manual

Ford Gas/LPG BngineWorkshop Manu

Engine Removal

COOLING SYSTEM

Cooling System Troubleshooting

Cooling System Testing and Maintenance

Fan Belt Replacement

Radiator Removal and Replacement

FUEL SYSTEM

Fuel System Troubleshooting

Air Induction System

The IMPCO Fuel System

Removal of IMPCO Vaporizing System

TRANSMISSION

Transmission Maintenance and Service Manual

Transmission Removal and Installation

Transmission Drain and Refill

Transmission Oil Cooler Checks

Neutral Start Switch

ELECTRICAL SYSTEM

wiring C&r C5de.s

ElectricalDiagrzns

BlectlicalChecks

StarterandAltemator

DRIVEAXLE

Drive Axle Description

Drive Axle Dissassembly

Drive Axle Assembly

Drive Axle Adjustment and Fastener Torque Values

Drive Axle Ends Disassembly and Assembly

Drive Axle Removal and Installation

Drive Axle Lubrication

(continued on next page)

SM 591, Aug ‘93 COIlbltS-1

Group#

21

21

22

22

22

22

22

23

23

23

23

23

23

23

23

25

25

25

25

26

26

26

26

26

26

29

29

29

29

30

30

30

30

30

30

32

32

32

32

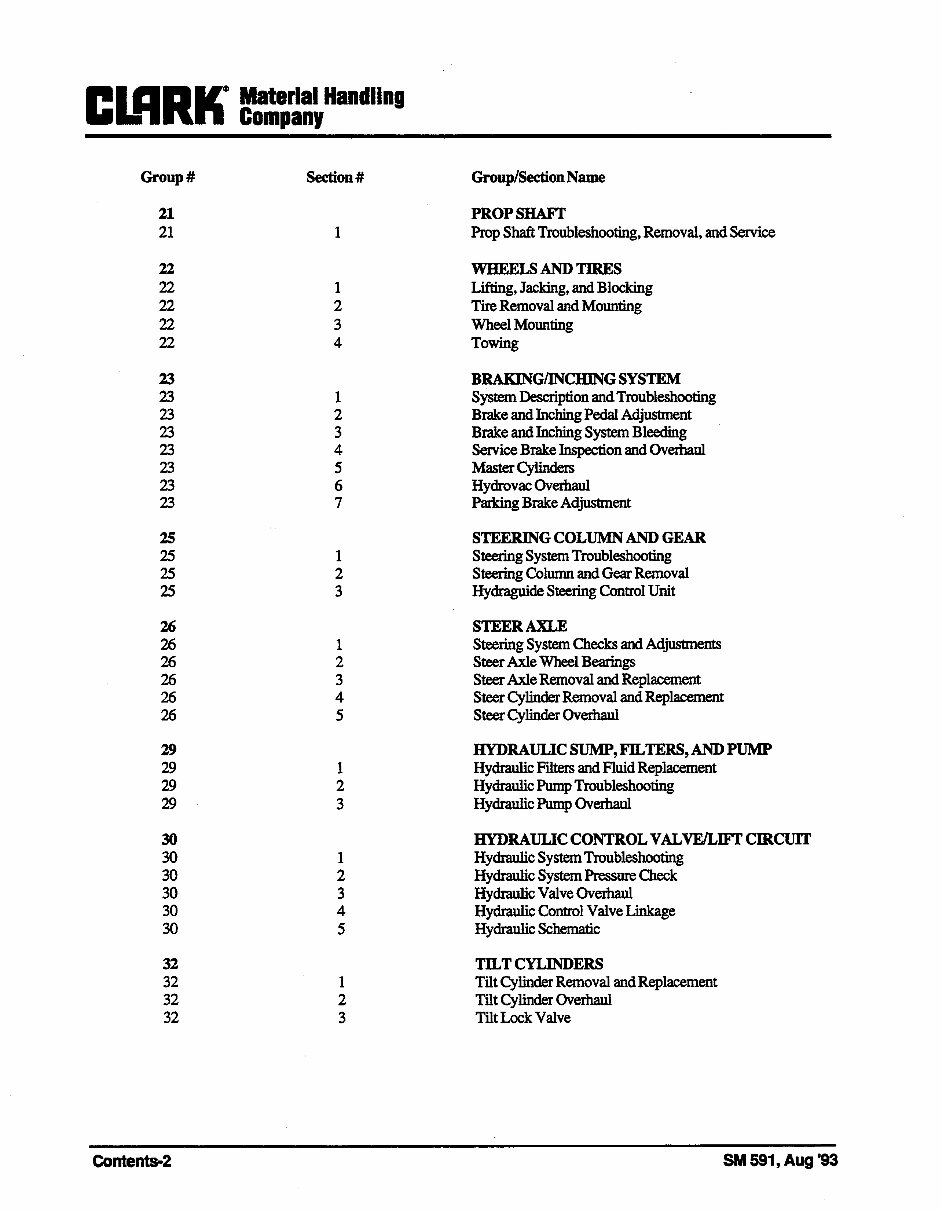

section# Group/Section Name

1 Prop Shaf& Troubleshooting, Removal, and Service

1

2

3

1

2

3

1

2

3

PROP !sHAFr

WHEELSANDTIRES

Lifting, Jacking, and Blocking

Tire Removal and Mounting

Wheel Mounting

Towing

BRAKING/lNCHINGSYSTEM

System Description and Troubleshooting

Brake and Inching Pedal Adjustment

Brake and Inching System Bleeding

ServiceBrakeInqxctionandOverhaul

MasterCylin~

Hydrovac Overhaul

Parking Brake Adjustment

STEERING COLUMN AND GEAR

Steering SystemTroubleshooting

Steering Column and Gear Removal

Hydraguide Steering Control Unit

STEER AXLE

Steering System Checks and Adjustments

SteerAxle WheelBearings

Steer Axle Removal and Replacement

Steer Cylinder Removal and Replacement

SteerCylinder Overhaul

HYDRAuLIcsuMP,FJLTERs,ANDPuMP

Hydraulic Filters and Fluid Replacement

Hydraulic Pump Troubleshooting

HydraulicPumpOverhaul

HYDRAuLIccoNTRoLvALvE/LlFTcIRcurr

Hydraulic System Troubleshooting

Hydraulic SystemPressureQxck

Hydraulic Valve Owrhanl

Hydraulic Control Valve Linkage

Hydraulic Schematic

TILT CYLINDERS

Tilt Cylinder Removal and Replacement

Tilt Cylinder Overhaul

Tilt Lock Valve

Contents-2

SM 591, Aug ‘93

CONTENTS

Group # Section# Group/Section Name

34

34

34

34

34

34

34

34

38

38

40

40

40

40

40

40

40

1

1

2

3

4

5

6

UPRIGHTS

Troubleshooting and Visual Iqection

OpltiOIldChtXkS

Carriage Check and Adjustment

Upright Check and Adjustment

Cylinder Repair

Lift ChainMaintenance

Upright Removal and Replacement

COUNTERWEIGHTS

Counterweight Removal and Replacement

SPEClFICATIONS

Namplates andDecals

GxxEralspecifications

PM and Driver’s Daily Inqection Forms

Lubricants and Shop Supplies

Special Tools

Lubrication charts and Intervals

SM 591, Aug ‘93 C43ntents-3

Emw

Introduction

Planned Maintenance

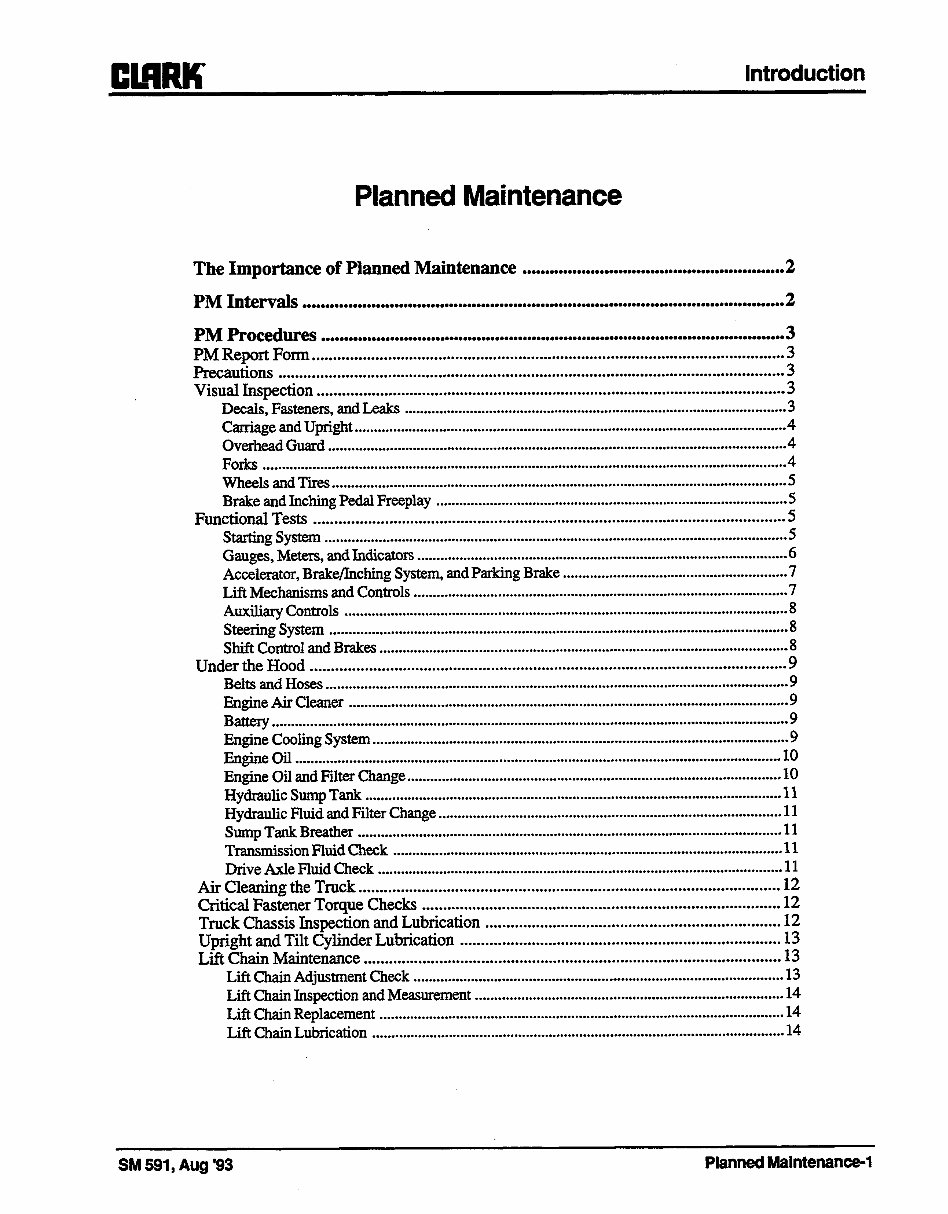

The Importance of Planned Maintenance ......................................................... 2

PM Intervals .........................................................................................................

2

PM Procedures .....................................................................................................

3

PM Report Form ................................................................................................................

Precautions ........................................................................................................................

;

Visual Inspection ...............................................................................................................

3

Decals, Fasteners, and Leaks

................................................................................................... 3

Carriage and Upright

................................................................................................................ 4

Overhead Guard .......................................................................................................................

4

Forks ........................................................................................................................................

4

Wheels and Tires ......................................................................................................................

5

Brake and Inching Pedal Freeplay ...........................................................................................

Functional Tests

................................................................................................................ :

Starting System ........................................................................................................................

5

Gauges, Meters, and Indicators

................................................................................................ 6

Accelerator, Brake/Inching System, and Parking Brake

.......................................................... 7

Lift Mechanisms and Controls

................................................................................................. 7

Auxiliary Controls

................................................................................................................... 8

Steering System .......................................................................................................................

8

Shift Control and Brakes

..........................................................................................................

Under the Hood

................................................................................................................. ;

Belts and Hoses

........................................................................................................................ 9

Engine Air Cleaner

.................................................................................................................. 9

Battery

...................................................................................................................................... 9

Engine Cooling System

............................................................................................................ 9

Engine Gil ..............................................................................................................................

10

Engine Oil and Filter Change

................................................................................................. 10

Hydraulic Sump Tank

............................................................................................................ 11

Hydraulic Fluid and Filter Change ......................................................................................... 11

SumpTankBreather

.............................................................................................................. 11

Transmission Fluid Check

..................................................................................................... 11

Drive Axle Fluid Check .........................................................................................................

11

Air Cleaning the Truck ....................................................................................................

12

Critical Fastener Torque Checks

..................................................................................... 12

Truck Chassis Inspection and Lubrication ......................................................................

12

Upright and Tilt Cylinder Lubrication ............................................................................

13

Lift Chain Maintenance ...................................................................................................

13

Lift Chain Adjustment Check

................................................................................................ 13

Lift Chain Inspection and Measurement ................................................................................

14

Lift Chain Replacement ......................................................................................................... 14

Lift Chain Lubrication

........................................................................................................... 14

SM 591, Aug ‘93

PlannedMaintenance-1

Introduction

cl!!mK

The Importance of Planned

Maintenance

A planned maintenance (PM) program of regular,

routine inspections and lubrication is important for

long life and trouble-free operation of your lift truck.

Make and keep records of your inspections. Use

these records to help establish the correct PM inter-

vals for your application and to indicate maintenance

required to prevent major problems from occurring

during operation.

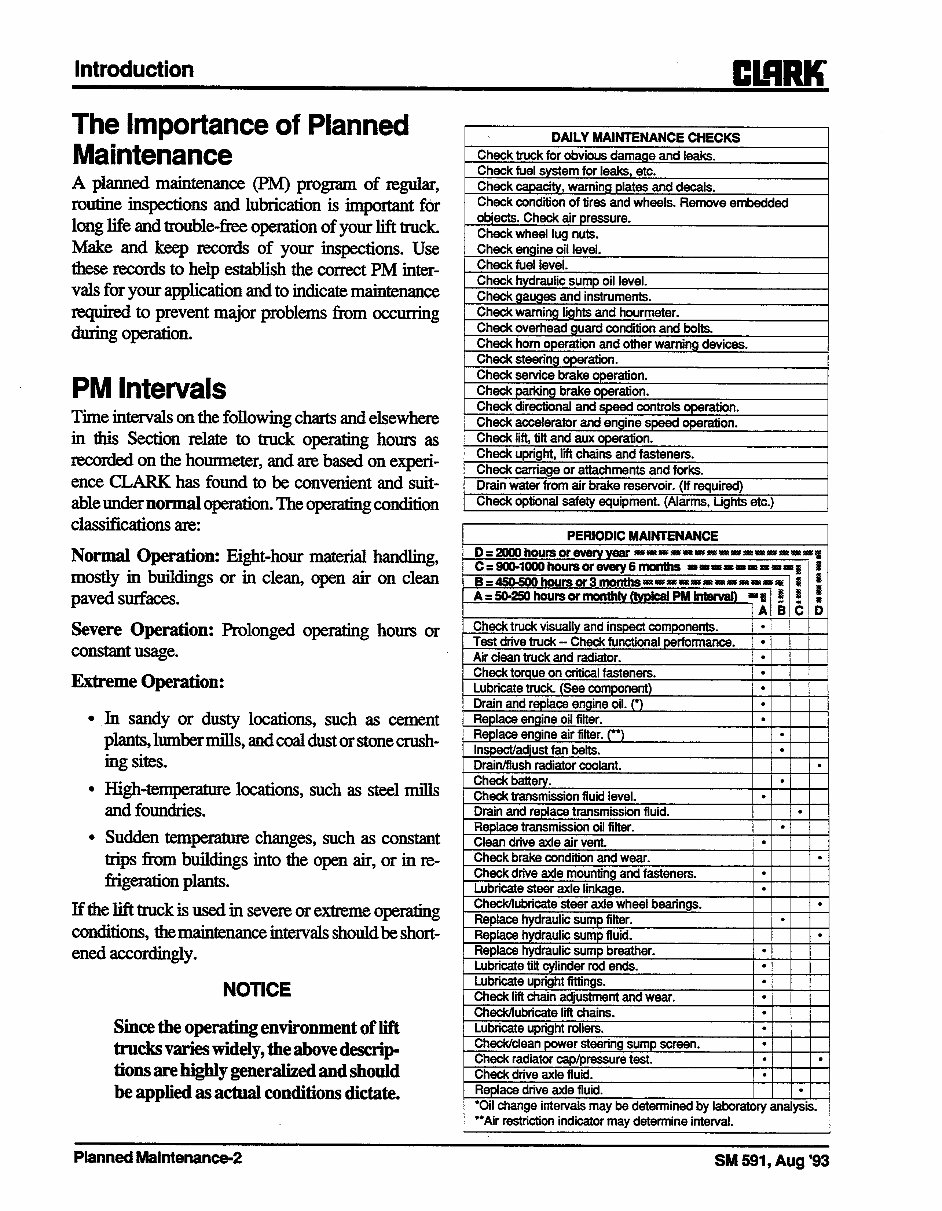

PM Intervals

Time intervals on the following charts and elsewhere

in this Section relate to truck operating hours as

recorded on the hometer, and ate based on experi-

ence CLARK has found to be convenient and suit-

able under normal operation. The operating condition

classifications are:

Normal Operation: Eight-hour material handling,

mostly in buikiings or in clean, open air on clean

paved surfaces.

Severe Operation: Prolonged operating hours or

constantusage.

Extreme Operation:

Jn sandy or dusty locations, such as cement

plants,lumbermills,andcoaldustorstonecrush-

ing sites.

H&h-temperature locations, such as steel mills

and foundries.

Sudden temperature changes, such as constant

trips from buildings into the open air, or in re-

frigeration plants.

If the lift truck is used in severe or extreme operating

conditions, the maintenance intervals shouldbe short-

ened accordingly.

NOTICE

Siucethe operating environment of lift

trucksvarieswidely,theabovedescrip-

tions are highly generalized and should

be applied as actual conditions dictate.

“*Air restriction indicator may determine interval.

PlannedMaintenance-2 SM 591, Aug ‘93

Introduction

PM Procedures

Visual Inspection

Daily checks and periodic maintenance should be

performed according to the following procedures.

PM Report Form

First, perform a visual inspection of the lift truck and

its components. Walk around the truck and take note

of any obvious damage andmaintenance problems.

A planned maintenance program of regular, routine

inspections and lubrication is important for long life

and trouble-free operation of your lift truck. Make

and keep records of your inspections. Use these

records to help establish the correct PM intervals for

your application and to indicate maintenance re-

quired to prevent major problems from occuning

during operation.

As an aid in performing and documenting your PM

inspections, Clark has prepared a “Gas, LPG or

Diesel Planned Maintenance Report” form. Copies

of this form may be obtained from your authorized

Clark dealer. We recommend that you use this form

as a checklist and to make a record of your inspec-

tion and truck condition. Please note the special

codingsystemforindicatingtheimportanceofneeded

repairs and/or adjustments.

The periodic maintenance procedures outlined in

thismanualateintendedtobeusedwiththePM

report form. They are arranged in groupings of main-

tenance work that are done in a logical and efficient

sequence.

Decals, Fasteners, and Leaks

Check for loose fasteners and fittings.

Check to be sure all capacity, safety, and warning

plates and decals are attached and legible.

NOTICE

Do not operate a lift truck with dam-

aged or missing decals and name-

plates. Replace them immediately.

They contain important iuformatio~~

When you have finished the PM inspections, be sure

to give a copy of the report to the designated author-

ity or the person responsible for lift truck mainte-

nance.

Inspect the truck before and after starting engine for

any signs of extemal leakage: fuel, engine oil or

coolant, transmission fluid, etc.

Precautions

/\

! CAUTION

Do not make repairs or adjustments

unless authorized to do so.

Check for hydraulic oil leaks and loose fittings. DO

NOT USE BARE HANDS TO CHECK. Oil may

be hot or under pressure.

A ! CAUTION

Disconnect the battery ground cable (-) from the

engine or frame before working on electrical com-

ponents. Always wear safety glasses. Wear a safety

(hard) hat in industrial plants and in special areas

where protection is necessary or required Remove

all jewehy (watch rings, bracelets, etc.) before work-

ing on the truck

HYDRAULIC FLUID PREssuRE.

Do not use your hands to check for

hydraulic leakage. Fluid under pres-

surecaupenetrateyourskinandcause

serious injury.

SM 591, Aug ‘93 PlannedMaintenance-3

Introduction

el!!mK

OverheadGuard

Forks

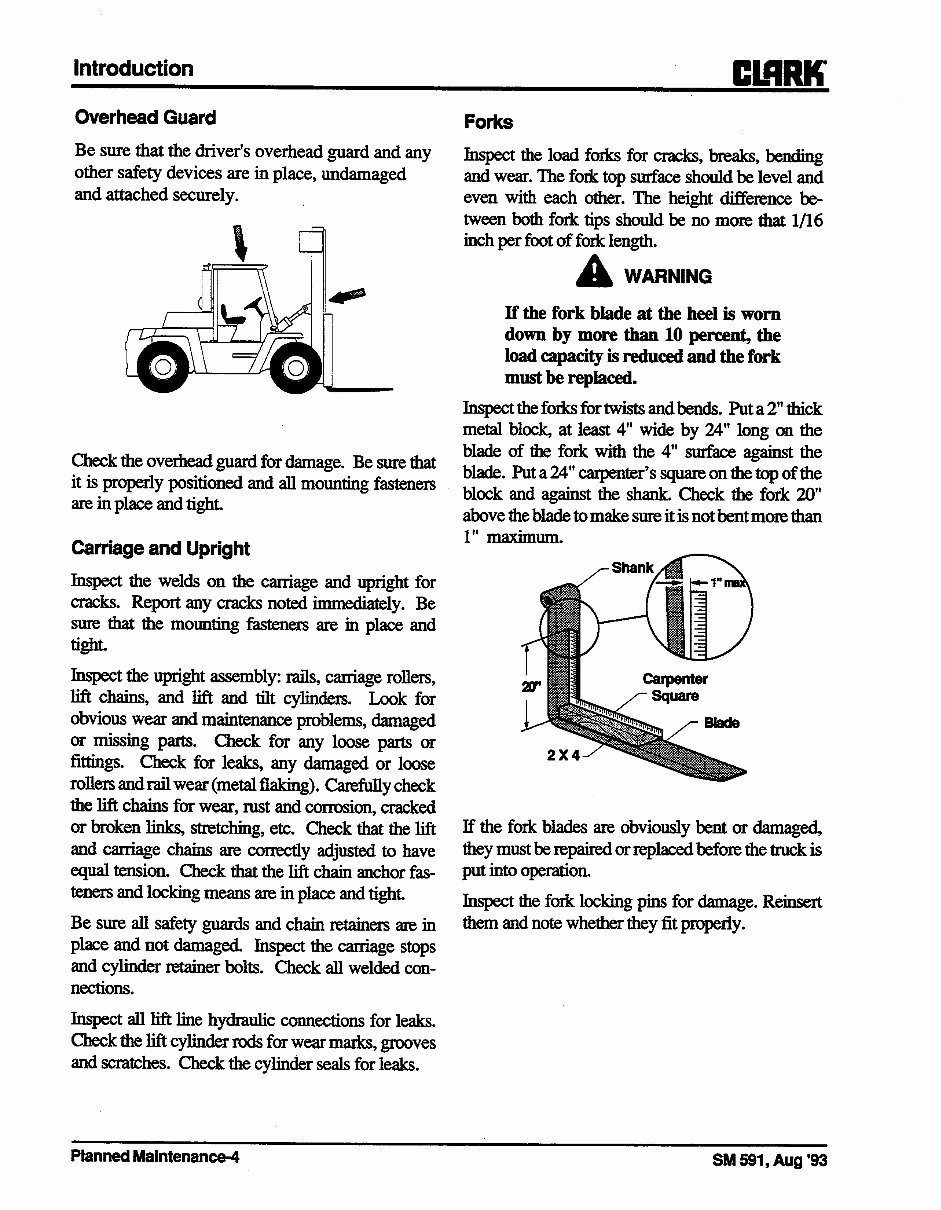

Be sure that the driver’s overhead guard and any

other safety devices are in place, undamaged

and attached securely.

Inspectthe load forks for cracks, breaks, bending

and wear. The fork top surface should be level and

even with each other. The height difference be-

tween both fork tips should be no more that l/16

inch per foot of fork length.

Check the overhead guard for damage. Be sure that

it is properly positioned and all mounting fasteners

are in place and tight.

Carriageand Upright

Inspect the welds on the carriage and upright for

cracks. Report any cracks noted immediately. Be

sum that the mounting fasteners are in place and

tight.

Inspect the upright assembly: rails, carriage rollers,

lift chains, and lift and tilt cylinders. Look for

obvious wear and maintenance problems, damaged

or missing parts. Check for any loose parts or

fittings. Check for leaks, any damaged or loose

rollers and rail wear (metal flaking). Carefully check

the lift chains for wear, rust and corrosion, cracked

or broken links, stretching, etc. Check that the hft

and carriage chains are cornxtly adjusted to have

equal tension. Check that the lift chain anchor fas-

teners and locking means are in place and tight

Besureallsafetyguardsandchainretainersamin

place and not damaged. Jnspect the carriage stops

and cylinder retainer bolts. Check all welded con-

nections.

Jnspect all lift line hydraulic connections for leaks.

Check the lift cylinder rods for wear marks, grooves

and scratches. Check the cylinder seals for leaks.

A

WARNING

If the fork blade at the heel is worn

down by more than 10 percent, the

load capacity is reduced and the fork

must be replaced.

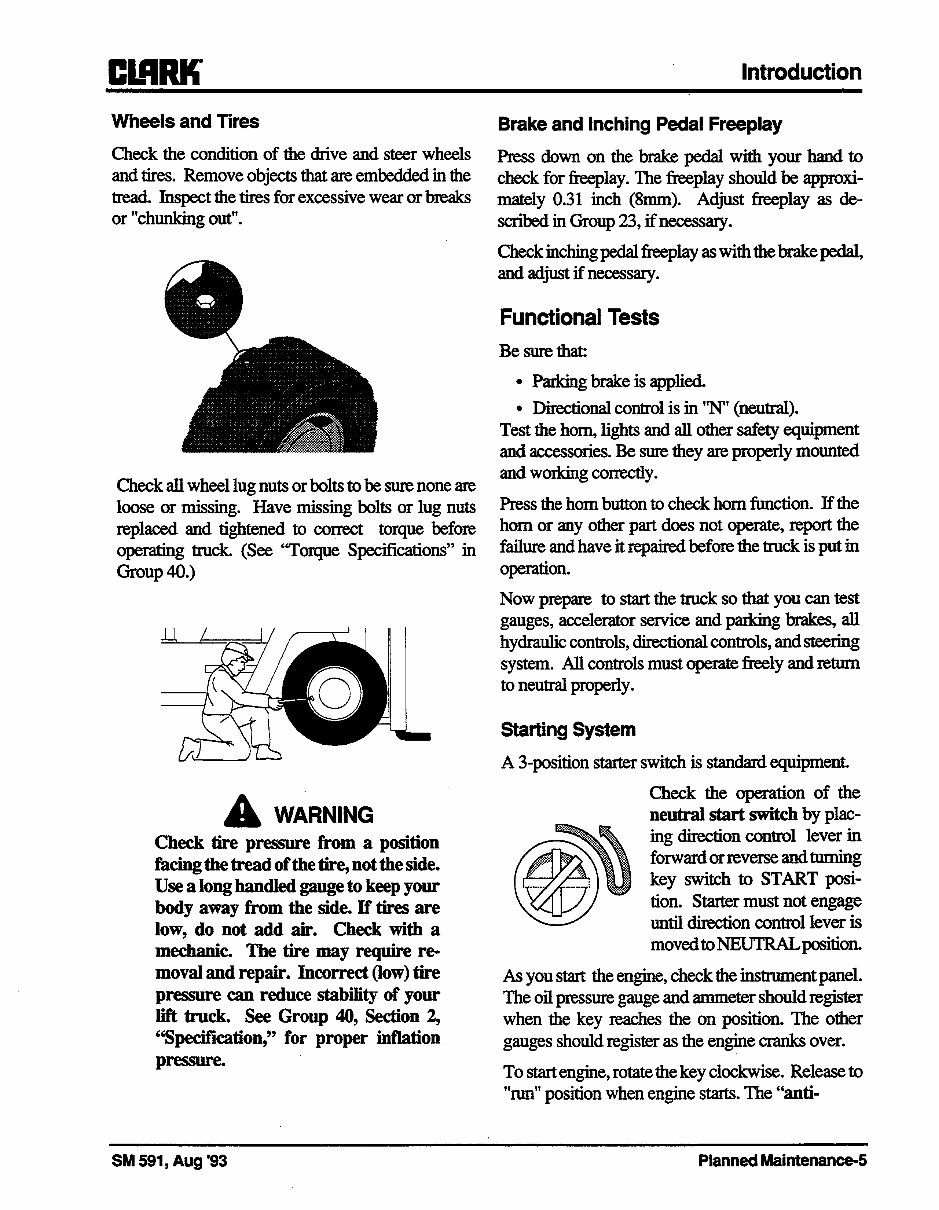

Inspecttheforksfortwistsandbends. Puta2”thick

metal block, at least 4” wide by 24” long on the

blade of the fork with the 4” surface against the

blade. Put a 24” carpenter’s square on the top of the

block and against the shank. Check the fork 20”

above the blade to make sure it is not bent more than

1” maximum.

If the fork blades ate obviously bent or damaged,

they mustbetepairedorreplacedbefore the track is

put into operation.

Inspect the fork locking pins for damage. Reinsert

them and note whether they fit properly.

PlannedMaintenance-rl

SM 591, Aug ‘93

Introduction

Wheels and Tires

Check the condition of the drive and steer wheels

and tires. Remove objects that ate embedded in the

tread. Inspect the tires for excessive wear or breaks

or “chunking out”.

Check all wheel lug nuts or bolts to be sure none are

loose or missing. Have missing bolts or lug nuts

replaced and tightened to correct torque before

opemting truck (See ‘Torque Specifications” in

Group 40.)

A

WARNING

Check tire pressure from a position

facing the tread of the tire, not the side.

Use a long handled gauge to keep your

body away from the side. If tires are

low, do not add air. Check with a

mechanic. The tire may require re-

moval and repair. Incorrect (low) tire

pressure can reduce stability of your

lift truck. See Group 40, Section 2,

T@ecification,” for proper inflation

Pm

Brake and Inching Pedal Freeplay

Pxessdownonthebrakepedalwithyourhandto

check for &play. The freeplay should be approxi-

mately 0.31 inch (8mm). Adjust fieeplay as de-

scribed in Group 23, if necessary.

checkinchingpedalfreeplayaswiththebrakepedal,

and adjust if necessary.

Functional Tests

Besurethat:

l Parking brake is applied.

l Directional control is in ‘W’ (neutral).

Test the horn, lights and all other safety equipment

and accessories. Be sure they are properly mounted

and working correctly.

Press the horn button to check horn function. If the

horn or any other part does not operate, report the

faihu-e and have it repaired before the truck is put in

operation.

Now prepare to start the truck so that you can test

gauges, accelerator service and parking brakes, all

hydraulic controls, directional controls, and steering

system. All controls must operate freely and return

to neutral properly.

Starting System

A 3position starter switch is standard equipment.

Check the operation of the

neutral start switch by plac-

ing direction control lever in

forwardorreverseandturning

key switch to START posi-

tion. Starter must not engage

until dim&ion control lever is

movedtoNEUTRALposition.

As you start the engine, check the instrument panel.

The oil pressure gauge and ammeter should register

when the key reaches the on position. The other

gauges should register as the engine cranks over.

To start engine, rotate the key clockwise. Release to

“run” position when engine starts. The “anti-

SM 591, Aug ‘93 PlannedMaintenance-5

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 35 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

The Clark forklift repair manual covers GPH/DPH 50 60 70 75 models and addresses most repair and service issues for these forklifts. Whether you are a professional mechanic or a DIY enthusiast, this manual provides comprehensive guidance for maintenance and repairs, allowing you to save money by doing it yourself. It is compatible with both Mac and PC computers, ensuring fast access to the information you need.