1988-1999 Suzuki DT25 DT35 2-Stroke Outboard Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

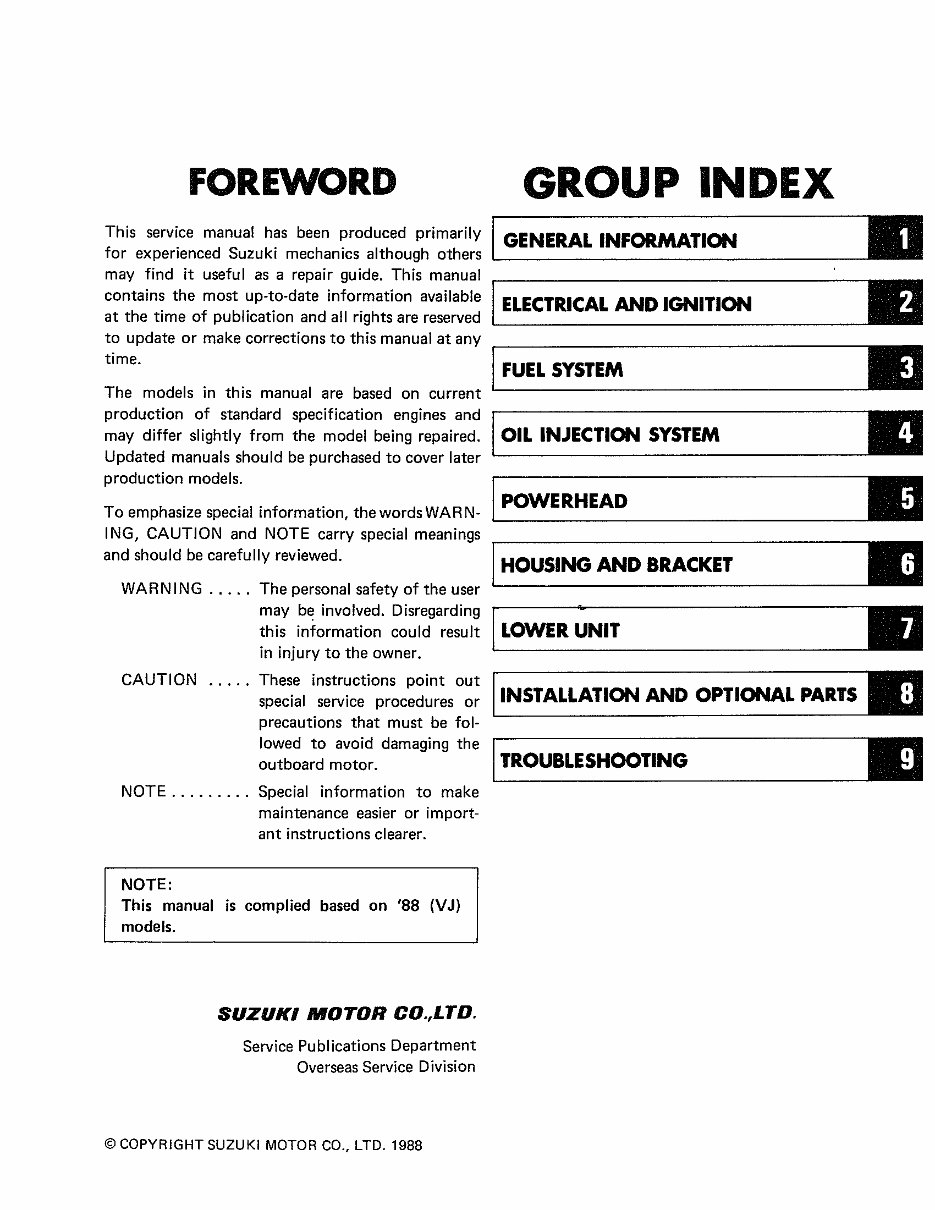

FOREWORD GROUP INDEX

This service manual has been produced primarily GENERAL INFORMATION

for experienced Suzuki mechanics although others L------------------

may find it useful as a repair guide. This manual

contains the most up-to-date information available ELECTRICAL AND IGNITION

at the time of publication and all rights are reserved

to update or make corrections to this manual at any ~------------------

time.

FUEL SYSTEM

The models in this manual are based on current L------------------

production of standard specification engines and

may differ slightly from the model being repaired. OIL INJECTION SYSTEM

Updated manuals should be purchased to cover later

production models. .-------------------

To emphasize special information, the words WARN-

ING, CAUTION and NOTE carry special meanings

and should be carefully reviewed.

POWERHEAD

HOUSING AND BRACKET

WARNING ..... The personal safety of the user L------------------

may be involved. Disregarding

this information could result LOWER UNIT

in injury to the owner.

CAUTION ..... These instructions point out

special service procedures or

precautions that must be fol-

lowed to avoid damaging the

outboard motor.

NOTE ......... Special information to make

maintenance easier or import-

ant instructions clearer.

NOTE:

This manual is complied based on '88 (VJ)

models.

SUZUKI MOTOR CO.,LTD.

Service Publications Department

Overseas Service Division

©COPYRIGHT SUZUKI MOTOR CO., LTD. 1988

I INSTALLATION AND OPTIONAL PARTS

I TROUBLESHOOTING

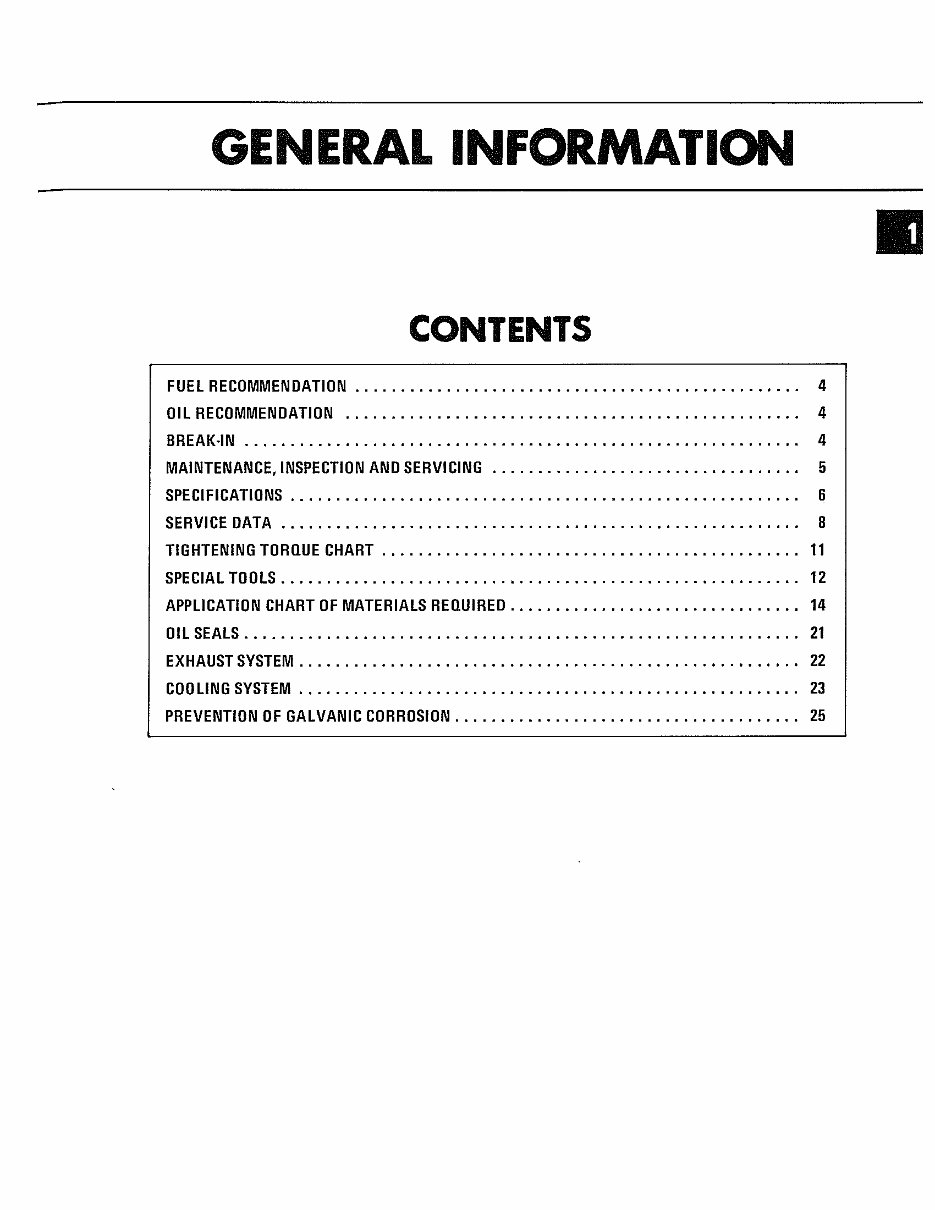

GENERAL INFORMATION

CONTENTS

FUEl RECOMMENDATION • . . . . . . . . . . . • . . • . . . . . • • . • . . • • • • . . • . • • • • • . . . . • • • • . 4

Oil RECOMMENDATION . . . . • • . . . . . . . . . . . • . . . • . . . . . • . . • . • . . • . . . . . . . . . . • • • • 4

BREAK·IN . . . . • . . . . • • • . . . • • . . • . . • . . . . . . . . . • • • . • • . . • • . • . • . . • . . . . . . . . • . • . 4

MAINTENANCE, INSPECTION AND SERVICING . . . . . . . • . . . • . . . . . . . • . • • . • • . • . . . . . • 5

SPECIFICATIONS . . . . • . . • . . • . • • . • • . . . . . . . . . . . . . . . . . . . . . . . . . . • • • . • • . • . . . • . 6

SERVICE DATA • • • . . • • . • . • • • . . • . • . . • . . . . . • . . . • . • . . . . . . . . • . . . . . . . • . • . . . . • 8

TIGHTENING TOR!lUE CHART .• ............ ••...••• ............ •..•..••.•.. 11

SPECIAl TOOlS ••.•..•.••..••..•...• .... •..•..••.• ..... • ..... •••• .... ••. 12

APPliCATION CHART OF MATERIALS RE!lUIREO . . • • • • • . • • • . . • . • • . . • • . • . • • . . . • • • 14

Oil SEAlS .• ........ ••.• ........... ••.•...•.•...•..•..•.• .... • ..... •... 21

EXHAUST SYSTEM . . . • . . . . . • • • • . . • . . • . . • • • . • . • • . • . . . • . • . . • . . . . . • . . • • • • • . • 22

COOliNG SYSTEM ........... ••.••.••.••.•••.•.••..•.••.•..••••..•..•.•.. 23

PREVENTION OF GAlVANIC CORROSION .•...••...• ..... •.•• ..... •.• ..... ••..• 25

4 GENERAL INFORMATION

FUEL RECOMMENDATION

Suzuki recommends that you use unleaded gasoline

containing no alcohol, with at least 85 pump octane

(.BfMmethod). Regular leaded gasoline containing

no alcohol, may also be used.

OIL RECOMMENDATION

Use Suzuki CCI oil or a Boating Industry Associa-

tion (B lA) certified outboard motor oil.

CAUTION:

Do not mix different types of oil. Mixing

different oil types can cause the oil to gel,

resulting in damage to your outboard motor.

BREAK-IN

The first 10 hours of engine operation are the most

important in the life of your engine. Proper opera-

tion during this break-in period will help ensure

maximum life and performance from your engine.

The following guidelines will explain proper break-

in p raced u res.

1. Use a 50 : 1 gasoline/oil mixture during the first

5 hours of engine operation. Use this mixture in

combination with the engine oil injection system

to help ensure adequate lubrication for break-in

operation. Be sure to use only Suzuki CCI oil

or a BIA-certified oil in the fuel mixuture. After

the break-in period, use straight gasoline for

fuel.

2. Allow sufficient idling time (more than 5

minutes) for the engine to warm up after cold

engine starting.

3. During the first 5 hours of operation, do not use

more than 1/2 throttle. For the remainder of the

break-in period, you may use full throttle, how-

ever, do not operate the engine continuously at

full throttle for more than 30 seconds at a time.

CAUTION:

Failure to follow the break-in procedures

described above can result in severe engine

damage.

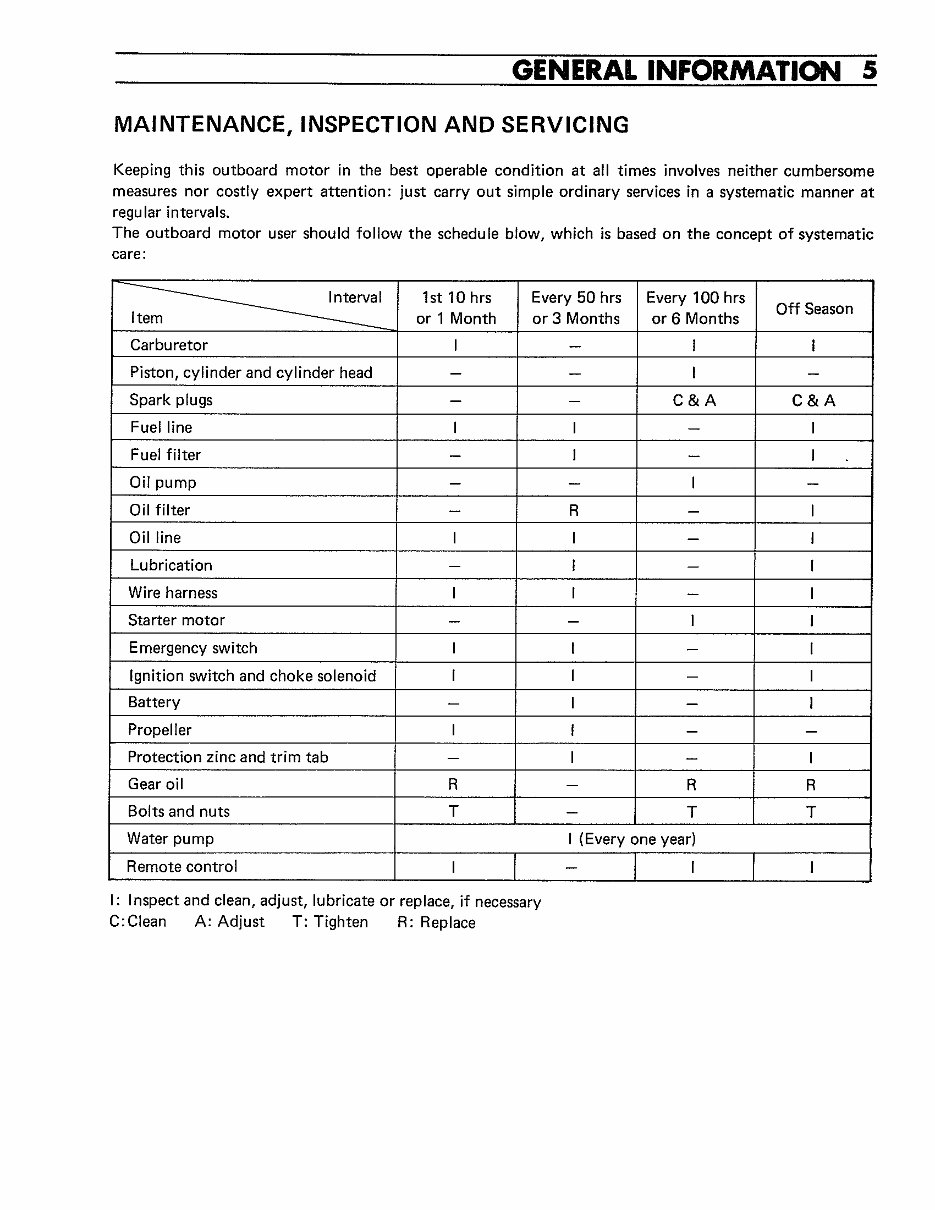

GENERAL INFORMATION 5

MAINTENANCE, INSPECTION AND SERVICING

Keeping this outboard motor in the best operable condition at all times involves neither cumbersome

measures nor costly expert attention: just carry out simple ordinary services in a systematic manner at

regular intervals.

The outboard motor user should follow the schedule blow, which is based on the concept of systematic

care:

~al

1st 10 hrs Every 50 hrs Every 100 hrs

Off Season

lte or 1 Month or 3 Months or 6 Months

Carburetor I - I I

Piston, cylinder and cylinder head - - I -

Spark plugs -

-

C&A C&A

Fuel line I I - I

Fuel filter - I - I

Oil pump - - I -

Oil filter - R - I

Oil line I I - I

Lubrication -

I -

I

Wire harness I I - I

Starter motor - - I I

Emergency switch I I - I

Ignition switch and choke solenoid I I - I

Battery - I - I

Propeller I I - -

Protection zinc and trim tab -

I - I

Gear oil R

-

R R

Bolts and nuts T - T T

Water pump I (Every one year)

Remote control I - I I

I: Inspect and clean, adjust, lubricate or replace, if necessary

C:Ciean A: Adjust T: Tighten R: Replace

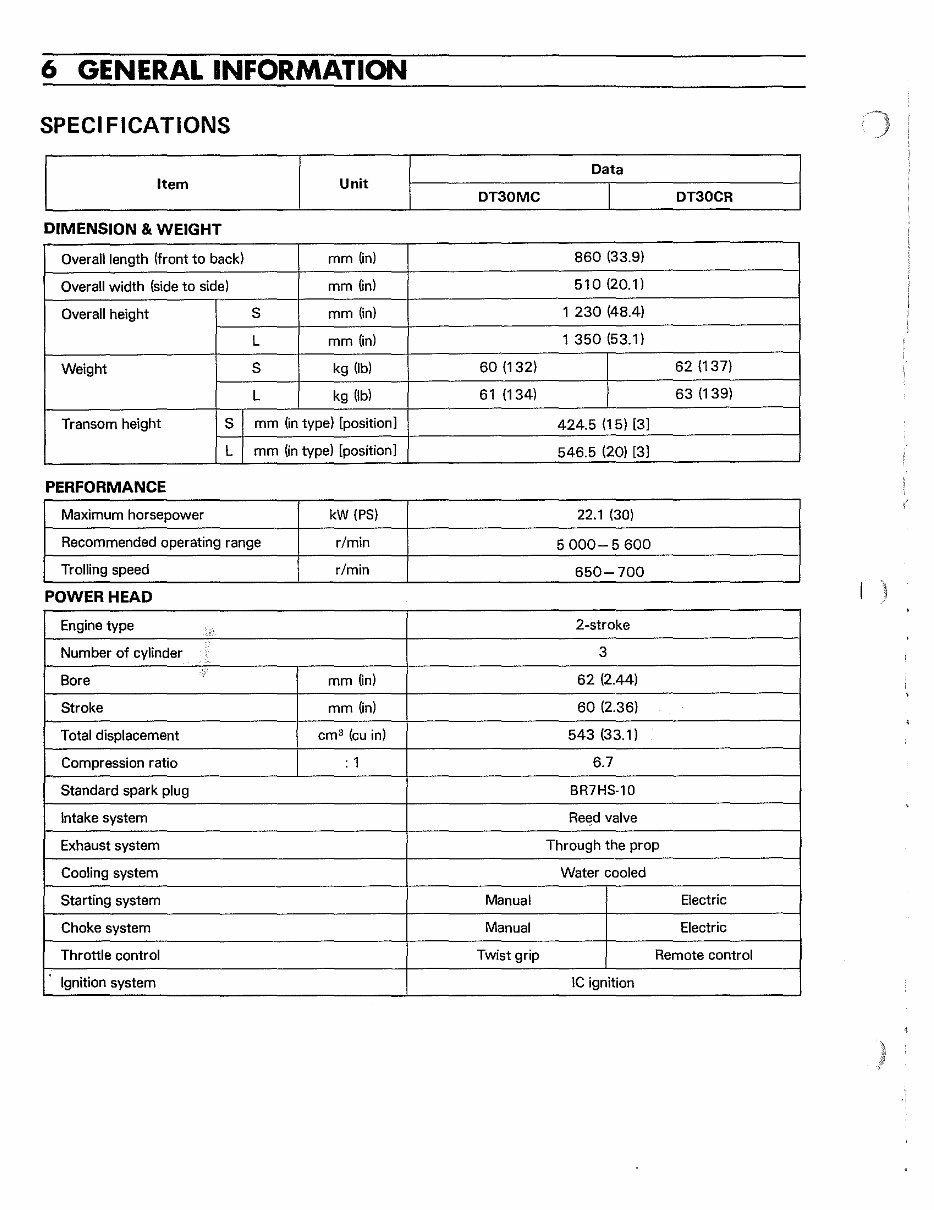

6 GENERAL INFORMATION

SPECIFICATIONS

Data

Item Unit

DT30MC DT30CR

DIMENSION & WEIGHT

Overall length (front to back) mm (in) 860 (33.9)

Overall width (side to side) mm (in) 510 (20.1)

Overall height s mm (in) 1 230 (48.4)

L mm (in) 1 350 (53.1)

Weight s kg (lb) 60 (132) 62 (137)

L kg (lb) 61 (134) 63 (139)

Transom height s mm (in type) [position] 424.5 (15) [3]

L mm (in type) [position] 546.5 (20) [3]

PERFORMANCE

Maximum horsepower kW (PS) 22.1 (30)

Recommended operating range r/min

5 000-5 600

Trolling speed r/min

650-700

POWER HEAD

Engine type 2-stroke

Number of cylinder 3

Bore

'

mm (in) 62 (2.44)

Stroke mm (in) 60 (2.36)

Total displacement cm

3

(cu in) 543 (33.1)

Compression ratio : 1 6.7

Standard spark plug BR7HS·10

Intake system Reed valve

Exhaust system Through the prop

Cooling system Water cooled

Starting system Manual Electric

Choke system Manual Electric

Throttle control Twist grip Remote control

Ignition system IC ignition

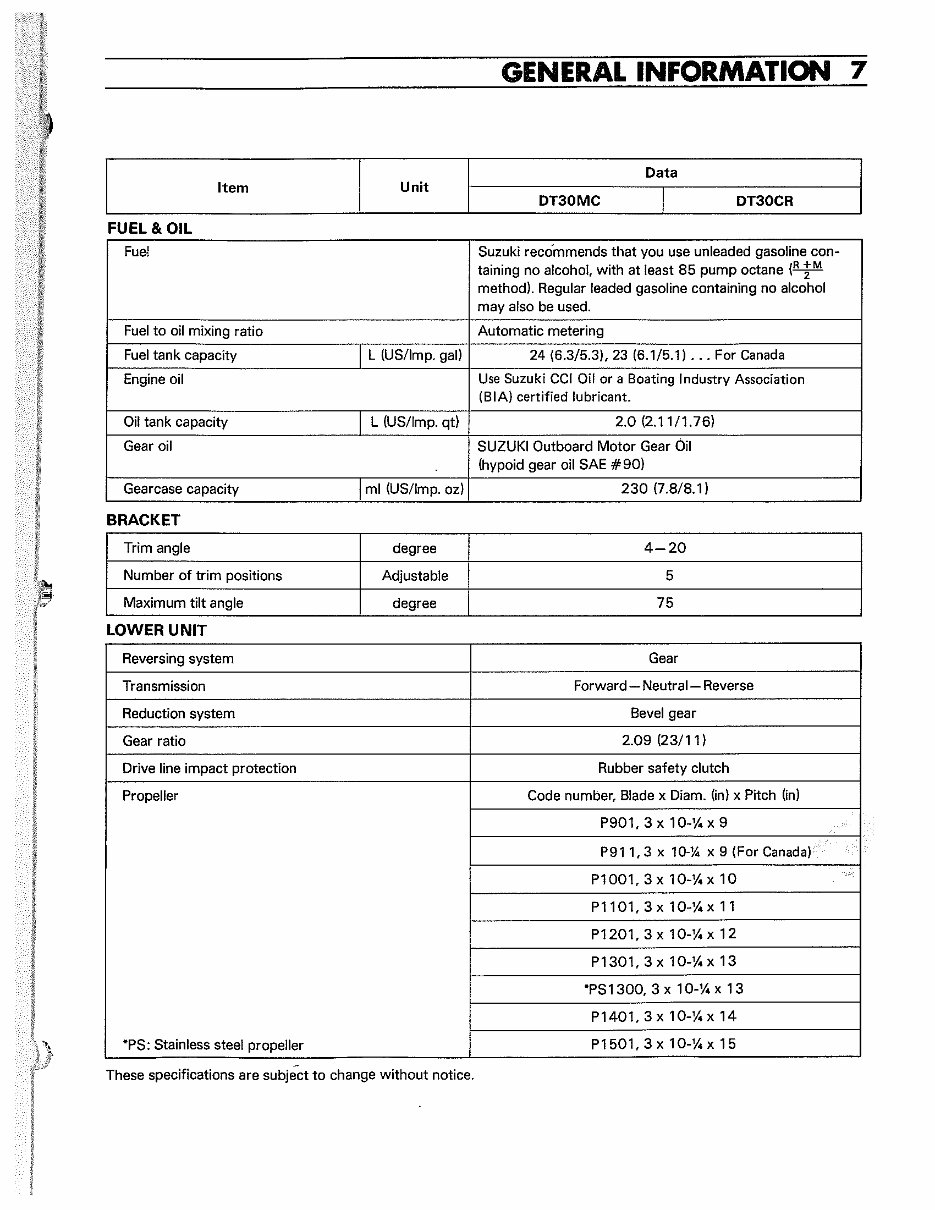

GENERAL INFORMATION 7

Data

Item Unit

DT30MC DT30CR

FUEL& OIL

Fue~ Suzuki recommends that you use unleaded gasoline con-

taining no alcohol, with at least 85 pump octane (R ~ M

method). Regular leaded gasoline containing no alcohol

may also be used.

Fuel to oil mixing ratio Automatic metering

Fuel tank capacity I L (US/Imp. gal) 24 (6.3/5.3). 23 (6.1/5.1) ... For Canada

Engine oil Use Suzuki CCI Oil or a Boating Industry Association

(BIA) certified lubricant.

Oil tank capacity I L (US/Imp. qt) 2.0 (2.11/1.76)

Gear oil SUZUKI Outboard Motor Gear Oil

(hypoid gear oil SAE # 90)

Gearcase capacity I ml (US/Imp. oz) 230 (7.8/8.1)

BRACKET

Trim angle degree 4-20

Number of trim positions Adjustable 5

Maximum tilt angle degree 75

LOWER UNIT

Reversing system Gear

Transmission Forward- Neutral- Reverse

Reduction system Bevel gear

Gear ratio 2.09 (23/ 11)

Drive line impact protection Rubber safety clutch

Propeller Code number, Blade x Diam. (in) x Pitch (in)

P901, 3 X 10-Y,.x 9

P911,3 x 10-Y.i x 9 (For Canada)

P1001,3x 10-Y.x 10

.•.

P1101,3x10-Y.x11

P1201, 3 X 1 0-Y. X 12

P1301, 3 X 10-Y,. X 13

"PS1300, 3 x 10-Y.x 13

P1401, 3 X 10-Y,. X 14

"PS: Stainless steel propeller P1501,3x 10-Y.x 15

These specifications are subject to change without notice.

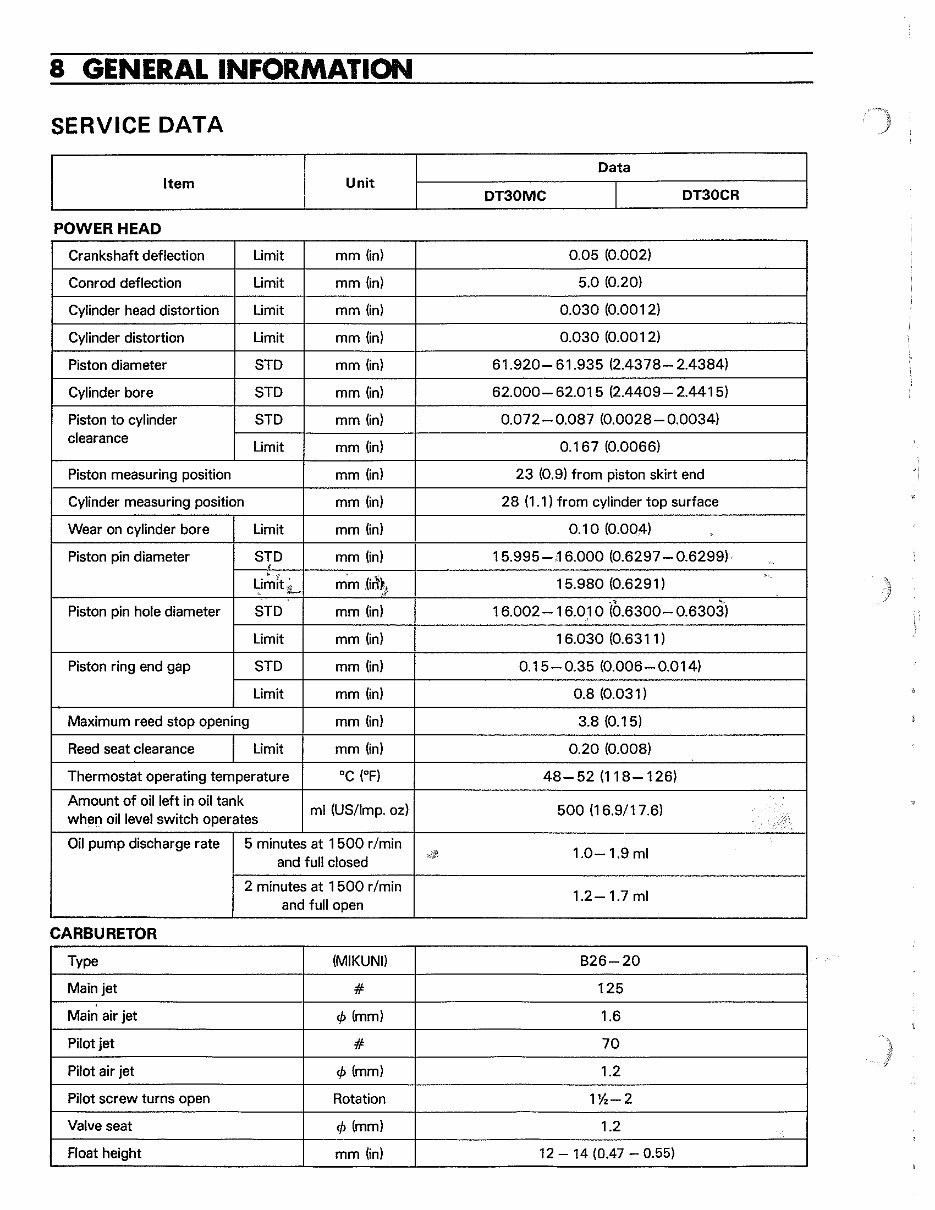

8 GENERAL INFORMATION

SERVICE DATA

Data

Item Unit

DT30MC DT30CR

POWER HEAD

Crankshaft deflection Limit mm (in) 0.05 (0.002)

Conrod deflection Limit mm (in) 5.0 (0.20)

Cylinder head distortion Limit mm (in) 0.030 (0.00 1 2)

Cylinder distortion Limit mm (in) 0.030 (0.00 1 2)

Piston diameter STD mm (in) 61.920-61.935 (2.4378- 2.4384)

Cylinder bore STD mm (in) 62.000-62.015 (2.4409- 2.4415)

Piston to cylinder STD mm (in) 0.072-0.087 (0.0028-0.0034)

clearance

Limit mm (in) 0.167 (0.0066)

Piston measuring position mm (in) 23 (0.9) from piston skirt end

Cylinder measuring position mm (in) 28 (1.1) from cylinder top surface

Wear on cylinder bore Limit mm (in) 0.1 0 (0.004)

.

Piston pin diameter STD

'

mm (in) 15.995 _,16.000 (0.6297- 0.6299)

u.:iJit i_ mm (id~

15.980 (0.6291)

.

Piston pin hole diameter STD mm (in) 16.002-16.010 (0.6300-0.630J)

Limit mm (in) 16.030 (0.6311)

Piston ring end gap STD mm (in) 0.15- 0.35 (0.006- 0.0 14)

Limit mm (in) 0.8 (0.031)

Maximum reed stop opening mm (in) 3.8 (0.15)

Reed seat clearance Limit mm (in) 0.20 (0.008)

Thermostat operating temperature

oc (oF)

48-52 (118-126)

Amount of oil left in oil tank

ml (US/Imp. oz) 500 (16.9/17.6)

when oil level switch operates ,: .

Oil pump discharge rate 5 minutes at 1500 r/min

1.0-1.9 ml

and full closed

/}'.

2 minutes at 1500 r/min

1.2-1.7ml

and full open

CARBURETOR

Type (MIKUNI) 826-20

Main jet # 125

Main air jet ¢ (mm) 1.6

Pilot jet # 70

Pilot air jet ¢ (mm) 1.2

Pilot screw turns open Rotation 1]1,-2

Valve seat ¢ (mm) 1.2

Float height mm (in) 12- 14 (0.47- 0.55)

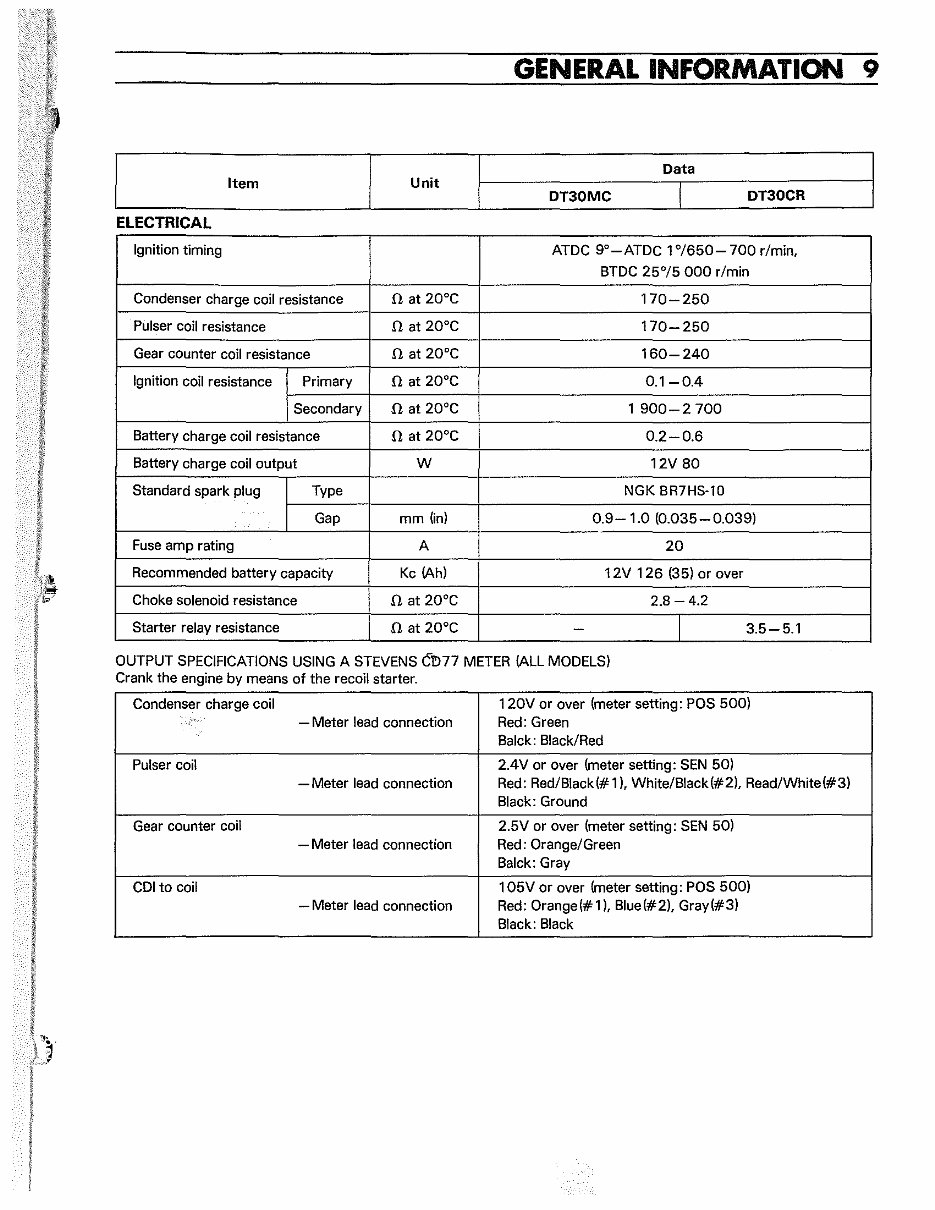

GENERAL INFORMATION 9

Data

Item Unit

DT30MC DT30CR

ELECTRICAL

Ignition timing ATDC 9•-ATDC 1°/650-700 r/min,

BTDC 25°/5 000 r/min

Condenser charge coil resistance a at 20°C 170-250

Pulser coil resistance a at 20°C 170-250

Gear counter coil resistance a at 20°C 160-240

Ignition coil resistance Primary a at 20°C 0.1-0.4

Secondary a at 2o•c 1900-2700

Battery charge coil resistance a at 20°C 0.2-0.6

Battery charge coil output w 12V 80

Standard spark plug Type NGK BR7HS-10

Gap mm !in) 0.9-1.0 (0.035-0.039)

Fuse amp rating A 20

Recommended battery capacity Kc (Ah) 12V 126 (35) or over

Choke solenoid resistance a at 2o•c 2.8-4.2

Starter relay resistance a at 20°C -

I

3.5-5.1

OUTPUT SPECIFICATIONS USING A STEVENS tf::J77 METER (ALL MODELS)

Crank the engine by means of the recoil starter.

Condenser charge coil 120V or over (meter setting: POS 500)

- Meter lead connection Red: Green

Salek: Black/Red

Pulsar coil 2.4V or over (meter setting: SEN 50)

-Meter lead connection Red: Red/Biack(#1), White/Biack(#2), Read/White(#3)

Black: Ground

Gear counter coil 2.5V or over (meter setting: SEN 50)

-Meter lead connection Red: Orange/Green

Salek: Gray

CDI to coil 1 05V or over (meter setting: POS 500)

-Meter lead connection Red: Orange(#1), Blue(#2), Gray(#3)

Black: Black

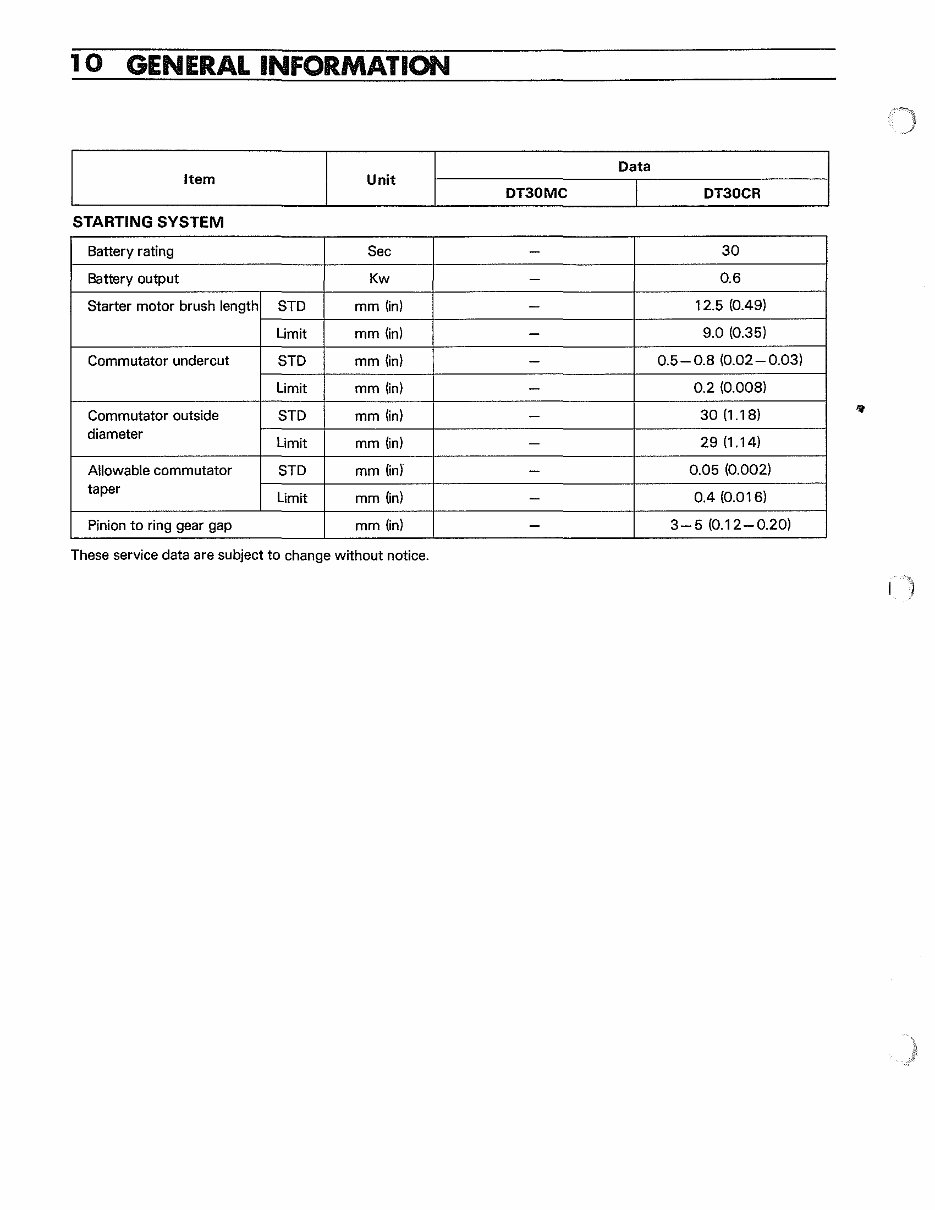

10 GENERAL INFORMATION

Data

Item Unit

DT30MC DT30CR

STARTING SYSTEM

Battery rating Sec - 30

Battery output Kw

- 0.6

Starter motor brush length STD mm (in) -

12.5 (0.49)

Limit mm (in) -

9.0 (0.35)

Commutator undercut STD mm (in) -

0.5-0.8 (0.02-0.03)

Limit mm (in)

-

0.2 (0.008)

Commutator outside STD mm (in) -

30 (1.18)

diameter

Limit mm (in) 29 (1.14) -

Allowable commutator STD mm (in) -

0.05 (0.002)

taper

Limit mm (in) -

0.4 (0.016)

Pinion to ring gear gap mm (in) -

3-5 (0.12-0.20)

These service data are subject to change without notice.

I )

GENERAL INFORMATION 11

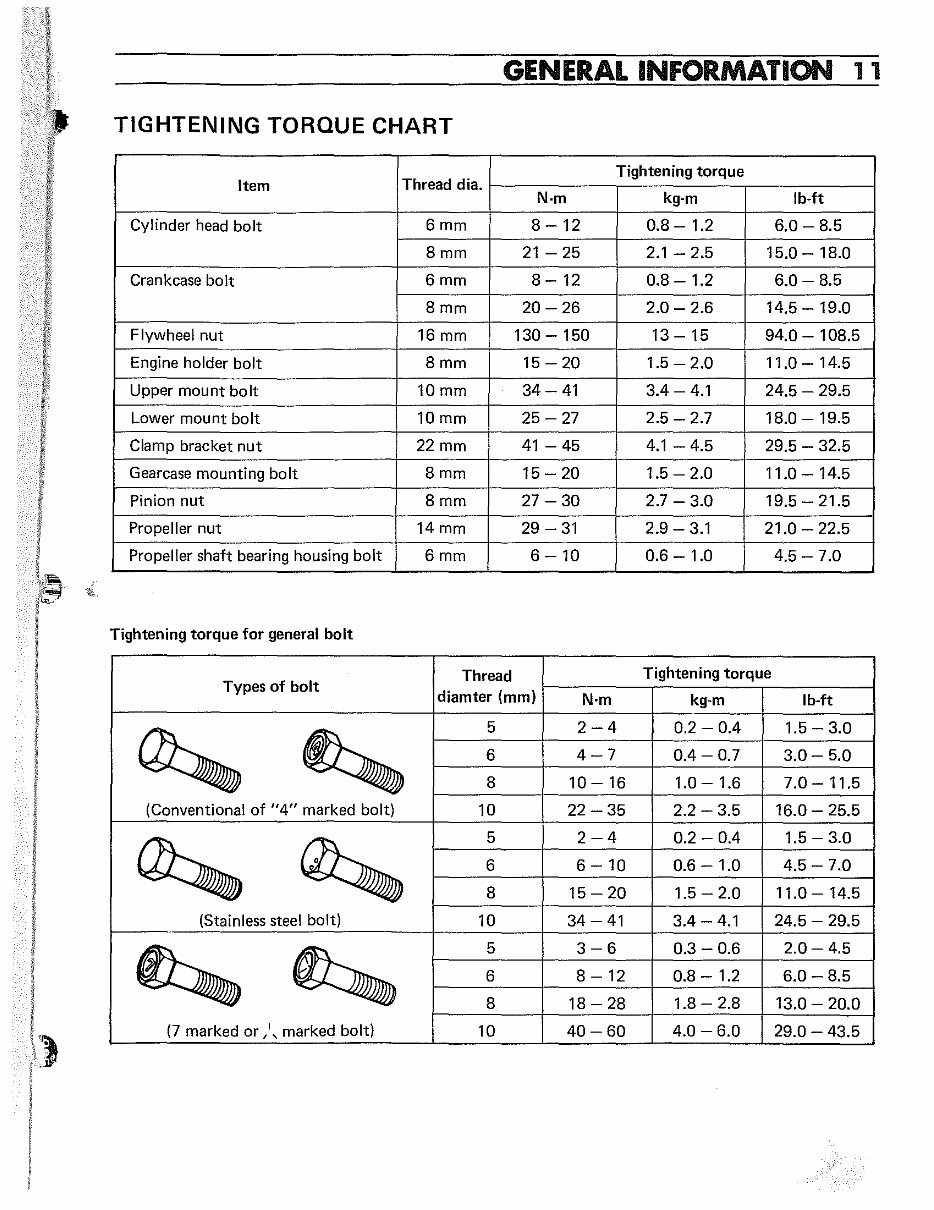

TIGHTENING TORQUE CHART

Thread dia.

Tightening torque

Item

N-m kg-m lb-ft

Cylinder head bolt 6mm 8-12 0.8-1.2 6.0-8.5

8mm 21-25 2.1-2.5 15.0- 18.0

Crankcase bolt 6mm 8- 12 0.8- 1.2 6.0-8.5

8mm 20-26 2.0-2.6 14.5- 19.0

Flywheel nut 16 mm 130- 150 13- 15 94.0-108.5

Engine holder bolt 8mm 15-20 1.5-2.0 11.0- 14.5

Upper mount bolt 10 mm 34-41 3.4-4.1 24.5-29.5

Lower mount bolt 10mm 25-27 2.5-2.7 18.0- 19.5

Clamp bracket nut 22 mm 41-45 4.1-4.5 29.5-32.5

Gearcase mounting bolt 8mm 15-20 1.5-2.0 11.0- 14.5

Pinion nut 8mm 27-30 2.7-3.0 19.5-21.5

Propeller nut 14 mm 29-31 2.9-3.1 21.0- 22.5

Propeller shaft bearing housing bolt 6mm 6-10 0.6-1.0 4.5-7.0

Tightening torque for general bolt

Types of bolt

Thread

Tightening torque

diamter (mm)

N·m kg-m lb-ft

~ ~

5 2-4 0.2-0.4 1.5-3.0

6 4-7 0.4-0.7 3.0-5.0

8 10- 16 1.0- 1.6 7.0- 11.5

(Conventional of "4" marked bolt) 10 22-35 2.2-3.5 16.0- 25.5

~

~

5 2-4 0.2-0.4 1.5-3.0

6 6-10 0.6-1.0 4.5-7.0

8 15-20 1.5-2.0 11.0-14.5

(Stainless steel bolt) 10 34-41 3.4-4.1 24.5-29.5

~ ~

5 3-6 0.3-0.6 2.0-4.5

6 8-12 0.8-1.2 6.0-8.5

8 18-28 1.8-2.8 13.0-20.0

(7 marked or,', marked bolt) 10 40-60 4.0-6.0 29.0-43.5

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

$51.99

Viewed 46 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

$51.99

- This full service and repair manual is a comprehensive factory workshop manual for the Suzuki DT25 DT35 2-Stroke Outboard models manufactured between 1988-1999.

- It is a professional manual that covers all repair, servicing, and troubleshooting procedures with detailed photos, diagrams, step-by-step instructions, and highly detailed exploded diagrams.

- It is suitable for use by both professional mechanics and DIY enthusiasts.

- You can print out single pages or the entire manual as per your requirement.

- This manual can be used on multiple computers without any limitations or trial periods.

- There is no expiry date, renewal fee, or need to pay any extra for continued use of this manual.

- It is fully compatible with Windows and MAC computers.

For instant access to this comprehensive manual, please click on the provided button.