2001 Mercury Marine Outboard Models Factory Service & Work Shop Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

CONTENTS

HOW TO USE THIS MANUAL 1·2

BOATING SAFETY 1-4

BOATING EQUIPME~ ( NOT REQUIRED

BUT RECOMMENDED) 1010

SAFffi IN SERVICE 1·12

TROUBLESHOOTING , ·1 3

SHOP EQUIPMENT '·17

TOOLS 1-19

fASTENERS, MEASUREMENT , AND CONVERSIONS 1-27

SPECIFICATIONS '·28

GENERAL INFORMATION 2·2

LUBRICATION 2-4

ENGINE MAINTENANCE 2·9

BOAT MAINTENANCE 2·28

TUNE-UP 2-31

TIMING AND SYNCHRONIZATION 2-40

STORAGE 2·73

CLEARING A SUBMERGED MOTOR 2·n

SPECIFICATIONS 2·79

FUEL AND COMBUSTION BASICS 3-2

FUEL TANK AND LINES 3·7

CARBURETED FUEL SYSTEM 3·12

ELECTRONIC FUEL INJECTION 3-44

OPTIMAX DIRECT FtlEl l NJECTJON ( OFI) 3-73

SPECIFICATIONS 3-107

UNDERSTANDING AND TAOUBLESHOOTING

ELECTRICAL SYSTEMS 4-2

IGNITION SYSTEMS 4-8

CHARGING CIRCUIT 4-40

SPECIFICATIONS 4-43

ELECTRICAL SWITCHISOLENOIO SERVICE 4-64

WIAING DIAGRAMS 4-66

OIL I NJECTION SYSTEM 5-2

COOLING SYSTEM 5-11

WARNING SYSTEMS 5-31

COOLING SYSTEM FLOW SCHEMATICS 5-41

SPECIFICATIONS S-46

POWERHEAD MECHANICAL

POWERHEAD RECONDITIONING

POWERHEAO BREAK-IN

SPECIFICATION CHARTS

LOWER UNIT

JET DRIVE

MECHANICAL TILT (UNASSISTED)

GAS ASSIST nlT SYSTEM

POWER TllTfTRIM - SINGLE RAM INTEGRAL

POWER nLT/1RIM· THREE RAM INTEGRAL

REMOTE CONTROLS

nllER HANDLE

WIRING DIAGRAMS

HAND ReWIND STARTER

MASTER INDEX

6-2

6-57

.. 9

6-70

7-2

7-79

8-2

..

8-10

8-2<1

9-2

9-7

9-14

1~2

1!H5

<

CONTENTS

MASTER INDEX

BOAT MAINTENANCE .. . . . •• . . ••• . . •••. 2·28

BATIERI ES . . . . . . . . . . 2·28

MAINTENANCE. 2·28

STORAGE. . . . 2·29

TESTING. . . .. . . . .. . . . .• 2·29

FI BERGlASS HULL. 2·30

INTERIOR ... .. ... . ..... .. .. . .... .. .. 2-30

CLEARING A SUBMERGED MOT OR •••..•• 2·77

ENGINE MAINTENANCE .. .• . •• . . . •• . . •• 2·9

AIR FILTER .. ...... .. . .. .. .. 2·26

REMOVAL & INSTALLATION . 2·26

ANODES ( ZINCS). . . . 2·23

INSPECTION. . . . . . . . . . . . . 2·24

SERVICING . . . . . . . . . . .. 2·24

COOLING SYSTEM . • . 2·9

FLUSHI NG JET DRIVES .. . .. . .. .. ... 2 ·11

FLUSHING THE SYSTEM . 2·9

DRIVE BELT. . . . . . . .. . . . 2·24

INSPECTION. . . . . . . . . . . . . •. 2·24

REMOVAL & IN STAL LATION .. . ........ 2·25

ENGINE COVERS. . . . . .. . . . . 2·9

REMOVAL & I NSTALLATION . . . . . . 2·9

FUEL FILTERIFUEL WATER SEPARATOR. 2·12

RELEASING PRESSURE. ..... 2· 13

SERViCE ............ • ............. 2·14

JET DRIVE I MPELLER . . . . . . . . . . . . . 2·22

IM PELLER CLEARANCE .. . 2·22

INSPECTION . 2·22

OIL FILTER. . .. . . . . . . . . . . . . . . . . . . • . . 2·27

REMOVAL & INSTALLATION. . . 2·27

PROPELLER. . . ................ 2·16

GENERAL IN FORMATION . .. . .. ...... 2 ·1 6

IN SPECTI ON .... . .. ... .. 2 ·1 8

REMOVAL & INSTALLATI ON . 2·18

2·STROKE OIL. . . . . . . . . •. . 2· 12

FI LLI NG .... .. ... . ..... 2·12

OIL RECOMMENDATIONS .. .. .. .. 2· 12

GENERAL INFORMATION •• . . ••• . ••. . . .. 2·2

BEFOREfAFTER EACH USE 2·2

ENGINE IDENTIFICATION. . . . . . . . . 2·2

MAINTENANCE COVERAGE . . . • . . . . . 2·2

MAINTENANCE EQUALS SAFETY. . . . . . . . 2·2

OUTBOARDS ON SAIL BQATS. . •• . . . . . .. 2·2

LUBRiCATION. ... . ••• . . ••• . . •••• ••• . . 2-4

ABOUT LUBRICATION . . 2·4

JET DRIVE BEARING . . . 2·8

LOWER UNIT. . . . . . . . . . . . . . . . . 2-4

LUBRICATION INSIDE THE BOAT . . . . 2·4

LUBRICATI NG THE M OTOR. . ..... .. . ... 2·4

POWER TRIMITILT RESERVOIR 2-9

S TORAGE . . ••• . . ••• . ••. . . ... . . 2·73

PREPPING FOR STORAGE ... 2·74

RE -COMMISSI ONING. . ........ 2·76

REMOVAL FROM STORAGE. 2·76

WINTERIZATION .. . . . . . . . . . . . . . . . . . . . 2·73

TIM ING AND SyNCHRONiZATION •• .. ••• . • 2·40

2.513.3 HP MODELS .... .. ... . ... 2·41

IDLE SPEED . 2·41

I GNI TION TIMING. 2·41

THROmE JET NEE DL E.. 2-4 1

415 HP MODELS. . . . . . • . . . . . . . . . . 2·42

IDLE SPEED & MIXTURE .......... 2·43

IGNITION TIM ING . . . .. 2·42

618 & 9.911 0115 HP MODELS 2-43

IDLE SPE ED ..... 2·43

IDLE WIRE .. . . ... . .. .. 2·45

IGN ITION TIMING . . . . . . . . . . . . . . . 2-44

LOW SPEED MIXTURE . .. . . . . . . . • . . . 2-43

20120 JET/25 HP MODELS. . . . . 2·45

CARBURETOR & LINKAGE . . .. 2-45

IDLE SPEED & MIXTURE. . . . . . . . . . . 2·47

I GNITION TIMING. . . . . . . . . . . . . . . . 2-47

30140 HP CYL MODELS . . . . . 2-47

IDLE SPEED & MIXTURE .......... 2·48

IGNITION TIM ING 2·49

OIL PUMP ....... .. ....... . ........ 2·50

REMOTE CONTROL CABLE .. . . . . . 2·48

4I}-125 HPCAAElJRETEDJ..tW4-CYLt.OES . 2·50

IDLE SPEED . . . . . . . . . . . . . . 2·52

IGNITION TIMI NG. .. .. .•...•. 2·51

SYN CHRONtZATI ON . . . . . . . . . . 2·50

75190/115 HP OPTIMAX MODELS 2·53

THRomE LINKAGE ADJUSTMENT . . 2·53

1 50·200 HP (2. 5L) V6 CARB MODE LS. 2·53

IDLE SPEED. . . . . . .. . . . . . . . . . 2·56

IGNITION TIMING . . .. . . . .. . . . • . 2· 55

SYN CHRON IZATION . . . . . 2·54

TIMING POINTER ADJUST . . . .. ... 2·53

150·200 HP (2.5L) V6 EFI· 2001 2,57

DYNAMIC IDLE TIMING... .. .. . .. 2·60

DYNAMIC MAX TIMING .. . 2·61

IDLE SPEED . . . . . . . . . . . ... . ... 2·60

MAXIMUM THROmE .•. 2·59

STATIC IDLE TIMI NG ............. 2·58

STATIC MAX TIMING .. .... . .. 2·58

THROmE CABLE PRELOAD . . 2·61

THROmE CAM. . . . . . . . . . . . . 2·58

THROmE POSITI ON SENSOR .. 2·59

THROmE VAL VE & OIL PUMP SYNCH .. 2·61

TIMER P OINTER. . . . . . . . . . 2·57

TRIGGER LINK ROD. . . . . . . . . . • 2·57

1 50·200 HP (2. 5L) V6 EFI· 2002·05 . 2, 61

I DLE SPE ED . . . . 2·62

I GNITION TIM ING . . . . . . . . • . 2·62

MAXIM UM THRomE • .... •. 2·62

THROTILE CABLE INSTALl. . . 2·63

TH RomE CAM . . . . . . . . . . . . . . . 2·62

nmOTILE PLATE SCREW. . . . 2-64

THROmE POSITION SE NSOR. . . . . 2·62

135· 175 HP ( 2.5L) V6 OPTIMAX . . . . . 2-64

I DLE SPEED. . . . . . . . . . . . . . . . . . . . . 2·65

MAXIMUM nmomE .. . . . . . . . . . 2·64

THRomE CAM. . . . . . . . . . . . 2·64

THROmE PLATE SCREW .. . .. 2-65

THROmE POSITION SENSOR .. 2-65

225·250 HP (3.0L) V6 E FI . 2001 .•. 2-65

CRANKSHAFT POSITION SENSOR. .. . 2·66

I DLE SPEED. . . . . . . . . . . . . . . . . . . . . . 2·68

MAXI MUM THRomE .... . . . . . . . . .. 2·66

THRomE CAM . . . . . . . . . . . . . . 2·66

THRomE POSITION SEN SOR . 2·67

THROTILE VALVE & OIL PUMP SYNCH .. 2-66

TI MER POINTER . . . . . . . . . . . . . . . . 2·66

200,250 HP ( 3.0LJ V6 EFt - 2002·05 ... . ... 2·68

I DLE SPEED ••...•...• .... • ....... • 2·69

IGNI TION TIMING. . . 2-69

MAXIMUM THRomE 2·69

THRomE CABLE . . . . . . . . . . . . . . . . . 2·69

THROTTLE CAM. . . . . . . . . . . . . . 2·68

THROmE PLATE SCREW.. .... 2 ·70

T HROTtlE POSI T ION SENSOR . . . 2·69

200·225 HP (3.0L) V6 OPTIMAX. . . . . 2·70

CRANKSHAFT POSITION SENSOR 2·70

IDLE SPEED .. .. 2·73

MAXIMUM THRomE 2·71

THROmE CAM . . . . . .. . . . . 2-70

THROmE P LATE SCREW. ... . . •. 2·73

THRomE POSITION SENSOR. 2·73

TUNE·UP ••• . . ••• . . •• . . •• . . ••. . •• 2·31

COMPRESSION T ESTING . . . . . . . . . 2·32

COMPRESSION CHECK . • . . . • . . . 2·32

LEAK TESTING . . 2·33

LOW COMPRESSION . . . . . . . . . . . .. . 2·33

EL ECTRICAL SYSTEM CHECKS . 2·39

FUEL SYSTEM CHECKS. . . . . . . . . . . . . 2·40

IGNITION SYSTEM. 2-38

INTRODUCTION..... 2 ·31

SPARK PLUG WIRES . 2·38

REMOVAL & INSTALLATiON. 2-38

TESTING. . . . . . . . . . 2,38

SPARK PLUGS . 2·34

HEAT RANGE . . . . . . . . . . . . .• . . 2·34

INSPECTION & GAP PI NG. 2·38

READI NG SPARK PLUGS . . 2·36

REMOVAL & INST ALLATION. 2·35

TUNE· UP SE QUENCE ....... . ... 2·31

SPECiFiCATiONS •• ... ••..••..••..•• . •• 2·79

GENERAL ENGINE (2.5·125 HPj... 2·79

GENERAL ENGINE (135·250 HP). . . . . • . .. 2·80

MAINTENANCE INTERVALS ..... .... 2·S1

TWO·STROKE MOTOR FUEL:OIL RATIO.. 2-82

CAPACITIES. .. . . . . . . . . . . . . . . . . . . . 2·82

TUNE·UP ( 2.5·1 25 HP). 2·83

TUN E-UP (135-250 HPJ. . . . . . . . . . . 2·84

2·2 MAINTENANCE

GENERAL INFORMATION (WHAT EVERYONE SHOULD KNOW ABOUT MAINTENANCE)

At Seloc, we estimate that 75% of engine repair work can be directly or

indirectly attributed to lack of proper care tor the engine. This is especially

true 01 care during the off-season period. There is no w<fI on this green earth

for a mechanical engine, particularly an outboard motor, 10 be left sitting idle

for an extended period of time, say tor six months, and then be ready lor

instant satisfactory service.

Imagine, if you will, leaving your car or truck for six months, and then

expecting to turn the key, having it roar to lile, and being able to dr ive off in

the same manner as a daily occurrence.

Theretore ij is critical tor an outboard engine to either be run (at least

once a month), preferably, in the water and properly maintained between

uses or for il to be specifically prepared for storage and serviced again

immediately belora the start of the season .

Only through a regular maintenance program can the owner expect to

receive long l ife and satistactory performance at minimum cost.

Many times, if an outboard is not performing properly, the owner will

' nurse" H through the season w ith good intentions of working on the unH

once it is no longer bei ng used. As with many New Year' s resolutions, the

good intentions are not completed and the outboard may lie for many months

before the work is begun or the unH is taken to the marine shop for repair.

Imagine, it you will , the cause of the problem being a blown head gasket

And let us assume water has found its way into a cylinder. This water,

allowed to remain over a long period of time , will do consklerably more

damage than ~ would have if the unit had been disassembl ed and the repair

work performed immedi ately. Therefore, if an outboard is not functioning

properly, do not stow it away with promises to get at it when you get time,

because the work and expense will only get worse the longer corrective

action is postponed. In the example ot the blown head gasket, a relatively

sillllie and inexpensive repair job could very well develop into major

overhaul and rebuild work.

Maintenance Equals Safety

OK, perhaps no one thing that we do as boaters will protect us trom risks

invol ved with enjoying the wind and the water on a powerboat But, each

time we perform maint enance on our boat or mot or, we increase the

likelihood that we will find a potential hazard before it becomes a pr obl em,

Each time we inspect our boat and motor, we decrease the possibilrty that it

could leave us stranded on the water.

In this way, perlorming boat and engine service is one of the most

important ways that we, as boat ers, can help protect ourselves, our boats,

and the friends and family that we bring aboard.

Outboards On Sail Boats

(),yners of sailboats pride themselves in their abWty to use the wind to

clear a harbor or for movement from Pori A to Port B, or maybe just for a day

sail on a lake. For some, the outboard is carried only as a last resort· in

case the wind fails completely, or in an emergency sHuation or tor ease of

docking.

Therefore, in some cases, the outboard is slowed below, usually in a very

poorly ventilated area, and subjected to moisture and stale air· in short, an

excellent environment for ' sweating' and corrosion.

If the owner could just take the time at least once every month, to pull out

the outboard, dean it up, and give it a shorl run, not only would he/she have

'peace of mind" knowlng it will start in an emergency, but aJso maintenance

costs will be drastically reduced.

Maintenance Coverage In This Manual

At Seloc, we strongly feel that every boat owner should pay dose

attention to this section. We also know that it is one of the most frequently

used portions ot our manuals. The material in this section is di vided into

sections to help simpl ify the process of maintenance. Be sure to read and

thoroughly understand the various tasks that are necessary to keep your

outboard in tip-top shape.

TOpics covered in this secti on include:

t. General Information (What Everyone Should Know About

Maintenance) . an introduction to the benefits and need for proper

maintenance. A guide to tasks that should be performed before and alter

each use.

2. Lubrication Service· after the basic inspections that you should

perform each Eme the motor is used, the most frequent form of perlodic

maintenance you wi ll conduct wil l be the Lubrlcati on Service. This section

takes you through each 01 the various steps you must take to keep corrosion

fr om slowly destr oyi ng your motor before your very eyes.

3. Engine Maintenance· the various procedures that must be

perlormed on a regular basis in order to keep the motor and all of its various

systems operating properly.

4. Boat Maintenance· the various procedures that must be performed

on a regular basis in or der to keep the boat hull and its accessories looking

and working like new.

5. Tune·Up· also known as the pre·season tune-up, but donllet the

name 1001 you. A complete tune·up is the best way to det ermine the

condition of your outboard while also preparlng it for hours aoo hours 01

hopefully trouble·lree enjoyment And if you use your boat enough during a

single season, a second or even third tune·up could be required.

6. Wint er Storage and Spring Commissioning Checklists· use Ihese

sections to guide you through the various parts 01 boat and motor

maint enance that protect your valued boat through periods of storage and

return ~ to operaEng condi tion when ~ is time to use ~ agai n.

7. Specification Charts · located at the end of the section are quick·

reference, easy to read charts that provide you wHh critical informaflon such

as General Engine Specifications, Maintenance Intervals and Capaciti es.

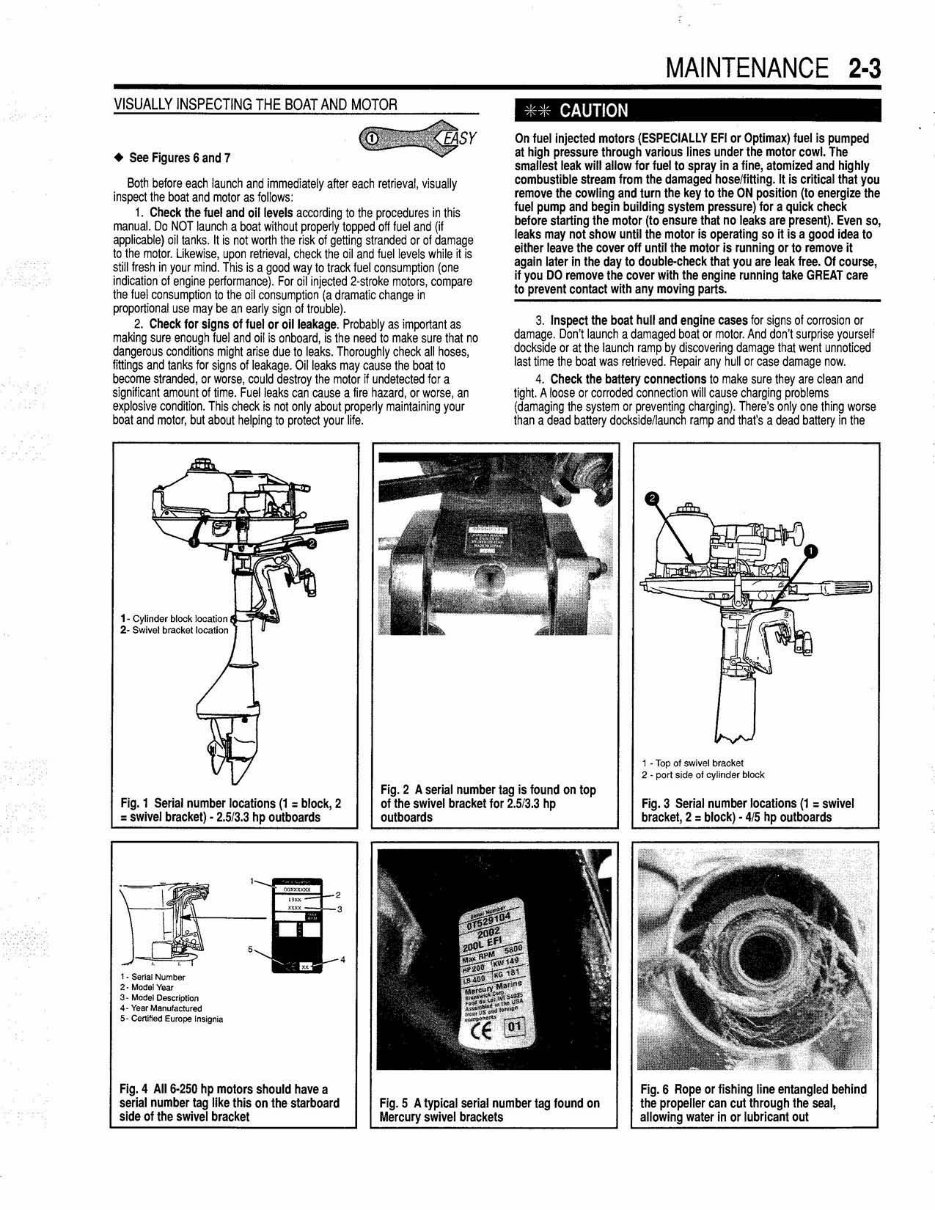

Engme (and Senal Number) Identificatton

• See Figures 1 thru 5

For many years the engine serial numbers were Mercury's key to engine

changes. These numbers identify the year of manufacture, the horsepower

rating and the paris boo k ident~ication. If any correspondence or paris are

required, it is still a good klea to use the engine serial number to make

SURE you get the right part.

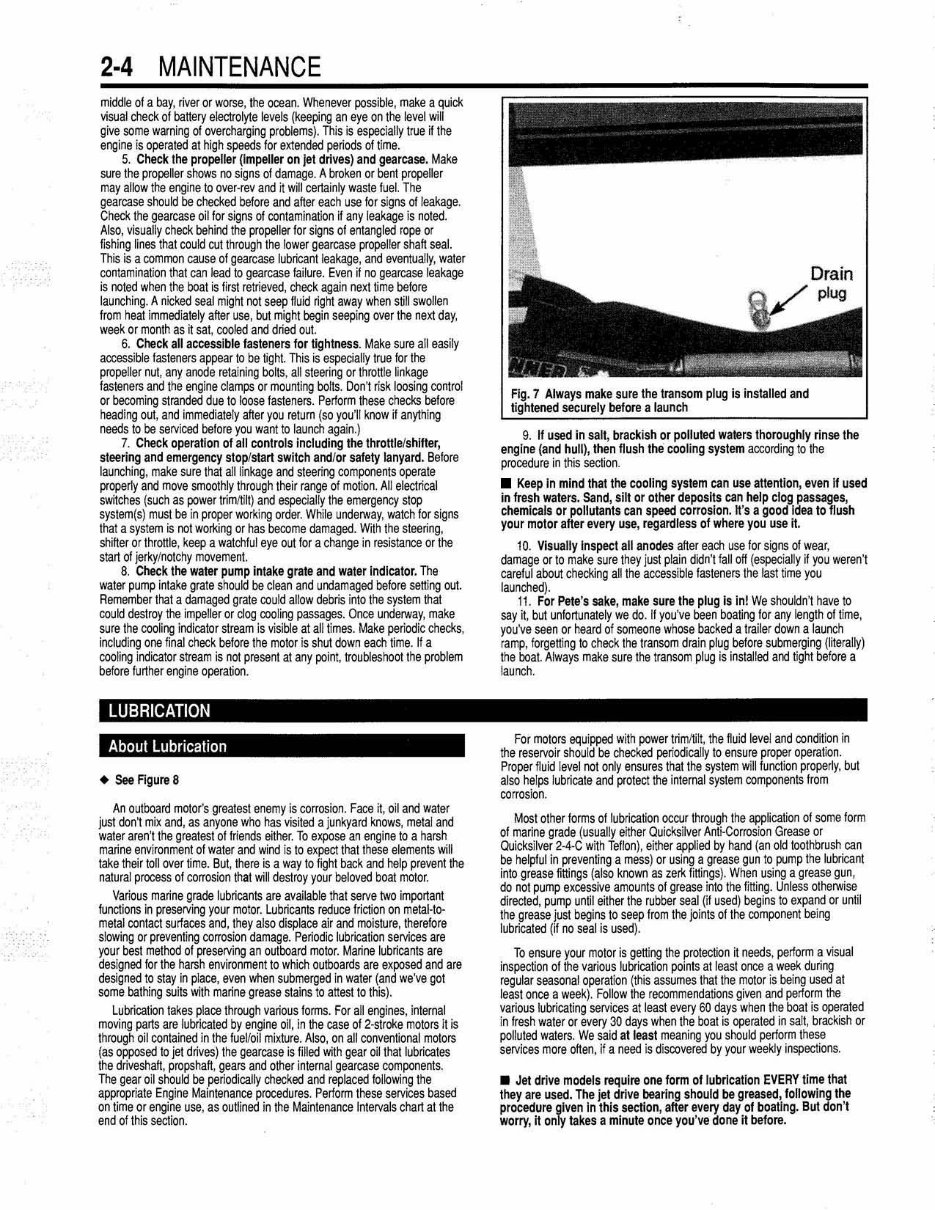

However, we're happy to report that more and more Mercury has come in

line with other engine manufacturers and is slicking doser and closer to

model years than ever before. At l east one of the serial number tags used by

Mercury on their newer 2·strokes i ncludes a specifiC spot which displays the

MODEL YEAR of the mot or (along wHh the serial number, hp rating, weight

rating, and year of manufactural .

• Al so remember that the serial number tag estab lishes the model

year and th e y'ear In which the engine was produced which is (or are)

not necessarily the year of first installation.

Two serial numbers tags were placed on each of these mot ors. One is

attached to the powerhead itseH, usually on the lower starboard side of the

powerhead, but on some 75 hp and larger motors ~ may be instead affixed

to the TOP of the powerhead.

All motors are also equipped with a serial number ID tag on the swivel

bracket. For the smallest mot ors (2.5/3.3 hp models) this tag may be on the

top center of the swivel bracket, but for most Mercury motors it is found on

the starboard SIDE 01 the swivel bracket.

F or mora information on engine identification and specifications, please

refer to the General Engine Specifications charls later in this section.

Before After Each Use

As stat ed earlier. the best means of extending engine lile and helping to

protect your self while on the water is to pay close attention to boaVergine

maintenance. This starts with an inspection of syst ems and components

before and after each time you use your boat.

A list of checks, inspections or requi red maintenance can be found in the

Maintenance Intervals Chart at the end of this section. Some of these

inspectjons or t asks are performed before the boat is launched , some only

after it is retrieved and the rest , both times .

VISUAllY I NSPECTI NG T HE BOAT AND MOTOR

• See Figures 6 and 7

~SY

Both before each launch and immediately after each retrieval , vi sually

inspect the boat and motor as follows :

1. Check the fuel and oil levels according to the procedures in this

manual. 00 NOT launch a boat without properly topped off f uel and (i l

applicable) oil tanks. 1\ is not worth the risk of getting stranded or at damage

to the motor. Ukewlse, upon retrieval, check the oil and fuel levels while if is

still fresh in your mind. This is a good way 10 track fuel consumption (one

indica1ion 01 engine performance). For oil injected 2·stroke motors, compare

the fuel consumption 10 the oil consumption (a dramatic change in

proportional use may be an early sign of trouble).

2. Check lor signs of fuel or oil leakage. Probably as important as

making sure enough f uel and oil is onboard, is the need to make sure that no

dangerous conditions might arise due 10 leaks. Thoroughly check all hoses.

littings and tanks for signs of leakage. Oil leaks may cause the boat to

become stranded. or worse. could destroy the motor jf undetected for a

significant amount of time. Fuel leaks can cause a fire hazard, or worse, an

explosive condition. This check is not only about properly mai ntaining your

boat and motor, but about hetping to protect your tife.

MAINTENANCE 2-3

, CAUTION

On fuellnjecled motors (ESPECIAllY EFI or Optlmax) fuel is pumped

at high pr essure through various lines under the motor cowl. The

smallest leak will allow for fuel to spray in a fine, atomized and highly

combustible stream from the damaged hoselfilling. It is critical that you

remove the cowling and tum the key 10 Ihe ON position ( 10 energize the

fuel pump and begin building system pressure) for a quick check

before starling the motor (to ensure that no leaks are present). Even so,

leaks may not show until the molor is operating so II is a good idea to

either leave the cover off untillhe molor Is running or 10 remove it

again laler In the day to double-check thai you are leak tree. 01 course,

if you DO remove the cover with the engine running take GREAT care

10 prevent contact with any moving paris.

3. Inspect the boat hull and engine cases for signs 01 corrosion or

damage. Don't launch a damaged boat or motor. And don·t surprise yourseH

dockside or at the launch ramp by discovering damage that went unnoticed

last lime the boat was retrieved. Repair any hull or case damage now.

4. Check the battery connections to make sure they are clean a nd

tight. A loose or corroded connection will cause charging problems

(damaging the system or preventing charging). There's only one thing worse

than a dead battery docks1deJIaunch ramp and thaI's a dead battery in the

, • Top of $Wi ..... bracket

2 . port side ot cylind",. bIocl<

Fig. 1 Serial number locations (1 = block, 2

= swivel bracket) - 2 .513 .3 hp outboards

Fig. 2 A serial number tag is found on top

of the swivel bracket for 2 .513 .3 hp

outboards

Flg. 3 Serial number locations (1 = swivel

brackel, 2 = block) - 415 hp outboards

, . SariaI Number 2· __

3._~

4· Y_ ManuT_o:rure<l

5· CenIti«I Europe lnsIgnio

Flg.4 All 6-250 hp motors should have a

serial number tag like this on the starboard

side of the swivel bracket

serial number lag found on

Fig. 6 or fishing line entangled behind

the II cut through the seal,

water In or lubricant out

2-4 MAINTENANCE

middle of a bay, river or worse, the ocean. Whenever possible , make a q uick

visual check of battery electrolyte levels ( keeping an eye on the lavel will

give some w arning of overcharging pr oblems). This is especi ally true ~ the

engi ne is operated at high speeds for extended periods of time.

5. Check the propeller (Impeller on jet drives) and gearcase. Make

sure the propeller shows no signs of damage. A broken or bent propeller

may allow the engine to over·rev and it will certai nly waste fuel. The

gearcase should be checked before and after each use lor si gns of leakage.

Ch eck the gearcase oil for signs 01 ronlamination ff any l eak age is noted.

Also, visually ch eck beh ind the propeller for signs of enlangled rope or

fishi ng lines that could CUl1hrough the lower gearcase propeller shaft seal.

This is a common cause 01 gearcase lubricanl l eakage, and eventually, w ater

contaminati on that can lead to gearcase failure. Even ff no gearcase leakage

is noted w hen the boat is first retrieved, check again next time betore

launching . A n ick ed seal might not seep Huid right away when still swollen

from heat i mmediately after u se , but might begin seeping over the next day,

w eek or month as ij sal, coo'ed and dried out.

6. Check aU accessible fasteners for tightness. Make su re all easily

accessi bie lasteners appear to be tight. This is especially true tor the

propell er nut, any anode retaining bolts, all steering or th rott le li nkage

lasteners and the engi ne cl amps or mounting bo~s. Don't risk loosing control

or becoming stranded due to loose fasteners. Perform these checks before

h eading out, and immediately after you return ( so you' ll know it anything

needs to be serviced before you want to lau nch again .)

7. Check operation of all controts including the throtlle/shlf1er ,

steering and emergency stopfstar1 switch and/ or safety lanyard. Betore

launching, make su re that all linkage and steeri ng components operate

properly and move smoothly th rou gh their range of motion. AU electrical

switches ( such as power trimtti lt) and especially the emergency stop

system(s) must be in proper working order. While u nderway, walCh for signs

that a syst em is not working or has become damaged. With the steering ,

shifter or throttle, keep a watchful eye out for a change in resistance or the

start of jerkytnotchy movement.

8. Check the water pump intake grate and wat er Indicator. The

water pump intake grate shou ld be clean and u rdamaged before selling out

Remember that a damaged grate coul d allow debris i nto the system that

cou ld destroy the impeller or dog coo l ing passages. Once underway, make

sure the cooling indicator stream is visi bie at all limes. Make periodic ch ecks,

includi ng one final check before the motor is shut down each time. If a

cool ing indicat or stream is not present at any point, troubieshoot the problem

before further engi ne operation.

LUBRICATION

About Lubrication

• See Figure 8

An ou tboard motor's greatest enemy is corrosion. Face ij, oil and water

just don1 mix and , as anyone who has visited a junk yard MOWS, metal and

water aren't the greatest 01 friends either . To expose an engine to a h arsh

marine env i ronment of w ater and wind is to expect that th ese elements will

take their toll over time. But, there is a way to fight back and help prevent the

natural process of corrosion that will destroy your beloved boat motor.

Various marine grade lu bricants are available that serve two important

functions in preserving your mot or . Lubricants reduce fr iction on metal-to-

metal contact surlaces and. th ey al so displace air and moisture, therefore

slowing or preventing corrosion damage. Periodic lubrication services are

your best method of preserving an outboard motor. Marine lubricants are

desi gned for the harsh environment to which outboards are exposed and are

designed to stay in place, even when submerged in water (and we've got

some bathing sui ts with marine grease stains to a tt est to this).

Lubrication takes pl ace through various forms. For a ll engi nes. i nternal

moving parts are l ubricated by engine oil, in the case of 2-stroke motors it is

th rough oil contained in the fuell oil mixture. Also, on all conventional motors

( as opposed to jet drives) the gearcase is fiJled with gear oil that lubricates

the driveshaft, propshaH, gears and other internal gearcase components.

The gear oil should be peri odically checked and replaced lollowing the

appropriate E ngi ne Maintenance procedures. Perlonn these services based

on time or engine use, as outl i ned in the Maintenance Intervals chart at the

end of this secti o n.

Afwa ys make sure the transom plug Is installed and

launch

9. If used In sail, brackish or poHuled walers Ihoroughly rinse the

engine ( and huH), then flush the cooling system according to the

procedure in this section.

• Keep In mind that the cooling syslem can use al tenllon, even if used

in fresh waters. Sand , silt or other deposits can help clog passages,

chemicals or pollutants can speed corrosion . II's a good idea 10 flush

your motor after every use, regardless of where you use it.

10. Visually Inspect all anodes after each use for signs of wear,

damage or to make su re they just plain didn't f all off ( especiall y ~ you w eren't

caref ul about checklng all the accessible fasteners the last time you

launched).

11 . For Pete's sake, make sure the plug Is In! We shouldn't h ave to

say it, but unfortunately we do. If you've been boating for any length of lime ,

you 've seen or heard of someone whose back ed a trailer down a launch

ramp, forgetting to check the transom drain plug before submerging ( literally)

the boat Always make sure the transom plug is installed ard ti ght before a

lau nch.

For motors equipped wi th pow er tri mltilt, the nuid levei and condition in

the reservoir shoul d be check ed periodical ly to ensure proper operation.

Pr oper fluid level not only ensures th at the system wi ll function properly, but

also hel ps lubri cate and protect the internal system components from

corrosion.

Most oth er lonns 01 lubrication occur through the application of some fonn

of marine grade ( usually either Qui cksi lver Anti-Corrosion Grease or

Quicksilver 2·4-C wi th Tefl on ), either appli ed by hand (an old toothbrush can

be helpful in preventing a mess) or using a grease gun to pump the lubricant

into grease fittings (also known as zerlo; fittings). When using a grease gun ,

do not pump excessive amounts of grease into the f rtl ing. Unless otherwise

directed, pump unlit either the rubber seal (i f used) begins to expand or until

the grease just begins to seep from the joints of the romponent being

lubricated (il no seal is used).

To ensure your motor is getti ng the protection ~ needs, perfonn a visual

inspection of the various lubricalion points at least o nce a week during

regular seasonal operation ( this assumes that the motor is being used at

least once a week). Follow the r ecommendations given and perlorm the

various lubricating services at least every 60 days when the boat is operated

in fresh water or every 3{) days when the boat is operated in salt, brack ish or

polluted waters. We sa id at least meaning you should perform th ese

services more often. H a need is di scovered by your weekly inspections.

• J et drive models require ooe form of tubrlc al ion EVERY time thal

they are used. The jet drive bearing shoutd be greased , followinglhe

procedure jlV en In this section, after every day of boating. But don 't

worry, it on y takes a minute once you've done it before.

Fig. 8 Mercury/Quic ksil ver products will do much to keep the

outboard unit running right

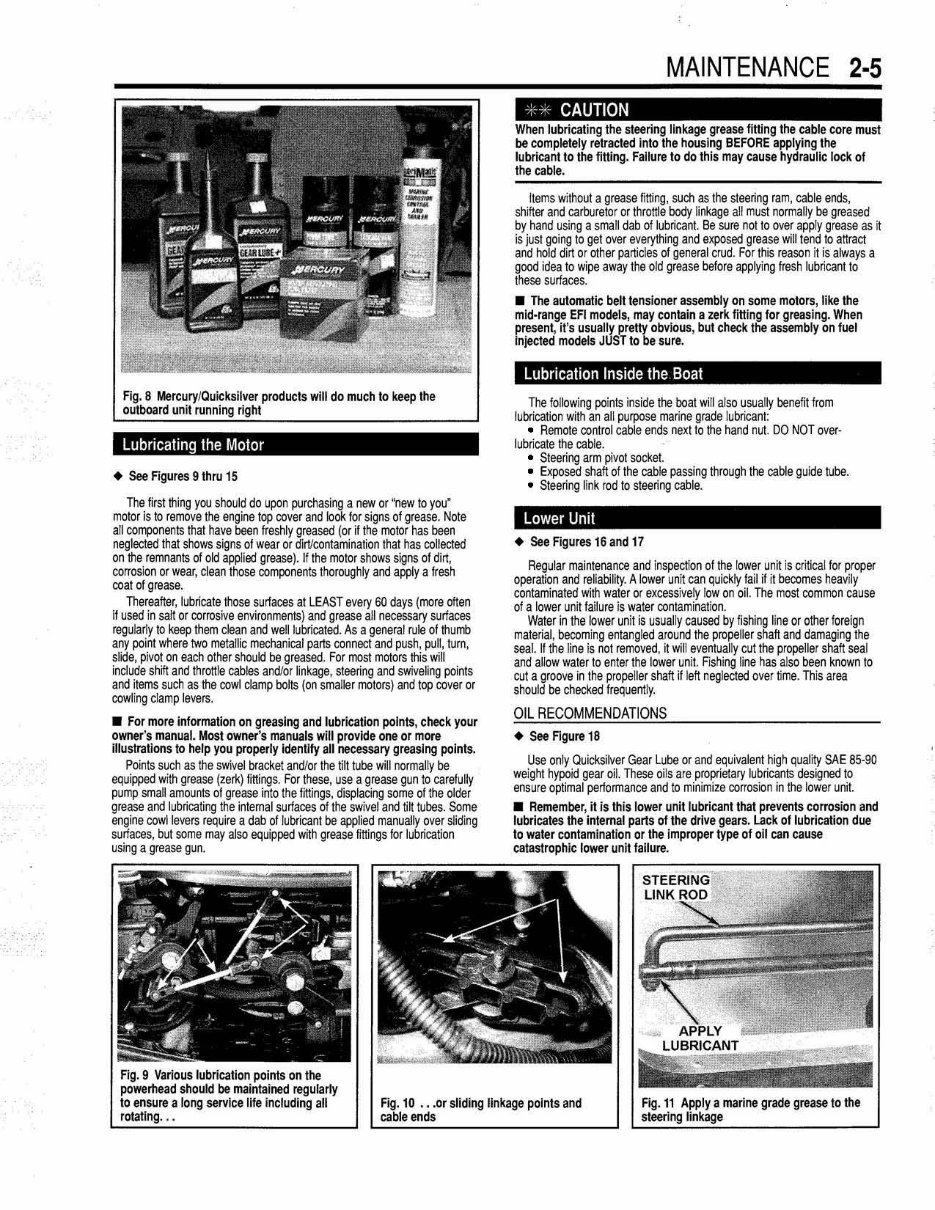

lubricating the Motor

• See Figur es 9 thru 15

The first thing you should do upon purchasing a new or "new 10 you'

molor is to remove the engine top cover and look for signs of grease, Nole

all COfTllOllents that have been freshly greased (or if the motor has been

neglected that shows signs of wear or dirVcontamination thai has collected

on the remnants of okl applied grease). If the motor shows signs of dirt,

corrosion or w ear, dean those components thoroughly and apply a Iresh

coat of grease.

Thereafter, lubricate those surfaces at LEAST every 60 days (more often

if used in salt or corrosive environments) and grease all necessary surfaces

regul arly to keep them clean and well lubricated. As a general rule of Ihurrb

any point where two metallic mechanical parts connect and push , pul l, lum,

slide, pivot on each other should be greased. For most motors this w ill

incl u de shifl and throttle cables and/or linkage, steering and swiveling points

and items such as the cowl damp bolts (on smaller motors) and top cover or

cowling clamp levers.

• For more information on greaslng and lubrication poI nts, check your

owner"s manual. Most owner's manuals will provide one or more

UluslraUons to help you properly ldenUfy all necessary greasing poInts.

Points such as the swivel bracket and/or the tilt tube will normally be

equipped with grease (zerk) littings. For these, use a grease gun to carelully

pump small amounts of grease into the littings, displacing some of the older

grease and lubricating the intemal surfaces of the swivel and ti~ tubes. Some

engine cowl levers require a dab of lubricant be applied manually over sliding

surfaces, but some may also equipped with grease fittings for lubrication

using a grease gun.

MAINTENANCE 2·5

· - CAUTION

When lubricating the steering linkage grease fitting Ihe cable core must

be completely retrac1ed Inlo the housing BEFORE applying the

lubricant 10 the fitting. Failure to do this may cause hydraulic lock of

the cable.

Items without a grease fitting, such as the steering ram, cable ends,

shifter and carburetor or throttle body li nkage all must normally be greased

by hand using a small dab of lubricant. Be sure not to over apply grease as H

is just going to get over everything and exposed grease will tend to attract

and hold dirt or other particles of general crud. For this reason it is always a

good idea to wipe aw ay the old grease before applying fresh lubricant to

these surfaces.

• The automatic belilensioner assembly on some motors, like the

mid· range EFI models, may contain a zerk fitting for greasing. When

present, it's usually pretty obvious, but check the assembly on fuel

Injected models JUST to be sure.

Lubrication InSide the Boat

The following poi nts inside the boal will also usual ly benefit from

lubrication with an all purpose marine grade lubricant:

• Remote control cable ends n9}:t to the hand nut. DO NOT over-

lubricate the cable.

• Steering arm pivot socket.

• Exposed shaft 01 the cable passing through the cable guide tUbe .

• Steering link rod to steering cable.

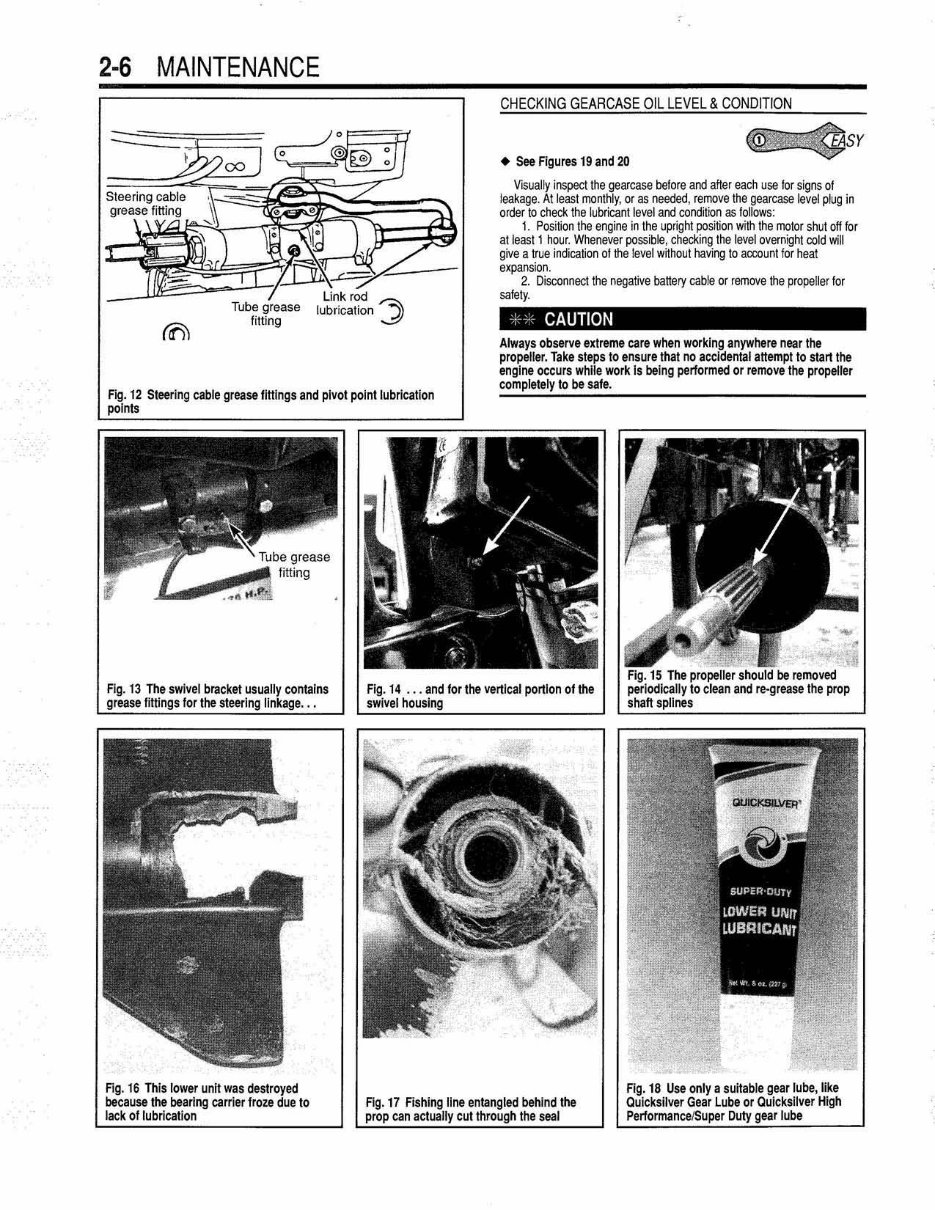

Lower Unit

• See Figures 16 and 17

Regular maintenance and inspection of the lower unit is critical for proper

operation and reliability . A lower unit can quickly fail if it becomes heavi ly

contaminated with water or excessi vely Iow an oil. The most common cause

of a lower uni t failure is w ater contaminati on .

Water in the low er unit is usual ly caused by fishing line or other f oreign

material, becoming ent angl ed around the propeller shah and damaging the

seal. If the l ine is not removed , ~ wil l eventually cut the propeller shaft seal

and allow water to enter the lower uni t. FIShi ng line has also been known 10

cut a groove in Ihe propel ler shah if left negl ected over time. This ar ea

should be checked frequently.

O IL RE COMM ENDA T IONS

• See Figure 18

Use only Quicksilver Gear Lube or and equivalent high quality SAE 85·90

weight hypoid gear oil. These oi ls ale proprietary lubricants designed to

ensure optimal performance and to minimize corrosion in the lower unit.

• Remember, it is thi s lower unit lubricant Ihat prevents corrosion and

lubricates the internal parts of the drive gears. Lack of lubrication due

to water contamination or the Improper type of all can cause

catastrophic lower unit failure.

Fig . 9 Various lubrication points on the

powemead should be maintained regularly

to ensure a long service life including all

rotallng . ..

Fig. 10 ••• or sliding linkage points and

cable ends

2-6 MAINTENANCE

CHECKING GE A RCA SE OIL LEVEL & CONDI T ION

• See Figures 19 and 20

~SY

Visually inspect the gearcase before and after each use tor signs of

leakage. At least monthly, or as needed , remove the gearcase level plug in

order to check the lubricant le vel and condition as follows:

I. Position the engine in the upright position wi th the motor shut off for

alleasl1 hour. Whenever possible, checking the level overnight cold will

give a true indica~on 01 the level w ithout having to account f or heat

expanSion.

2. Disconnect the negative banery cable or remove the propeller for

safety.

CAUTION

12 Steering cable grease fitting s and pivot poinllubricalion

Always observe extreme care when working anywhere near the

propeller. Take steps to ensure lhal no accIdental allempllo start the

engine occurs whil e work Is being performed or remove the propeller

completely to be sale.

Fig. 13

grease

II contains

Fig. 16 This low er unit was destroyed

because the bearing carrier froze due to

lack 01 lubrication

Fig. 17 Fishing line entangled behind the

prop can actually cut through the seal

3. Position a small drain pan under the gearcase, toon unthread the

drainlfiller plug al the bottom of the housing and allow a small sample (a

teaspoon or l ess) to drain from the gear cast!. Quickly inSlalllhe drain/filler

plug and tight en securely.

4. Examine the gear oil as fol lows:

a. Visually check the oi l for obvious signs of water. A small amount 01

moisture may be present from condensation, especiall y if a motor has been

stored for some ti me, but a milky appearance ind i cates that either the fluid

has not been changed in ages or the gearcase allowing some water to

intrude. If significant water contamination is present, the firs t suspect is the

propeller shaft seal.

b. Dip an otherwise cl ean finger into the oil, then rub a small amount 01

the fluid between your finger and your thumb to check for the presence of

debris. The lubricant should feel smoot h. A very small amount 01 met allic

shavirgs may be present, but should not really be f eM. large amounts of grit

or met allic partides indi cate the need to overhaul the gearcase looking for

damaged!wom gears, shafts, bearings or thrust surfaces.

Fig. 19 Mercury often labels the oil vent/level plug (or plugs) on

their

Fig. -20 Typical oil ventilevel and drain plug locations on a Mercury

gearcase

MAINTENANCE 2-7

• If a large amount 01 lubricant escapes when the level/vent plug is

remo v ed In the nen step, either the gearcase was seriously overfilled

on the last servIce, the crankcase is slilltoo hot from runnI ng the

molor in gear (and the lIuid is expanded) or a large amount 01 water

has entered the gearcase. If the later is true, some water should escape

before the 011 and/or the oil will be a milky white in appearance

(showing the moisture contamination).

5. Next, remove the leveVvent plug Irom the lop of the gearcase and

ensure the lubricanllevel is up to the bottom of the leveVvent plug opening.

A very smal l amount of fluid may be aclded through the level plug, but l arger

amounts of fluid should be added through the drainlfiller plug opening to

make certain that the case is pr operly filled. If necessary, acid gear oil unt il

fluld flows from the IeveVvent opening. If much more than 1 oz. (29 ml) is

required to fill the gearcase , check the case carefully for leaks. InstaJl the

drainlfiller plugs and/or the leveVvent plug , then tighten both securely.

• One trick that makes adding gearcase oil less messy is to install the

level / vent plug BEFORE removing the pump from the drainlfiller

opening and threading the drainJfilier plug back into position.

6. Once fluid is pumped into the gearcase, let the un~ si t in a shaded

area f or at least 1 hour lor t he lIuid to settle. Recheck the lIuid level and, il

necessary, add more lubricant.

7. Install the propeller and/or connect the negative battery cable, as

applicable.

DRAINING AND FI L LING

• See Figures 21 and 22

CAUTION

The EPA warns that prolonged contact with used engine oil may cause

a number of skin disorders, including cancer! You should make every

effort to minimize your exposure to used engine oil. Protec1ive gloves

should be wom when changing the 011. Wash your hands and any other

exposed skln areas as soon as possible after exposure to used engine

oil. Soap and water or waterless hand cleaner should be used.

1. Place a suitable container under the lower un~. n is usua lly a good

idea to place the outboard in the @ed pos~ion so the drain plug is at the

lowest pos~ion on the gearcase, this will help ensure the oil drains fully.

2. Loosen the oilleveVvent plug ( or plugs if they are separate) on the

lower unit. This step is important! II the oilleveVvent plug (s) cannot be

loosened or removed, you cannot refill the gearcase w~h fluid and purge ~ of

air.

• Never remove the vent or filler plugs when the lower unit is hot.

Expanded lubricant will be released through the hole.

3. Remove the drainlfill er plug from the lower end of the gear housing

followed by the oillevelfvent plug(S).

4. Allow the lubricant to completely drain from the lower unit.

5. If applicabfe, check the magnet end of the drain screw lor metal

particles. Some amount of metal Is considered nor mal wear is to be

expected but ~ there are si gns of metal chips or excessive metal particl es,

the gearcase needs to be disassembled and inspected.

6. Inspect the lubricant for the presence of a milky wMe substance,

water or metallic particles. II any of these cond~ions are present, the lower

un~ should be serviced i mmediately.

7. Place the outboard In the proper pos~ion for filling the lower un~

(straight up and down) . The lower unit should not list to either port or

starboard and should be completely vertical.

8. Insen the lubricant tube into the oil drain hole at the bottom of the

lower un~ and injed lubricant until the excess begins to come out the oil

l evel hote.

• The lubricant must be IUled from the bottom to prevent air from

being trapped in the lower unit . Air displaces lubricant and can cause a

lack of lubrication or a false lubricant level in the lower unit.

9. Oil should be squeezed in using a tube or with the larger quantities,

by using a pump kit to fill the gearcase thr ough the drain p lug.

• One Irick that makes adding gearcase 011 less messy is 10 install the

level /Vent plug(S) BEFORE removing the pump from the drainlfiller

opening and threading the drainlfiUer plug back into position.

2-8 MAINTENANCE

10. Using new gasketslwashels (~equipped) install the oil JeveV venl

pl ug(sj first, then instalilhe oil fill plug.

11. Wipe the excess oil from the lower un it and inspect the unit for leaks.

12. Place the used lubricant in a suitable container for transportation to

an authorized recycling facility.

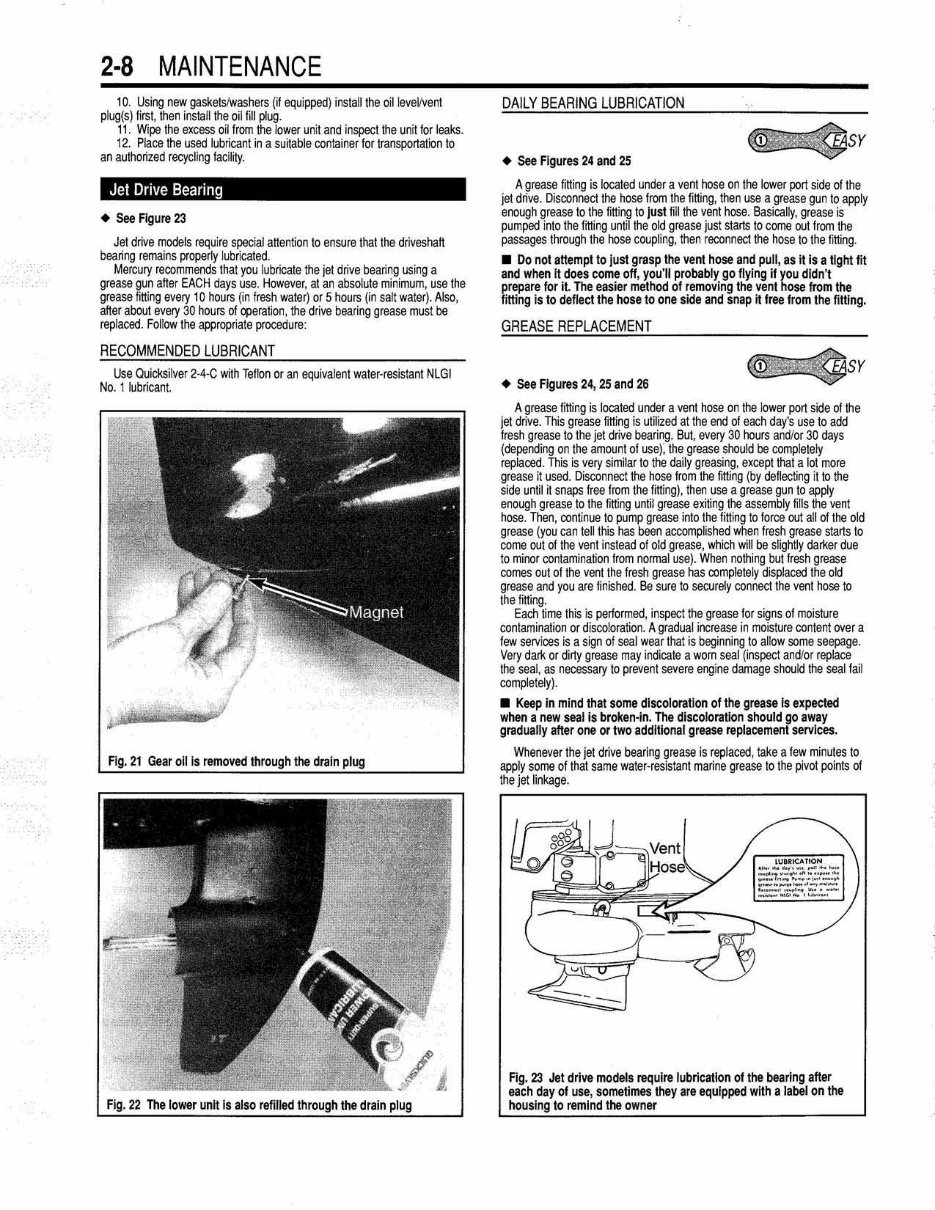

Jet Drtve Bearing

• See Agure 23

Jet drive models requ i re special attention 10 ensure that the driveshaft

bearing remains properly lubricated .

Mercury recommends that you lubricate the jet drive bearing using a

grease gun after EACH days use. However, at an absolute minimum, use the

grease fitting every 10 hours (in fresh water) or 5 hours (in salt water). Also,

after about every 30 hours of qleraflon, the dr ive bear ing grease must be

replaced. Follow the appropriate procedure:

RECOMMENDED LUBRICANT

Use Quicksi l ver 2·4-C with Tellon or an equival ent water-resistant NlGI

No . t lubricant.

Flg. 21 Gear 011 is the drain

F ig. 22 The lower unh is I the drain

DAILY BEARING LU BRICATI ON

• See FiQures 24 aoo 25

~SY

A grease fitting is located under a vent hose on the lower port side of the

jet drive. Disconnect the hose from the fitting, then use a grease gun to apply

enough grease to the fitt i ng to Just fill the vent hose. BaSically, grease is

pumped into Ihe fming until the old grease just slarts to come out Irom the

passages through Ihe hose coupling, then r econnect the hose to the fitting .

• Do not atte mpt to Just grasp the vent hose and pull, as it iii a UglYt lit

and when It does come off, you'll probably go Hying if you didn't

prepare for it. The easier method of removing the vent hose from the

litting is to deflect the hose to one side and snap it lree from lhe IiIUng.

GREASE REPLACEMENT

• See Figures 24, 25 and 26

~SY

A grease fitting is located under a vent hose on the loWE!( port side of the

jet drive. This grease fitting is utilized at the end of each day's use to add

fresh grease to the jet drive bearing. But, (!Very 30 hours andlor 30 days

(depending on the amount of use): the grease should be completely

replaced. This is very similar to lhe daily greasing, except that a lot more

grease it used. Disconnect the hose from lhe fitting (by deflecting illo the

side until ij snaps froo from the filting), Ih en use a grease gun to apply

enough grease to the filting unti! grease exiting the assembly fi l ls the venl

hose. Then, continue to pump grease into the fitting 10 torce out all of the old

grease (you can tell this has been accomplished when fresh grease starts to

come out of the vent instead ot old grease, which will be slightly darker due

to minor contamination trom normal use). When nothing but fresh grease

comes out of the vent the fresh grease has completely displaced the old

grease and you are finished. Be sure 10 securely connect the vent hose 10

the filling.

Each time this is performed, inspect the grease for signs of moisture

conlamination or discoloration. A gradual increase in moisture conlent over a

few servlces is a sign of seal w ear that is beginning to allow some seepage.

Very dark or dirty grease may indicate a worn seal (inspect and/or replace

the seal, as necessary to prevent severe engi ne damage should the seal fail

completely) .

• Keep in mind that some discoloration 01 the grease is expeC1ed

when a new seal is broken-In. The discoloration shoul d go away

gradually after one or two additional grease replacement services.

Whenever the jet drive bearing grease is replaced, take a tew minutes to

awly some of that same water-resistant marine grease to the pivot points of

the jet linkage.

--

-

Fig. 23 Jet dri ve models require lubrication of the bearing after

each day 01 use, sometimes they are equI pped with a Jabel on the

housing to remind the owner

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

$51.99

Viewed 57 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

$51.99

- The 2001-2005 Mercury Mariner 2.5HP to 225HP Outboards Service & Repair Manual is a comprehensive resource for fixing problems on your outboard, providing troubleshooting and replacement procedures recommended by the manufacturer.

- It includes step-by-step instructions, clear images, and exploded-view illustrations to assist both professional mechanics and DIY enthusiasts in maintaining and repairing their outboard.

- Regular maintenance is essential for outboards, and this manual offers the manufacturer's recommended troubleshooting charts and replacement procedures to ensure the outboard's reliability.

- With this manual, you can save on repairs, increase your outboard's reliability, and effectively address issues as they arise.

- Conveniently, the manual eliminates the need to search through numerous pages, providing easy access to specific information without the risk of damage or loss.

- It is available in a printable format and compatible with various electronic devices, including PC & Mac computers, Android and Apple smartphones & tablets, etc. The only requirement is Adobe Reader, which is free to use.