2010-2015 Johnson Evinrude 115hp 130hp 150hp 175hp 200HP V4 V6 E-Tec Outboard Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Printed in the United States.

© 2010 BRP US Inc. All rights reserved.

TM, ® Trademarks and registered trademarks of Bombardier Recreational Products Inc. or its affiliates.

BRP US Inc.

Technical Publications

250 Sea Horse Drive

Waukegan, Illinois 60085 United States

† AMP, Superseal 1.5, Super Seal, Power Timer, and Pro-Crimper II

are registered trademarks of Tyco International, Ltd.

† Amphenol is a registered trademark of The Amphenol Corporation.

† BEP is a registered trademark of Actuant Corporation.

† Champion is a registered trademark of Federal-Mogul Corporation.

† Deutsch is a registered trademark of The Deutsch Company.

† Dexron is a registered trademark of The General Motors Corporation.

† Fluke is a registered trademark of The Fluke Corporation

† GE is a registered trademark of The General Electric Company.

† GM is a registered trademark of The General Motors Corporation.

† Locquic and Loctite are registered trademarks of The Henkel Group.

† Lubriplate is a registered trademark of Fiske Brothers Refining Company.

† NMEA is a registered trademark of the National Marine Electronics Association.

† Oetiker is a registered trademark of Hans Oetiker AG Maschinen.

† Packard is a registered trademark of Delphi Automotive Systems.

† Permatex is a registered trademark of Permatex.

† STP is a registered trademark of STP Products Company.

† Snap-on is a registered trademark of Snap-on Technologies, Inc.

The following trademarks are the property of BRP US Inc. or its affiliates:

Evinrude

®

Twist Grip™

Johnson

®

Nut Lock™

Evinrude

®

E-TEC

®

Screw Lock™

FasTrak™ Ultra Lock™

S.A.F.E.™ Moly Lube™

SystemCheck™

Triple-Guard

®

Grease

I-Command™ DPL™ Lubricant

Evinrude

®

ICON™ 2+4

®

Fuel Conditioner

Evinrude

®

/ Johnson

®

XD30™ Outboard Oil

Carbon Guard™

Evinrude

®

/ Johnson

®

XD50™ Outboard Oil

HPF XR™ Gearcase Lubricant

Evinrude

®

/ Johnson

®

XD100™ Outboard Oil

HPF PRO™ Gearcase Lubricant

Gel-Seal II™

2

T ABLE

OF

CONTENTS

SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PAGE

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1 SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2 INSTALLATION AND PREDELIVERY . . . . . . . . . . . . . . 27

3 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

4 ENGINE COVER SERVICE . . . . . . . . . . . . . . . . . . . . . 101

5 ENGINE MANAGEMENT MODULE (EMM) . . . . . . . . . 105

6 SYSTEM ANALYSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

7 ELECTRICAL AND IGNITION . . . . . . . . . . . . . . . . . . . . 137

8 FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

9 OILING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

10 COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

11 POWERHEAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

12 MIDSECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

13 GEARCASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

GEARCASE – STANDARD ROTATION . . . . . . . . . . . . 317

GEARCASE – COUNTER ROTATION . . . . . . . . . . . . . 349

14 TRIM AND TILT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 367

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S–1

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–1

TROUBLE CHECK CHART . . . . . . . . . . . . . . . . . . . . . . . . T–1

DIAGRAMS

INTRODUCTION

3

INTRODUCTION

CONTENTS

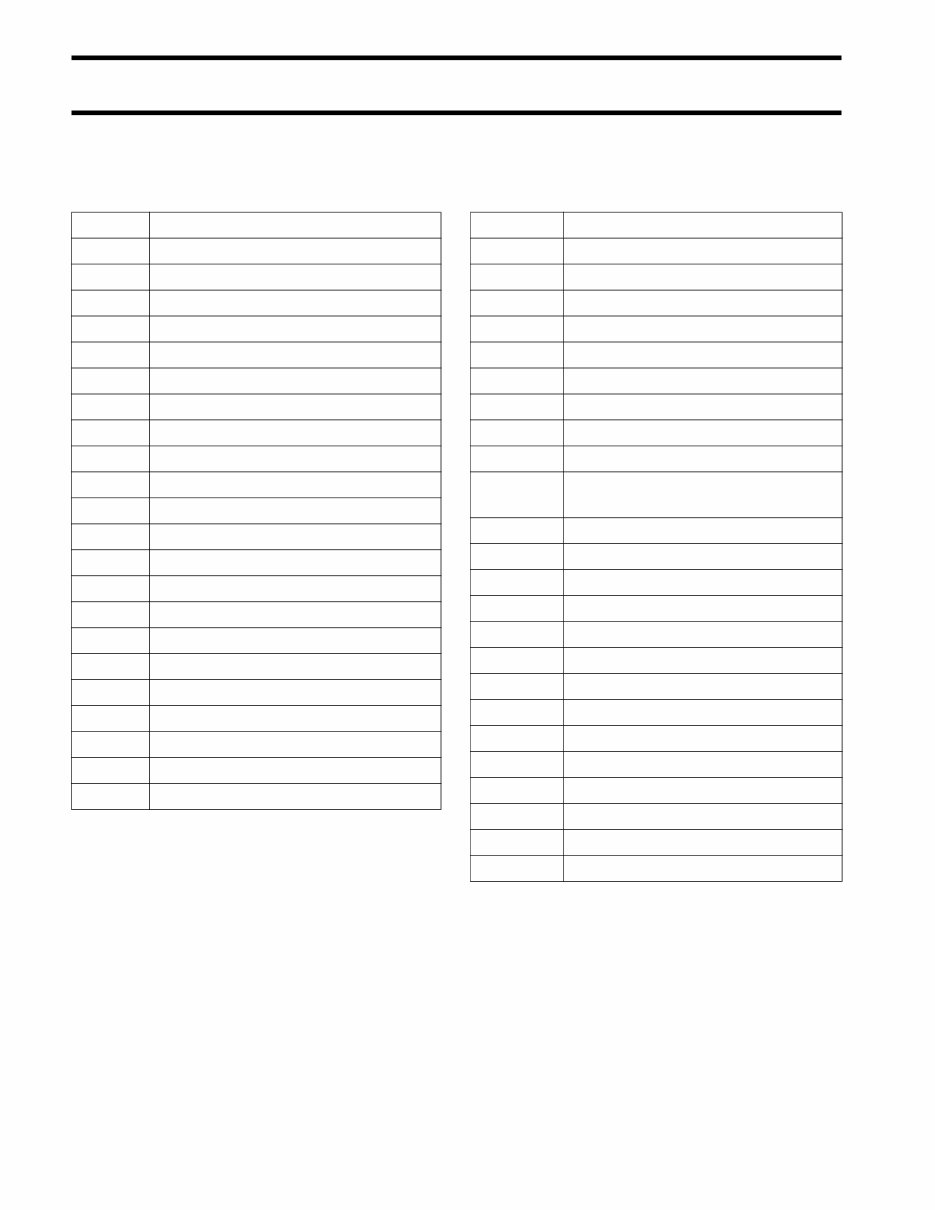

ABBREVIATIONS USED IN THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

UNITS OF MEASUREMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

LIST OF ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

EMISSION-RELATED INSTALLATION INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

MANUFACTURER’S RESPONSIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

DEALER’S RESPONSIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

OWNER’S RESPONSIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

EPA EMISSION REGULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

MODEL DESIGNATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

MODELS COVERED IN THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SERVICE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

STANDARD TORQUE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PRODUCT REFERENCE AND ILLUSTRATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SAFETY INFORMATION

Before working on any part of the outboard, read the SAFETY section at the end of this manual.

This publication is written for qualified, factory-

trained technicians who are already familiar with

the use of Evinrude/Johnson Special Tools. The

included information is not a substitute for work

experience. It is an organized guide for reference,

repair, and/or maintenance.

The following symbols and/or signal words

may be used in this document:

Indicates an instruction which, if

not followed, could severely damage engine

components or other property.

These safety alert signal words mean:

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

IMPORTANT: Identifies information that con-

trols correct assembly and operation of the prod-

uct.

DO NOT perform any work until you have read

and understood these instructions completely.

Torque wrench tightening specifications must

strictly be adhered to.

Should removal of any locking fastener (lock tabs,

locknuts, or patch screws) be required, always

replace with a new one.

When replacement parts are required, use

Evinrude/Johnson Genuine Parts or parts with

equivalent characteristics, including type, strength

and material. Use of substandard parts could

result in injury or product malfunction.

Always wear EYE PROTECTION AND APPRO-

PRIATE GLOVES when using power tools.

Unless otherwise specified, engine must be OFF

when performing this work.

Always be aware of parts that can move, such as

flywheels, propellers, etc.

Some components may be HOT. Always wait for

engine to cool down before performing work.

If you use procedures or service tools that are not

recommended in this manual, YOU ALONE must

decide if your actions might injure people or dam-

age the outboard.

This document may be translated into other lan-

guages. In the event of any discrepancy, the

English version shall prevail.

DANGER

Indicates a hazardous situation which, if

not avoided, will result in death or serious

injury.

WARNING

Indicates a hazardous situation which, if

not avoided, could result in death or seri-

ous injury

CAUTION

Indicates a hazardous situation which, if

not avoided, could result in minor or mod-

erate personal injury.

NOTICE

DANGER

Contact with a rotating propeller is likely to result in serious injury or death. Assure the

engine and prop area is clear of people and objects before starting engine or operating boat.

Do not allow anyone near a propeller, even when the engine is off. Blades can be sharp and

the propeller can continue to turn even after the engine is off. Remove propeller before ser-

vicing and when running the outboard on a flushing device.

DO NOT run the engine indoors or without adequate ventilation or permit exhaust fumes to

accumulate in confined areas. Engine exhaust contains carbon monoxide which, if inhaled,

can cause serious brain damage or death.

WARNING

Wear safety glasses to avoid personal injury, and set compressed air to less than 25 psi (172

kPa).

The motor cover and flywheel cover are machinery guards. Use caution when conducting

tests on running outboards. DO NOT wear jewelry or loose clothing. Keep hair, hands, and

clothing away from rotating parts.

During service, the outboard may drop unexpectedly. Avoid personal injury; always support

the outboard’s weight with a suitable hoist or the tilt support bracket during service.

To prevent accidental starting while servicing, disconnect the battery cables at the battery.

Twist and remove all spark plug leads.

The electrical system presents a serious shock hazard. DO NOT handle primary or secondary

ignition components while outboard is running or flywheel is turning.

Gasoline is extremely flammable and highly explosive under certain conditions. Use caution

when working on any part of the fuel system.

Protect against hazardous fuel spray. Before starting any fuel system service, carefully

relieve fuel system pressure.

Do not smoke, or allow open flames or sparks, or use electrical devices such as cellular

phones in the vicinity of a fuel leak or while fueling.

Keep all electrical connections clean, tight, and insulated to prevent shorting or arcing and

causing an explosion.

Always work in a well ventilated area.

Replace any locking fastener (locknut or patch screw) if its locking feature becomes weak.

Definite resistance to tightening must be felt when reusing a locking fastener. If replacement

is indicated, use only authorized replacement or equivalent.

6

INTRODUCTION

ABBREVIATIONS USED IN THIS MANUAL

ABBREVIATIONS USED IN THIS MANUAL

Units of Measurement List of Abbreviations

A Amperes

amp-hr Ampere hour

fl. oz. fluid ounce

ft. lbs. foot pounds

HP horsepower

in. inch

in. Hg inches of mercury

in. lbs. inch pounds

kPa kilopascals

ml milliliter

mm millimeter

N·m Newton meter

P/N part number

psi pounds per square inch

RPM revolutions per minute

°C degrees Celsius

°F degrees Fahrenheit

ms milliseconds

μs microseconds

Ω Ohms

V Volts

VAC Volts Alternating Current

VDC Volts Direct Current

ABYC American Boat & Yacht Council

ATDC after top dead center

AT air temperature sensor

BPS barometric pressure sensor

BTDC before top dead center

CCA cold cranking amps

CFR Code of Federal Regulations

CPS crankshaft position sensor

EMM Engine Management Module

EPA Environmental Protection Agency

ICOMIA International Council of Marine

Industry Associations

ID Inside dimension

MCA marine cranking amps

MWS modular wiring system

NMEA National Marine Electronics Assoc.

ROM read only memory

S.A.F.E. speed adjusting failsafe electronics

SAC start assist circuit

SAE Society of Automotive Engineers

SYNC synchronization

TDC top dead center

TPS throttle position sensor

USCG United States Coast Guard

WOT wide open throttle

WTS water temperature sensor

7

INTRODUCTION

EMISSION-RELATED INSTALLATION INSTRUCTIONS

EMISSION-RELATED

INSTALLATION

INSTRUCTIONS

Failing to follow these instructions when

installing a certified engine in a vessel violates

federal law (40 CFR 1068.105 (b)), subject to

fines or other penalties as described in the

Clean Air Act.

Maintenance, replacement, or repair of the emis-

sion control devices and systems may be per-

formed by any marine SI (spark ignition) engine

repair establishment or individual.

Manufacturer’s Responsibility

Beginning with 1999 model year outboards, man-

ufacturers of marine outboards must determine

the exhaust emission levels for each outboard

horsepower family and certify these outboards

with the United States of America Environmental

Protection Agency (EPA). An emissions control

information label, showing emission levels and

outboard specifications, must be placed on each

outboard at the time of manufacture.

Dealer’s Responsibility

When performing service on all 1999 and more

recent Evinrude/Johnson outboards that carry an

emissions control information label, adjustments

must be kept within published factory specifica-

tions.

Replacement or repair of any emission related

component must be executed in a manner that

maintains emission levels within the prescribed

certification standards.

Dealers are not to modify the outboard in any

manner that would alter the horsepower or allow

emission levels to exceed their predetermined

factory specifications.

Exceptions include manufacturer’s prescribed

changes, such as altitude adjustments, for exam-

ple.

Owner’s Responsibility

The owner/operator is required to have outboard

maintenance performed to maintain emission lev-

els within prescribed certification standards.

The owner/operator is not to, and should not allow

anyone to, modify the outboard in any manner

that would alter the horsepower or allow emis-

sions levels to exceed their predetermined factory

specifications.

Tampering with the fuel system to change horse-

power or modify emission levels beyond factory

settings or specifications will void the product war-

ranty.

EPA Emission Regulations

All new 1999 and more recent Evinrude/Johnson

outboards are certified to the EPA as conforming

to the requirements of the regulations for the con-

trol of air pollution from new watercraft marine

spark ignition outboards. This certification is con-

tingent on certain adjustments being set to factory

standards. For this reason, the factory procedure

for servicing the product must be strictly followed

and, whenever practical, returned to the original

intent of the design. The responsibilities listed

above are general and in no way a complete list-

ing of the rules and regulations pertaining to the

EPA requirements on exhaust emissions for

marine products. For more detailed information on

this subject, you may contact the following loca-

tions:

VIA U.S. POSTAL SERVICE:

Office of Mobile Sources

Engine Programs and Compliance Division

Engine Compliance Programs Group (6403J)

401 M St. NW

Washington, DC 20460

VIA EXPRESS or COURIER MAIL:

Office of Mobile Sources

Engine Programs and Compliance Division

Engine Compliance Programs Group (6403J)

501 3rd St. NW

Washington, DC 20001

EPA INTERNET WEB SITE:

www.epa.gov

8

INTRODUCTION

MODEL DESIGNATION

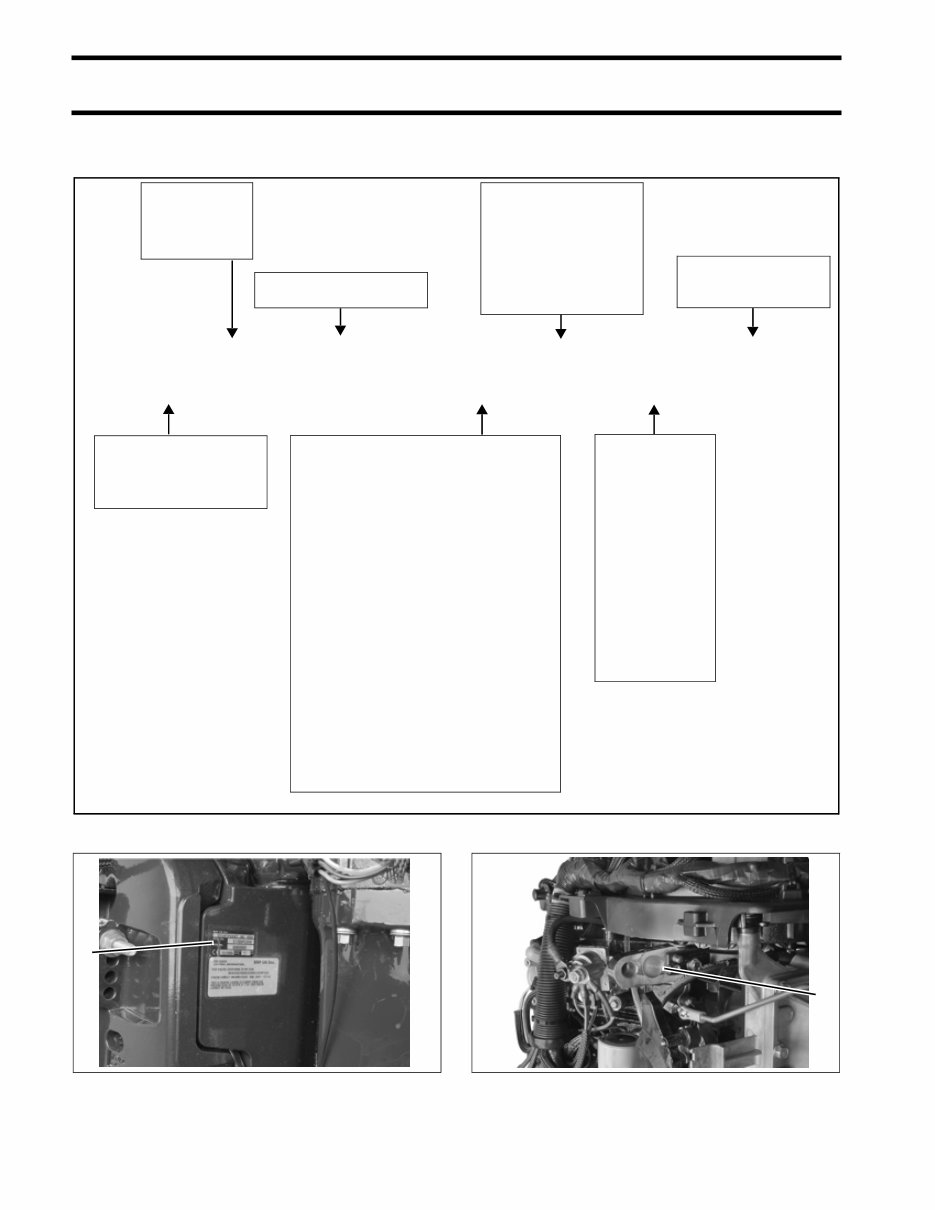

MODEL DESIGNATION

Model and serial numbers are located on the swivel bracket and on the powerhead.

B E 200 DP X IS E

STYLE:

J = Johnson

E = Evinrude

HORSEPOWER

LENGTH:

= 15” Std.

L = 20” Long

Y = 22.5” Special

X = 25” X-long

Z = 30” XX-long

MODEL YR:

I = 1

N = 2

T = 3

R = 4

O = 5

D = 6

U = 7

C = 8

E = 9

S = 0

Ex: IS = 2010

MODEL RUN

or SUFFIX

DESIGN FEATURES:

B = Blue Paint

C = Counter Rotation

D = Evinrude E-TEC

®

E = Electric Start w/Remote Steering

F = Direct-Injection

G = Graphite Paint

H = High Output

J = Jet Drive

M = Military

P = Power Trim and Tilt

R = Rope Start w/Tiller Steering

S = Saltwater Approved

T = Tiller Steering

TE = Tiller Electric

V = White Paint

W = Commercial Model

PREFIX:

B = Bodensee model

D = ICON model

1. Model and serial number 005231

1

1. Serial number 005232

1

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

$51.99

Viewed 96 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

$51.99

- This is a comprehensive factory service repair workshop manual for Johnson Evinrude 115hp, 130hp, 150hp, 175hp, 200HP V4 V6 E-Tec Outboard models from 2010 to 2015.

- It is available for instant access on your computer, tablet, or smartphone without any extra fees or expiry dates.

- Professionally designed to cover all repairs, servicing, and troubleshooting procedures with detailed photos, diagrams, step-by-step instructions, and highly detailed exploded diagrams.

- You can print out a single page or the entire manual as per your requirement.

- This manual can be used on multiple computers without any limitations or trial periods.

- There are no renewal fees or expiration dates; you can use this manual for life.

- It is fully compatible with Windows and MAC computers.

For more information, please click on the button.