EVC

EC

-C

Electronic Vessel Control

D4, D6, D9, D12, D16

Installation

1(1)

B E

Installation

Electronic Vessel Control

EVC

EC

-C

D4, D6, D9, D12, D16

Contents

Safety precautions . .............................................. . 5

General information . ............................................ . 7

Engine monitoring and the EVC system . ........... . 10

. Engine.monitoring.system . ............................... . 10

. The.EVC-C.system .......................................... . 11

Installation tools and literature . .......................... . 13

Other special equipment ..................................... . 14

Major components ............................................... . 15

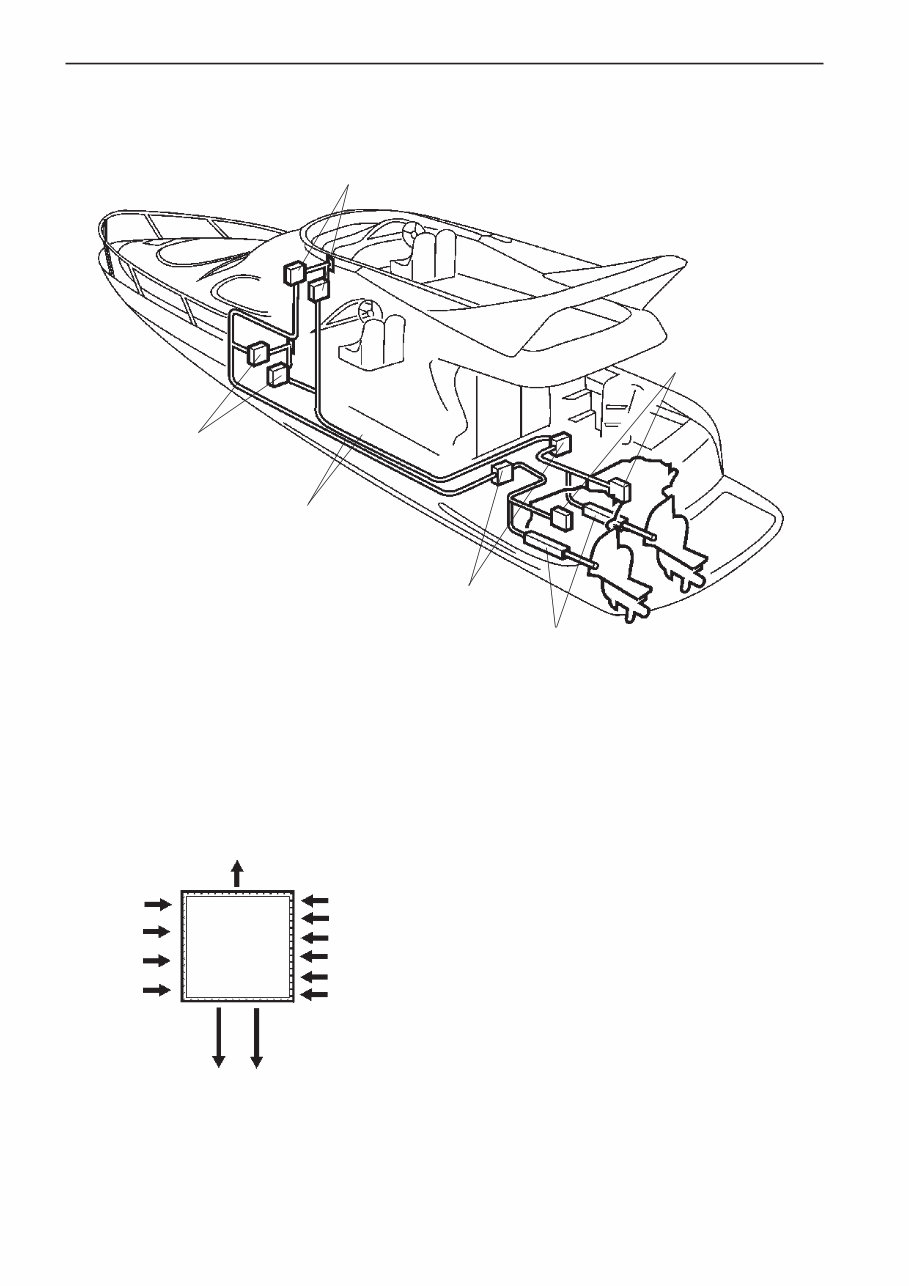

. General.view .................................................... . 15

Installation procedure, general . .......................... . 28

. Cable.routing . ................................................... . 29

. Marking.and.color.coding.of.cables ................. . 32

. Building.an.EVC.network ................................. . 33

. Identification.of.the.PCU.and.the.HCU ............ . 34

Installation procedure, engine room .................. . 35

. Location.and.mounting.of.the.PCU.and.HCU .. .35

. Engine–PCU.cable,.stern.drive . ....................... . 36

. Engine–PCU.cable,.Inboard.engine . ................ . 36

. Transmission.cables . ........................................ . 37

. Checking.rotation.of.propeller,.D4/D6 . ............. . 38

. Checking.rotation.of.propeller,.D9/D12/D16 . .... . 39

. Volvo.Penta.Lowspeed.and.Trolling . ................. . 42

. PCU,.installation .. ............................................. . 43

. Fuel.and.fresh.water.level.senders . ................. . 43

. Rudder.indicator .. ............................................. . 46

. Standard.bus.cable.PCU–HCU .. ...................... . 45

. HCU,.installation .............................................. . 47

. Powertrim.system,.D4/D6.stern.drive .............. . 48

. Gear.shift.actuator,.D4/D6.stern.drive . ............. . 48

© .2007.AB.VOLVO.PENTA

All.rights.to.changes.or.modifications.reserved .

Printed.on.environmentally-friendly.paper

3

Contents cont.

Installation procedure, helm ............................... . 49

. Y-connector ...................................................... . 49

. Key.switch.and.relay ........................................ . 49

. Start/stop.panel . ............................................... . 50

. EVC.control.panel . ........................................... . 52

. Powertrim.panel ............................................... . 54

. Relay.for.external.accessories . ........................ . 55

. Instruments ...................................................... . 57

. Instrument,.panels.and.auxiliary.cable . ............ . 59

. Buzzer . ............................................................. . 60

. Auxilliary.dimmer.unit.(ADU) . ........................... . 61

. Synchronizing.cable,.twin.installtions . .............. . 62

. EVC.system.display ......................................... . 63

. NMEA.0183.interface . ...................................... . 68

. NMEA.2000.interface . ...................................... . 69

. Multisensor . ...................................................... . 71

. Controls,.electronic .......................................... . 72

. Adapter.for.mechanical.controls . ...................... . 75

. Controls,.mechanical ....................................... . 76

. Interface.4–20.mA . ........................................... . 79

EVC control panels .............................................. . 82

Calibration and settings ...................................... . 83

. General ............................................................ . 83

. Calibration.mode . ............................................. . 84

. Auto.configuration ............................................ . 84

. EVC.control.lever.combinations..

. Calibration.summary . ....................................... . 86

. Lever.calibration . .............................................. . 88

. Select.language.and.units . ............................... . 91

. Powertrim.calibration . ....................................... . 92

. Powertrim.Assistance,.PTA . ............................. . 93

. Trolling.calibration ............................................ . 94

. Slip.calibration . ................................................. . 95

. Idling.speed.calibration .................................... . 96

. OEM-mode . ...................................................... . 97

. Fuel.tank.settings . ............................................ . 97

. Fuel.tank.calibration . ........................................ . 98

. Multisensor.calibration ..................................... . 100

. EVC.system.display ......................................... . 102

Diagnostic function . ............................................. . 107

Fault register ........................................................ 109

Parameter settings . .............................................. . 117

Starting the engine .............................................. . 119

Wiring color and pin-out schematics . ................ . 123

Templates for controls and panels . .................... . 125

References to Service bulletins . ......................... 136

4

Contents. EVC-C

Important!

The.following.special.warning.symbols.are.found.in.

this.manual.and.on.the.engine .

.

WARNING! .Possible.danger.of.personal.injury,.

damage.to.property.or.mechanical.malfunction.if.

the.instructions.are.not.followed .

IMPORTANT! Used.to.draw.your.attention.to.

something.that.can.cause.damage.to.or.malfunc-

tion.of.a.product.or.damage.to.property .

NOTE! Used.to.draw.your.attention.to.important.in-

formation.that.will.facilitate.the.work.or.operation.in.

progress.

A.summary.is.given.below.of.the.risks.and.safety.pre-

cautions.you.must.observe.or.carry.out.when.install-

ing.and.calibrating.the.EVC.system .

.Before.carrying.out.electric.arc.welding,.remove:.

-.connector.from.the.engine.control.unit..

-.8-pin.connector.from.the.PCU .

Safety precautions

Introduction

This.Installation.Manual.contains.the.information.you.

will.need.to.install.and.test.the.Electronic.Vessel.Con-

trol.(EVC).system .

Read.this.Installation.Manual.carefully.before.instal-

lation. .Incorrect.installation.may.result.in.personal.

injury.or.damage.to.property.or.the.engine.itself .

If.you.do.not.understand.or.are.uncertain.about.any.

operation.or.information.in.this.Installation.Manual,.

please.contact.the.Volvo.Penta.organization .

Installation

This.Installation.Manual.is.intended.for.professional.

use.only .

The.Manual.must.be.used.in.conjunction.with.the.rel-

evant.Engine.Operator’s.Manual .

Volvo.Penta.will.not.assume.any.liability.for.damage.

to.materials.or.personal.injury,.which.may.result.if.the.

installation.instructions.are.not.followed.or.if.the.work.

is.carried.out.by.non-professional.personnel .

The.installer.is.responsible.for.ensuring.that.the.

system.operates.in.accordance.with.this.Installation.

Manual. .

Work procedures

These.instructions.are.for.use.by.suitably.qualified.

personnel,.referred.to.as.the.installer.in.these.instruc-

tions.

Refer.to.the.specific.Engine.Operator’s.manual.for.

relevant.information.where.necessary,.especially.re-

garding.safety.and.engine.operation .

The.work.must.be.done.at.Volvo.Penta’s.service.

workshops,.boat.builders.or.other.authorised.and.

suitably.equipped.workshops.with.personnel.who.

have.the.appropriate.qualifications.and.experience .

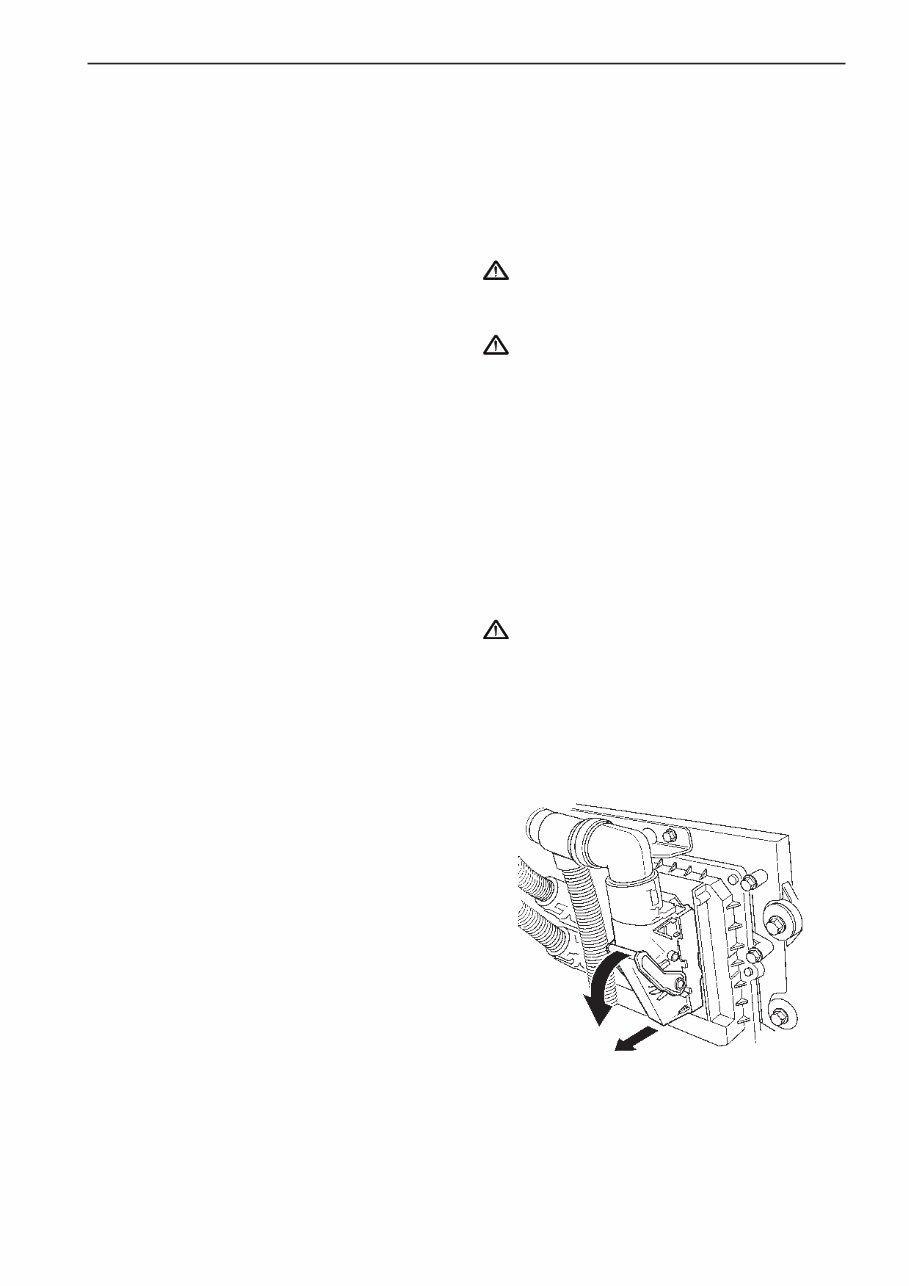

D4 and D6 engines

Press.the.lock.tab.down.and.pull.the.connector.out . .

Refit.the.connector.to.the.engine.control.unit.after.

disconnecting.the.welding.equipment .

5

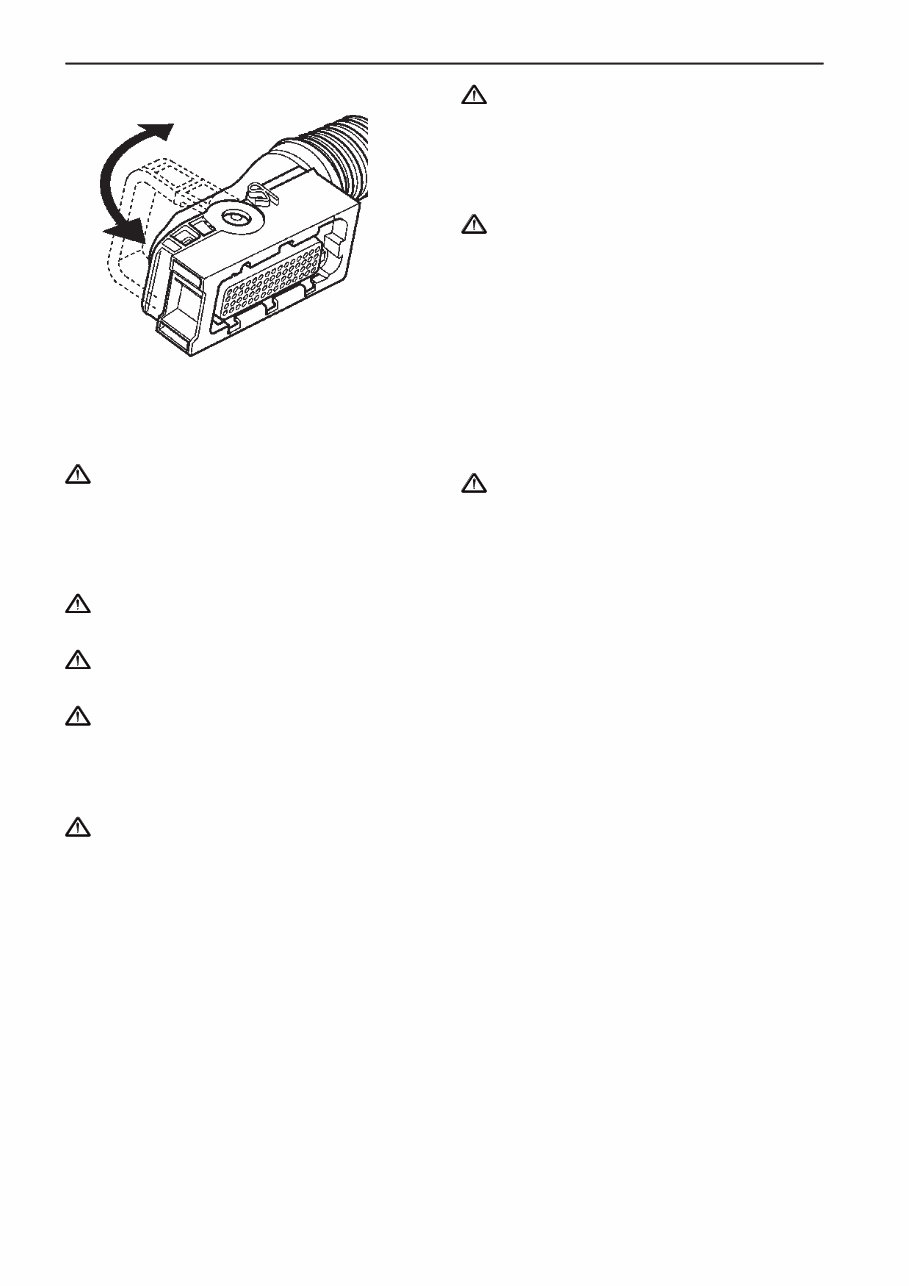

D9, D12 and D16 engines

Press.the.lock.tab.up.and.pull.the.connector/connec-

tors.out . .Refit.the.connector.to.the.engine.control.unit.

after.disconnecting.the.welding.equipment .

Take.care.to.avoid.all.moving.parts.of.the.engine.

during.testing.and.operation . .Approaching.an.

engine.which.is.operating.is.a.hazard.to.personal.

safety. .Loose.clothing.or.long.hair.can.become.

entangled.in.moving.parts,.and.may.cause.seri-

ous.personal.injury .

.Never.carry.out.work.on.an.engine.that.is.sus-

pended.from.a.hoist .

.The.engine.must.not.be.run.in.areas.where.there.

are.explosive.materials.or.gases .

.Only.start.the.engine.in.a.well-ventilated.area . .

If.operating.the.engine.in.a.closed.area.ensure.

that.there.is.exhaust.ventilation.leading.out.of.the.

work.area.to.remove.exhaust.gases.and.crank-

case.ventilation.emissions .

.Never.allow.an.open.flame.or.electric.sparks..

near.the.batteries . .Never.smoke.close.to.the.bat-

teries. .The.batteries.give.off.hydrogen.gas.during.

charging,.which.can.form.an.explosive.mixture.

when.mixed.with.air . .This.gas.is.easily.ignited.

and.highly.flammable . .Incorrect.connection.of.

the.battery.can.cause.a.single.spark,.which.is.

sufficient.to.cause.a.gas.explosion . .Do.not.alter.

the.battery.connections.when.attempting.to.start.

the.engine.(spark.risk).and.do.not.lean.over.any.

of.the.batteries . .Refer.to.the.instructions.in.the.

Engine.Instruction.Manual .

.Always.ensure.that.the.+.(positive).and.–.(nega-

tive).battery.leads.are.correctly.installed.on.their.

corresponding.terminal.posts.on.the.batteries . .In-

correct.installation.can.result.in.serious.damage.

to.the.electrical.equipment . .Refer.to.the.wiring.

diagrams.in.the.Engine.Instruction.Manual .

.Always.use.protective.goggles.when.charging.

or.handling.the.engine.batteries . .The.battery.

electrolyte.fluid.contains.sulfuric.acid.which.is.

highly.corrosive . .If.the.battery.electrolyte.comes.

into.contact.with.unprotected.skin,.wash.it.off.im-

mediately.using.copious.amounts.of.clean.water.

and.soap,.then.seek.medical.assistance . .If.the.

electrolyte.fluid.comes.into.contact.with.the.eyes,.

flush.your.eyes.immediately.(preferable.using.an.

eye.bath).with.copious.amounts.of.clean.water,.

and.obtain.medical.assistance.without.delay .

. IMPORTANT! .AB.Volvo.Penta.has.developed.

and.tested.the.complete.EVC.system.and.its.

components. .However,.non.Volvo.Penta.compo-

nents.or.components.installed.in.a.way.that.differ.

from.the.instructions.may.cause.the.system.to.

malfunction. .In.this.case.Volvo.Penta.do.not.ac-

cept.any.responsability .

6

Safety.precautions. EVC-C

General information

About the Installation Manual

This.publication.is.intended.as.a.guide.for.the.instal-

lation.of.Volvo.Penta.EVC.system.for.D4,.D6,.D9,.

D12.and.D16.engines,.Aquamatic.and.inboard.use . .

The.publication.is.not.comprehensive.and.does.not.

cover.every.possible.installation,.but.is.to.be.regard-

ed.as.recommendations.and.guidelines.applying.to.

Volvo.Penta.standards . .Detailed.Installation.Instruc-

tions.are.included.in.most.of.the.accessory.kits .

These.recommendations.are.the.result.of.many.years.

of.practical.experience.of.installations.from.all.over.

the.world . .Departures.from.recommended.proce-

dures.etc . .can.be.necessary.or.desirable,.however,.in.

which.case.the.Volvo.Penta.organization.will.be.glad.

to.offer.assistance.in.finding.a.solution.for.your.par-

ticular.installation .

It.is.the.sole.responsibility.of.the.installer.to.ensure.

that..the.installation.work.is.carried.out.in.a.satisfac-

tory.manner,.it.is.operationally.in.good.order,.the.ap-

proved.materials.and.accessories.are.used.and.the.

installation.meets.all.applicable.rules.and.regulations .

This.Installation.Manual.has.been.published.for.

professionals.and.qualified.personnel . .It.is.therefore.

assumed.that.persons.using.this.book.have.basic.

knowledge.of.marine.propulsion.systems.and.are.

able.to.carry.out.related.mechanical.and.electrical.

work.

Installation.of.electrical.systems.shall.only.be.carried.

out.by.a.professional.boat.electrician .

Only.components,.cables,.connections.etc,.delivered.

or.approved.by.the.manufacturer.may.be.used . .The.

manufacturer.will.accept.no.responsibility.what.so.

ever.if.this.requirement.is.ignored .

Volvo.Penta.continuously.upgrades.its.products.and.

reserves.the.right.to.make.changes . .All.the.informa-

tion.contained.in.this.manual.is.based.on.product.

data.available.at.the.time.of.print . .Notification.of.

any.important.modifications.to.the.product.causing.

changes.to.installation.methods.after.this.date.will.be.

made.in.Service.Bulletins .

NOTE! .Commercial.and.classified.systems.including:

-. MCC.system.

-. CU.305.system.

-. SDU.(Shut.Down.Unit)

Please.refer.to. Installation Marine Propulsion, Die-

sel Engines D5–D16 .

Plan installations with care

Great.care.must.be.taken.in.the.installation.of.en-

gines.and.their.components.if.they.are.to.operate.

perfectly. .Always.make.sure.that.the.correct.specifica-

tions,.drawings.and.any.other.data.are.available.be-

fore.starting.work . .This.will.allow.for.correct.planning.

and.installation.right.from.the.start .

Plan.the.engine.room.so.that.it.is.easy.to.carry.out.

routine.service.operations.involving.the.replacement.

of.components . .Compare.the.engine.Service.Manual.

with.the.original.drawings.showing.the.dimensions .

It.is.very.important.when.installing.engines.that.no.

dirt.or.other.foreign.matter.gets.into.the.fuel,.cooling,.

intake.or.turbocharger.systems,.as.this.can.lead.to.

faults.or.engine.seizure . .For.this.reason.the.systems.

must.be.sealed . .Clean.supply.lines.and.hoses.before.

connecting.them.to.the.engine . .Only.remove.protec-

tive.engine.plugs.when.making.a.connection.to.an.

external.system .

Important

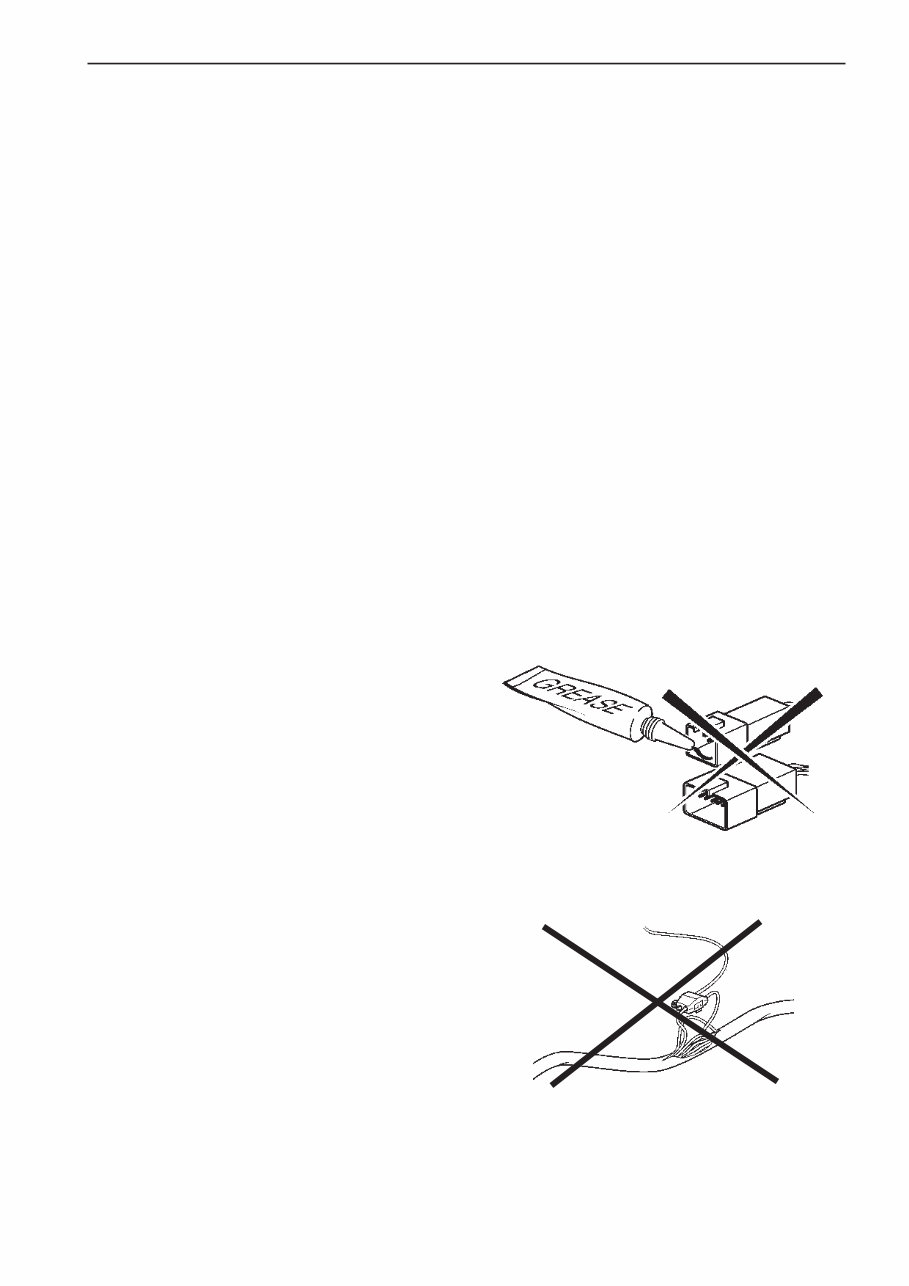

Never.cut.or.modifiy.the.Volvo.Penta.EVC.cable.har-

nesses. .For.extra.power.supply.use.the.Volvo.Penta.

relay.for.accessories . .

Refer.to.the. Relay for external accessories .section .

Never.use.any.kind.of.grease.in.the.EVC.connectors .

7

Certified engines

The.manufacturer.of.engines.certified.for.national.

and.local.environmental.legislation.(Lake.Constance.

for.example).pledges.that.this.legislation.is.met.by.

both.new.and.currently.operational.engines . .The.

product.must.compare.with.the.example.approved.

for.certification.purposes . .So.that.Volvo.Penta,.as.a.

manufacturer,.can.pledge.that.currently.operational.

engines.meet.environmental.regulations,.the.follow-

ing.must.be.observed.during.installation:

•. Servicing.of.ignition,.timing.and.fuel.injection.

systems.(gasoline).or.injector.pumps,.pump.set-

tings.and.injectors.(diesel).must.always.be.car-

ried.out.by.an.authorised.Volvo.Penta.workshop . .

•. The.engine.must.not.be.modified.in.any.way.ex-

cept.with.accessories.and.service.kits.developed.

for.it.by.Volvo.Penta . .

•. Installation.of.exhaust.pipes.and.air.intake.ducts.

for.the.engine.compartment.(ventilation.ducts).

must.be.carefully.planned.as.its.design.may.af-

fect.exhaust.emissions . .

•. Seals.may.only.be.broken.by.authorised.person-

nel. .

IMPORTANT! .Use.only.Volvo.Penta.Genuine.

Parts. .

Using non-genuine parts will mean that AB

Volvo Penta will no longer take responsibility

for the engine meeting the certified design. ..

All.damage.and.costs.caused.by.the.use.of.non-

genuine.replacement.parts.will.not.be.covered.

by.Volvo.Penta .

Seaworthiness

It.is.the.boat.builder’s.duty.to.check.that.the.security.

requirements.apply.to.the.market.in.which.the.boat.

is.sold . .In.the.USA.for.example,.these.are.the.US.

Federal.Regulations.for.pleasure.boats.described.

in.Title.46 . .The.requirements.described.below.apply.

to.the.EU.principles . .For.information.and.detailed.

descriptions.of.the.safety.requirements.that.apply.to.

other.markets,.contact.the.authority.for.the.country.

concerned.

As.of.June.16.1998,.pleasure.boats.and.certain.as-

sociated.equipment.marketed.and.used.within.the.

EU.must.bear.CE.labels.to.confirm.that.they.meet.

the.safety.requirements.stipulated.by.the.European.

Parliament.and.Council.of.Europe’s.directive.for.plea-

sure.boats . .The.normative.requirements.can.be.found.

in.the.standards.drawn.up.to.support.the.directive’s.

objective.of.uniform.safety.requirements.for.pleasure.

boats.in.EU.countries .

Certificates.that.grant.the.right.for.CE.label.use.and.

confirm.that.boats.and.equipment.meet.safety.re-

quirements.are.issued.by.approved.notified.bodies . .

In.many.Member.States.the.classification.societies.

have.become.the.notified.bodies.for.pleasure.boats,.

e.g. .Lloyd’s.Register,.Bureau.Veritas,.Registro.Italiano.

Navale,.Germanischer.Lloyd,.etc . .

In.many.cases.completely.new.institutions.have.been.

approved.as.notified.bodies . .The.directive.also.allows.

boat.builders.and.component.manufacturers.to.issue.

assurances.of.compliance.with.the.requirements.of.

the.directive . .This.requires.the.manufacturer.to.store.

the.prescribed.product.documentation.in.a.place.that.

is.accessible.to.the.monitoring.authority.for.at.least.

ten.years.after.the.last.product.is.produced .

Life.boats.and.boats.for.commercial.activities.are.ap-

proved.by.classification.societies.or.by.the.navigation.

authority.for.the.boat’s.registered.country .

Joint liability

Each.engine.consists.of.many.components.working.

together. .One.component.deviating.from.its.technical.

specification.can.cause.a.dramatic.increase.in.the.

environmental.impact.of.an.engine . .It.is.therefore.vital.

that.systems.that.can.be.adjusted.are.adjusted.prop-

erly.and.that.Volvo.Penta.Genuine.Parts.are.used . .

Certain.systems.e .g.components .in.the.fuel.system.

may.require.special.expertise.and.special.test.equip-

ment. .Some.components.are.sealed.at.the.factory.for.

environmental.reasons . .No.work.should.be.carried.

out.on.sealed.components.except.by.authorised.per-

sonnel.

Remember.that.most.chemical.products.damage.the.

environment.if.used.incorrectly . .Volvo.Penta.recom-

mends.the.use.of.biodegradable.degreasing.agents.

for.cleaning.engine.components,.unless.otherwise.

indicated.in.a.Workshop.Manual . .Take.special.care.

when.working.on.board.boats.to.ensure.that.oil.and.

waste.are.taken.for.destruction.and.not.accidentally.

pumped.into.the.environment.with.bilgewater .

8

General.information. EVC-C

Conversion factors

Metric to U.S. or IMP. conversion factors: U.S. or IMP. to metric conversion factors:

To convert To convert

from To Multiply by from To Multiply by

Length . mm.. inch.. 0.03937 .. inch.. mm.. 25.40

. . cm.. inch.. 0.3937 .. inch.. cm.. 2.540

. . m.. foot.. 3.2808 .. foot.. m.. 0.3048

Area . mm².. sq.in. .. 0.00155 .. sq. .in . .. mm².. 645.2

. . m².. sq. .ft . .. 10.76 .. sq. .ft . .. m².. 0.093

Volume . cm³. .cu . .in . .. 0.06102 .. cu. .in . .. cm³.. 16.388

. . litre,.dm³.. cu. .ft . .. 0.03531 .. cu. .ft . .. litre,.dm³.. 28.320

. . litre,.dm³.. cu. .in . .. 61.023 .. cu. .in . .. litre,.dm³.. 0.01639

. . litre,.dm³.. imp. .gallon.. 0.220 .. imp. .gallon.. litre,.dm³.. 4.545

. . litre,.dm³.. U.S. .gallon.. 0.2642 .. U.S. .gallon.. litre,.dm³.. 3.785

. . m³.. cu. .ft . .. 35.315 .. cu.ft. .. m³.. 0.0283

Force . N.. lbf.. 0.2248 .. lbf.. N.. 4.448

Weight . kg.. lb. .. 2.205 .. lb. .. kg.. 0.454

Power . kW.. hp.(metric).

1)

.. 1.36 .. hp.(metric).

1)

.. kW.. 0.735

. . kW.. bhp.. 1.341 .. bhp.. kW.. 0.7457

. . kW.. BTU/min.. 56.87 .. BTU/min.. kW.. 0.0176

Torque . Nm.. lbf.ft.. 0.738 .. lbf.ft.. Nm.. 1.356

Pressure . Bar.. psi.. 14.5038 .. psi.. Bar.. 0.06895

. . MPa.. psi.. 145.038 .. psi.. MPa.. 0.006895

. . Pa.. mm.Wc.. .0 .102 .. mm.Wc.. Pa.. 9.807

. . Pa.. in.Wc.. 0.004 .. in.Wc.. Pa.. 249.098

. . kPa.. in.Wc.. 4.0 .. in.Wc.. kPa.. 0.24908

. . mWg.. in.Wc.. 39.37 .. in.Wc.. mWg.. 0.0254

Energy . kJ/kWh.. BTU/hph.. 0.697 .. BTU/hph.. kJ/kWh.. 1.435

Work . kJ/kg.. BTU/lb.. 0.430 .. BTU/lb.. kJ/kg.. 2.326

. . MJ/kg.. BTU/lb.. 430.. BTU/lb.. MJ/kg.. 0.00233

. . kJ/kg.. kcal/kg.. 0.239 .. kcal/kg.. kJ/kg.. 4.184

Fuel . g/kWh.. g/hph.. 0.736 .. g/hph.. g/kWh.. 1.36 .

consump. . g/kWh.. lb/hph.. 0.00162 .. lb/hph.. g/kWh.. 616.78

Inertia . kgm².. lbft².. 23.734 .. lbft².. kgm².. 0.042

Flow, gas . m³/h.. cu.ft./min. .. 0.5886 .. cu.ft./min. .. m³/h.. 1.699

Flow, liquid m³/h.. US.gal/min.. 4.403 .. US.gal/min.. m³/h.. 0.2271

Speed . m/s.. ft./s .. 3.281 .. ft./s .. m/s.. 0.3048 .

. . mph. knots. 0.869 . knots. mph. 1.1508

Temp. . °F=9/5.x.°C+32.. . °C=5/9.x.(°F–32)

.

1).All.hp.figures.stated.in.the.catalogue.are.metric .

9

EVC-C. General.information

Engine monitoring system

The.engines.are.equipped.with.common.rail.system.

and.electronically.controlled.injectors.(D4,.D6).or.unit.

injectors.(D9,.D12,.D16).with.an.electronic.control.

Engine monitoring and the EVC system

unit. .

The.injectors.contain.an.electro-magnetic.valve.which.

sets.the.amount.of.fuel.injected.and.the.correct.tim-

ing. .The.monitoring.system.measures.the.charge.air.

pressure.and.temperature,.and.calculates.the.avail-

able.air.mass . .This.determines.the.maximum.amount.

of.fuel.that.can.be.injected.(smoke.limiter.function) .

The.system.also.limits.the.maximum.torque.available.

at.the.engine.speed.registered.to.protect.the.engine.

and.transmission.from.overload .

To.protect.the.engine.at.too.high.coolant.or.charge.air.

temperatures.and.boost.pressure.as.well.as.oil.pres-

sure,.the.monitoring.system.reduces.the.amount.of.

fuel.(reduced.engine.output).until.the.current.values.

are.normalized .

The.engine.monitoring.system.also.has.a.diagnostic.

system,.which.helps.users.and.service.technicians.to.

determine.the.cause.of.any.malfunctions.in.the.sys-

tem.quickly.by.using.the.diagnostic.tool . .

Any.fault.is.shown.on.the.EVC.system.tachometer.

display./.EVC.system.display.and.the.VODIA.diag-

nostic.scan.tool . .The.diagnostic.tool.has.menus.in.

several.languages .

Diagnostics

Engine.speed

Throttle

Oil.pressure

Oil.temp .

Cooling.temp .

Charge.air.press .

Charge.air.temp .

Fuel.temp .

Water.in.fuel

Camshaft.pos .

Ignition.

timing

Fuel..

quantity

Engine

Control

Unit

HCU.

(Helm.station.

Control.Unit)

PCU.

(Powertrain..

Control.Unit)

ECU.

(Engine..

Control.Unit)

HCU.

(Helm.station.

Control.Unit)

CAN.bus

Actuator.

(gear.shifting..

DPH/DPR)

10

You're Reading a Preview

What's Included?

Lifetime Access

Access PDF Contents & Bookmarks

Print one or all pages of your manual

Add to Cart

$26.99

$35.99

![Volvo Penta D4, D6, D9, D12, D16 EVC EC-C Electronic Vessel Control [en] Volvo Penta D4, D6, D9, D12, D16 EVC EC-C Electronic Vessel Control [en]](https://cdm.emanualonline.com/media/catalog/product/cache/518e89fe08903fc357b0d05eb410bb22/4/9/490736-1.jpg)