gray marine vintage chris craft engine manuals 4 & 6 cyl

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

I

Maintenance

Manual

Form No. 865

MAINTENANCE

MANUAL

GRAYMARINE

GASOLINE ENGINES

FOUR AND SIX

CYLINDER MODELS

Specifications for Current

9 and

Non-Current Models

Pages S-2 through S-15

Tab/e o f Conteots Page 1

Maintenance Instructions ........................ 3

Sta,iing Engine First Time ........................ 6

Operating Instructions. ......................... 8

Adjustments on New Engine .................... .lO

Fuel and Fueling ................................ 10

Engine Installation ............................. .12

Water Piping Diagram .......................... 14

Fuel System ................................... 1 6

lubricating System.

...........................

.20

Cooling System. .............................. .23

Electrical System. ............................. .30

Transmission.

................................

.43

Cylinder Head ................................. 5 5

Valves ........................................ 5 7

Timing ........................................ 6 0

Laying-Up Instructions .........................

.61

Starting’ Engine After Storage ...................

.63

Trouble-Shooting Guide ........................

.65

Propeller Sizes, Average. ......................

.75

Condensed Specifications ............. .Center Section

Condensed Adjustment Data .......... .Center Section

Wiring Diagrams .................... .Center Section

Engine Installation Data .............. .Center Section

Gray Service Warranty ............... .Center Section

INTRODUCTION

This pocket-sired hand book is supplied as a service to

Gray owners. It is one evidence of our determination to

make Gray service the most complete and useful in the

industry. It covers both current models and older models.

The scope of this manual is necessarily limited by its

size but includes gasoline marine engine operating in-

structions, trouble shooting guide and directions for mak-

ing simple adjustments to engine and accessories: such

operations as can be done on the engine in the boat.

Note that the section on “Installation” covers only such

details as affect the care of the engine.

The intent of the booklet is one of usefulness, and not to

encourage tinkering. In the interest of good service,

safety and long engine life the manufacturer recommends

that major repairs can always best be done by experipnced

marine service stations with a reputation for competent

workmanship and a proper acceptance of the responsibility.

Gray Marine Engine Division will be glad to recommend

the nearest competent marine shop if your boat 1s not

located near an authorized dealer. Also, remember that

carburetors and electric accessories are made by com-

panies with widespread service facilities; consult the classi-

fied telephone directory.

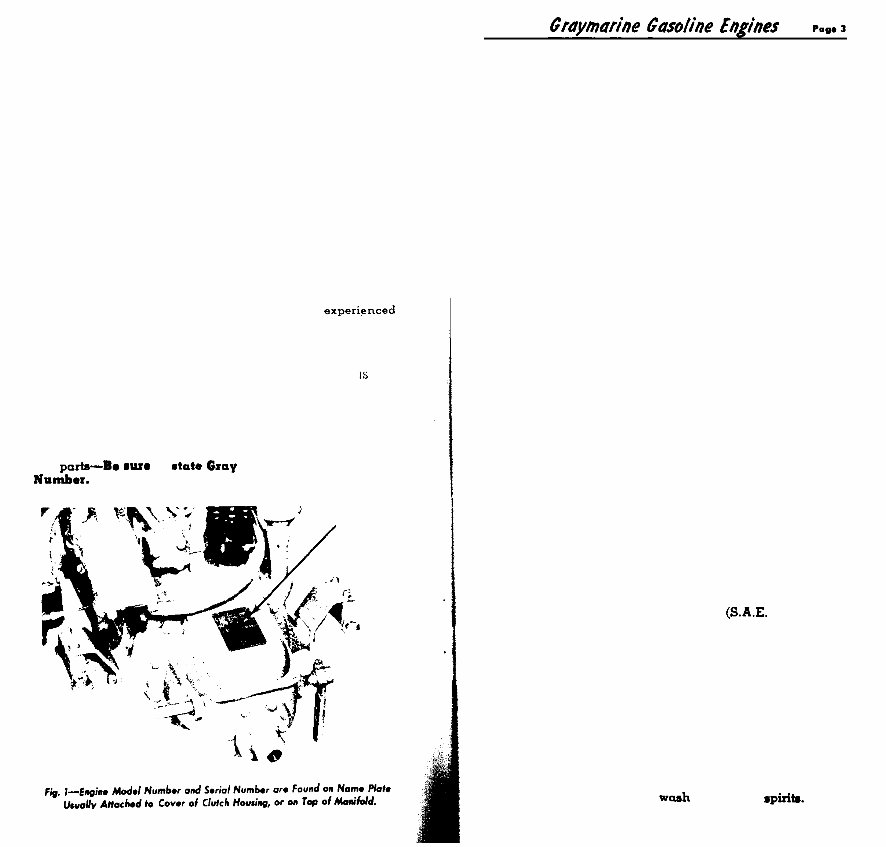

Important-When requesting information or when order-

ing parts--b. sure to state Gxay Engine Model and Serial

Nllmber.

MAINTENANCE

INSTRUCTIONS

DAILY

l Ventilate engine compartment thoroughly

before starting engine.

l Check pump flow by observing water and

steam at exhaust outlet, each time engine

is started. Do this at once.

. Check lubricating oil level in crankcase

(engine not running), and when necessary

refill to high level mark on depth stick, using

S.A.E. 30 oil.

l At the same time, check oil level in hydraulic

reverse gear. (This applies only to engines so

equipped, when reverse gear has a separate

oil supply.) Note: if oil needs to be added,

look for a leak, because reverse gear normally

consumes no oil.

l Give grease cups on water pump one-half

turn. Use water-proof grease. Do not over

grease.

EVERY 50 HOURS

OF OPERATION

l Inspect sea water strainer.

l Check water level in battery. Proper fluid

gravity is 1.275.

l Put 3 to 5 drops of engine oil (S.A.E. 30)

in the oiler on the outside of distributor

body; or give grease cup one-half turn.

depending on model.

l Remove oil from crankcase, using Gray sump

pump, and refill with fresh oil, S.A.E. 30, to

high mark on oil depth gauge. Note: Before

removing old oil. run the engine until it is

thoroughly warm.

l Put 3 or 4 drops of engine oil (SAX. 30) in

oiler on generator, and two drops in oiler on

cranking motor. (Some models have sealed

bearings, so will have no oilers.)

ONCE A MONTH

l Inspect and clean Thermogard element. See

page 27

l Clean sediment bowl on fuel pump.

l Check adjustment of clutch and reverse gear.

See pages 43 to 52 for directions.

l Inspect flame arrester to make sure the air

passages are clean and free from oil or lint.

If dirty, remove and wash in mineral spiriti.

?ope 4 Graytnahe Gasolrire Engines

EVERY 150 HOURS

0 Replace cartridge in lubricating oil filter, if

engine is so equipped.

l Apply one drop only of light engine oil

(S.A.E. 10) to the breaker arm hinge pin in

distributor.

l Givegrease cup on tachometer drive one turn.

(Applies only to right angle type mounted on

cylinder head.)

l Remove the distributor rotor and apply 3 to

5 drops of light engine oil (S.A.E. 10) to the

felt in the top of the breaker cam and to the

governor weight pivots.

TWICE A SEASON

“TUNE UP”

l Clean the engine thoroughly.

. Check distributor setting. See page 39.

l Check carburetor adjustment. See page 18.

l Check engine coupling for misalignment.

Tighten lag bolts holding engine to bed.

l Check valve tappet adjustment. For correct

clearance, see pages S-3, S-4, S-13 and S-15.

in center section.

l Chock grease in drive gear housing of double

gear type water pumps. Add bearing grease

(EQ-2095) if required.

0 Remove the distributor head and smear a bit

of grease the size of a match head on the

lobes of the breaker cam.

0 Clean and adjust breaker points on distrib-

utor. Points should contact evenly, and gap

must not exceed .020” or condenser can be

burned out. See page 37.

l Check spark plugs and set gap, using a round

wire feeler gauge. Clean fouled plugs and

ooarch for cause of fouling. Replace crocked

or doubtful plugs. Use plugs of correct heat

range.

KEEP A SERVICE LOG

Maintenance lnstmctions

l Inspect all wiring for loose connections or

worn insulation. Clean battery terminals

with soda solution and coat lightly with

Vaseline or grease after connection is made.

EVERY 1000 HOURS

OR ONCE A SEASON

l Change oil in hydraulic reverse gear if engine

is so equipped. Use Automatic Transmission

Oil Type “A”, Suffix “A”, (SAE 30 engine oil

may be used only in an emergency.) IM-

PORTANT: after running engine briefly in

both forward and reverse, stop engine and

recheck transmission oil level. See page 52.

l Grind and adjust valves.

l Check valve stems for carbon.

a Give engine a thorough going-over.

0 Clean Oil Cooler.

l Clean commutator on generator, using No. 00

sandpaper. Do not use emery cloth.

l Ii compression is weak, look for imperfectly

seating valves or rings stuck in groove* on

piston.

EVERY 2500 HOURS

l Time for a major overhaul.

l Install new piston rings. Check piston clear-

ance.

l Check bearings. When oil presmure drops be-

low 20 pounds, this ia an indication of worn

bearings.

Graymarhe Gasohe bghes

INSTRUCTIONS ON STARTING ENGINE

FIRST TIME

BEFORE STARTING THE ENGINE

After the engine has been properly installed ond all con-

trols properly connected. the following instructions are to

be carried out before starting a new engine:

1. Check Fuel Supply: Be sure the tank is clean, then fill

with a good grade of gasoline. Refer to page S-2 in

center section for fuel recommendation. Some models

require premium ethyl.

2. Check Lubricating Oil in Crankcase: Engine is shipped

dry from factory with oil drained from the crankcane.

Do not fail to check oil level. Fill to the high level notch

on oil depth gauge, using a good grade of oil, S.A.E.

viscosity No. 30. Lift oil depth gauge during filling to

permit escape of air. Note: If engine is equipped with

hydraulic reverse gear, check oil depth stick on trans-

mission for separate oil supply, using Automatic

Transmission Oil, Type “A”, Suffix “A”.

3. Check Lag Bolts holding engine to bed: must be tight.

IMPORTANT: If the boat came off a train or truck, or if

it has been out of the water for considerable time, check

the shaft alignment. (Instructions on page 16.)

4. Inspect the Engine for loose nuts or screws. Transpor-

tation frequently loosens fastenings on a new engine,

on account of gasket shrinkage. After engine has had a

preliminary run, take up on cylinder head nuts. See p. 56

5. Check Storage Battery: Make sure that storage battery

is filled, with water level at least 3,s” above the plates,

and fully charged. Proper fluid gravity is 1.275. Low

battery will result in slow cranking speed and weak

spark.

6. Check All Electrical Connections including battery

cables. Make sure they are tight, and all connections

soldered. (Use rosin flux in soldering.)

7. Check Water Circulation System: Open the gate valve

on the cooling water intake line. This valve should be

located in the bottom of the boat. Caution: if water

pump is rubber impeller type, it must be primed at first

start of the season.

6. Check All Controls to make sure they are working

freely with sufficient travel so that they do not strike

against woodwork. This refers to choke, throttle and

rover*8 controls.

ODefatiirp lnZrruction.5

9. Safety Precautions: Check engine compartment and

bilge for gasoline fumes. If boat is equipped with

ventilating fan, run it for 5 minutes before starting;

otherwise open hatch or engine box and let dead air out.

10. Turn on the Gasoline: The shut-off cock is properly

located near the fuel tank.

11

12.

1.

2.

3.

4.

Fig. l--Fuel Pump Primer

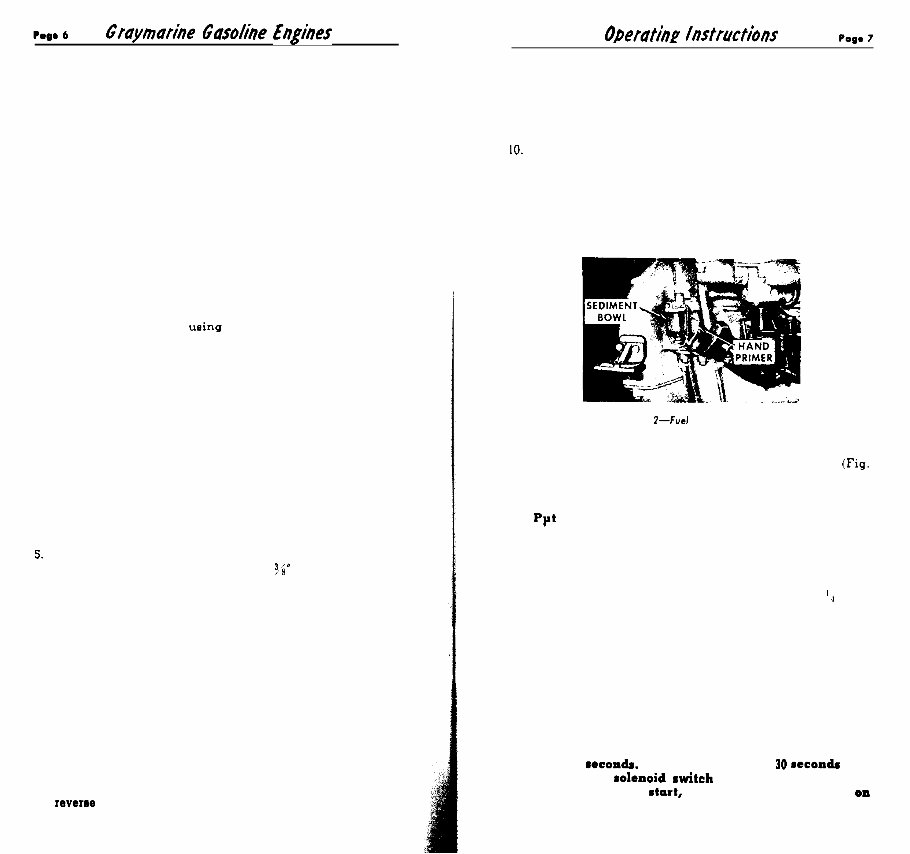

Fill Carburetor: Use hand primer on fuel pump (Fig.

2 to fill sediment bowl and carburetor. (Note: on some

small engines fuel pump does not have hand primer.

Ppt Clutch in Neutral.

HOW TO START THE ENGINE

Set the Throttle above idling position, about I4 open.

Pull Out the Choke: Keep your hand on it for quick

adjustment as soon as the engine starts. A marine

engine, particularly if it has two carburetors. needs

plenty of choke to start.

Turn on Ignition Switch.

Press Starter Button.

CAUTION: Do not operate cranking motor longer

than 30 8eCOAdI. A longer period than 30 recondr may

damage the rolenoid awitch and cranking motor. If

l agiae does not 8tart, refer to detailed instructions OA

Page 65.

hp. 8 Graymarine Gasoline Engines

NOTE: Engines which have been in transit and storage

for a period of weeks may start hard the first time. In

such case, remove spark plugs and clean the electrodes.

While the plugs are out, put a tablespoonful (no more)

of light oil, SAE 10. in each cylinder to provide an

initial oil seal between piston rings and cylinder walls.

Memo on Flooding: If you flood the engine by too

much choking, the correct way to dry it out is to open

the throttle wide. Put the choke in the running or

non-choking position. Then with ignition on, crank

the engine a half dozen times. This draws nothing but

air through the carburetor, as the idling jet is out of

action at full throttle, and the engine does not revolve

fast enough for the main jet to go into action.

OPERATING INSTRUCTIONS

1. To Drive the Boat Forward push operating lever

forward until it snaps into a locked position.

2. To Reverre, pull lever back as far as it will go. Reduce

speed before shifting.

CAUTION: The engine must not be operated unless the

cooling water is circulating. See instructions below.

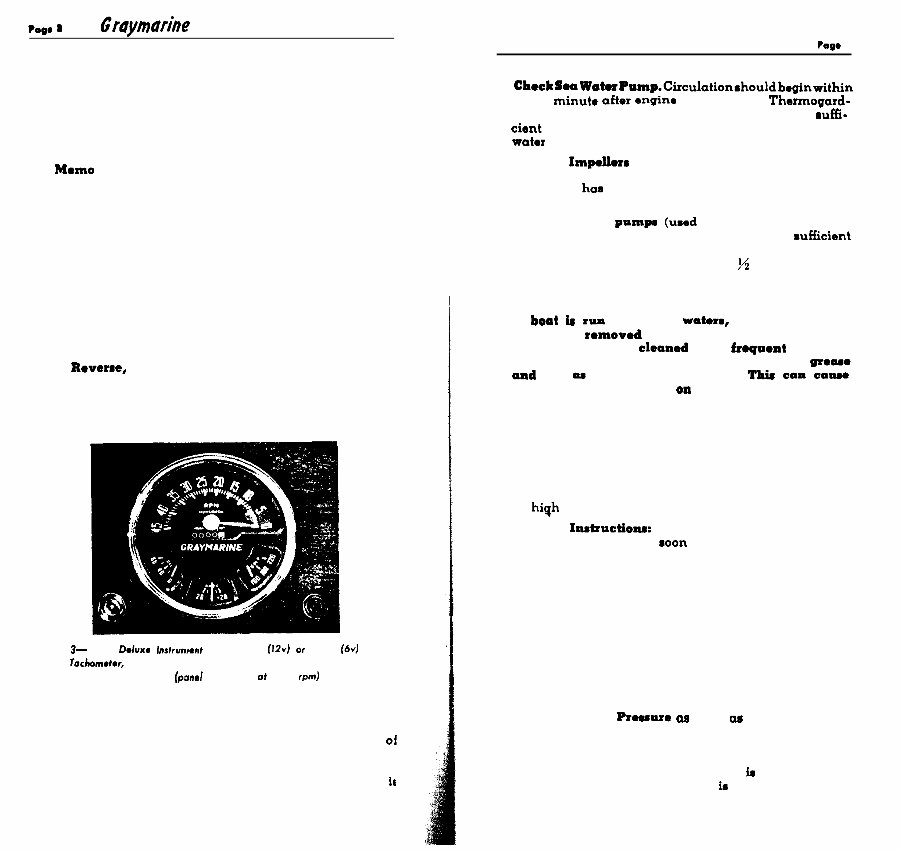

Fig. 3- Gray D&nca Inrlrunren~ Panel 77800 (12~) or 75650 (6~) with

Tachometer, Operating Hours Register, Oil Temperature Gauge,

and Ammeter fpanel calibrated of 1796 rpm)

AFTER THE ENGINE STARTS

Check Oil Pressure Gauge: Normal oil pressure at

operating speeds is 30-40 pounds. An oil pressure 01

less than 20 pounds calls for investigation (5 to 15

pounds is satisfactory at idle). NOTE: Gauge may

show no pressure for a minute or two while the filter ir

filling with oil.

Operating Instructions Pago 9

2. CheckSoaWoterPnmp.Circulationshouldbeginwithin

a half minute aftor engino is started. On Thermogard-

equipped models. only a small amount of water muffi-

cient to cool the tailpipe will be expelled, the rest of the

water being recirculated until engine warms up.

Neoprene Impellorr are lubricated by the flow of water.

Consequently, never operate a dry pump. Always prime

pump if it haa become dry after draining or extended

idleness.

On bronze gear pumpa (used on smaller four-cylin-

der engines) the prime of pump is assisted by sufficient

grease sealing the impellers. If pump does not operate

immediately, turn grease cup down yz turn.

NOTE: Pictures of these units shown on Pages 24, 25.

CAUTION : (Applies only to bronze gear pump) :

If boat t run in muddy woterm, the water pump

should be rcmovcd and all old grease in impeller

housing thoroughly cleaned out at froquont intervals.

Silt which entered the pump will mix with the geam

and act aa a grinding compound. Thir can caume

exceptionally rapid wear on metal parts.

3. The first time the engine is started, run it at idle for 5

minutes, no longer, then stop engine and recheck oil

level in crankcase, and in reverse gear housing when

applicable. (Do not check oil level while engine is

running.) Oil level may be found low due to the fact

that considerable oil is required to fill the oil passages:

or it may be found high if depth gauge was not removed

for venting air during the initial filling. Bring oil level

to high mark on depth gauge.

4. Warm-up Iastructfoas: (To be followed every time you

start a cold engine.) As soon as possible put the clutch

lever in forward position and run at fast idle for 10 to 15

minutes. in order to bring the oil up to proper tempera-

ture for full throttle work. An indication of warm oil

is that the oil pressure will drop off about 5 pounds

from what it was when engine was cold.

IMPORTANT: Do not under any circumstances race

the engine with clutch disengaged.

FULL THROTTLE OPERATION

1. Recheck the Oil Preuwe a soon W you try out the

boat at full speed. If indicating needle on the oil

pressure gauge fluctuates wildly, this will indicate

either a leak in the oil line, or that the angle of the

engine is such that oil pick-up screen ia not completely

submerged. The remedy for this in to stop engine and

add more oil. See Fig. 10, page 21. for an understanding

of the relationship between pick-up screen and oil level.

?ega 10 Graymarine Gasoline Enghes

2. RadPce Engine Speed When Reversing: Gear should

not be reversed at full engine speed except in extreme

emergency.

3. Although all Graymarine engines ara thoroughly

tested at the factory, good judgment is expected on

the warm-up and operation during the early life of

the engine. It takes from fifteen to twenty hours run-

in to break in an engine for peak performance. On

high speed models, oil consumption will be more until

the piston rings fit themselves perfectly inside cylinder

walls, after a few hours of fast operation.

ADJUSTMENTS ON A NEW ENGINE

1. Propeller Shaft Alignment: If the boat is new. be sure

to check the alignment within a few days, after the

hull has soaked up some water, because the hull is

liable to change its shape slightly, especially when

loaded, resulting in binding on the shaft.

2. Carburetors: Careful adjustment is made in the test

room. Never re-adjust carburetor unless engine is

warm and under full load. Make sure that control ex-

tensions permit full travel of throttle and choke levers.

3. Clutch Adjustment: After the first few hours of opera-

tion examine the adjustment of manual gear. Clutch

lever should stay in either position without being held.

It should snap into the forward position and shouldstay

in reverse without forcing. (NOTE : This does not apply

to some four-cylinder models which have wedge mech-

anism for reverse position, and must be held in reverse.)

For instructions on clutch adjustment, see pages 45 to 52.

Wanting: Never operate engine with loose and slipping

clutch, because this condition will generate heat by

friction, warping and galling the clutch plates, causing

permanent damage. Clutch trouble is nearly always

due to negligence.

4. After first 10 hours of operation, have the valve tappets

readjusted to specified clearance (see center section) by a

competent marine service station. This is your responsibihty.

5. Valve Sticking: Sometime5 valve5 on new engine5 or

those which have been in storage tend to stick. See

page 59 for remedy.

FUEL

The Gray Marine Motor Company approve5 the use of high

grade gasolines as marketed by reputable refiners. Good,

fresh gasoline of the correct octane for the particular model

engine should be used; the correct grade for each model

Opefating hstfucth Pm00 11

is shown in the data section for current models (page

S-2) on tinted paper at center of book. Good gasolines are

processed against gum forming tendencies even whon

subjected to long time storage. Some gasolines form gum

deposits rather quickly; these deposits appear as a jelly-

like coating within the copper fuel tanks; they are also

observed as a whitish precipitate in the fuel lines, also in

carburetor float bowls and jets, which deposits impair or

restrict fuel flow. This gum-forming tendency with at-

tendant deposit can also contribute to impaired operation

of engtne intake valves. Where the boat is to be out of

commission for 30 days or more. drain the fuel tanks, fuel

linem, fuel pump and the carburetor as a precaution

against possible gum forming deposits within these parts.

Use good gasolino muppliod by a reputable fuel marketer, a

gasolino of the required octane value am prescribed for your

Graymarine engine.

On brand new steel tanks, the first fill of gasoline will often

carry off rust-inhibitor coatings, flux and other matter

which will bo detrimental to the carburetor. Thorofore, we

suggest the addition of a solvent such as Siloo, Casito, or

equivalent, in new tanks.

MOTORBOAT FUELING INSTRUCTIONS

(Issued by the United Staterr Court Guard)

1. Fuel tanks should be properly installed and vonted.

2. Fueling should be completed before dark except in

l mergenciu.

3. Whenover boat is moored at service l tation for fueling:

(a) Do not mmoke. strike matches, or throw switchem.

(b) Stop all engines, motors, fans, and dovices liable

to produce mparkm.

(c) Put out all lights and galley fires.

4. Before mtarting to fuel:

(a) See that boat is moored securely.

(b) Close all ports. windows, doors and hatohr.

(c) Aaoertain dofinitoly how much additional fuel the

tanks will hold.

5. During fueling :

(a) Keep nosxlo of hose or can in contact with fill

opening to guard againmt ponible static spark.

(b) See that no fuel spills got into hull or bilges.

6. After fumling is completed :

(a) Close El1 openingm.

(b) Wipe up a11 spilled fuel.

(c) Open all ports, windows, doors and hatches.

(d) Permit boat to ventilate for at least 5 minutes.

(e) See that there is no odor of gasoline in the l ngtne

room or below decks beforo l tartfng machinq or

lighting fire.

(f) Be prepared to cast off moorings as soon a engine

l tartm.

rag* 12 G faymarhe Gasohe Engines

ENGINE INSTALLATION

Proper installation is a condition of the Gray Warranty. This

brief section is included to give emphasis to some essential details,

because a high percentage of service troubles are caused by

faulty installation.

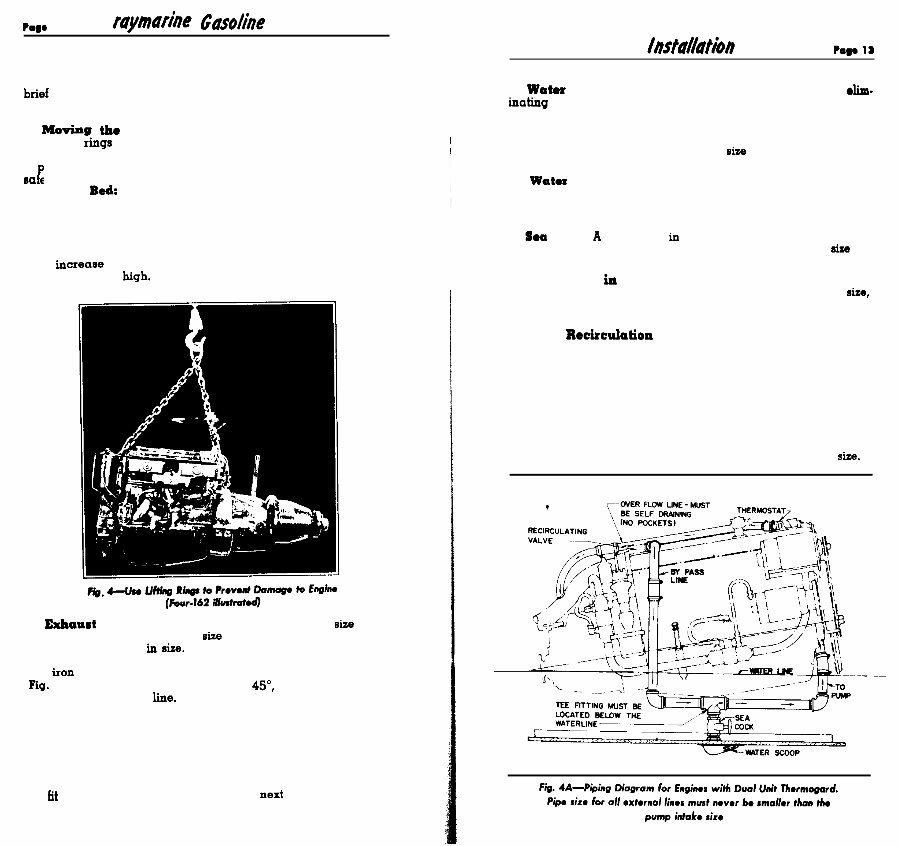

1. Moving tie Engine: The engine is fitted with either one or

two lifting rings designed to carry the full weight of the engine,

therefore auxiliary slings are not required or desired. Never try

to

so ely, and may damage accessories. P

ut a sling around the engine, as this will not hold the engine

2. Engine Bedr This should always be of sufficiently heavy

section to insure rigidity, and well secured to the hull. Maximum

operating angle of the engine at full speed, as mounted on this

bed should not exceed 16 degrees from water level, because at

a higher angle the lubricating oil pick-up screen may not be

fully submerged (see Fig. 10, page 21). Remember that the angle

may increase if the boat is loaded deeply at the stern and the

bow is light and high.

3. Exkaurt Piping: This must never be reduced in sire at any

point smaller than the flange size supplied on exhaust manifold.

It may be increased in sise. Use standard pipe and fittings only,

or tubing of equal or larger inside diameter than the correspond-

ing iron pipe sire. Do not use “street ells” for connections (see

pig. 5). No bends should be more than 45”, and all exhaust exits

must be above water line. For most installations, all of the dis-

charged cooling water can be carried by the tailpipe., Water

MUST enter exhaust pipe at a point lower than exhaust mani-

fold, preferably 6 to 8 inches from flange, so that there will be

no danger of any water getting back through the exhaust valves,

regardless of boat’s pitch. Water stream should enter exhaust

flow diagonally; not at right angle. We recommend the use of a

Graymarine water-cooled elbow at this point, available in sizes

to fit all engine models. (See diagram next page).

4. Watox Piping: Use standard pipe and fittings only, eltm-

inattng all “street ells” which impose a restriction on the flow

(refer to Fig. 5). Connect sections with hose over pipe and hose

clamps for vibration joints. IMPORTANT: Intake piping to water

pump should never be smaller than the I.P.S. of intake fitting on

pump. We recommend using nest pipe size larger than intake of

pump for free flow. Avoid sharp bends.

5. Water Intake Scoop: Through-hull fitting should always be

one size larger than the pump intake sire. Locate the scoop so

that the intake pipe to pump will be as short and straight as

possible. Bends reduce flow and add to load on pump.

6. Soa Cock: A gate valve in water intake pipe is desirable but

not essential. It must be of free tlow type and of sufficient sise to

prevent any restriction to flow.

7. Check Valve in Water Intake Line: When this is an item

of the installation use valve one size larger than intake pipe sise,

reducing to intake pipe size with bushings, to provide adequate

flow area.

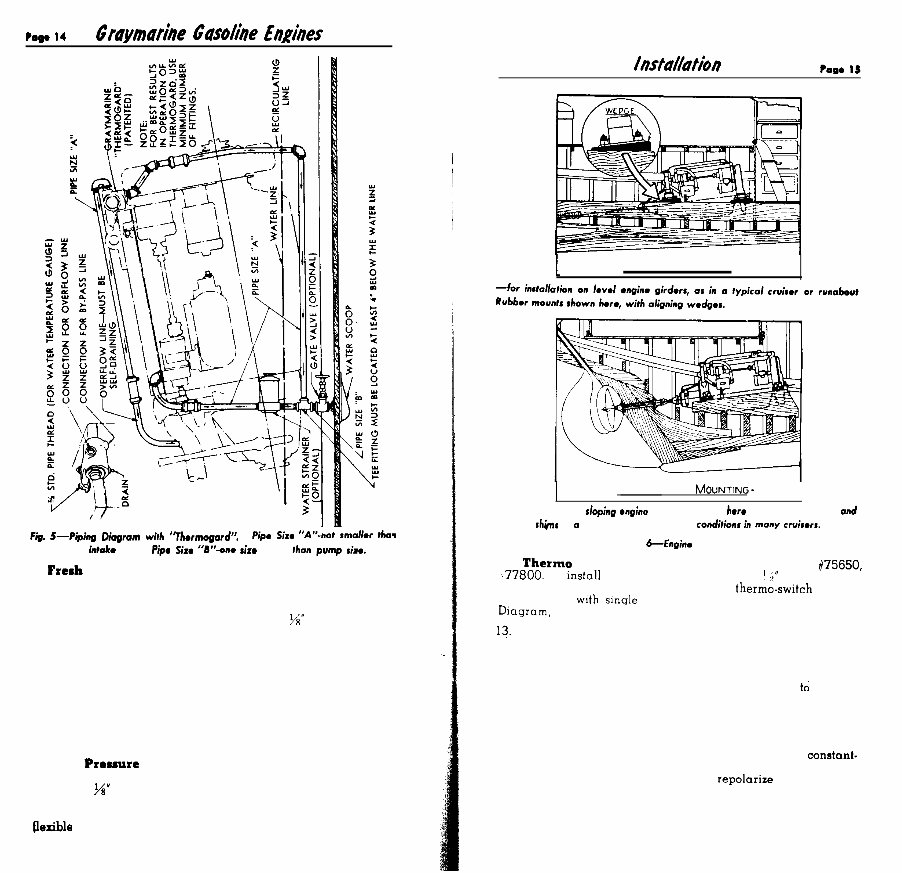

8. Water Recixculation Line: All current models of engines

up to and including those with piston displacement of 226 cu. in.

use a dual unit Thermogard temperature control system with

choke-type thermostat at the outlet to overflow line, and a

pressure valve at the outlet for the recirculation line, piping for

which is shown in Fig. 4h. Larger engines use a single unit

Thermogard valve, shown in Fig. 17, to be piped as shown in

Fig. 5. In both types note that the T-fitting for recirculation line

MUST be located below the load-water-line of boat. It is important

that no restrictions of any kind exist in the recirculation line or the

overflow line. Neither must be smaller than pump intake size.

Pmp. 14 Graymarrie Gasolrire E&/ires

Ffg. 5-Pbfng Diagram with ‘Thermogord”.

Pipe Size “A’‘-not smollw thwa

pump intake size. Pfpo Size ‘W-one sfza larger then pump sire.

9. Fresh Water Cooling System: For engines with this equip-

ment, we insist upon use of a heat exchanger unit approved for

adequate size and proper design. Units supplied by Gray Marine

Motor Company will give perfect service because they are en-

gineered to fit the engine. CAUTION: Remove W” pipe plug vent,

in pump-to-manifold pipe, when filling the system with coolant.

See pages 23-30.

10. Fuel Tubing: Size must not be smaller than the size indi-

cated by the tube nut on fuel pump fitting supplied with engine.

A flexible section of sufficient size is desirable between the fuel

line and fuel pump, or a loop in the tubing may be provided to

prevent breakage due to vibration and strains.

Note: On twin engine installations, if you do not have two gas

tanks, be sure to run a separate line from the tank to each

engine-not through a header line.

11. Oil Prerrure Tube to oil pressure gauge on instrument

panel is connected to a brass fitting on carburetor side of cylinder

block. Use W” tubing, anchored with tape to prevent chafing, and

with a loop in the tubing at engine end to prevent metal fatigue

from normal engine movement. On rubber mounted engines, use

flexible tubing or a flexible section at engine end.

1

A NGLE M OUNTING

I

H ORIZONTAL MOUNTING-

I

-for installation on sloping engino beds, as shown here using solid mounts and

aligning shims in Q typical auxiliary. Similar condffions in many crvisws.

Fig. 6-Fnginm Mounts

12. Therm0 Switch (supplied with Instrument Panels #75650,

z.77800. To mstall this, remove pipe plug from J 5” I.P.S. threaded

hole at front end of cylinder head. Insert thermo-switch element,

and connect with smgle wire to instrument panel. See Wiring

Diagram, page S-6.

13. Tachometer Cable (supplied only with instrument panel).

Connect from instrument panel to fitting on side of reverse gear

housing on most models. Note: on some models this connection

is located in center of cylinder head.

14. Electrical Connections: Follow wiring diagram to conform

to type of generator on engine (pgs. S-6-S-1 1) and use wire sizes

no smaller than those ‘indicated. Solder all connections. Locate

battery as close to engine as possible, with short cable, not

smaller than No. 0. For ground connections, see page S-5.

15. Voltage Regulator (supplied for engines with constant-

voltage generator.) This should conform to ground polarity (see

page S-5). After wiring is completed, repolarize the generator

(instructions are on page S-8). NEVER polarize an alternator.

16. Propeller Size: Final selection of propeller should be size

which will permit the engine to turn close to its maximum rated

rpm. Tables of suggested propeller sizes are on pages 74-75.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

Viewed 42 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

Get access to comprehensive maintenance and service manuals for Gray Marine vintage Chris Craft engines. These manuals cover 4 and 6 cylinder gasoline engines from 1939 onwards, providing valuable technical information for professional mechanics and DIY enthusiasts alike.