Beta 10 BZ482 Beta 16 BD722 and Beta 25 Marine Engine Complete Workshop Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Operator’s

Maintenance

Manual

CALIFORNIA – Proposition 65 Warning: Diesel engine exhaust and some of its constituents are known to

the state of California to cause cancer, birth defects and other reproductive harm.

Heat

Exchanger

and Keel Cooled

Small Diesel Engine Range: Beta 10,

BZ482, Beta 16, BD722 & Beta 25

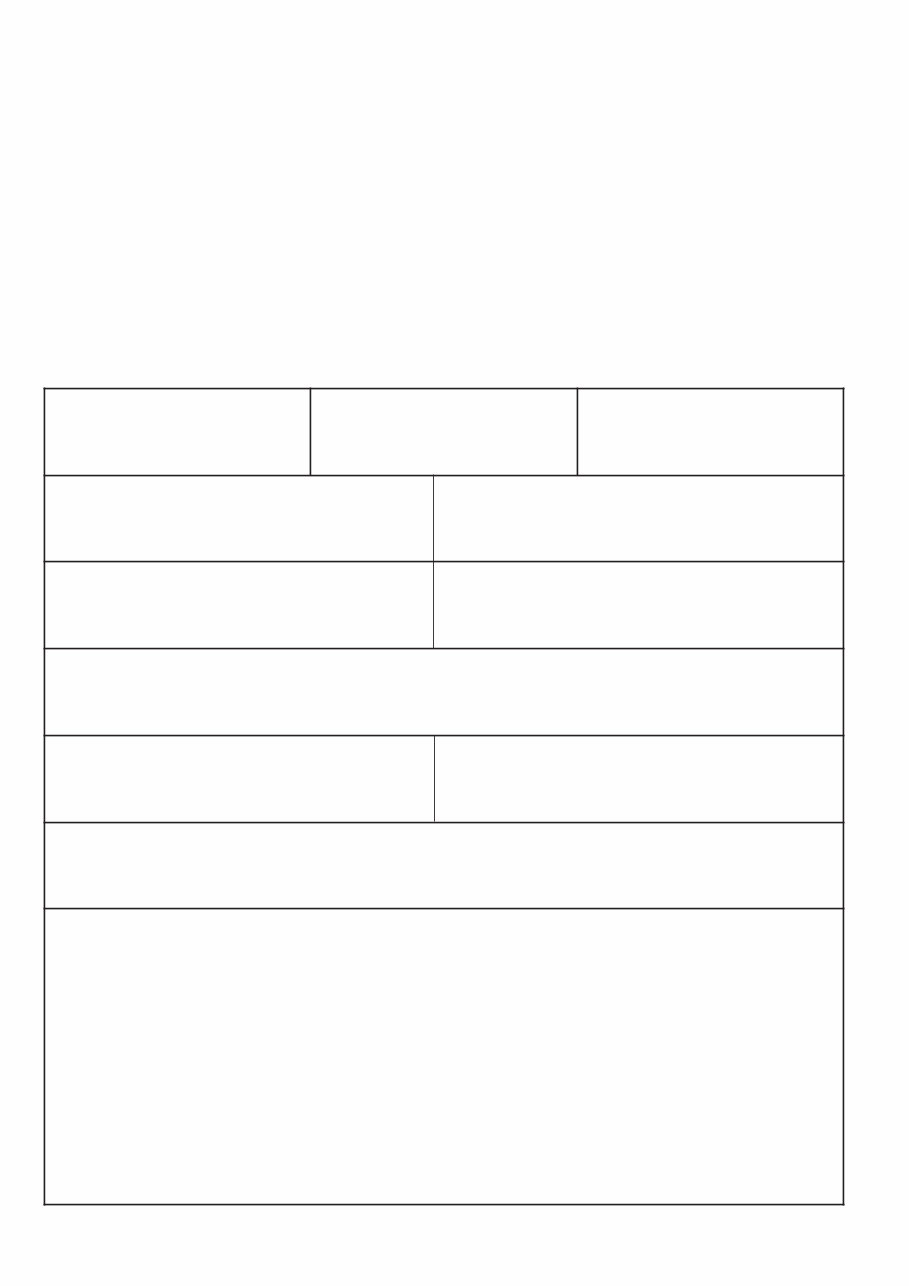

Engine Details

Engine Type: Power: bhp Speed: rpm

BETA WOC NO: K

Gearbox Type:

Purchased from:

Invoice No:

Date Commissioned:

Specification / Special Details

IMPORTANT – Please fill in details at moment of purchase – it really will

help you! (and it will really help us specify the correct spare parts for you).

1

INTRODUCTION 2

Engine Identification 2

Initial Receipt of the engine 2

Engine Storage 2

SAFETY PRECAUTIONS 3

TECHNICAL SPECIFICATIONS 4

SECTION 1: GUIDELINES FOR OPERATION OF ENGINE

Important checks prior to initial use 5

Initial Start-up and Bleeding The Fuel System 5

Starting/Stopping 6

SECTION 2: MAINTENANCE AND SERVICE GUIDELINES

Maintenance Schedule: 7

Lubrication – Checking and changing oil 8

Fuel System - Pumps, Filter, fuel/water separator 9

Cooling - Fresh water system, Keel Cooling, Heat Exchanger 10

Sea Water Pump, Heat Exchanger 12

Belt Tensioning 13

Air Filter 13

Electrical 14

Laying up - Winterising 14

Troubleshooting 15

Torque Settings 26

SECTION 3: INSTALLATION GUIDELINES

Engine Mounting 27

Alignment - Drives, Flanges, Flexible Drives 27

Exhausts & Bends 28

Mounting Exhausts 28

Fuel Supply 29

Cooling 30

Calorifier System 31

Electrical installations 32

Appendices –wiring diagrams and general arrangements 32

Component identification at rear of manual. 63

Maintenance Record 65

Contents

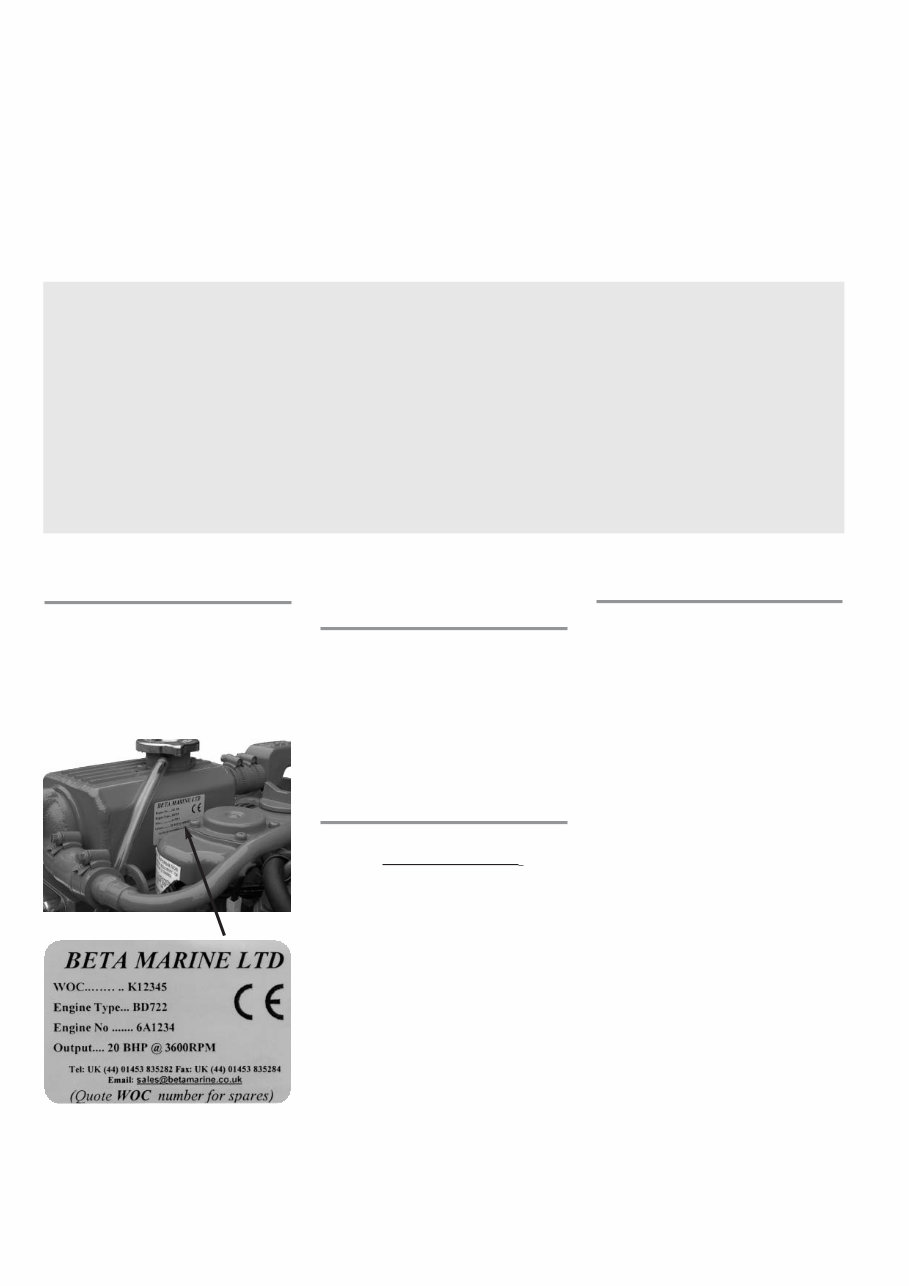

ENGINE IDENTIFICATION

NOTE: In all communications with

the distributor or Beta Marine, the

engine number, type, and W.O.C.

number must be quoted.

BETA 10, BZ482, BETA 16,

BD722 & BETA 25

The engine serial number is stamped

above the fuel lift pump on the

starboard side of the engine, and is

shown on the rocker cover label.

INITIAL RECEIPT

OF THE ENGINE

A full inspection of the engine must

be made immediately on delivery to

confirm that there is no damage. If

there is any damage then write this

clearly on the delivery note and

inform your dealer or Beta Marine

within 24 hours.

ENGINE STORAGE

The engine must be stored in a dry,

frost free area and this is best done in

its packing case. If storage is to be

more than six months then the

engine must be inhibited (contact

your dealer or Beta Marine). Failure

to inhibit the engine may result in the

formation of rust in the injection

system and the engine bores, this

could invalidate the warranty.

OPERATION AND MAINTENANCE MANUAL FOR THE FOLLOWING

BETA MARINE ENGINES BASED ON KUBOTA MINI SERIES

Beta 10, BZ482, Beta 16 (BZ602),

BD722 & Beta 25 (BD902)

2

This manual has been compiled to

provide the user with important

information and recommendations

to ensure a trouble free and

economical operation of the

engine.

For further advice or technical

assistance, application should be

made to BETA MARINE LIMITED

or its distributors.

All information and

recommendations given in this

publication are based on the latest

information available at the time of

publication, and are subject to

alteration at any time. The

information given is subject to the

company’s current conditions of

Tender and Sale, is for the

assistance of users, and is based

upon results obtained from tests

carried out at the place of

manufacture and in vessels used

for development purposes. We do

not guarantee the same results will

be obtained elsewhere under

different conditions.

SAMPLE

3

A Keep the engine, gearbox

and surrounding area clean,

including the area immediately

below the engine

B DRIVES - Power Take Off

Areas

i) Gearbox Output Flange

The purpose of a marine diesel

propulsion engine is to provide

motive power to propel a vessel.

Accordingly the gearbox output

shaft rotates at between 300 and

2400 rev/min. This flange is

designed to be coupled to a

propeller shaft by the installer and

steps must be taken to ensure

adequate guarding.

ii) Forward End Drive

Engines are supplied with

unguarded vee belt drives to

power the fresh water pump and

battery charging alternator. The

installer must ensure that it is not

possible for injury to occur by

allowing accessibility to this area

of the engine. The three pulleys

run at high speed and can cause

injury if personnel or clothing

come in contact with the belts or

pulleys, when the engine is

running.

iii) Power Take Off Shaft

(Engine Mounted Option)

Shaft extensions are available as

an option and rotate at between

850 and 3600 rev/min. If

contact is made with this shaft

when the engine is running, injury

can occur.

C EXHAUST OUTLET

Diesel marine propulsion engines

emit exhaust gases at very high

temperatures - around 400-

500°C. Engines are supplied with

either wet exhaust outlet (water

injection bend) or dry outlet (dry

exhaust stub) - see option list. At

the outlet next to the heat

exchanger/header tank, the

exhaust outlet can become very

hot and if touched, can injure.

This must be lagged or avoided by

ensuring adequate guarding. It is

the responsibility of the installer to

lag the exhaust system if a dry

system is used. Exhaust gases

are harmful if ingested, the

installer must therefore ensure that

exhaust lines are lead overboard

and that leakage in the vessel

does not occur.

D FUEL

i) Fuel Lines

Diesel engines are equipped with

high pressure fuel injection

pumps, if leakages occur, or if

pipes fracture, fuel at a high

pressure can harm personnel.

Skin must be thoroughly cleaned

in the event of contact with diesel

fuel.

ii) Fuel Supply Connections

Engines are supplied with 8 mm

compression fittings. The installer

must ensure that when

connections are made, they are

clean and free of leaks.

E OIL

The Beta propulsion is supplied

with 2 dipsticks, one for the

engine and one for the gearbox.

Ensure dipsticks are returned and

secure after checking, if not oil

leaks can cause infection when

touched. All oil must be removed

from the skin to prevent infection.

F SCALDING

An engine running under load will

have a closed circuit fresh water

temperature of 85° to 95°C. The

pressure cap on the top of the

heat exchanger must not be

removed when the engine is

running. It can only be removed

when the engine is stopped and

has cooled down.

G TRANSPORTATION/LIFTING

Engines are supplied on

transportable pallets. Lifting eyes

on engines are used for lifting

engine and gearbox assembly

only, not the pallet and

associated kit.

GENERAL DECLARATION

This machinery is not intended to

be put into

service until it has been

incorporated into or with other

machinery. It is the responsibility of

the purchaser/installer/owner, to

ensure that the machinery is

properly guarded and that all

necessary health and safety

requirements, in accordance with

the laws of the relevant country, are

met before it is put into service.

Signed:

J A Growcoot, C.E.O,

Beta Marine Limited

NOTE: Recreational Craft

Where applicable, the

purchaser/installer/owner and operator

must be responsible for making sure

that the Recreational Craft Directive

94/25/EC is complied with.

SAFETY PRECAUTIONS!

TECHNICAL SPECIFICATIONS

MINI SERIES – STANDARD ENGINES

Maximum Angle of Installation: Trim 15°, Roll 30° (intermittent)

Rotation: ANTI CLOCK ON FLYWHEEL, CLOCKWISE ON OUTPUT GEARBOX FLANGE FOR USE WITH RIGHT HAND PROP IN AHEAD

Diesel fuel must conform to BS2869-1970 class A1 or A2. The fuel must be a distillate, and not a residual oil or blend.

Lubricant: Engine - Engine oil must meet MIL-L-2104C (see section 2 for details)

Gearbox - see operator’s manual for the gearbox oil type and capacity

Oil pressure – minimum (tickover) 0.5 bar

Power outputs: These comply with BS EN ISO 8665:1996 crankshaft power

Note: Declared Powers to ISO8665:1995

1. The declared powers are at the same engine speed as the ISO 3046 figures. This speed is the speed related to the outputs / powers shown.

2. Declared powers are at the gearbox coupling (coupling to the propeller shaft) as per clause 3.2.1 with standard specifications as per our current price lists.

Additional accessories or alternative gearboxes may affect the declared powers.

3. Operation at parameters outside the test parameters may affect the outputs / powers which in any case are subject to the ISO tolerance bands.

4

BETA 10 BZ482 Beta 16 BD722 Beta 25

Cylinder 2 2 2 3 3

Bore (mm) 67 67 72 67 72

Stroke (mm) 68 68 73.6 68 73.6

Displacement (cc) 479 479 599 719 898

Combustion 3 Vortex E-TVCS

Cooling Water

Starter voltage (V) 12

Starter output (kW) 0.8

Starter alternator output (Amps) 40 (standard)

Glow plug resistance (each) 1Ω

Engine speed (RPM) 3,000 3,600

Power output to ISO3046 (BHP) 10.0 13.3 16.7 20.0 24.8

Declared power ISO8665 (kW) 7.4 8.7 11.0 13.1 16.3

Fuel timing BTDC 21°

Capacity of standard sump approx (litres) 2.0 - 2.5 2.4 - 2.9 3.1 - 3.8 3.7 – 4.5

Capacity of shallow sump approx (litres) 2.2 2.6 3.4 3.8

Nett dry weight with gearbox (kg) 87.2 94.1 101.7 110.6

Fuel Diesel oil class A1 / A2

Coolant 33%-50% maximum antifreeze / water

Coolant capacity approx (H/E litres) 2.25 3.00 3.25

Min. recommended battery capacity 12V, 40Ah 12V, 75Ah

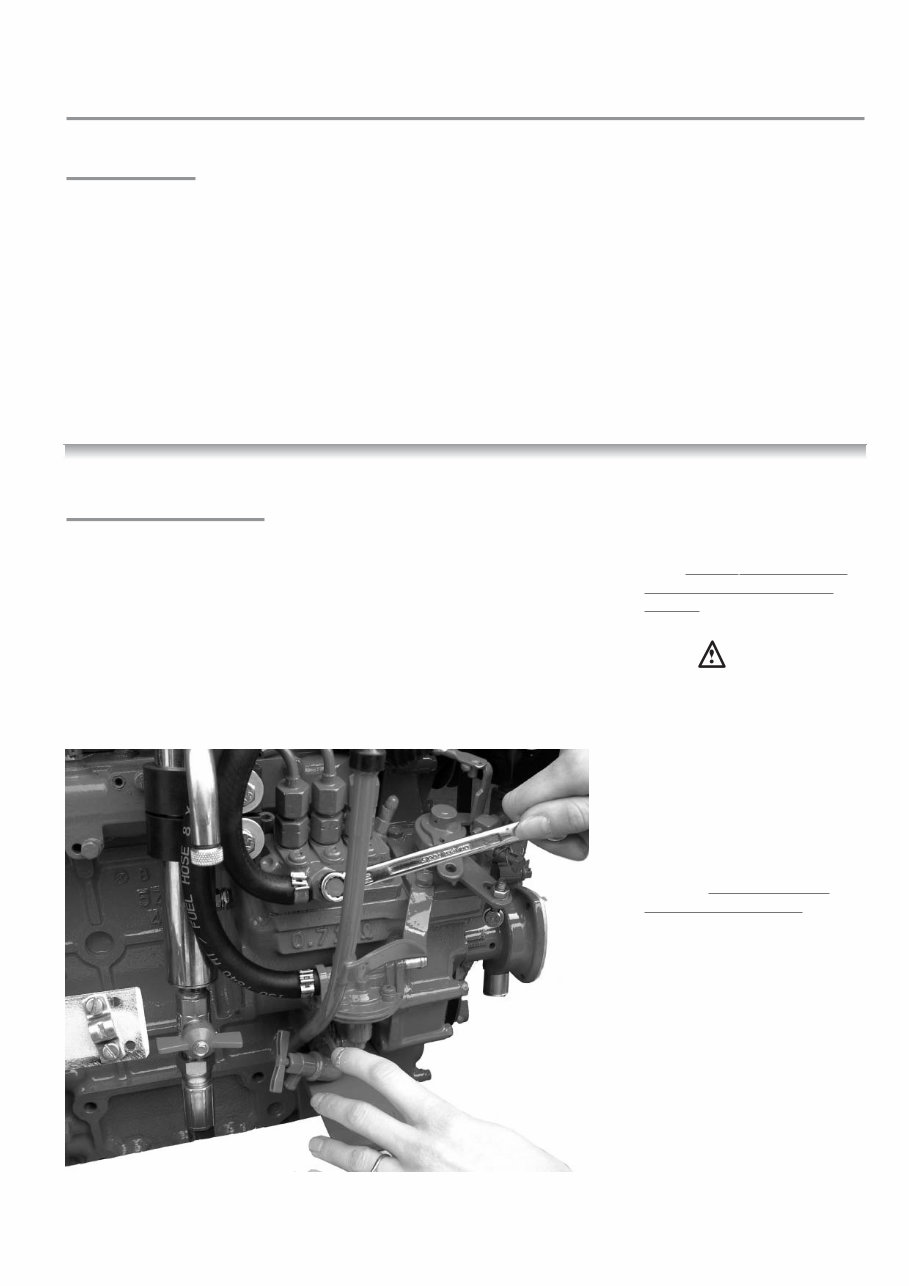

INITIAL STARTUP AND

BLEEDING THE SYSTEM

(a) Open fuel bleed screw on

injection pump by 1

1

/2 turns. See

diagram 1a.

(b) Move hand priming lever on fuel

lift pump up and down until fuel

with no bubbles comes out of the

bleed screw.

(c) Shut/tighten the bleed screw.

Clean area thoroughly with tissue

paper.

(d) Continue to hand prime for 30

seconds to push fuel through the

fuel pump.

(e) Start engine (see normal starting).

Note the engine may have to be

turned over with the starter for a

few seconds before it fires. Do

not run the starter for more than

20 seconds. If the engine has not

started after 20 seconds then

disengage the starter and

continue to hand prime for a

further 30 seconds, then repeat.

(f) If engine does not start after 3

attempts then allow 5 minutes for

the starter to cool down before

repeating (a) to (e).

Note: The star ter windings can

be burnt out with continuous

cranking

CAUTION

To avoid personal injury:

• Do not bleed a hot engine as this

could cause fuel to spill onto a hot

exhaust manifold creating a danger

of fire.

• Do not mix gasoline or alcohol

with diesel fuel. This mixture can

cause an explosion.

• Do not get diesel on the flexible

mounts – they will deteriorate

rapidly if soaked in diesel .

• All fuel must be removed from skin

to prevent infection.

5

Diagram 1a

SECTION 1

GUIDELINES FOR OPERATION OF ENGINE

IMPORTANT CHECKS PRIOR

TO INITIAL USE

1. Generally, a new engine has the

oil and anti-freeze removed after

the works test. Fill the engine

with the correct oil and anti-

freeze (see sections on ENGINE

OIL and COOLING). Check

gearbox oil level - see separate

operator’s hand book.

2. Ensure the engine is free to turn

without obstructions.

3. Ensure battery is fully charged

and connected (the isolator is in

the ‘ON’ position).

4. Ensure Morse speed and gearbox

cables are fitted correctly and that

cable travel lengths are correct.

Gear selection lever –all

mechanical gearboxes: care must

be taken to ensure that the

remote control cable is adjusted

so that the selector lever on the

gearbox moves FULL travel and

brought “hard up” against its end

stop in both directions. Failure to

achieve the correct adjustment

will reduce efficiency of the

clutch and may cause slippage at

low revs. Warranty will not be

accepted on gearboxes returned

in the warranty period for failure

due to incorrect adjustment.

5. Ensure engine is out of gear with

1/3 throttle - see single lever

control instruction manual.

6. Open the fuel stopcock and bleed

the fuel water separator of air as

shown in manufacturers

literature.

7. Fuel should now be at the fuel lift

pump, see diagram 1a.

8. Open the sea cock.

6

STOPPING

Every propulsion engine is fitted with a

stop solenoid which is energised to

stop. To stop engine simply press stop

push button, hold in until engine

stops, then turn key from ‘RUN’ to

‘OFF’ position.

When leaving the boat for an extended

period,

• Turn off sea-cock (heat exchanger

cooled engines).

• Turn off battery isolator.

Do not turn the key to the off

position when the engine is running.

This will not allow the alternator to

charge.

*WARNING

Do not leave the key in ‘HEAT’ position

for more than 15 seconds - this will

damage the heater plugs and eventually

lead to poor starting.

Do not depress stop button for more

than 10 seconds as this will lead to

overheating and failure of the solenoid.

NOTES FOR ALL PANEL TYPES:

Do not depress the stop button for

more than ten seconds as this will

lead to overheating and failure of the

solenoid.

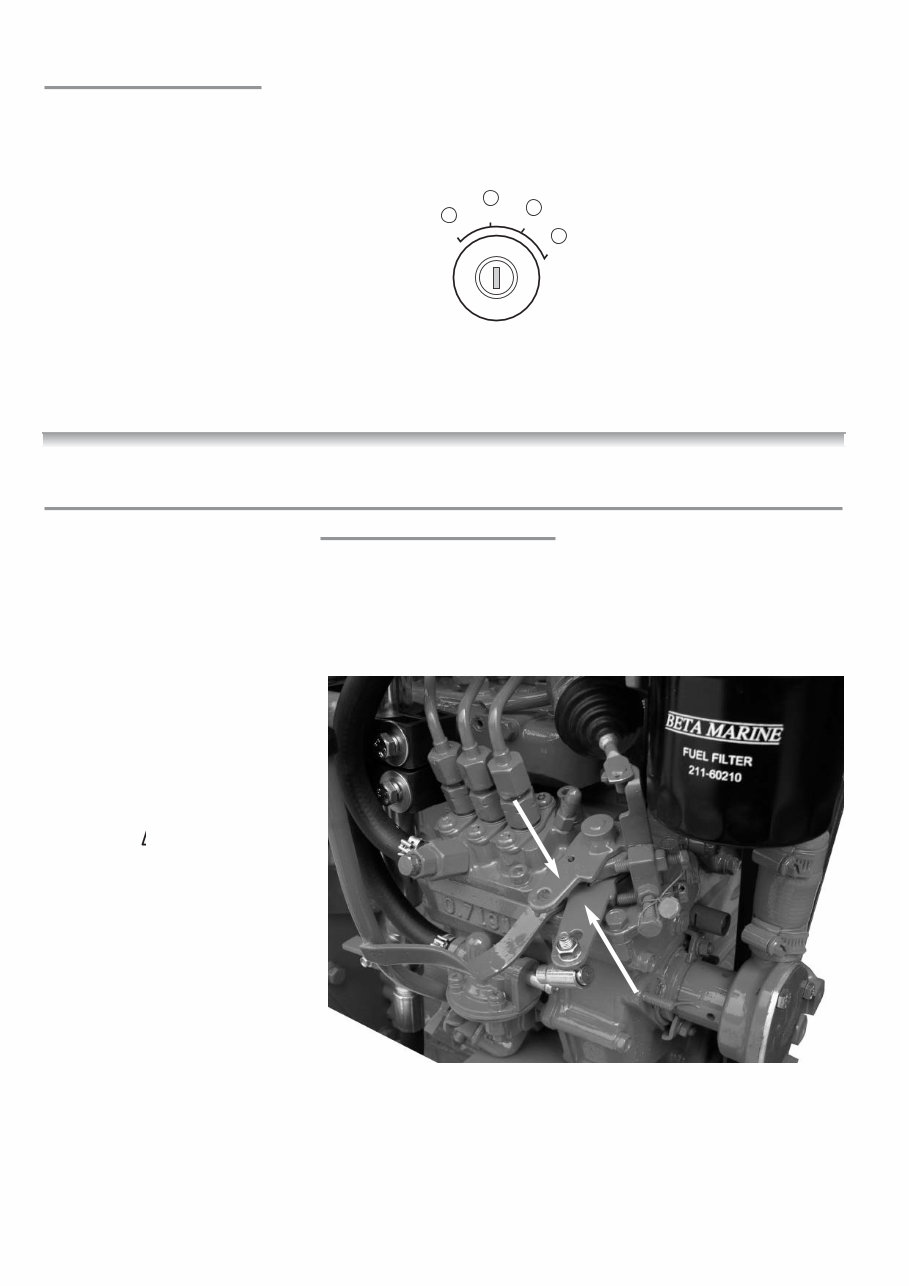

The Mini range of engines are

equipped with a mechanical stop lever

in the event of electrical system failure.

This lever is located on the starboard

side of the engine above the speed

control lever. See illustration below:

Stop lever Stop lever

Speed lever Speed lever

NORMAL STARTING (ALL BETA

PANELS WITH SILVER KEYSWITCH)

With the engine out of gear, set speed

control lever to 1/3 throttle. Turn key

anti-clockwise to HEAT* (A) position

and hold for ten seconds, turn key

clockwise to RUN (C) position. At this

stage the instrument panel should

illuminate, an alarm buzzer will sound

and two (or three*) red warning lights

will illuminate:

STARTER BATTERY CHARGE

DOMESTIC BATTERY CHARGE* (D

in battery symbol - AB & C PANELS

ONLY)

*(Note: this will only illuminate if 2nd

alternator is fitted)

OIL PRESSURE and green POWER

ON / RUN LIGHT (this will stay on)

Turn to START

(D) position and

engine will

motor, hold in

position until

engine fires (see

initial start-up

section for maximum time starter can

be used).

Release key (when engine has started)

to RUN position. Ensure alarm buzzer

is not sounding and that warning

lights are extinguished. If one or both

of the alternator warning lights are still

on, then increase engine speed to

excite the alternator - then return to

idle. The battery charge lights should

then go out. The run light will remain

on (green LED).

Note: for panels without keyswitches

see seperate instruction sheet

(page 24).

RUN

C

START

D

OFF

B

HEAT

A

7

SECTION 2

MAINTENANCE SCHEDULE

DAILY OR EVERY 8 HOURS

RUNNING

• Check engine oil level.

• Check gearbox oil level.

• Check coolant level.

• Check battery fluid.

• Check drive belt tension

• Ensure raw water inlet strainer is

clear.

• Check stern gland lubrication.

• Drain off any water in fuel water

separator.

AFTER THE FIRST 25 HOURS

RUNNING

• Change gearbox lubricant (See

separate gearbox manual).

• Check that all external nuts, bolts

and fastenings are tight. See table

for torque values. Special attention

should be paid to the flexible

mount lock nuts, these should be

checked for tightness, starting

with lower nut first in each case.

If the lower nuts are found to be

very loose, then the alignment of

the shaft to the gearbox half

coupling should be re-checked.

Poor alignment due to loose

flexible mount nuts will cause

excessive vibration and knocking.

• Check the belt tension on any

second alternators fitted and

adjust –see page 11

• Check ball joint nyloc nuts for

tightness on both gearbox and

speed control levers. Grease both

fittings all over.

AFTER FIRST 50 HOURS

• Change engine lubricating oil.

• Change oil filter.

• Check for leaks on header tank

tubestack. Tighten end cap bolt if

required.

• Drain off any water in fuel/water

separator.

EVERY 150 HOURS

• If shallow sump (option) is fitted,

change engine lubricating oil and

filter.

EVERY YEAR -OR EVERY 250

HOURS IF SOONER

• Change engine lubricating oil

(standard sump)

• Change lubricating oil filter

• Check air cleaner element

• Check sea water pump impeller

and change if worn.

• Check wasting anode condition,

replace when necessary. In some

environments this may be 6

montly or less.

• Remove heat exchanger tube

stack, by undoing the bolt each

end of the tube stack. Remove

end cover, pull out tube stack and

clean. Replace rubber ‘O’ rings

and re-assemble. Immediately

engine is started check for leaks.

• Spray the key switch with WD40

or equivalent to lubricate the

barrel.

• Check that all external nuts, bolts

and fastenings are tight. See table

for torque values.

• Check ball joint nyloc nuts for

tightness on both gearbox and

speed control levers. Grease both

fittings all over.

EVERY 750 HOURS

• As every 250 hours plus the

following:-

• Change air cleaner element.

• Change fuel filter.

• Change antifreeze.

• Change gearbox oil.

• Check electrical equipment,

condition of hoses and belts,

replace as necessary.

8

Engine oil: Engine oil should be MIL-

L-2104C or have properties of API

classification CC/CD/CE grades. The

following table gives grades of oil

required for various ambient

temperatures.

Note: A good quality 15W/40

mineral or multigrade oil as used in

most diesel car engines will meet

these requirements. Do not use

‘Turbo Diesel Oil’ or additives.

CHECKING ENGINE OIL

LEVEL

For quantities of oil required see

section marked ‘Technical

Specification’, Page 4

When checking the engine oil level,

do so before starting, or more than

five minutes after stopping.

1. To check the oil level, draw out

the dipstick, wipe it clean, re-

insert it, and draw it out again.

Check to see that the oil level lies

between the two notches.

2. If the level is too low, add new oil

to the specified level - Do not

overfill,

IMPORTANT

When using an oil of different make

or viscosity from the previous one,

drain old oil. Never mix two different

types of oil. Engine oil should be

changed after first 50 hours running

time and then every year or every

250 hours if sooner. Oil filter is a

cartridge type mounted on the port

side of the engine.

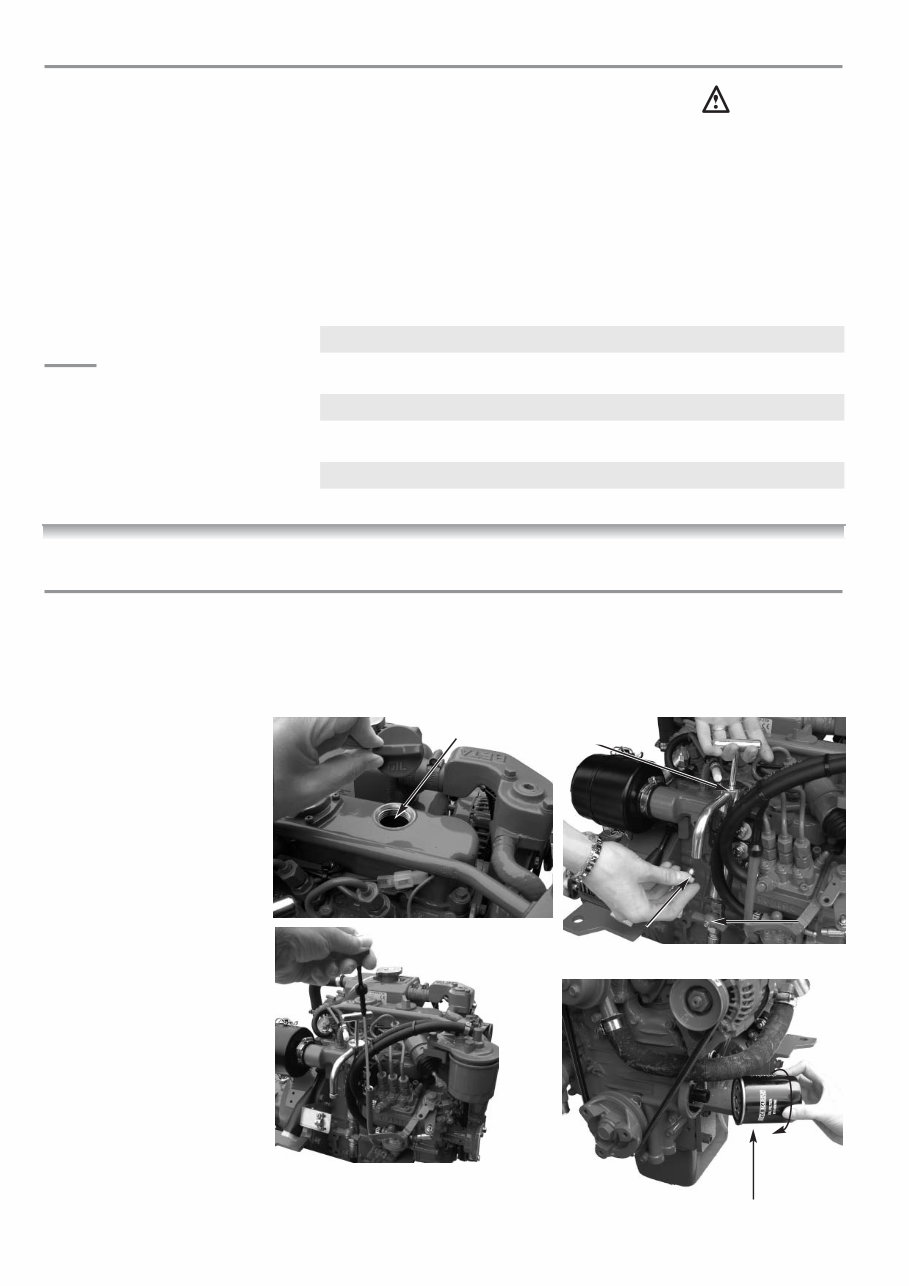

(1) Run the engine for 10 minutes to

warm up the oil.

(2) Your engine is provided with a

sump drain pump (option on

Beta Ten, see note below).

Unscrew the end cap on the

end of the pump (if fitted),

turn the tap to ‘on’. Use the

hand pump as shown to

pump out the oil into a

bucket. Turn the tap to off

position and replace end

cap. See diagram 2c.

(3) Unscrew the oil filter and

replace with a new one. See

diagram 2d.

Note: It is best to have a

plastic bag wrapped round

the filter to catch any oil left

in the system. (Always keep

your bilges clean!) Before

screwing in the new filter

spread a thin film of oil

round the rubber gasket to

ensure a good seal and

screw in – hand tight.

Note: On the Beta Ten not fitted with

a sump drain pump the engine oil

must be drained off by unscrewing

the sump drain plug (see diagram

100-00030 at rear of book). This is

best done with the oil filler cap

removed. Replace the plug and

tighten firmly.

(4) Fill the engine with new oil as

described above.

LUBRICATION

AMBIENT TEMP SINGLE GRADE MULTI GRADE

-30°C TO 0°C SAE 10W S AE 10W/30

-15°C TO +15°C SAE 20W SAE 15W/40

0°C TO +30°C SAE 30 SAE 15W/40

25°C AND ABOVE SAE 30 SAE 15W/40

CHANGING ENGINE OIL

Fig. 2b. Dip stick

Fig. 2a

Oil goes in here

Sump pump

Tap

Oil filter

End Cap

Fig. 2c

Fig. 2d

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

$54.99

Viewed 85 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

$54.99

Beta 10 BZ482 Beta 16 BD722 and Beta 25 Marine Engine Complete Workshop Service Repair Manual

Thanks for taking the time to look at this Complete Service Repair Workshop Manual.

This manual covers every Service & Repair Procedure you will need.

Description:

- You can now save yourself BIG money by doing your own repairs! This manual makes any service or repair job easy to do with very easy to follow step-by-step instructions & pictures on all areas of servicing & repairs.

- Once you have this manual it is yours to keep forever. You can print out one page, chapter or the whole thing. You can also save it to your tablet or smart phone if required.

Models Covered:

- All Models/Engines/Trim/Transmissions Types Are Covered.

Contents:

- This high quality Service Repair Workshop Manual covers all repair procedures A-Z.

- Every repair and service procedure is covered.

Computer Requirements:

- This downloadable Manual will work on All PC & MAC Computers, tablets, mobile phones Etc. The only software needed is adobe reader which in most cases is already loaded onto your computer, if not can be downloaded for free.

Instant Delivery:

- This manual will be instantly emailed to the email address you used when checking out after receiving your payment by Visa, MasterCard or PayPal.

Customer Satisfaction Guaranteed.