Onan P216, P218, P220, P224 Performer Series Full Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

P216, P218

P220, P224

Performer Series

Printed in U.S.A. 965-0762

12-96

Safety Precautions .

It is recommended that you read your engine manual and

become thoroughly acquainted with your equipment before

you start the engine.

This symbol if used warns of imme-

diate hazards which will result in

severe personal injury or death.

1 This symbol refers io a hazard or

LAWARNING unsafe practice which can result in

severe personal injury or death.

This symbol refers to a hazard or

unsafe practice which can result in

personal injury or product or properfy damage.

Fuels, electrical equipment, batteries, exhaust gases and

moving parts present potential hazards that can result in

serious, personal injury. Take care in following these recom-

mended procedures. All local, state and federal codes should

be consulted and complied with.

This engine is not designed or in-

IeWARNiNG’ fendedforuseinanytype ofaircraft.

Use of this engine in aircraft can result in engine failure

and causes serious personal injury or death.

General

0 Provide appropriate fire extinguishersand install them in

convenient locations. Use an extinguisher rated ABC by

NFPA.

0 Make sure that all fasteners on the engine are secure and

accurately torqued. Keep guards in position over fans,

driving belts, etc.

0 If it is necessary to make adjustments while the engine is

running, use extreme caution when close to hot exhausts,

moving parts, etc.

Protect Against Moving Parts

0 Do not wear loose clothing in the vicinity of moving parts.

such as PTO shafts. flywheels, blowers, couplings, fans,

belts, etc.

0 Keep your hands away from moving parts.

Batteries

Before starting work on the engine. disconnect batteries

to prevent inadvertent starting of the engine.

DO NOT SMOKE while servicing batteries. Lead acid

batteries give off a highly explosive hydrogen gas which

can be ignited by flame, electrical arcing or by smoking.

Verify battery polarity before connecting battery cables.

Connect negative cable last.

Fuel System

DO NOT fill fuel tanks while engine is running.

DO NOT smoke or use an open flame in the vicinity of the

engine or fuel tank. Internal combustion engine fuels are

highly flammable.

Fuel lines must be of steel piping, adequately secured,

and free from leaks. Piping at the engine should be

approved flexible line. Do not use copper piping for

flexible lines as copper will work harden and become

brittle enough to break.

Be sure all fuel supplies have a positive shutoff valve.

”

d

Exhaust System

0 Exhaust products of any internal combustion engine are

toxic and can cause injury, or death if inhaled. All engine

applications, especially those within a confined area,

should be equipped with an exhaust system to discharge

gases to the outside atmosphere.

0 Do not use exhaust gases to heat a compattment.

0 Make sure that your exhaust system is free of leaks.

Ensure that exhaust manifolds are secure and are not

warped by bolts unevenly torqued.

Exhaust Gas is Deadly!

Exhaust gases contain carbon monoxide, a poisonous gas

that can cause unconsciousness and death. It is an odorless

and colorless gas formed during combustion of hydrocarbon

fuels. Symptoms of carbon monoxide poisoning are:

0 Dizziness 0 Vomiting

Headache 0 Muscular Twitching

0 Weakness and Sleepiness

If you experience any of these symptoms, get out into fresh air

immediately, shut down the unit and do not use until it has

been inspected.

The best protection against carbon monoxide inhalation is

proper installation and regular, frequent inspections of the

complete exhaust system. If you notice a change in the sound

or appearance of exhaust system, shut the unit down

immediatelyand have it inspected and repaired at once by a

competent mechanic.

0 Throbbing in Temples

Cooling System

.

0 Coolants under pressure havea higher boiling point than

water. DO NOT open a radiator pressure cap when

coolant temperature is above 212OF (100°C) or while

engine is running.

Keep the Unit and Surrounding Area Clean

0 Make sure that oily rags are not left on or near the enginc

0 Remove all unnecessary grease and oil from the unit.

Accumulated grease and oil can cause overheating and

subsequent engine damage and present a potential fire

hazard.

E-6

Table of Contents

TITLE PAGE

General Information ................................................... .I-1

Specifications ........................................................ .2-I

Dimensions and Clearances ........................................... .3-1

Assembly Torques and Special Tools ................................... .4-1

Engine Troubleshooting ............................................... .5-1

Oil System ........................................................... .6-1

Fuel System .......................................................... .7-1

Ignition and Battery Charging .......................................... .8-1

Engine Wiring Diagram ................................................ .8-7

Starting System.. ..................................................... .9-1

Engine Disassembly, ................................................. 10-1

~AWARNING I

EXHAUST GAS IS DEADLY!

Exhaust gases from all fuels (including diesel, gasoline, 1iqu.J propane, natura

gas) contain carbon monoxide, an odorless and colorless gas. Carbonmonoxide

is poisonous and can cause unconsciousness and death. Symptoms of carbon

monoxide poisoning can include:

0 Dizziness

0 Nausea 0 Muscular Twitching

0 Headache 0 Vomiting

0 Weakness and Sleepiness

0 Throbbing in Temples

0 Inability to Think Coherently

IF YOU OR ANYONE ELSE EXPERIENCEANY OF THESESYMPTOMS, GET OUT

INTO THE FRESH AIR IMMEDIATELY. If symptoms persist, seek medical

attention. Shut down the unit and do not operate until it has been inspected and

repaired.

Protection against carbon monoxide inhalation includes proper installation,

ventilation and regular, frequent visual and audible inspections of the complete

exhaust system.

i

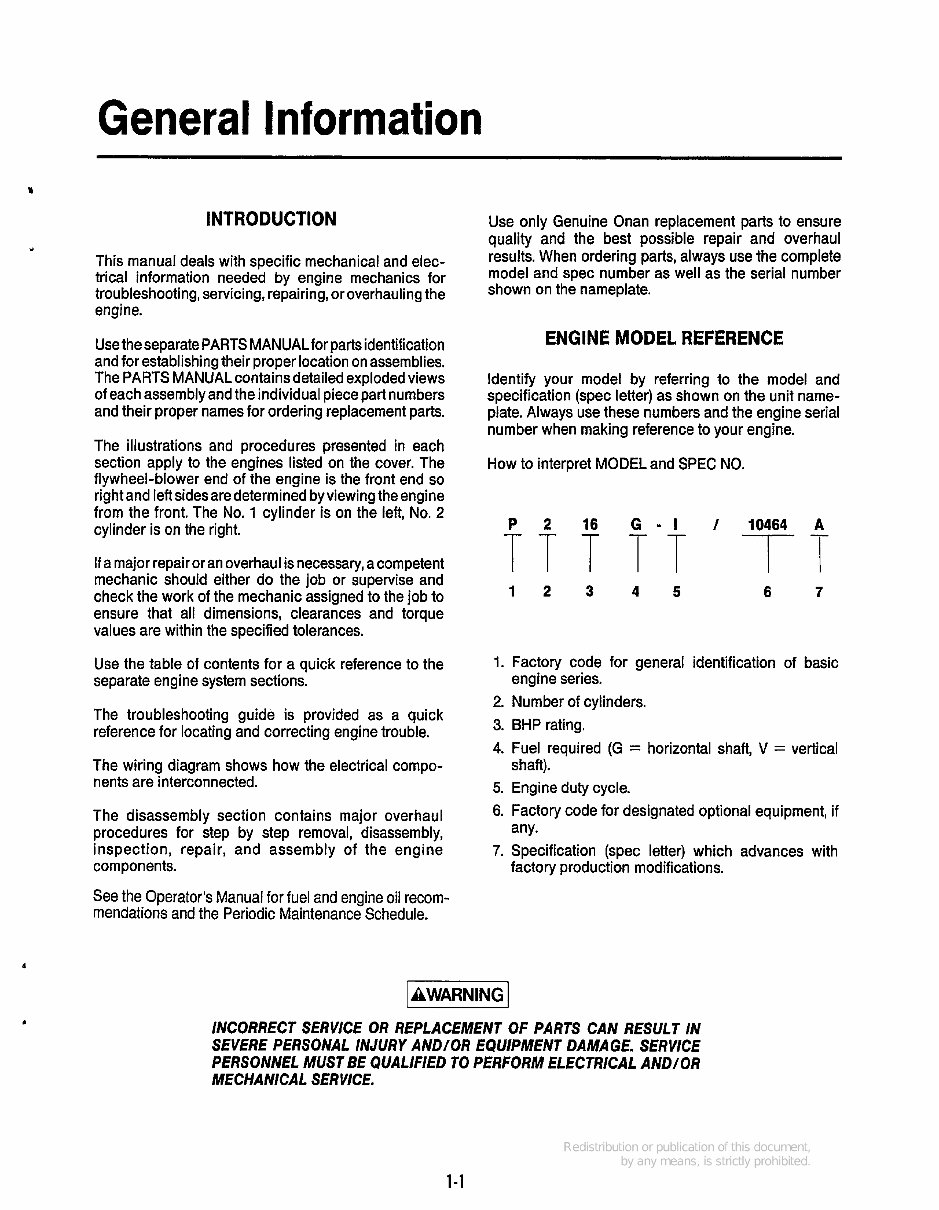

General Information

INTRODUCTION

This manual deals with specific mechanical and elec-

trical information needed by engine mechanics for

troubleshooting, servicing, repairing, or overhaulingthe

engine.

Usethe separatePARTS MANUALfor parts identification

and for establishingtheir proper location on assemblies.

The PARTS MANUALcontains detailedexploded views

of each assembly and the individual piece part numbers

and their proper names for ordering replacement parts.

The illustrations and procedures presented in each

section apply to the engines listed on the cover. The

flywheel-blower end of the engine is the front end so

right and left sidesaredeterminedby viewing theengine

from the front. The No. 1 cylinder is on the left, No. 2

cylinder is on the right.

If a major repair or an overhaul is necessary, a competent

mechanic should either do the job or supervise and

check the work of the mechanic assigned to the job to

ensure that all dimensions, clearances and torque

values are within the specified tolerances.

Use the table of contents for a quick reference to the

separate engine system sections.

The troubleshooting guide is provided as a quick

reference for locating and correcting engine trouble.

The wiring diagram shows how the electrical compo-

nents are interconnected.

The disassembly section contains major overhaul

procedures for step by step removal, disassembly,

inspection, repair, and assembly of the engine

components.

See the Operator’s Manualfor fuel and engine oil recom-

mendations and the Periodic Maintenance Schedule.

Use only Genuine Onan replacement parts to ensure

quality and the best possible repair and overhaul

results. When ordering parts, always use the complete

model and spec number as well as the serial number

shown on the nameplate.

ENGINE MODEL REFERENCE

Identify your model by referring to the model and

specification (spec letter) as shown on the unit name-

plate. Always use these numbers and the engine serial

number when making reference to your engine.

How to interpret MODEL and SPEC NO.

P 2 16 G - I / 10464 A

1.

2.

3.

4.

5.

6.

7.

1 2 3 4 5 6 7

I AWARNING I

Factory code for general identification of basic

engine series.

Number of cylinders.

BHP rating.

Fuel required (G = horizontal shaft, V = vertical

shaft).

Engine duty cycle.

Factory code for designated optional equipment, if

any.

Specification (spec letter) which advances with

factory production modifications.

INCORRECT SERVICE OR REPLACEMENT OF PARTS CAN RESULT IN

SEVERE PERSONAL INJURY AND/OR EQUIPMENT DAMAGE. SERVICE

PERSONNEL MUST BE QUALIFIED TO PERFORM ELECTRICAL AND/OR

MECHANICAL SERVICE.

1-1

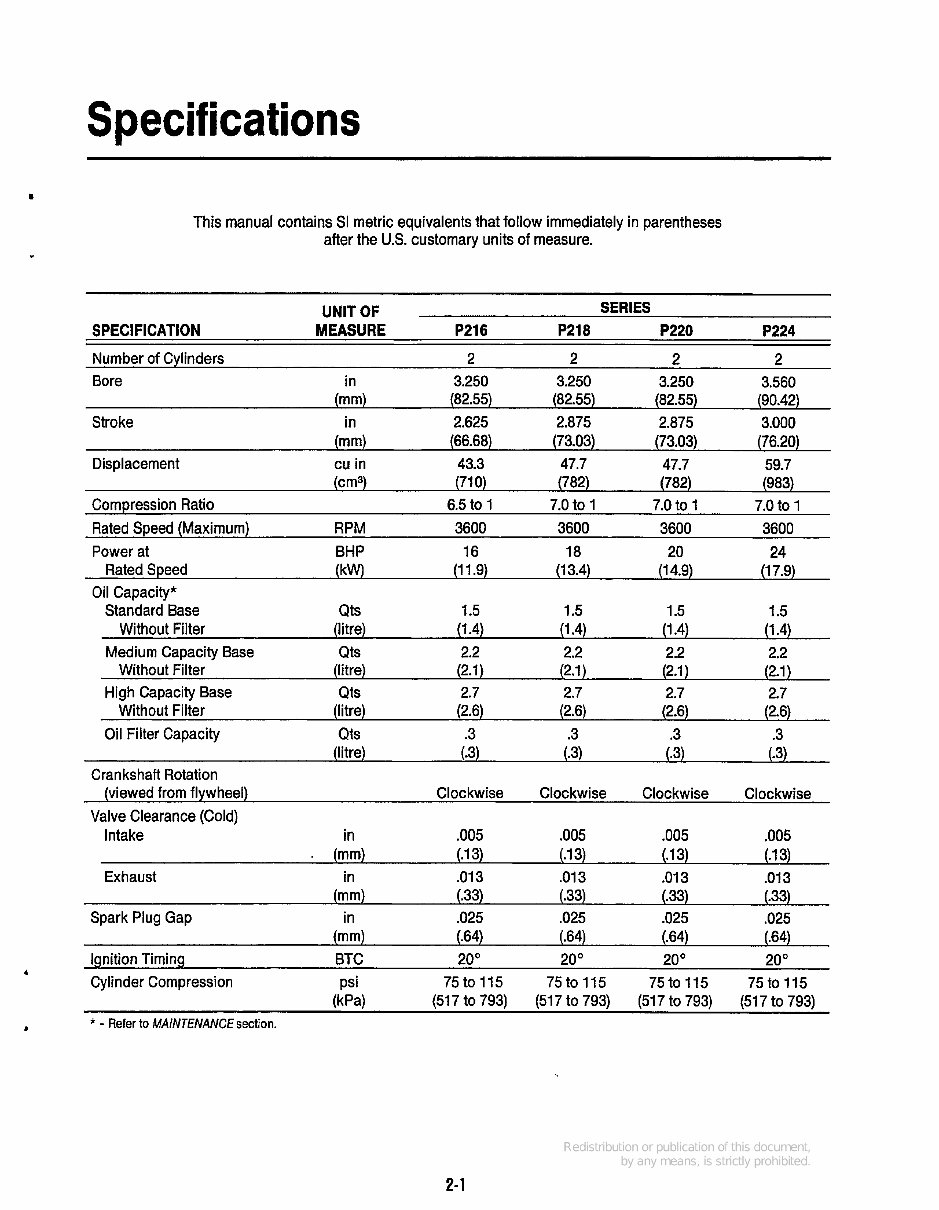

Specifications

This manual contains SI metric equivalents that follow immediately in parentheses

after the US. customary units of measure.

UNIT OF SERIES

4

SPECIFICATION MEASURE P216 P218 P220 P224

Number of Cylinders 2 2 2 2

Bore in 3.250 3.250 3.250 3.560

(mm) (82.55) (82.55) (82.55) (90.42)

Stroke in 2.625 2.875 2.875 3.000

(mm) (66.68) (73.03) (73.03) (76.20)

(cm3) (71 0) (782) (782) (983)

Compression Ratio 6.5 to 1 7.0 to 1 7.0 to 1 7.0 to 1

Rated Speed (Maximum) RPM 3600 3600 3600 3600

Power at BHP 16 18 20 24

Oil Capacity*

Displacement cu in 43.3 47.7 47.7 59.7

Rated Speed (kW) (1 1.9) (13.4) (1 4.9) (1 7.9)

Without Filter (litre) (1.4) (1.4) (1.4) (1.4)

Medium Capacity Base Qts 2.2 2.2 2.2 2.2

Without Filter (litre) (2.1) (2.1) (2.1) (2.1)

Standard Base Qts 1.5 1.5 1.5 1.5

High Capacity Base Qts 2.7 2.7 2.7 2.7

Without Filter (litre) (2.6) (2.6) (2.6) (2.6)

Oil Filter Capacity Qts .3 .3 .3 .3

(litre) (.3) (.3) (.3) (.3)

Crankshaft Rotation

Valve Clearance (Cold)

(viewed from flywheel) Clockwise Clockwise Clockwise Clockwise

Intake in ,005 ,005 .005 ,005

Exhaust in .013 .013 .013 .013

Spark Plug Gap in ,025 .025 .025 .025

(mm) (64) (.64) (.64) (.64)

. (mm) (.13) (.13) (.13) (.13)

(mm) (.33) (.33) (.33) (.33)

Ignition Timing BTC 20" 20" 20" 20"

Cylinder Compression psi 75 to 115 75 to 115 75 to 115 75 to 115

* - Refer to MAlNTENANCE section.

(kPa) (517 to 793) (51 7 to 793) (517 to 793) (517 to 793)

2- 1

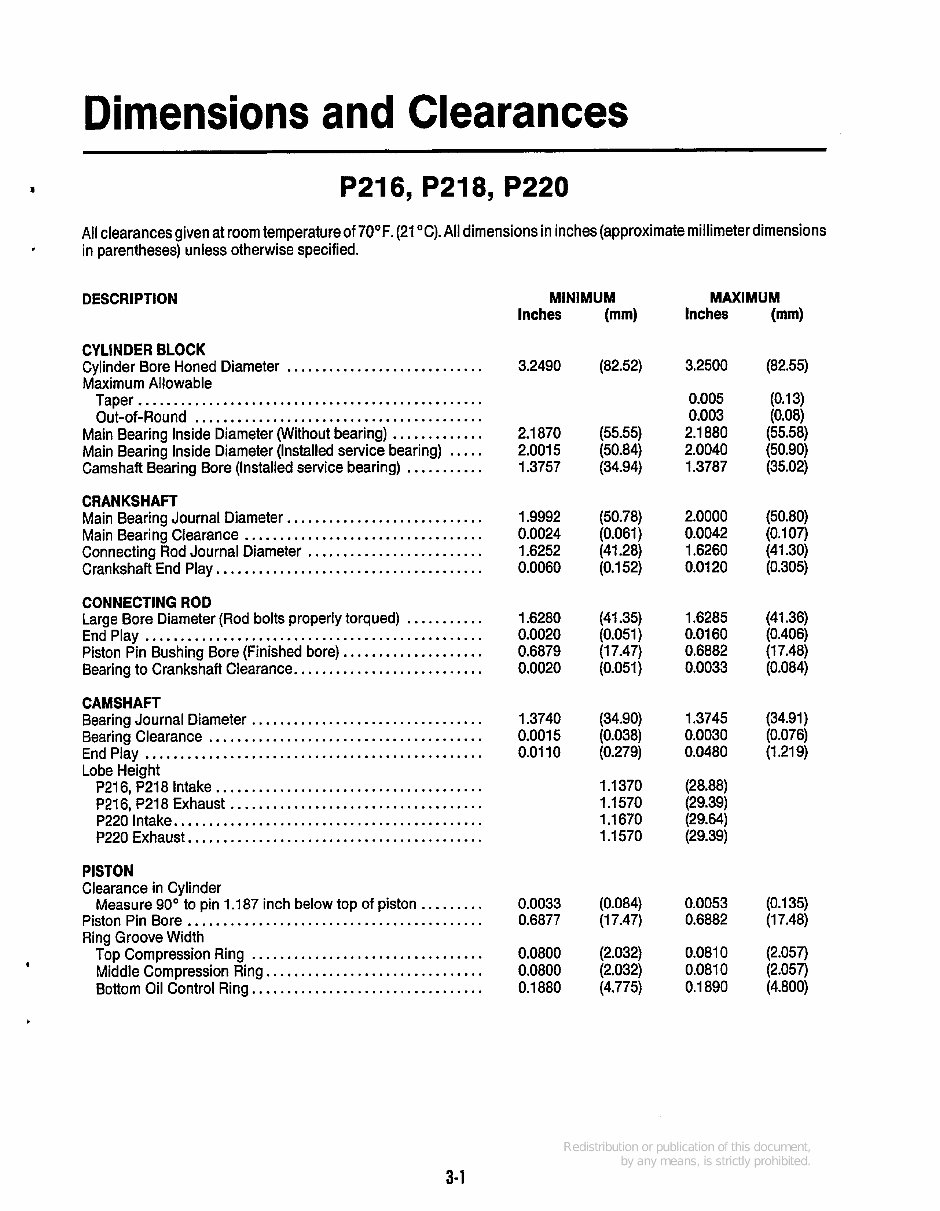

Dimensions and Clearances

I

P216, P218, P220

All clearancesgiven at room temperature of 70°F. (21OC).All dimensionsin inches (approximatemillimeter dimensions

in parentheses) unless otherwise specified.

DESCRIPTION MINIMUM MAXIMUM

Inches (mm) Inches (mm)

CYLINDER BLOCK

Cylinder Bore Honed Diameter ............................ 3.2490 (82.52) 3.2500 (82.55)

Maximum Allowable

Out-of-Round ......................................... 0.003 (0.08)

Main Bearing Inside Diameter (Without bearing) ............. 2.1 870 (55.55) 2.1 880 (55.58)

Main Bearing Inside Diameter (Installed service bearing) ..... 2.0015 (50.84) 2.0040 (50.90)

Camshaft Bearing Bore (Installed service bearing) ........... 1.3757 (34.94) 1.3787 (35.02)

CRANKSHAFT

Main Bearing Journal Diameter ............................ 1.9992 (50.78) 2.0000 (50.80)

Main Bearing Clearance .................................. 0.0024 (0.061) 0.0042 (0.1 07)

Connecting Rod Journal Diameter ......................... 1.6252 (41.28) 1.6260 (41.30)

Crankshaft End Play.. .................................... 0.0060 (0.152) 0.01 20 (0.305)

Taper ................................................. 0.005 (0.13)

CONNECTING ROD

Large Bore Diameter (Rod bolts properly torqued) ........... 1.6280 (41.35) 1.6285 (41.36)

End Play ................................................ 0.0020 (0.051) 0.01 60 (0.406)

Piston Pin Bushing Bore (Finished bore) .................... 0.6879 (17.47) 0.6882 (1 7.48)

Bearing to Crankshaft Clearance.. ......................... 0.0020 (0.051) 0.0033 (0.084)

CAMSHAFT

Bearing Journal Diameter ................................. 1.3740 (34.90) 1.3745 (34.91)

Bearing Clearance ....................................... 0.0015 (0.038) 0.0030 (0.076)

0.0480 (1.219)

Lobe Height

End Play ................................................ 0.0110 (0.279)

P216, P218 Intake.. .................................... 1.1 370 (28.88)

P216, P218 Exhaust .................................... 1.1 570 (29.39)

P220 Intake.. .......................................... 1.1670 (29.64)

P220 Exhaust.. ........................................ 1.1 570 (29.39)

PISTON

Clearance in Cylinder

Measure 90° to pin 1.187 inch below top of piston ......... 0.0033 (0.084) 0.0053 (0.1 35)

Piston Pin Bore 0.6877 (17.47) 0.6882 (1 7.48)

Ring Groove Width

..........................................

Top Compression Ring ................................. 0.0800 (2.032) 0.081 0 (2.057)

Bottom Oil Control Ring. ................................ 0.1 880 (4.775) 0.1 890 (4.800)

*

Middle Compression Ring., ............................. 0.0800 (2.032) 0.081 0 (2.057)

C

3-1

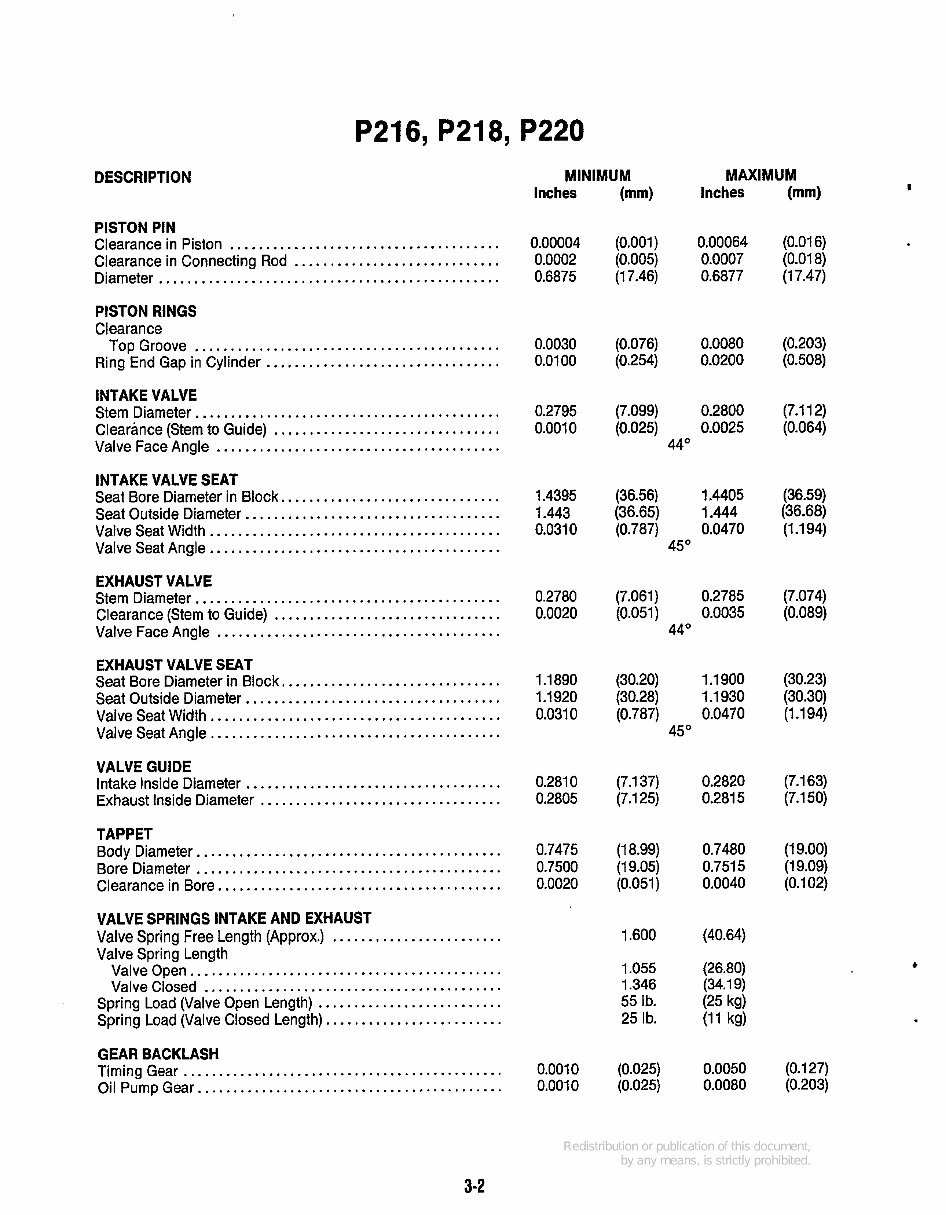

P216. P218. P220

DESCRIPTION

PISTON PIN

Clearance in Piston ......................................

Clearance in Connecting Rod .............................

Diameter ................................................

PISTON RINGS

Clearance

Top Groove ...........................................

Ring End Gap in Cylinder .................................

INTAKE VALVE

Stem Diameter ...........................................

Clearance (Stem to Guide) ................................

Valve Face Angle ........................................

INTAKE VALVE SEAT

Seat Bore Diameter in Block ...............................

Seat Outside Diameter ....................................

Valve Seat Width .........................................

Valve Seat Angle .........................................

EXHAUST VALVE

Stem Diameter ...........................................

Clearance (Stem to Guide) ................................

Valve Face Angle ........................................

EXHAUST VALVE SEAT

Seat Bore Diameter in Block ...............................

Seat Outside Diameter ....................................

Valve Seat Width .........................................

Valve Seat Angle .........................................

VALVE GUIDE

Intake Inside Diameter ....................................

Exhaust inside Diameter ..................................

TAPPET

Body Diameter ...........................................

Bore Diameter ...........................................

Clearance in Bore ........................................

VALVE SPRINGS INTAKE AND EXHAUST

Valve Spring Free Length (Approx.) ........................

Valve Spring Length

Valve Open ............................................

Valve Closed ..........................................

Spring Load (Valve Open Length) ..........................

Spring Load (Valve Closed Length) .........................

GEAR BACKLASH

Timing Gear .............................................

Oil Pump Gear ...........................................

MINIMUM MAXIMUM

Inches (mm) Inches (mm)

0.00004 (0.001) 0.00064 (0.01 6)

0.0002 (0.005) 0.0007 (0.01 8)

0.6875 (17.46) 0.6877 (1 7.47)

0.0030 (0.076) 0.0080 (0.203)

0.01 00 (0.254) 0.0200 (0.508)

0.2795 (7.099) 0.2800 (7.1 12)

0.001 0 (0.025) 0.0025 (0.064)

44O

1.4395 (36.56) 1.4405 (36.59)

1.443 (36.65) 1.444 (36.68)

0.031 0 (0.787) 0.0470 (1.1 94)

45O

0.2780 (7.061) 0.2785 (7.074)

0.0020 (0.051) 0.0035 (0.089)

44"

1.1 890 (30.20) 1.1 900 (30.23)

1.1 920 (30.28) 1 . 1930 (30.30)

0.031 0 (0.787) 0.0470 (1.1 94)

45O

0.281 0 (7.137) 0.2820 (7.163)

0.2805 (7.1 25) 0.281 5 (7.150)

0.7475 (18.99) 0.7480 (1 9.00)

0.7500 (19.05) 0.751 5 (1 9-09)

0.0020 (0.051) 0.0040 (0.102)

1.600 (40.64)

1.055 (26.80)

1.346 (34.1 9)

55 Ib . (25 kg)

25 Ib . (11 kg)

0.001 0 (0.025) 0.0050 (0.1 27)

0.001 0 (0.025) 0.0080 (0.203)

3-2

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 48 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

- This is a comprehensive factory service repair workshop manual for Onan P216, P218, P220, P224 Performer Series.

- It is available for instant access on your computer, tablet, or smartphone.

- The manual covers all repairs, servicing, and troubleshooting procedures with detailed photos and diagrams.

- Professional mechanics and technicians use this type of manual, which includes step-by-step instructions and highly detailed exploded diagrams and pictures for accurate job completion.

- You have the option to print out a single page or the entire manual.

- This manual can be used on multiple computers without any limitations or trial periods.

- There is no expiration or renewal fee for this full manual, and it can be used for life.

- It is fully compatible with all Windows and MAC computers.

Thanks for considering this item. Please click on the button for more information.