Onan KV Microlite 2800 Series Generator Complete Workshop Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

w

MicroLite'" 2800 Series

Printed in U.S.A.

981 -0506

3-91 (Spec A & B)

Safety Precautions

Before operating tho generator set, read the Operator's

Manual and become familiar with it and the ui ment. Safe

proper1 operatad and malntalned. Many accidents are

The following symbols. found throughout this manual, alert you

to potentiall dangerousconditionsto the operator, service per-

and etnclent opontlon can be achieved on 77 y f the unlt Is

caused ?I y failure to follow fundamentalrules and precautions.

sonnel. or t x e equipment.

Thls symbol warns of lmmedlate haz-

anis whlch wlll result In seven? personal lnjuty or

death.

A+W-AFINING~ Thls symbol refers to a hazard or unsafe

practlce whlch can result In severe personal lnjqf

or death.

&CAUTION? - _.__ Thls symbol refers to a hazard or unsafe

- - .

practice which can result In personal InjuIy or prod-

uct or property damage.

FUEL AND FUMES ARE FLAMMABLE. Fire, explosion, and

personal injury can resutt from improper practices.

DO NOT fill fuel tanks while engine is running. Fuel contact

with hot engine of exhaust is a potential fire hazard.

DO NOT SMOKE OR USE AN OPEN FLAME nearthe gen-

orator set or fuel thank

Fuel lines must be adequately secured and free of leaks.

Fuel connection at the engine should be made with an ap-

provedflexible, nor~~nductive line. Do not use copper pip-

ing on flexible lines as copper will work harden and become

bnttle.

Be sure all fuel supplies have a positive shutoff valve.

GASOLINE AND LPG FUEL MAY BE ACCIDENTAUY IG

NmED BY ELECTRICALSPARKS, rumntlngthr huardof

Jury or death. Whon lnrtalllng tho generator set:

fln or explosion, whkh an rosu P t In savere p ond In-

Do not tie electrical wiring to fuel lines.

Do not run electrical lines and fuel lines through the same

compartment openings.

Keep electrical and fuel lines as far apart as possible.

Place a physical barrier between fuel lines and electrical

lines wherever possible.

If electrical and fuel lines must pass throughthe same com-

partment opening, make certain that they are physically

ssparated by ruming them thrwgh individual channels, or

by passing each line through a separate piece of tubing.

DO NOT SMOKE while servicing batteries. Lead acid bat-

teries emit a highly explosive hydrogen gas that can be ig-

nited by eiectricai arcing or by smoking.

EXHAUST GASES ARE DEADLY

0 Never sleep in the vehicle with the generator set running un-

less vehicle is equipped with an operating carbon monoxide

detector.

Provide an adequate exhaust system to properly expel dis-

charged gases. Inspect exhaust system daily for leaks per

the maintenanceschedule. Ensure that exhaust manifokls

are secure and not warped. Do not use exhaust gases to

heat a compartment.

Be sure the unit is well ventilated.

MOVING PARTS CAN CAUSE SEVERE PERSONAL IN-

JURY OR DEATH

Beforestarting work on the generator set. disconnect batter-

ies. This will prevent accidental arcing.

Keep your hands away from moving parts.

0 Make sure that fasteners on the generator set are secure.

Tighten supports and clamps. keep guards in position over

fans, drive belts, etc.

0 Do not wear loose clothing or jewelry while working on gen-

erator sets. Loose clothingand jewelry can become caught

in moving parts. Jewelry can short out electrical contacts

and cause shock or burning.

0 If adjustment must be made while the unit is running, use ex-

treme caution around hot manifolds, moving parts, etc.

ELECTRICAL SHOCK CAN CAUSE SEVERE PERSONAL

INJURY OR DEATH

I

I

Disconnect starting battery before removing protective

shields or touching electricalequipment. Use rubber insula-

tive mats placed on dry wood platforms over floors that are

metalor concretewhen around electrical equipment. Do not

wear darnpclothing (particularlywet shoes) orallawskin sur-

faces to be damp when handling electrical equipment.

Use extreme caution when working on electrical compo-

nents. High voltages can cause injury or death.

FoUowall state and local electrical codes. Have all electrical

installations performed by a qualified licensed electrician.

Tag open switches to avoid accidental closure.

DO NOT CONNECT GENERATOR SE3 DIRECTLY TO

ages can flow from the generator set intothe utility line. This

croates a potential for electrocution or property damage.

Connect onlythrough an approved device and after building

main switch is open. Consult an electriaan in regard to

emergency power use.

ANY BUILDING ELECTRICAL SYSTEM. Hazardous volt-

GENERAL SAFETY PRECALmONS

Haveafire extinguishernearby. Maintainextinguisher prop-

erly and become familiar with its use. Extinguishers rated

ABC by the NFPA are appropriate for all applications. Con-

dt the local fire department for the meet type of extin-

guisher for various applications.

Hot codants under pressure can cause severe personal in-

jury. DO NOTopen a radiator pressurecap w hii th4 engine

b running. Stop the engine and carefully Meed the system

-e-

Benzene and lead. f w n d in some gasdine, have been iden-

tified by some state and federal agencies as causing cancer

orreproductive toxicity. When checking, draining or adding

gasoline. take care not to ingest, breathe the fumes, or con-

tact gasdine.

Used engine oils have been identified by some state or fed-

eral agencies as causing cancer or reproductive toxicity.

When chec#ng or changing engine oil. take care not to in-

gest, breathe the fumes. or contact used oil.

Removeall unnecessary grease and oil from the unit. Accu-

mulated grease and oil can cause overheating and engine

damage, which presents a potential fire hazard.

DO NOTstore anything in the generator compartment such

as oil or gas cans, oily rags, chains, wooden blocks, portable

propane cylinders, etc. A fire could resuH or the generatoi

set operation (cooling, noise and vibration) may be ad.

versely affected. Keep the compartment floor clean and dry.

Do not work on this equipment when mentally or physically

fatigued, or after consuming any alcohol or drugthat makes

the operation of equipment unsafe.

RV-8

Table of Contents

SECTION

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

9 .

TITLE PAGE

SAFETY PRECAUTIONS .......................... Inside Front Cover

INTRODUCTION ............................................ 1-1

About this Manual ......................................... 1-1

Model Identification ........................................ 1-1

SPECIFICATIONS ........................................... 2-1

DIMENSIONS AND CLEARANCES ............................... 3-1

TORQUE SPECIFICATIONS ................................... 4-1

PREPARING TO SERVICE ..................................... 5-1

Troubleshooting ........................................... 5-1

SpecialTools ............................................. 5-1

Safety Considerations ....................................... 5-1

Set Removal .............................................. 5-2

ENGINE-PRIMARY SYSTEMS .................................. 6-1

Introduction .............................................. 6-1

Troubleshooting Engine Primary Systems ........................ 6-1

Exhaust System ........................................... 6-5

Cooling System ........................................... 6-8

ignition System ............................................ 6-8

Crankcase Ventilation System ................................ 6-10

Governor ............................................... 6-10

Gasoline Fuel System ...................................... 6-11

LPG Fuel System ......................................... 6-18

Electric Starter ........................................... 6-21

CONTROL ................................................. 7-1

Introduction .............................................. 7-1

Control Description ........................................ 7-1

Control Operation - Gasoline Fueled ............................ 7-1

Control Operation - LPG Fueled ............................... 7-3

Control Troubleshooting ..................................... 7-6

GENERATOR ............................................... 8-1

Introduction .............................................. 8-1

Generator Description ...................................... 8-1

Generator Operation ........................................ 8-2

Generator Troubleshooting ................................... 8-2

Generator Service ......................................... 8-8

Brushes and Slip Rings ..................................... 8-10

Voltage Regulator (VR1) Test ................................ 8-11

Generator Testing ......................................... 8-11

Rotor Bearing Replacement ................................. 8-15

ENGINE-BLOCK ASSEMBLY .................................. -9-1

introduction .............................................. 9-1

Oil Pan and Oil Level Switch .................................. 9-1

Head Cover .............................................. 9-2

Cylinder Head ............................................ 9-2

Valve System ............................................. 9-2

Crankcase Cover .......................................... 9-5

Camshaft and Tappet Removal ................................ 9-5

Governor ................................................ 9-6

Piston Assembly Removal and Service .......................... 9-6

Crankshaft .............................................. 9-10

Cylinder Block ........................................... 9-10

Timing Gears ............................................ 9-12

Bearings ............................................... 9-12

OilSeal ................................................ 9-12

Table of Contents

SECTION TITLE PAGE

10 . SERVICE CHECKLIST ........................................................... 10-1

General ......................................................................... 10-1

Mounting ....................................................................... 10-1

Lubrication ..................................................................... 10-1

Wiring .......................................................................... 10-1

Initial Start Adjustments ........................................................ 10-1

Output Checks ................................................................. 10-1

Exhaust System ................................................................ 10-1

Fuel System .................................................................... 10-2

Control ......................................................................... 10-2

Mechanical ..................................................................... 10-2

ii

Section 1 Introduction

I

ABOUT THIS MANUAL

This manual provides service information for the Onan

KV generator set. It is intended for the experienced

serviceperson. This manual covers troubleshooting,

disassembly, repair, reassembly, and adjustments for

the engine, generator, and control. The serviceperson

should be thoroughly familiar with the principles of gas-

oline engine operation and have a basic knowledge of

electrical fundamentals. Other Onan publications such

as Electrical/Mechanical Fundamentals (932-0408),

Onan Generator Training Manual (932-0404), and KV

Operator’s Manual (981 -01 29) and Installation Manual

(981 -0626) are recommendedas additional sources of

information.

I

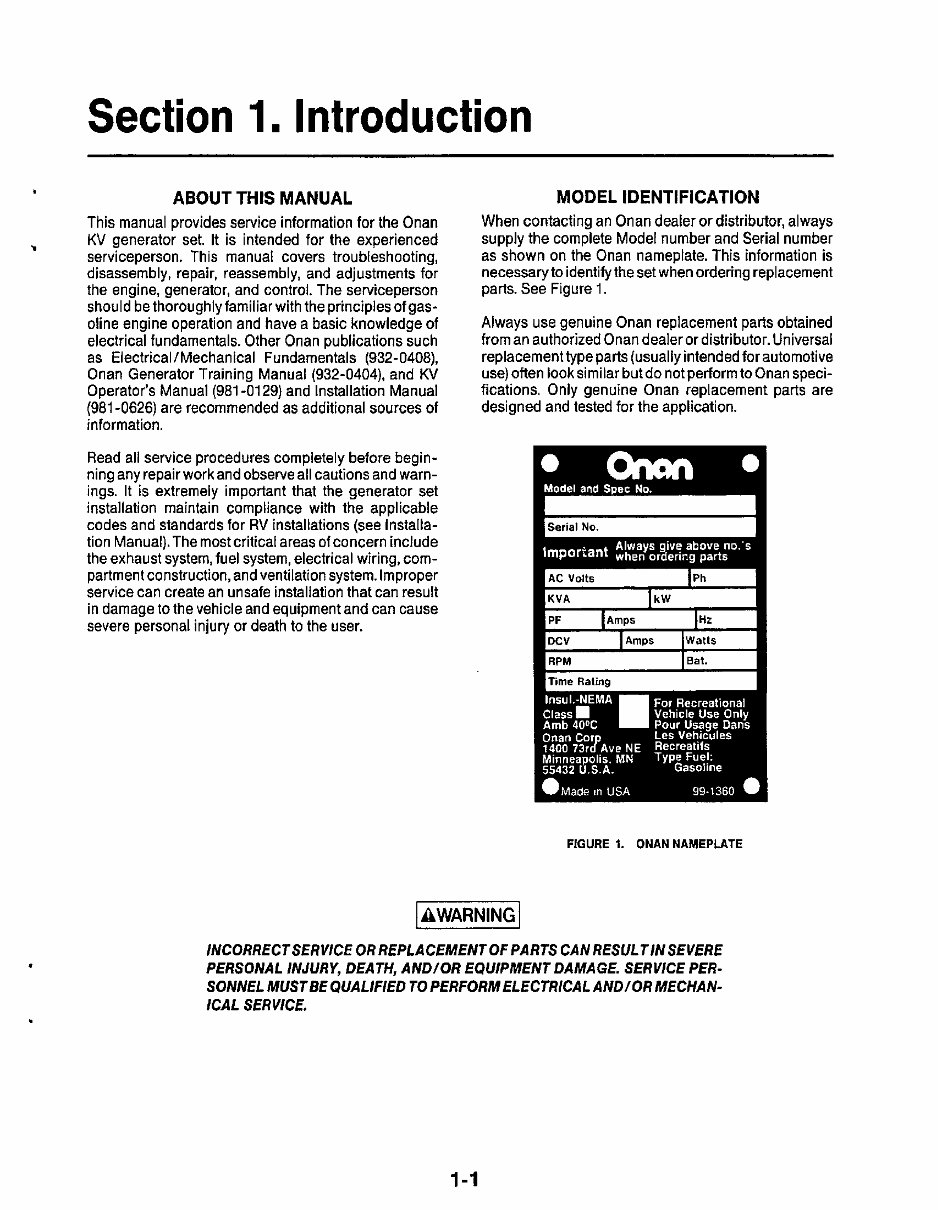

MODEL IDENTIFICATION

When contacting an Onan dealer or distributor, always

supply the complete Model number and Serial number

as shown on the Onan nameplate. This information is

necessaryto identifythe set when ordering replacement

parts. See Figure 1.

Always use genuine Onan replacement parts obtained

from an authorized Onan dealer or distributor. Universal

replacementtype parts (usually intendedfor automotive

use)often look similar but do not Derformto Onan speci-

fications. Only genuine Onan ieptacement

designed and tested for the application.

parts are

Read all service procedures completely before begin-

ning any repair work and observe all cautions and warn-

ings. It is extremely important that the generator set

installation maintain compliance with the applicable

codes and standards for RV installations (see Installa-

tion Manual).The most critical areas of concern include

the exhaust system, fuel system, electrical wiring, com-

partment construction, and ventilation system. Improper

service can create an unsafe installation that can result

in damage to the vehicle and equipment and can cause

severe personal injury or death to the user.

l AWARNING I

H Serial NO. I

PF Amps Hz

FIGURE 1. ONAN NAMEPLATE

INCORRECTSERVICE OR REPLACEMENT OF PARTS CAN RESULTIN SEVERE

PERSONAL INJURY, DEATH, AND/OR EQUIPMENT DAMAGE. SERVICE PER-

SONNEL MUSTBE QUALIFIED TO PERFORM ELECTRICALAND/OR MECHAN-

ICAL SERVICE.

1-1

.

Section 2. Specifications

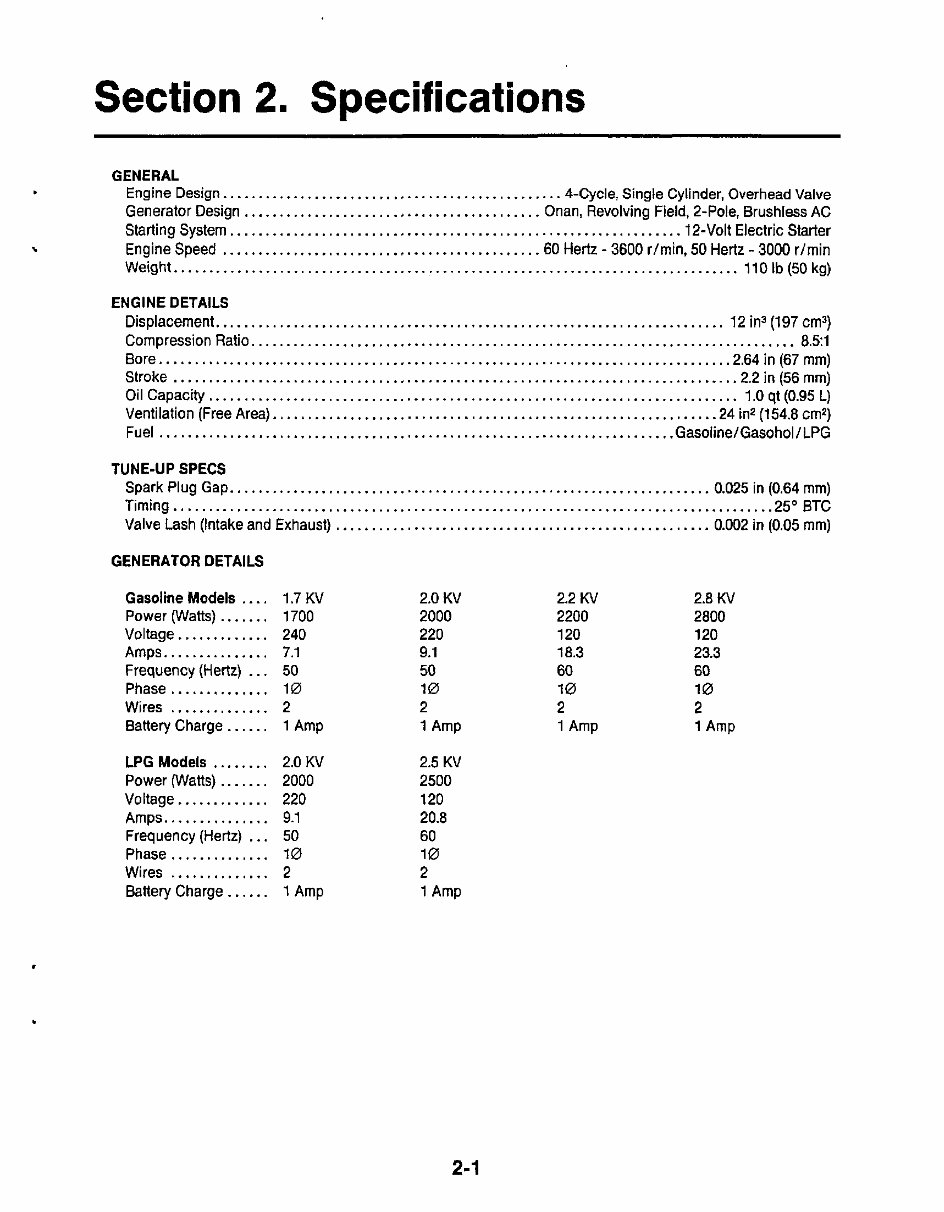

GENERAL

.

Engine Design. ............................................... 4-Cycle, Single Cylinder, Overhead Valve

Generator Design .......................................... Onan, Revolving Field, 2-Pole, Brushless AC

Starting System ............................................................... .12-V0lt Electric Starter

Engine Speed ............................................ .60 Hertz . 3600 r/min, 50 Hertz - 3000 r/min

Weight.. .............................................................................. 110 Ib (50 kg)

\

ENGINE DETAILS

Displacement.. ...................................................................... 12 ins (197 cm3)

Compression Ratio.. ........................................................................... 8.51

Bore.. .............................................................................. .2.64 in (67 mm)

Stroke ............................................................................... .2.2 in (56 mm)

Oil Capacity.. ......................................................................... 1.0 qt (0.95 L)

Ventilation (Free Area). ............................................................. .24 in2 (154.8 cm2)

Fuel ......................................................................... Gasoline/Gasohol/LPG

TUNE-UP SPECS

Spark Plug Gap.. .................................................................. 0.025 in (0.64 mm)

Timing.. .................................................................................. .25" BTC

Valve Lash (Intake and Exhaust) ..................................................... 0.002 in (0.05 mm)

GENERATOR DETAILS

Gasoline Models .... 1.7 KV 2.0 KV 2.2 KV 2.8 KV

Power (Watts) ....... 1700 2000 2200 2800

Voltage ............. 240 220 120 120

Amps.. ............. 7.1 9.1 18.3 23.3

Frequency (Hertz) ... 50 50 60 60

Phase .............. 10 10 10 10

Wires .............. 2 2 2 2

Battery Charge.. .... 1 Amp 1 Amp 1 Amp 1 Amp

LPG Models ........

Power (Watts) .......

Voltage .............

Amps. ..............

Frequency (Hertz) . . ,

Phase ..............

Wires ..............

Battery Charge ......

2.0 KV

2000

220

9.1

50

10

2

1 Amp

2.5 KV

2500

120

20.8

60

10

2

1 Amp

2-1

ITEM

CYLINDER HEAD

Cylinder Head Deformation Limit

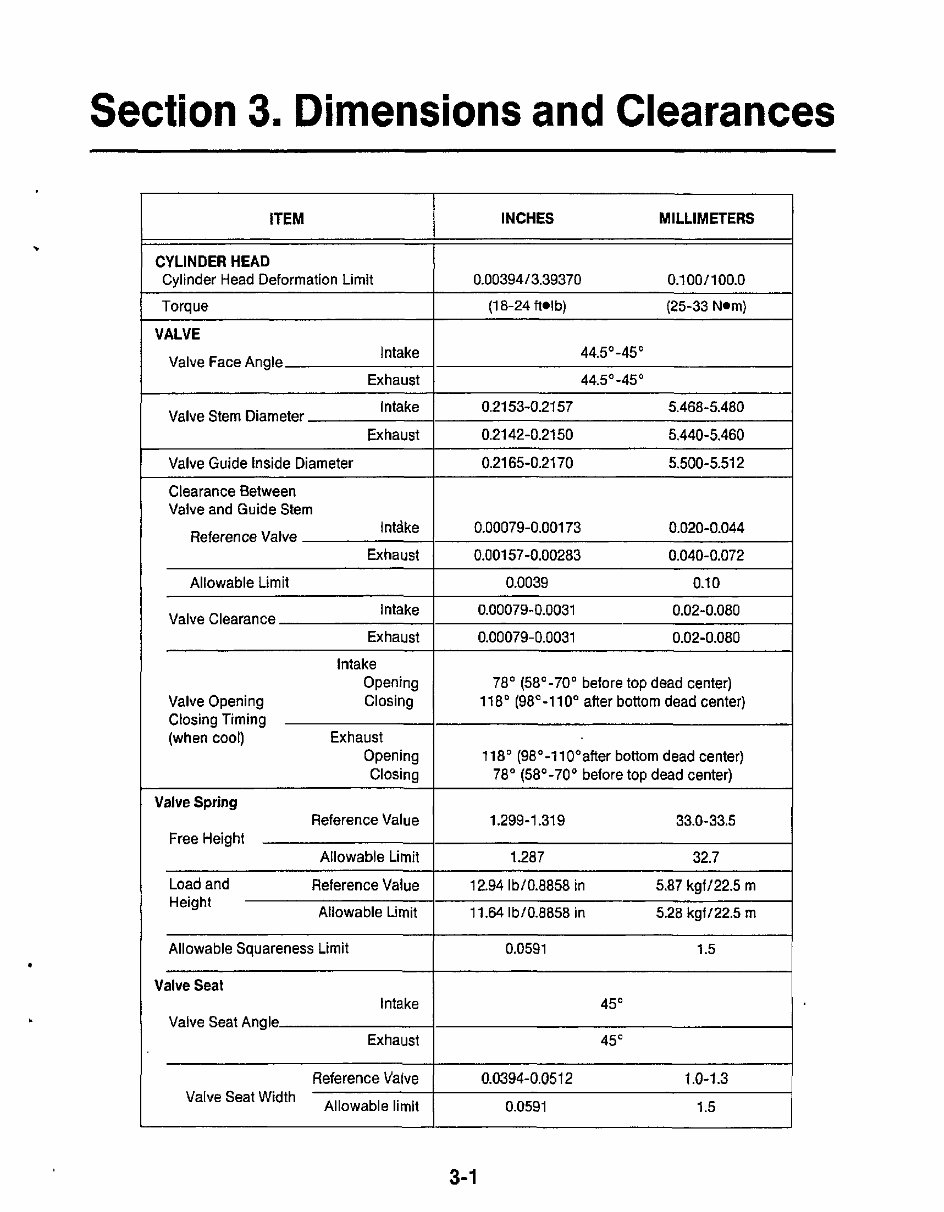

Section 3. Dimensions and Clearances

INCHES MILLIMETERS

0.00394/3.39370 0.1001100.0

Allowable Limit

Intake

Exhaust

Valve Clearance

Torque I (18-24 ftolb) (25-33 Nom)

0.0039 0.1 0

0.00079-0.0031 0.02-0.080

0.00079-0.0031 0.02-0.080

Intake 44.5"-45'

44.5" -45"

VALVE

Valve Face Angle

0.0591 1.5

0.2153-0.21 57 5.468-5.480

Exhaust 0.2142-0.2150 5.440-5.460

Valve Stem Diameter

Valve Guide Inside Diameter I 0.2165-0.21 70 5.500-5.512

Valve and Guide Stem

Clearance Between

Reference Valve

Intake 0.00079-0.001 73 0.020-0.044

0.001 57-0.00283 0.040-0.072

Intake

Opening

Valve Opening Closing

Closing Timing

(when cool) Exhaust

Opening

Closing

78' (58'-70' before top dead center)

118' (98"-110° after bottom dead center)

118' (98'-110°after bottom dead center)

78" (58"-70' before top dead center)

Reference Value 1.299-1.319 33.0-33.5

i Allowable Limit 1.287 32.7

Valve Spring

Free Height

Reference Value 12.94 Ibf 0.8858 in 5.87 kgff 22.5 m

11.64 lb/0.8858 in 5.28 kgfl22.5 m

Load and

Height

0.0591 1.5

I

Allowable Squareness Limit

Valve Seat

Intake

Exhaust

Valve Seat Angle

45"

45"

Reference Valve I 0.0394-0.051 2 1.0-1.3

3-1

Section 3. Dimensions and Clearances - Continued

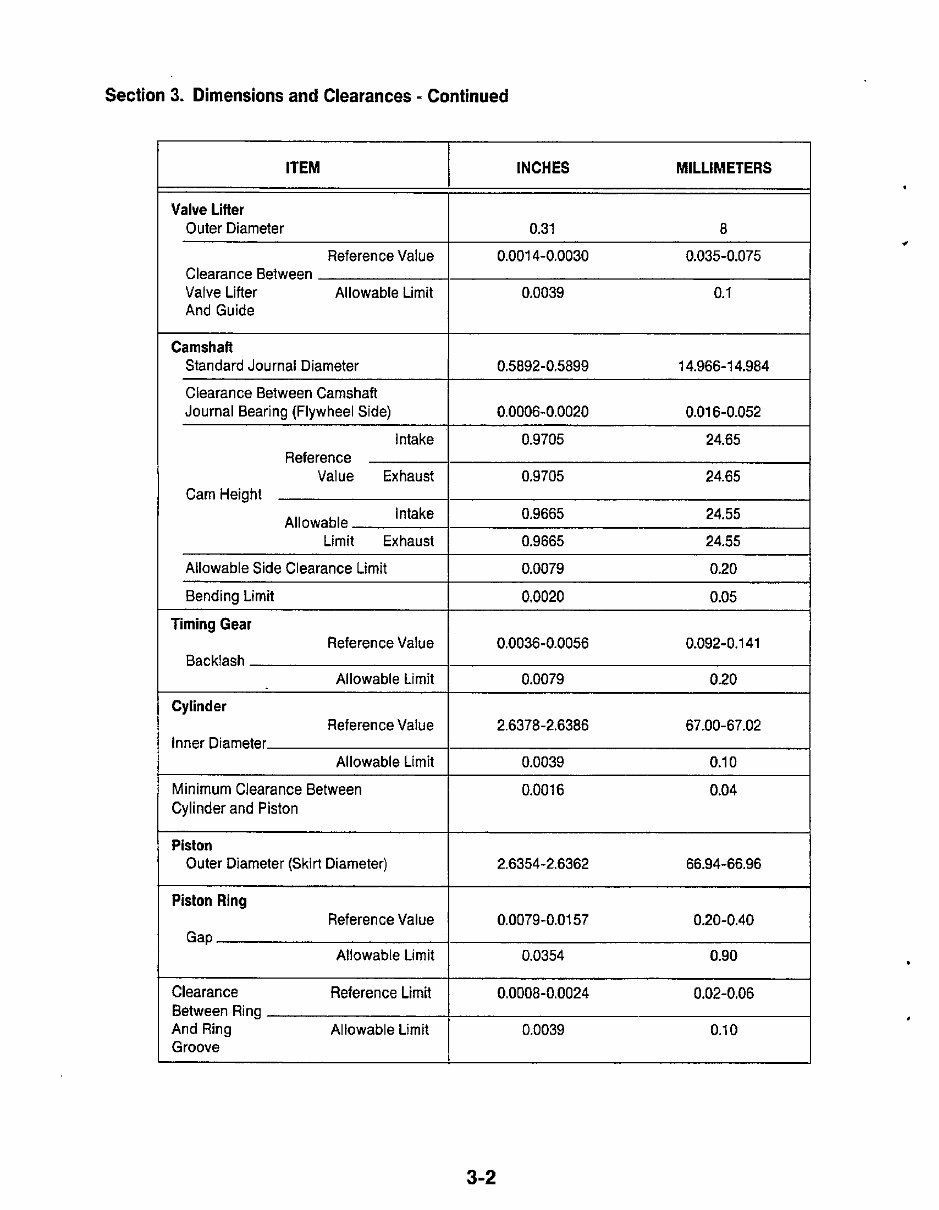

ITEM

Valve Lifter

Outer Diameter

ReferenceValue

Clearance Between

Valve Lifter Allowable Limit

And Guide

Camshaft

Standard Journal Diameter

Clearance Between Camshaft

Journal Bearing (Flywheel Side)

Intake

Value Exhaust

Intake

Limit Exhaust

Reference

Cam Height

Allowable

Allowable Side Clearance Limit

Bending Limit

Timing Gear

Backlash

ReferenceValue

Allowable Limit

ReferenceValue

Allowable Limit

Cylinder

Inner Diameter

Minimum Clearance Between

Cylinder and Piston

Piston

Outer Diameter (Skirt Diameter)

Piston Ring

ReferenceValue

Allowable Limit

Gap

Clearance Reference Limit

Between Ring

And Ring Allowable Limit

Groove

INCHES MILLIMETERS

- :

0.001 4-0.0030 0.035-0.075

I

0.0039 0.1

0.5892-0.5899 14.966-1 4.984

0.0006-0.0020 0.01 6-0.052

0.9705 24.65

0.9705 24.65

1

0.9665 24.55

0.9665 24.55

0.0079

0.0020

0.0036-0.0056 0.092-0.1 41

0.0079

2.6378-2.6386 67.00-67.02

0.0039 0.1 0 I

0.001 6 0.04

2.6354-2.6362 66.94-66.96

0.0079-0.01 57 0.20-0.40

0.0354 0.90

I

0.0008-0.0024 0.02-0.06

I

0.0039 0.1 0

.

3-2

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

$54.99

Viewed 15 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

$54.99

- The Onan KV Microlite 2800 Series Generator Complete Workshop Service Repair Manual is a comprehensive resource for servicing and repairing your generator.

- It provides user-friendly step-by-step instructions and illustrations, making every service and repair task effortless.

- This manual is a lifelong asset, allowing you to print specific pages, chapters, or the entire manual, or store it on your tablet or smartphone for easy access.

- Covering all models, engines, trim, and transmission types, this manual ensures you have the necessary information for any specific generator variant.

- It encompasses a comprehensive range of repair procedures, leaving no task unaddressed, and is compatible with all PC and MAC computers, tablets, and mobile phones.

- Adobe Reader is the only software requirement, which is often pre-installed on your computer or can be easily downloaded for free.

- Upon purchase with Visa, MasterCard, or PayPal, the manual will be promptly delivered to the provided email address.

- Empower yourself with the knowledge and guidance needed to maintain and repair your Onan KV Microlite 2800 Series Generator with this comprehensive manual.