Onan Service Manual DJBA DJB DJC DJE Diesel Engine

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Caution: This document contains mixed page sizes (8.5 x 11 or 11 x

17), which may affect printing. Please adjust your printer settings

according to the size of each page you wish to print.

4

f

Service

DJBA

DJB

DJC

DJE

Diesel Engines

967-0751

3-88

Printed in USA.

,

Safety Precautions

It is recommended that you read your engine manual and

become thoroughly acquainted with your equipment be-

fore you start the engine.

Fuels, electrical equipment, batteries, exhaust gases and

moving parts present potential hazards that could result in

serious, personal injury. Take care in following these

recommended procedures. '

S8fOty COdW

0 All local, state and federal codes should be consulted

and complied with.

0 This engine is not designed or intended for use 'in

aircraft. Any such use is at the owner's sole risk. .

'

General

Provide appropriate fire extinguishers and install them

in convenientlocations. Use an extinguisherratedABC

by NFPA.

Make sure that all fasteners on the engine are secure

and accurately torqued. Keep guards in position over

fans, driving belts, etc.

If It is necessary to makeadjustments whiletheengine is

running, use extreme caution when close to hot ex-

hausts, moving parts, etc.

Protect Against Movlng Parts

Do not wear loose clothing in the vicinity of moving

parts, such as PTO shafts, flywheels, tilowers, coup-

lings, fans, belts, etc.

Keep your hands away from moving parts.

Batted08

0 Before starting work on the engine. disconnect batter-

ies to prevent inadvertentstarting of the engine.

DO NOT SMOKE while servicing batteries. Lead acid

batteries give off a highlyexplosivehydrogengas which

can be ignited by flame, electricalarcingor by smoking.

Verify batterypolaritybeforeconnectingbatterycables.

Connect negative cable last.

FwI Systom

0 DO NOT fill fuel tanks while engine is runnirlg.

DO NOT smoke or use an open flame in the vicinity of

the engine or fuel tank. Internal combustion .engine

fuels are highly flammable.

Fuel lines must be of steel piping, adequately secured.

and free from leaks. PiDina at the enaine should be

approved flexible me. PO nor use copper piping ror

flexible lines as copper will work harden and become

brittle enough to break.

Be sure all fuel supplies have a positive shutoff valve.

b

.

E

Exhrust Systom

Exhaust products of any internal combustion engine

are toxic andcan cause injury, or death if inhaled. All

engine applications, especiallythose within a confined

area, should be equipped with an exhaust system to

discharge gases to the outside atmosphere.

Do not use exhaust gases to heat a.compartment.

Make sure that your exhaust system is free of leaks.

Ensure that exhaust manifolds are secure and are not

warped by bolts unevenly torqued.

Exhrust Gas is Dordlyi

Exhaust gases contain carbon monoxide, a poisonous gas

that might cause unconsciousness and death. It is an

odorless and colorless gas formed during combustion of

hydrocarbon fuels. Symptoms of carbon monoxide poi-

soning are:

Dizziness .Vomiting

Headache 0 Muscular Twitching

Weakness and Sleepiness

If you experience any of these symptoms, get out into fresh

air immediately, shut down the unit and do not use until it

has been inspected.

The best protection against carbon monoxide inhalation is

proper installationand regular, frequent inspectionsof the

complete exhaust system. If you notice a change in the

sound or appearance of exhaust system, shut the unit down

immediatelyand have It inspected and repairedat once by a

competent mechanic. b

'Cooling Systom .

0 Coolants under pressure have a higher boiling point

than water. DO NOT open a radiator pressure cap when

coolant temperature is above 212OF (100OC) or while

engine is running.

0 Throbbing in Temples

c

Y

Kwp the Unlt and SurroundingAroa Clem

0

0

'Make sure that oily rags are not left on or'near the

engine.

Remove all unnecessary grease and oil from the unit.

Accumulatedgrease and oil can cause overheatingand

subsequent engine damage and present a potential fire

hazard.

. E4

Table of Contents

c

TITLE PAGE

General Information .................................................. 2

Specifications ....................................... ..-. .............. 3

Dimensions and Clearances ........................................... 4

Assembly Torques and Special Tools .................................. 6

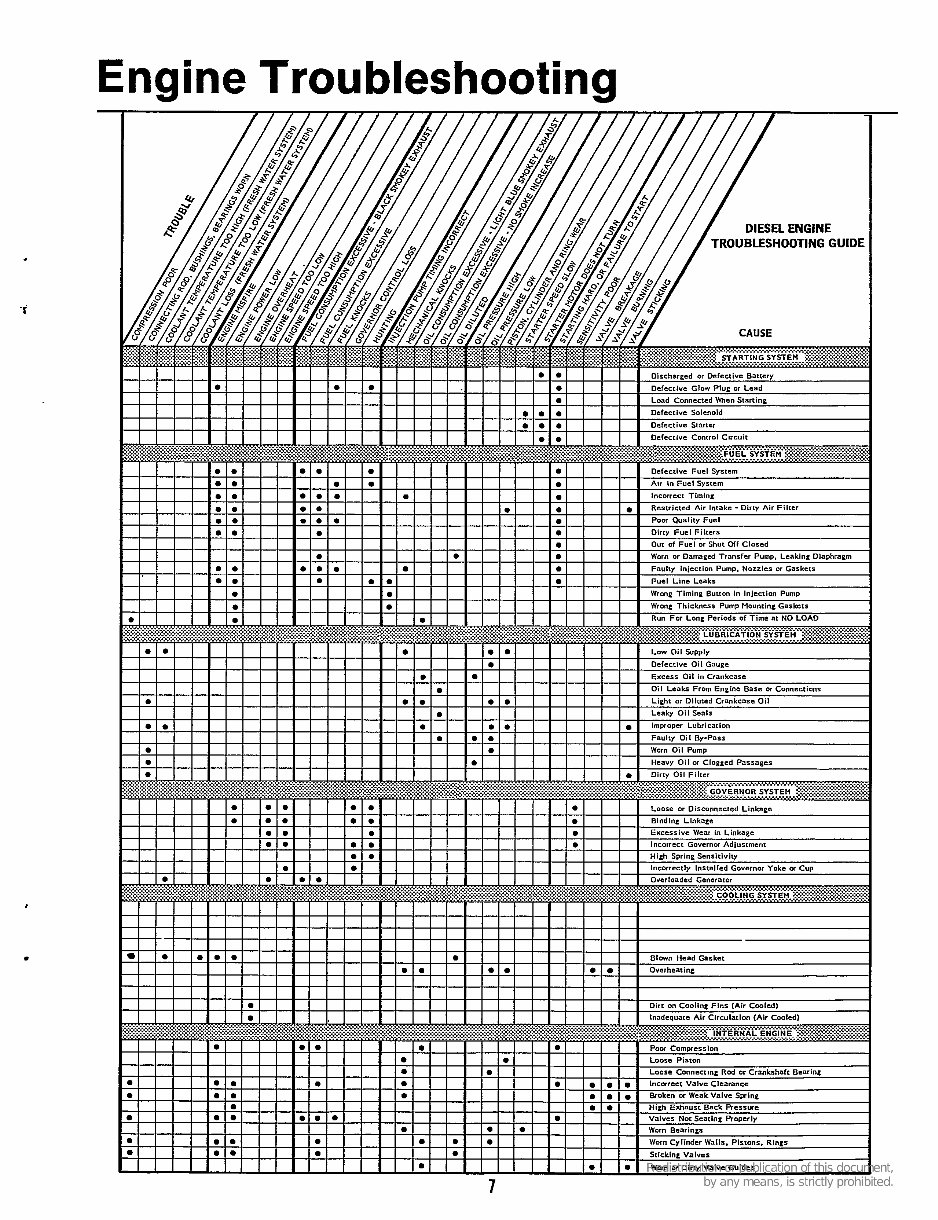

Engine Troubleshooting ............................................... 7

Service and Maintenance .............................................. 8

Exhaust System ..................................................... 14

Cooling System ...................................................... 16

Fuel System ......................................................... 18

Governor System .................................................... 38

Oil System .......................................................... 40

Starting System ...................................................... 45

Special Equipment ................................................... 67

Control System ...................................................... 68

Wiring Diagram .......... . ' . ........................................... 69

Flywheel Alternator .................................................. 51

EngineDisassembly ................................................. 55

I WARNING

INCORRECT SERVICE OR REPLACEMENT OF PARTS MIGHT RESULT IN

SEVERE PERSONAL INJURY AND/OR EQUIPMENT DAMAGE . SERVICE

PERSONNEL MUST BE QUALIFIED TO PERFORM ELECTRICAL AND/OR

MECHANlCAL SERVICE .

I

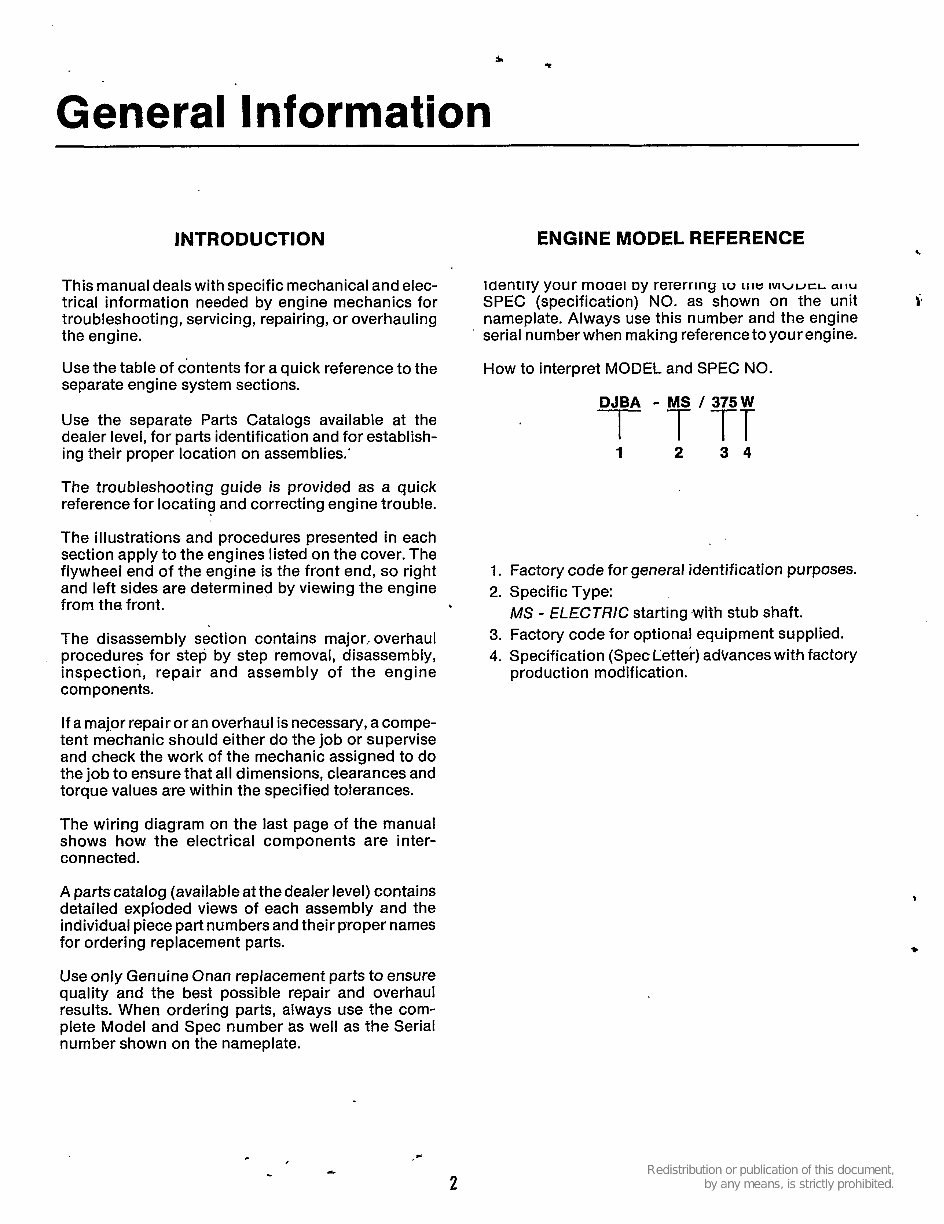

General Information

INTRODUCTION

This manual deals with specific mechanical and elec-

trical information needed by engine mechanics for

troubleshooting, servicing, repairing, or overhauling

the engine.

Use the table of contents for a quick reference to the

separate engine system sections.

Use the separate Parts Catalogs available at the

dealer level, for parts identification and for establish-

ing their proper location on assemblies.'

The troubleshooting guide is provided as a quick

reference for locating and correcting engine trouble.

The illustrations and procedures presented in each

section apply to the engines listed on the cover. The

flywheel end of the engine is the front end, so right

and left sides are determined by viewing the engine

from the front.

The disassembly section contains major,. overhaul

procedures for step by step .removal, disassembly,

inspection, repair and assembly of the engine

components.

If a major repair or an overhaul is necessary, a compe-

tent mechanic should either do the job or supervise

and check the work of the mechanic assigned to do

the job to ensure that all dimensions, clearances and

torque values are within the specified tolerances.

The wiring diagram on the last page of the manual

shows how the electrical components are inter-

connected.

A parts catalog (available at the dealer level) contains

detailed exploded views of each assembly and the

individual piece part numbers and their proper names

for ordering replacement parts.

Use only Genuine Onan replacement parts to ensure

quality and the best possible repair and overhaul

results. When ordering parts, always use the com-

plete Model and Spec number as well as the Serial

number shown on the nameplate.

ENGINE MODEL REFERENCE

c

IUentlTy your moael DY reTerririy LO LII~ IVIWLKL aiiu

nameplate. Always use this number and the engine

serial number when making reference to your engine.

SPEC (specification) NO. as shown on the unit ;

How to interpret MODEL and SPEC NO.

1 2 3 4

1. Factory code for general identification purposes.

2. Specific Type:

3. Factory code for optional equipment supplied.

4. Specification (Spec Letter) advanceswith factory

MS - ELECTRlC starting .with stub shaft.

production modification.

2

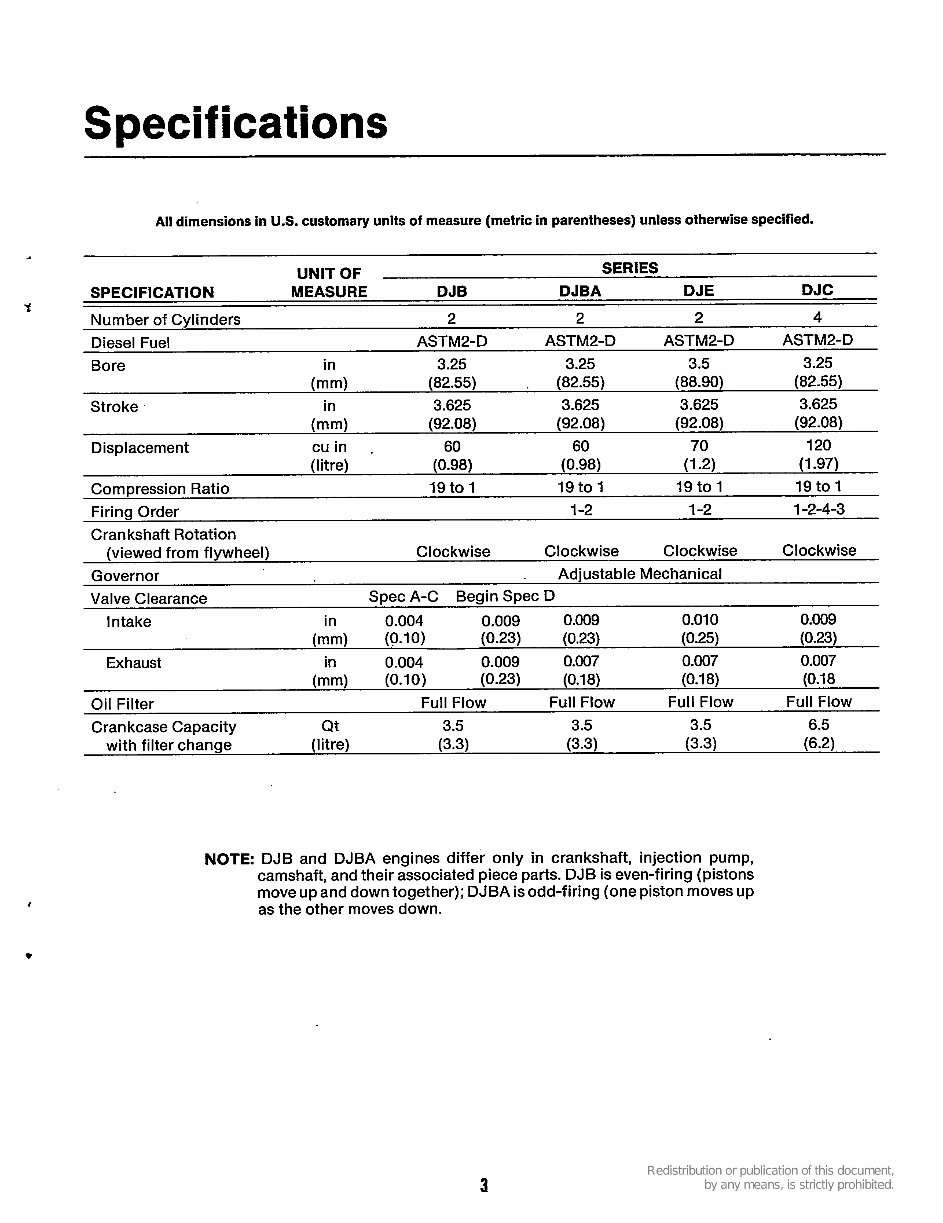

Specifications

All dimensions in U.S. customary units of measure (metric in parentheses) unless otherwise specified.

UNIT OF SERIES

SPECIFICATION MEASURE DJB DJBA DJE DJC

Number of Cylinders 2 2 2 4

ASTM2-D ASTM2-D ASTM2-D ASTM2- D Diesel Fuel

Bore in 3.25 3.25 3.5 3.25

(mm) (82.55) . (82.55) (88.90) (82.55)

Stroke in 3.625 3.625 3.625 3.625

(mm) (92.08) (92.08) (92.08) (92.08)

Displacement cuin . 60 60 70 120

(litre) (0.98) (0.98) (1-2) (1.97)

Compression Ratio 19 to 1 19 to 1 19 to 1 19 to 1

Firing Order 1-2 1-2 1-2-4-3

Crankshaft Rotation

Governor . Adjustable Mechanical

Valve Clearance Spec A-C Begin Spec D

Clockwise Clockwise Clockwise Clockwise

(viewed from flywheel)

Intake in 0.004 0.009 0.009 0.01 0 0.009

(mm) (0.10) (0.23) (0.23) (0.25) (0.23)

Exhaust in 0.004 0.009 0.007 0.007 0.007

(mm) (0.10) (0.23) (0.18) (0.1 8) (0.1 8

Oil Filter Full Flow Full Flow Full Flow Full Flow

Crankcase Capacity Qt 3.5 3.5 3.5 6.5

with filter change (I i tre) (3.3) (3.3) (3.3) (6.2)

NOTE: DJB and DJBA engines differ only in crankshaft, injection pump,

camshaft, and their associated piece parts. DJB is even-firing (pistons

move up and down together); DJBA is odd-firing (one piston moves up

as the other moves down.

3

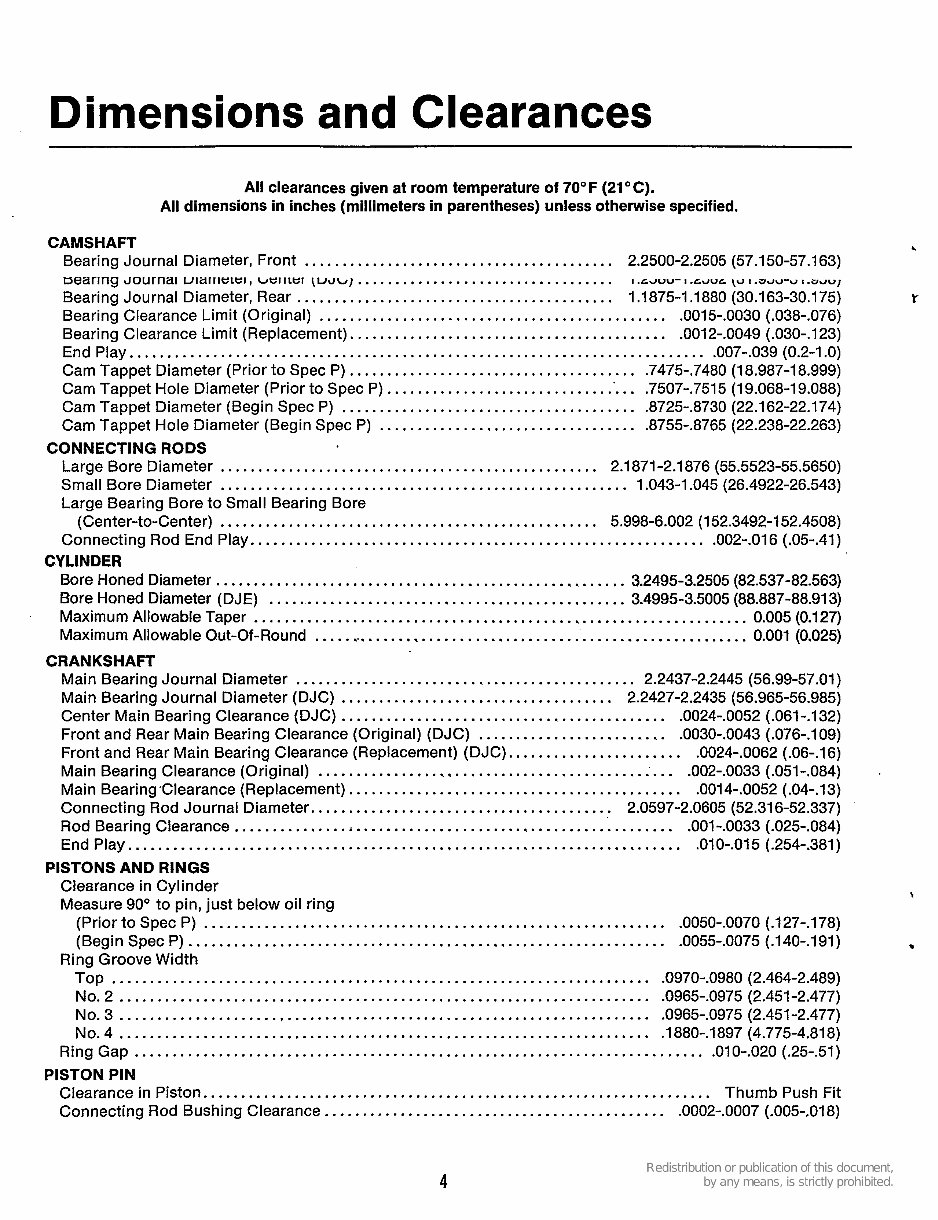

Dimensions and Clearances

All clearances given at room temperature of 70" F (21 O C) .

All dimensions in inches (millimeters in parentheses) unless otherwise specified .

CAMSHAFT

Bearing Journal Diameter. Front ......................................... 2.2500-2.2505 (57.150-57.1 63)

Bearing Journal Diameter. Rear .......................................... 1.1875-1.1880 (30.163-30.175)

Bearing Clearance Limit (Original) .............................................. .0015.. 0030 (.038-.076)

Bearing Clearance Limit (Replacement) .......................................... .0012-.0049 (.030-.123)

End Play ............................................................................ .007-. 039 (0.2-1.0)

Cam Tappet Diameter (Prior to Spec P) ...................................... .7475-. 7480 (18.987-18.999)

Cam Tappet Hole Diameter (Prior to Spec P) .................................. .7507-. 7515 (19.068-19.088)

Cam Tappet Diameter (Begin Spec P) ....................................... .8725.. 8730 (22.162-22.174)

Cam Tappet Hole Diameter (Begin Spec P) .................................. .8755-. 8765 (22.238-22.263)

Large Bore Diameter .................................................. 2.1871-2.1876 (55.5523-55.5650)

Small Bore Diameter ...................................................... 1.043-1.045 (26.4922-26.543)

Large Bearing Bore to Small Bearing Bore

(Center-to-Center) .................................................. 5.998-6.002 (152.3492-152.4508)

Connecting Rod End Play ............................................................ .002-. 016 (.05-.41)

Bore Honed Diameter ...................................................... 3.2495-3.2505 (82.537-82.563)

Bore Honed Diameter (DJE) ............................................... 3.4995-3.5005 (88.887-88.913)

Maximum Allowable Taper ................................................................. 0.005 (0.127)

Maximum Allowable Out-Of-Round .......................................................... 0.001 (0.025)

Main Bearing Journal Diameter ............................................. 2.2437-2.2445 (56.99-57.01)

Main Bearing Journal Diameter (DJC) .................................... 2.2427-2.2435 (56.965-56.985)

Center Main Bearing Clearance (DJC) ........................................... .0024.. 0052 (.061-.132)

Front and Rear Main Bearing Clearance (Original) (DJC) ......................... .0030.. 0043 (.076-.109)

Front and Rear Main Bearing Clearance (Replacement) (DJC) ....................... .0024-.0062 (.06-.16)

Main Bearing Clearance (Original) ............................................ .'. .. .002.. 0033 (.051-.084)

Main Bearing Clearance (Replacement) ............................................ .0014.. 0052 (.04-.13)

Connecting Rod Journal Diameter ........................................ 2.0597-2.0605 (52.316-52.337)

Rod Bearing Clearance .......................................................... .001.. 0033 (.025-.084)

End Play ......................................................................... .010-.015 (.254-.381)

Clearance in Cylinder

Measure 90" to pin. just below oil ring

Bearing Journai uiaiiieiei. ueii~ei \UJ~) .................................. I LJUU- I LJUC [U 1 .a c r ~ - ~ 1 . acruJ

CONNECTING RODS

CYLINDER

CRANKSHAFT

.

PISTONS AND RINGS

(Prior to Spec P) ............................................................. .0050.. 0070 (.127-.178)

(Begin Spec P) ............................................................... .0055-. 0075 (.140-.191)

Ring Groove Width

TOP ....................................................................... .0970-. 0980 (2.464-2.489)

No.2 ...................................................................... -0965-.0975 (2.451-2.477)

No . 3 ...................................................................... .0965.. 0975 (2.451-2.477)

NO . 4 ...................................................................... .1880.. 1897 (4.775-4.818)

Ring Gap ........................................................................... .010-. 020 (.25-51)

Clearance in Piston ................................................................... Thumb Push Fit

Connecting Rod Bushing Clearance ............................................. -0002-.0007 (-005-.018)

PISTON PIN

4

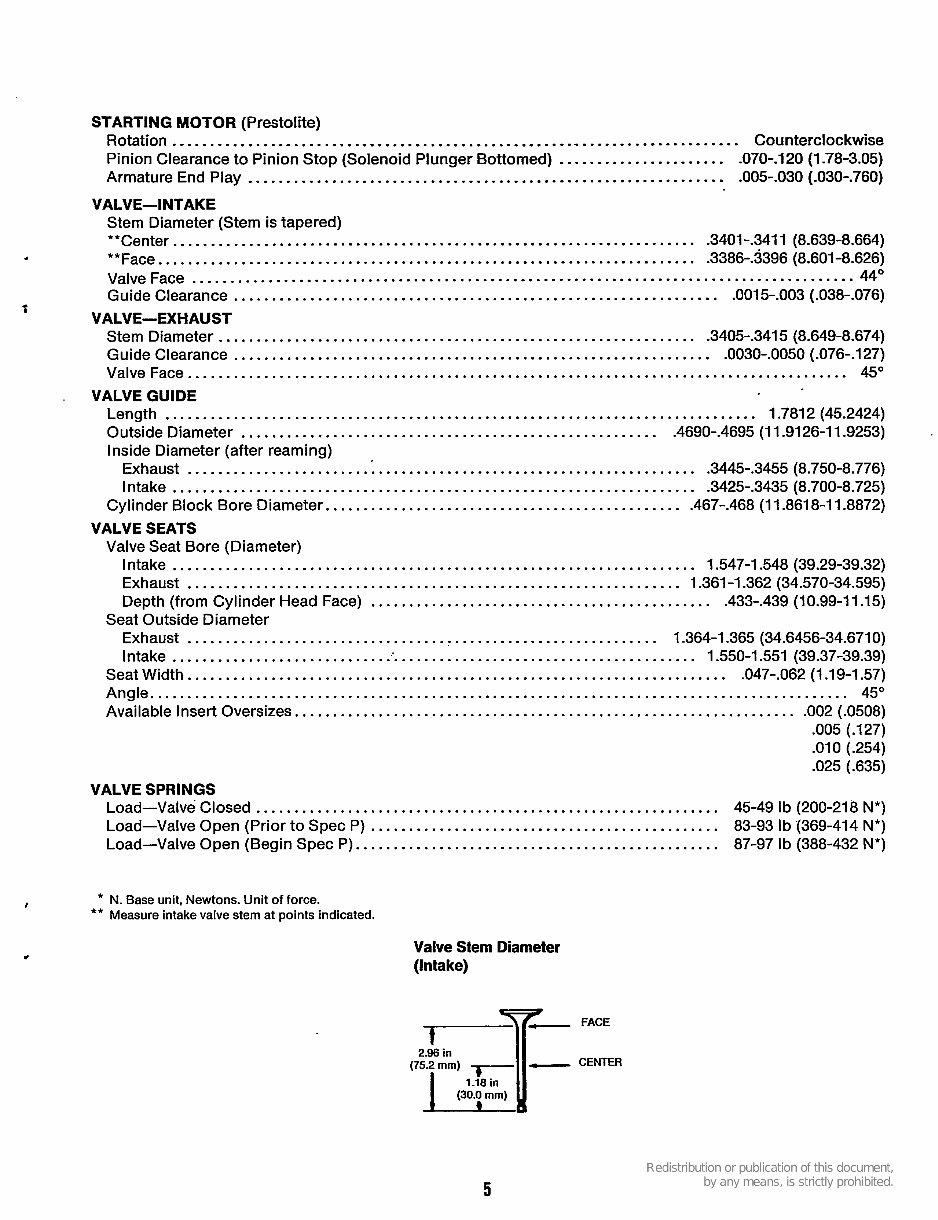

STARTING MOTOR (Prestolite)

Rotation ........................................................................... Counterclockwise

Pinion Clearance to Pinion Stop (Solenoid Plunger Bottomed) . .... . . ...... ... . .... . -070--120 (1 -78-3.05)

Armature End Play . ..... . .. ... . . .. . . . .... . .. . .. . . . . .. . .. . . . . ... . . ... . . ... . . ...... .005--030 (-030-.760)

Stem Diameter (Stem is tapered)

**Center .... ... . . . . .. ... . . . . .. . ..... . . . .. ... . . . .... . . . . ..... . . . . . . . . . . .. . .... -3401 -.3411 (8.639-8.664)

**Face ....... .. ... .. .. . . . . . .. . .. . . . . . .. . . . .. . . . ... .. .. . . . . . . . . . . . . . . . ... .. .. . .3386--3396 (8.601-8.626)

Valve Face ....................................................................................... 44'

Guide Clearance .. . .. . .. .. .. ..... . ... . .. . .. . . . . . . . . . . . .. . . . .. . .. ... .. ... .. . .. .. . .0015-.003 (-038-.076)

Stem Diameter . ... ... . . . . . .. ..... . ... . .. . . ... . .. ..... ........ ..... . .. . . .. . ... -3405--3415 (8.649-8.674)

Guide Clearance . . . ..... . . .. .. . . .. .. . . . .. .... . ......... . . . ... ..... .. . . ... . ..... .0030-.0050 (.076-.127)

Valve Face ....................................................................................... 45"

Length .............................................................................. 1.7812(45.2424)

Outside Diameter ....... . . .. . ... . .. ... . ...... . . . .... . . .... . .. ...... . .... .4690-.4695 (1 1.9126-1 1.9253)

Inside Diameter (after reaming)

Exhaust . . . . . .. . .. .. . . . ...... . ........ . .... . . . . ... . . . . .. . . . ...... .. .. . ..... .3445-.3455 (8.750-8.776)

Intake ..................................................................... .3425-.3435 (8.700-8.725)

Cylinder Block Bore Diameter.. ... ... . ... . .... . . . .... . . .. . . . . . . . .... . . ... . . . .467-.468 (11.8618-1 1.8872)

Valve Seat Bore (Diameter)

VALVE-INTAKE

t

VALVE-EXHAUST

. VALVEGUIDE

VALVE SEATS

Intake .... . ... . . . . .. . ... .... . .. . .. . ..... . . . . . . ...... . . .. . . . .. . . . . . . ... . ... . 1.547-1 548 (39.29-39.32)

Exhaust . ...... .. . .. ............ . .......... . . . ...... .. .. . . .. . . . ... . , .. . . . 1.361-1.362 (34.570-34.595)

Depth (from Cylinder Head Face) .. . . . ... . .. . . . ... ... . . . . . . .. .... . .. . . . . . .. .. . .433-.439 (10.99-1 1.15)

Exhaust .. . ... .. . . . .... . .... . .. . .... . ..... . .. .. . ... .... . . ........ . . .. 1.364-1.365 (34.6456-34.6710)

Intake .... . . .. .. . . ... . .. .. .. . . . . .. :'. . ......... . . ... .. . .. . . .... . . . .. . .... ... 1 S50-1.551(39.37-39.39)

Seatwidth ....................................................................... .047-.062 (1.19-1.57)

Angle.. . . . ............... . ... .... . .. . ........ . . . .. .. . . ... . . ... . ..... . . . ...... . . .. . . . . . . . .... . .. 45"

Available Insert Oversizes .. . ... . .. . .. . . . . . . .. ...... . ... . .... . . . . . . . . .. . ........ .. . .. . . . .... .002(.0508)

.005 (.127)

.010(.254)

.025(.635)

Load-Valve Closed . ... .. . .. . .. . ............... . .. . ... . . . . . . ............... . .. . . 45-49 Ib (200-218 N*)

Load-Valve Open (Prior to Spec P) . .... . .. . ... . . .. . ... . . . . . . . . . ..... .. ... . .... . . 83-93 Ib '(369-414 N*)

Load-Valve Open (Begin Spec P). ............ . . . .. .. .... .... . . . . ..... ..... . . . . .. 87-97 Ib (388-432 N*)

Seat Outside Diameter

VALVE SPRINGS

4

* N. Base unit, Newtons. Unit of force.

** Measure intake valve stem at points indicated.

*

Valve Stem Diameter

(Intake)

2.96 in

1.18 in

5

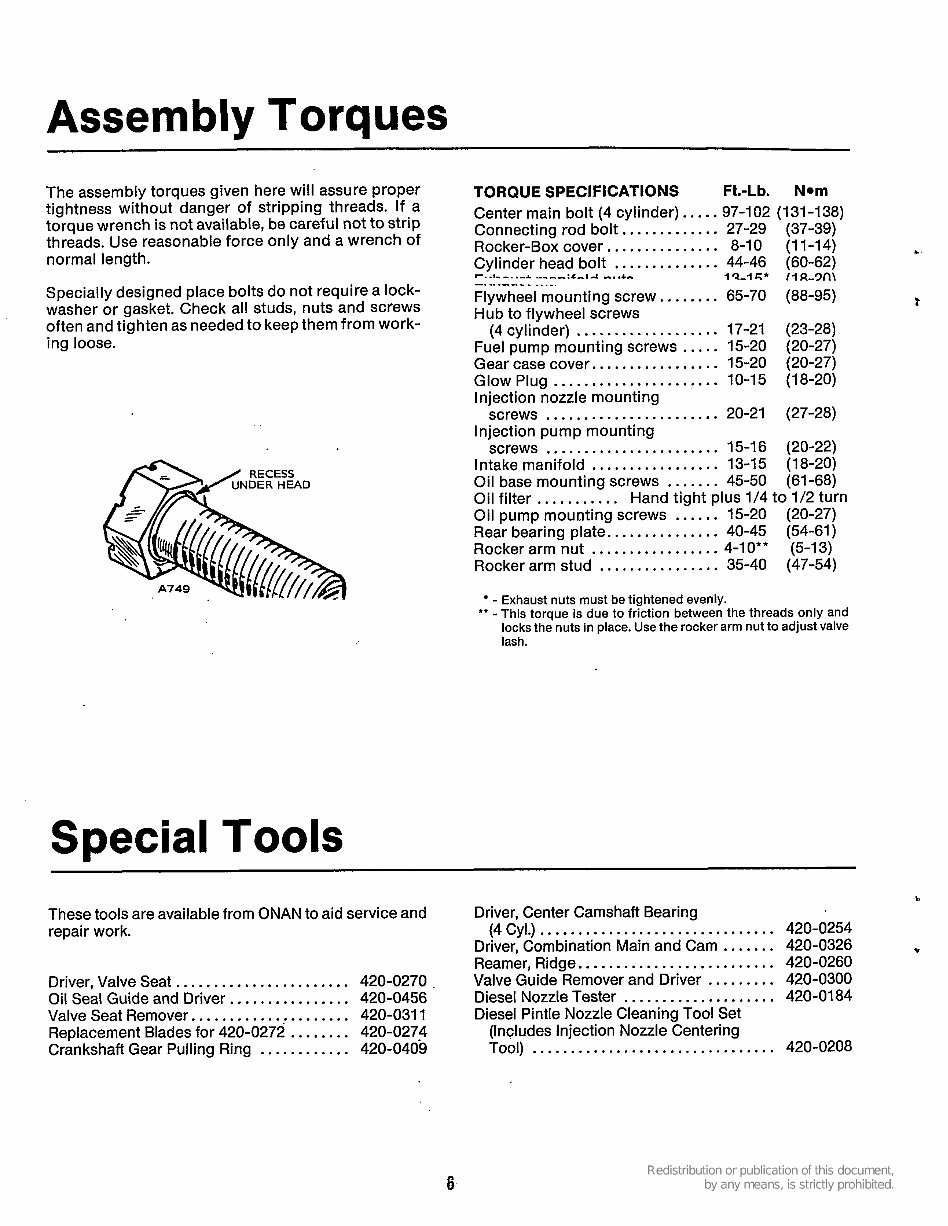

Assembly Torques

The assembly torques given here will assure proper

tightness without danger of stripping threads. If a

torque wrench is not available, be careful not to strip

threads. Use reasonable force only and a wrench of

normal length.

Specially designed place bolts do not require a lock-

washer or gasket. Check all studs, nuts and screws

often and tighten as needed to keep them from work-

ing loose.

Special Tools

TORQUE SPECIFICATIONS Ft.-Lb. Nom

Center main bolt (4 cylinder). . .. . 97-102 (131-138)

Connecting rod bolt., . .......... 27-29

Rocker-Box cover.. . . . . .. . .. . . .. 8-10

Cylinder head bolt . . . . . . . , .. .... 44-46

Flywheel mounting screw.. ..... . 65-70

Hub to flywheel screws

(4 cylinder) .. .. . . , . . . .. . .. . . . . 17-21

Fuel pump mounting screws . . . . . 15-20

Gear case cover.. . . ... . .... . . . . . 15-20

Injection nozzle mounting

screws .... . . . . . .... . ..... . . .. 20-21

Injection pump mounting

screws ... . . . . ... . . . . . . ....... 15-16

Intake manifold . . . . . . . . . ... . .... 13-15

Oil base mounting screws . . . . . . . 45-50

Oil filter . . . . . . ... . . Hand tight plus 1/4 to 1/2 turn

Oil pump mounting screws ...... 15-20

Rear bearing plate.. . . . . ... . . . . . . 40-45

Rocker arm nut . . . . . . ........... 4-IO**

Rocker arm stud . . . . . . . .... ... . . 35-40

(37-39)

(11-14)

(60-62)

(88-95)

(23-28)

(20-27)

(20-27)

(27-28)

(20-22)

(18-20)

(61-68)

(20-27)

(54-61)

(5-13)

(47-54)

1 Q-I r;* 1.1 R-3l-l\

n-. -1- -_.-A -- -.-:.C-i A -. . & , .

-. . . . -. -. - - . .. -.

Glow Plug ... . . . .. . . . . . . ........ 10-15 (18-20)

- Exhaust nuts must be tightened evenly.

** - This torque is due to friction between the threads only and

locks the nuts in place. Use the rocker arm nut to adjust valve

lash.

h

These tools are available from ONAN to aid service and Driver, Center Camshaft Bearing

Driver, Combination Main and Cam ....... 420-0326

Reamer, Ridge. . .. . .. . . .. .. ..... . ....... 420-0260

Valve Guide Remover and Driver . . . ... . . . 420-0300

Diesel Nozzle Tester . . .... . . ............ 420-0184

Diesel Pintle Nozzle Cleaning Tool Set

(Includes Injection Nozzle Centering

repair work. (4 Cyl.) . ... . ..... . ...... . . . .. . . . . . . ... 420-0254

*

Driver, Valve Seat . ....... . .. . . . . . . ... .. . 420-0270 .

Oil Seal Guide and Driver.. .. . . ... ...... . 420-0456

Valve Seat Remover. . . ... . .. . ... . . . .. . .. 420-031 1

Replacement Blades for 420-0272 . .. .. . . . 420-0274

Crankshaft Gear Pulling Ring . ... .... . . . . 420-0409 Tool) .... .... ..... . ... . .. . . . .. ... . . . . 420-0208

6

Engine Troubleshooting

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

Viewed 19 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

If you own or need to work on any of these engines, this is the service manual for you. It covers in great detail all the information you need, including:

- General Information

- Specifications

- Dimensions and Clearances

- Assembly Torques and Special Tools

- Engine Troubleshooting

- Service and Maintenance

- Exhaust System

- Cooling System

- Fuel System

- Governor System

- Oil System

- Starting System

- Special Equipment

- Control System

- Wiring Diagram

- Flywheel Alternator

- Engine Disassembly

This workshop service repair manual is fully bookmarked, allowing you to quickly navigate to the section you need.