STIHL 045 & 056 CHAIN SAWS Full Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

~

••

.~

~

4)

SERVICE MANUAL

STIHL 045,056

FOREWORD

This Service Manual covers model

045 chain saws up to machine number

5 919 430 as well as later machines

unless technical information bulletins

have been issued in the meantime

with updated repair procedures.

Model 045 have substantially the

same constructional features as

model 056 chain saws. This Service

Manual can therefore be used for the

056 chain saws as well.

In the event of faults it is quite pos-

sible that a single fault may have

several causes. It is therefore ad-

visable to consult the "Trouble-

shooting Chart" in each chapter when

tracing faults. We also recommend

that you make use of the exploded

views in the illustrated parts lists when

carrying out repair work.

This service manual and all technical

information bulletins are intended ex-

clusively for the use of STI HL servicing

dealers and staff and must not be

passed on to third parties.

Andreas Stihl

Postfach 1760

D-7050 Waiblingen

CONTENTS

Specifications

Saw Chain Drive with Clutch

Saw chain drive with clutch,

trouble shooting, disassembly

and repair

Driving Parts

Crankshaft with connecting

rod, cylinder and piston, ex-

posing the cylinder, removing

cylinder and piston, crank-

shaft and crankcase pressure

testing

Ignition System

Flywheel Magneto

Function, spark plug, high ten-

sion lead, short-circuit wire

and stop switch, checking and

adjusting the ignition timing,

flywheel, stator plate, ex-

changing the breaker point

set, ignition coil, condenser,

trouble shooting

Ignition System

Electronic Ignition

Advantages and function, con-

trolling the function of the elec-

tronic system on the motor-

checking and adjusting the

ignition timing - removal of

trigger plate - repair of the

electronic - trouble shooting

Rewind Starter

Design and operation - dis-

assembly and repair - instal-

lation of a new starter rope -

installation of rewind spring -

2 tensioning the rewind spring -

general repair

5

AV-Handle System

Disassembly and repair

Oil Pump

8 Operation - oil quantity con-

trol-removal of oil pump -

repair

Carburetor set-up and

Air Filter

Design and operation - dis-

assembly of carburetor and

elbow connector - repairing

16 component parts - carburetor

adjustment - pressure testing

Fuel Tank and Fuel Feed

Throttle Control

Special Tools

28

32

1

35

36'

38

44

45

46

2

SPECIFICATIONS 045

We reserve the right to change

design if this is deemed advan-

tageous or necessary.

4.94 cu. in (81 cm3)

2.0" (52 mm)

1.52" (38 mm)

0.76

9.5 :1

48.6 Nm at 5500 r.p.m.

11000 r.p.m.

1800 r.p.m.

Grooved ball bearing; bearing driving

side with integrated sealing ring

Split and two part

o 16 mm (0.630Jl) in diameter

o 13 mm (0.512") in diameter

70 mm (2.756") distances between

axes

Forced engagement with automatic

rewind of starter rope. Easy starting

by starting throttle lock

o 4.5x1000 mm (0.177x9.370")

in diameter

Heavy-duty centrifugal clutch with

pressed-on friction linings,

78 mm (3.071") in diameter

abt. 2500 r.p.m.

Testing pressure 0.5 bar

(7.1Ibf./in2)

Starter rope:

Rewind starter:

Clutch starting to engage at:

Pressure test of crankcase:

Clutch:

Crankshaft:

Crankpin:

Piston pin:

Length of conrod:

STIHL-one-cylinder two-cycle engine with heavy-chromium plated

cylinder wall

Piston displacement:

Cylinder bore:

Piston stroke:

Stroke-bore-ratio:

Compression:

Max torque:

Max. allowed speed:

Mean idle speed:

Bearings:

Engine

Fuel System

Carburetor:

Venturi:

High speed adjustment screw H:

Low speed adjustment screw L:

Press.ure test of carburetor:

Fuel tank capacity:

All position Tillotson diaphragm

carburetor HS with integral fuel pump

17.6 mm (0.693") in diameter

11/4turns open

1 turn open

0.4 bar (0.57 Ibf./in2)

0.821- 820 cm3 (1.73 pt)

1)

. .-

~J

Fuel mixture:

Air filter:

3

Regular grade gasoline and

branded two-cycle engine oil

1:40 with STIHL two-cycle engine oil

1:25 with other branded two-cycle

engine oils

Amply dimensioned wire mesh filter

Advanced ignition angle:

Breaker point gap:

Condenser:

Ignition System 045 AV

Ignition System 045 AVE/AVEQ

Bosch flywheel magneto, fully enclosed

Magneto edge gap: 6 9 mm (0.24 ... 0.35 in)

Advanced ignition: 2.5 2.7 mm (0.098 ... 0.106")

before top dead center

26.2 ... 27.50

before top dead center

0.35 ... 0.4 mm (0.014 0.016 in)

Capacity about 0.15 0.19 fLF

Magneto high tension condenser ignition system (capacitor discharge)

without breaker points, water- and dirtproof.

Advanced ignition: 2.5 ... 2.7 mm (0.098 ... 0.106")

before top dead center

Advanced ignition angle: 26.2 ... 27S

before top d~ad center

Spark plug: Bosch WSR 6 F

~

.-/

Torques for Screws and Nuts

Armature air gap:

Crankshaft nut

Magneto side M 10x1:

Crankshaft nut

Clutch side M 12x1.5 -Iefthand:

Clutch carrier

M 12x1.5 -Iefthand:

Cylinder head screws M 6x25:

Spark plug:

Heat range 175

Electrode gap 0.5 mm (0.02 in)

Spark plug thread M 14x1.25

Length of thread 9.5 mm (0.37 in)

0.2 ... 0.3 mm (0.007. .. 0.011 in)

30 Nm (21.70 ftllbf.)

35 Nm (25.32 ft/lbf.)

50 Nm (36.165 ftllbf.)

10 Nm (7.233 ft/lbf.)

30 Nm (21.70 ftllbf.)

4

Cutting Attachment

Guide bars:

Bar lengths:

Oilomatic-chains:

Chain speed:

Chain lubrication:

Maximum oil output:

Minimum oil output:

Mean oil output:

Oil tank capacity:

Chain sprocket:

STIHL Duromatic bar with carbide

tipped nose; STIHL Rollomatic bar

with spider nose. Either type is

protected from corrosion by

induction-hardened contact surfaces

Duromatic 40, 45, 50 and 63 cm

(16, 18, 20 and 25")

Rollomatic 37, 40, 45, 50 and 63 cm

(15,16, 18, 20 and 25")

9.32 mm (3fa")-Rapid and -Topic

10.26 mm (0.404")-Rapid

17.4 m/sec. (57.1ft per second)

at 8000 r.p.m. with 3/8" chain

19.2 m/sec. (63 ft per second)

at 8000 r.p.m. with 0.404" chain

Fully automatic oil pump with pump

plunger, output depending on chain

speed, pump supplying oil only

when chain is running, additional

quantity control by adjusting control

bolt.

15 cm3/min. (0.92 cu. in per minute)

at 6000 r.p.m.

8.5 cm3/min. (0.52 cu. in per minute)

at 6000 r.p.m.

12 cm3/min. (0.73 cu. in per minute)

at 6000 r.p.m.

0.36 I = 360 cm3 (0.76 pt)

7 teeth

Weights Motor dry

without bar and chain:

with 37 cm (15") bar and chain:

AViAVE:

7.9 kg (17.4 Ib)

9.1 kg (20.1Ib)

AVEQ:

8.3 kg (18.3 Ib)

9.5 kg (20.9 Ib)

Extras

STIHL repair kit (set of the most common wearing parts)

for friction shoe rewind starter 1115 900 5000

for single pawl rewind starter 1115 900 5001

Set of gaskets 1115 007 1050

e SAW CHAIN DRIVE AND CLUTCH

~

~

The power from the engine is trans-

mitted to the saw chain by a centri-

fugal clutch. This clutch is composed

of clutch carrier, clutch shoes and

clutch springs. But the two washers

in front of and behind the clutch as

well as the chain sprocket with

clutch drum riveted onto it are also

needed for a proper operation of

the clutch.

With increasing speed the clutch

shoes, held by the clutch springs,

Troubles

Bad engagement, clutch slips,

chain does not rotate

are forced to the outside; they are

pressed against the clutch drum

which is connected with the chain

sprocket thus transmitting the

engine power to the chain sprocket

and the saw chain.

The clutch springs have a certain

pre-tension so that clutch will not

engage before the engine speed of

about 2500 r.p.m. is reached. The

carburetor has to be adjusted in

such a way (see paragraph carbure-

Causes

Clutch linings worn

5

tor adjustment) that the chain does

not rotate at idle speed.

The clutch of the STIHL 045 AV and

045 AV electronic needs almost no

maintenance at all but, of course,

normal wear cannot be avoided.

Therefore, the clutch and the chain

sprocket must be checked on proper

condition periodically.

How to correct

Replace the complete set of clutch

shoes

Clutch and chain sprocket dirty (oil) Wash in clean gasoline, roughen

clutch linings with emery cloth

~

;.//

Saw chain does not stop running

when idling, extraneous noises

No chain lubrication

Extreme chain wear

Engine speed too high when idling

Spring stretched or fatigued

Spring hooks damaged

Needle cage damaged

Drive pin of cover plate broken

Worn chain sprocket

Readjust idle adjustment screw

Replace all springs

Replace needle cage

Install new cover plate

Replace chain sprocket

6

Disassembly and Repair

Locking screw

A dirty or improperly operating

clutch must be disassembled and

repaired.

For disassembly first loosen the two

hex. nuts with which the chain

sprocket cover is fastened and re-

move chain sprocket cover from bar

studs. Take off saw chain from chain

sprocket and remove with guide bar.

Pull off spark plug terminal and

unscrew spark plug with combi-

nation wrench, screw crankshaft

locking screw 11071911200 into

spark plug thread and tighten it by

hand. This will properly lock the

crankshaft.

Note: Hexagonal nut and clutch

have left-hand thread. Therefore,

unscrew by turning them clockwise.

Put combination wrench on hex. nut

and screw clockwise till piston rests

Top: Loosening the crankshaft nut

Bottom: Chain sprocket, ciutch with carrier,

clutch shoes and clutch springs

against the crankshaft locking

screw. Loosen and unscrew hex.

nut.

To guide the clutch shoes on the

clutch carrier the clutch is equipped

on both sides with a washer. The

washers are indented in their center

and must be installed in such a way

that they are resting with the recess

against the carrier. The front washer

is of larger diameter to better pro-

tect the clutch against saw dust.

Top: Clutch wrench

Bottom: Loosening the ciutch

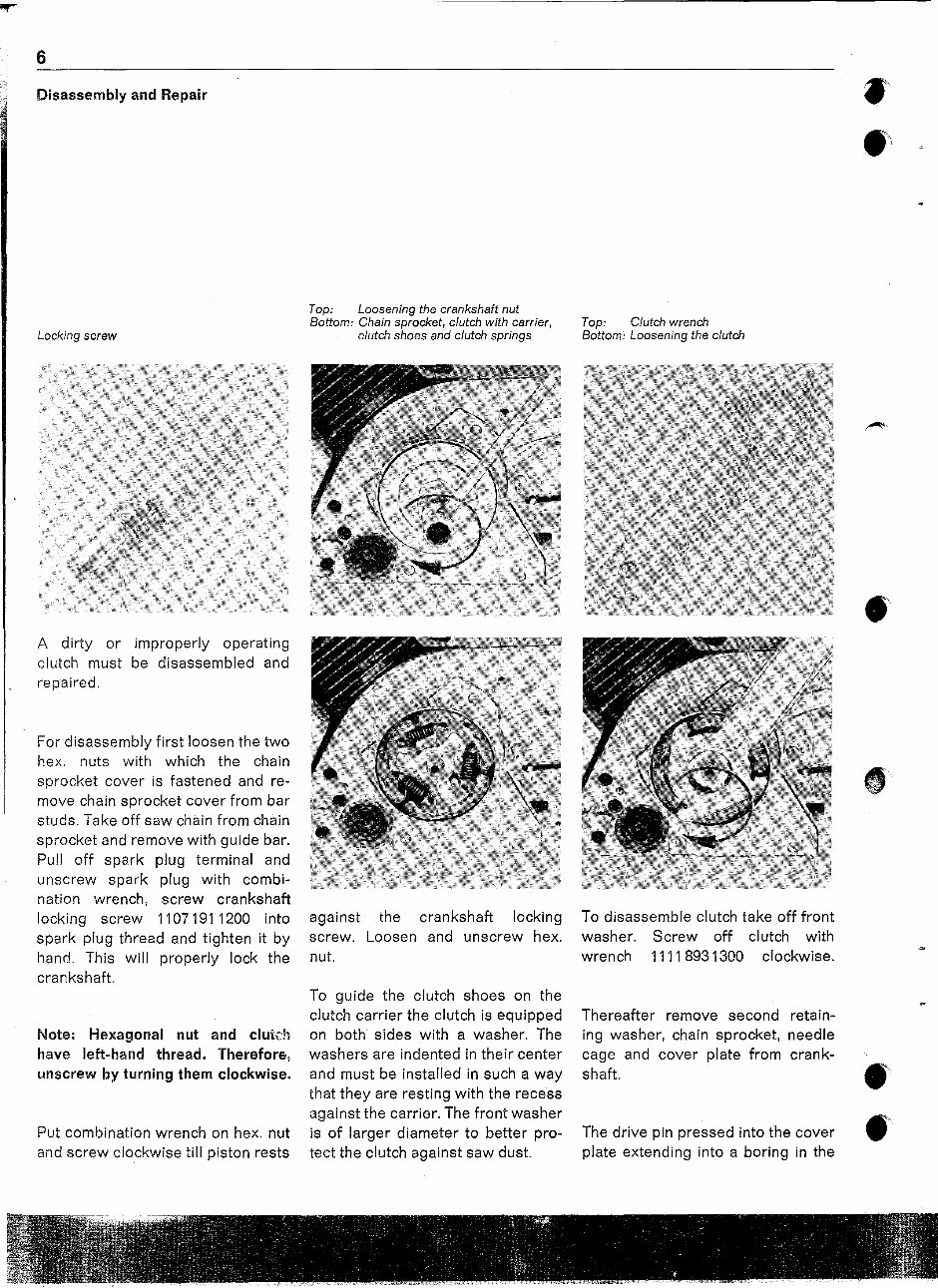

To disassemble clutch take off front

washer. Screw off clutch with

wrench 11118931300 clockwise.

Thereafter remove second retain-

ing washer, chain sprocket, needle

cage and cover plate from crank-

shaft.

The drive pin pressed into the cover

plate extending into a boring in the

~

.~

Torque wrench with insert

Top: Disassembly of clutch and sprocket

cover

Bottom: Tightening the crankshaft nut

7

~

;;/

chain sprocket and into the small

spur g~ar is driving the oil pump at

engaged clutch.

Replace damaged parts of the

clutch; only complete sets of clutch

shoes and clutch springs should bE:

replaced! If clutch is only fouled all

parts must be washed in clean ga-

soline and then cleaned with com-

pressed air. Roughen surfaces of

clutch linings with emery cloth.

Clean the dirty inside of the clutch

drum with a clean, dry rag.

The stress to the chain sprocket is

especially tough. If it shows visible

wear at the teeth it has to be ex-

.changed. This wear should not ex-

ceed a depth of 0,5 mm (0.019"). A

worn chain sprocket reduces the

life of the saw chain. If the cover

plate too is not in proper condition

it has to be replaced as well.

To reassemble the clutch place

cover plate onto crankshaft so that

driving pin extends into the boring

of the small spur gear of the oil

pump. Then put greased needle

cage, chain sprocket and the washer

which is smaller in diameter (ob-

serve correct inserting position)

back into place. Screw in clutch with

wrench anti-clockwise and tighten

with 5 kpm (36.165 ft/lbf.). Then put

front washer which is larger in

diameter onto crankshaft. Screw in

hex. nut and tighten with torque

wrench at 3,5 kpm (25,281 ft/lbf.).

Finally insert spark plug.

8

DRIVING PARTS

Crankshaft with connecting rod,

cylinder and piston

Disassembly of fan housing cover

Exposing the Cylinder

Top: Loosening the slotted nuts of the air

filter

Bottom: Loosening the hex. nuts Top and bottom: Removing the cover

The STIHL 045 AV and 045 AV elec-

tronic saws are driven by an air-

cooled one-cylinder two-cycle en-

gine. The split two part crankshaft

is supported in the crankcase made

of electron die cast metal (magne-

sium alloy). Crankshaft and connec-

ting rod are drop forged. The crank-

shaft is rigidly pressed together

when needle cage and connecting

rod are installed. Cylinder and

piston are made of a special alumi-

nium alloy. The cylinder wall is

heavily chromium impregnated.

Take off chain sprocket cover and

fan housing cover with rewind star-

ter. Unscrew locking screw of car-

buretor box cover and cover and

remove cover. Loosen two slotted

nuts of air filter and pull off filter

from the studs.

Pry off retaining washers at carbu-

retor from choke shaft and throttle

shaft and unhookstarter and throttle

rod on carburetor.

Unscrew 2 hex. nuts (SW 8) of the

carburetor fixation and remove car-

buretor from studs; to do so pry off

impulse hose from nipple at the

carbur8tor.

Now remove handle frame. To do

so unscrew collar screw at the right

front side as well as the 2 cyl. hd.

screws with inner hex. with which

the handle bar is tightened to the

handle frame and the 4 cyl. hd.

-'

~.

.-

;

,.--/

Top: Loosening the annular buffer

Bottom: Pulling off the short circuit wire

screws with which the handle frame

is screwed onto the carburetor box.

Unscrew collar stud next to the oil

inspection window with which the

carburetor box is fastened through

the rubber buffer to the crankcase

and unscrew also the annular buffer

with which the tank housing is fas-

tened.

Pull elbow connector with screw

driver from carburetor box and re-

Disassembly of fan cover

move impulse hose from nipple at

the cylinder.

Carefully disconnect short circuit

wire at the stop switch. Carburetor

box with tank housing can now be

removed completely. Remove ten-

sioning clamp at cylinder with flat-

nose pliers and pull off elbow con-

nector. Unscrew 3 cyl. hd. screws

M 4 x 16 of the fan cover fixation

and remove fan housing. First, ho-

wever, pullout high tension lead of

the guidance in the fan cover.

Now clean outside of cylinder

thoroughly and check for defective-

ness.

9

Disassembly of Cylinder

and Piston

Screwed in locking screw

Before unscrewing cylinder remove

spark plug and insert locking screw

into spark plug port by hand until it

fits tight.

Thereafter unscrew hex. nut for fas-

tening the flywheel and remove the

flywheel with the puller from the

crankshaft (see paragraph fly-

wheel).

Moreover, disassemble the hex. nut

for the fastening of the clutch as

well as the clutch from the crank-

shaft. Should you find out during

further disassembly that crankcase

or crankshaft happen to be defec-

tive the clutch cannot be removed

anymore from crankshaft with a

taken off cylinder.

Thereafter remove locking screw

again.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 23 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get instant access to the Complete Factory Service Repair Workshop Manual without any extra fees or expiry dates. This Professional Manual is suitable for both professional Mechanics and DIY enthusiasts, covering all repairs, servicing, and troubleshooting procedures with step-by-step instructions, detailed photos, diagrams, and highly detailed exploded diagrams & pictures.

Print out a single page or the entire manual as per your choice. The Manual can be used on multiple computers without any limitations or trial periods and can be used for life without the need to renew or pay any extra. It is fully compatible with all Windows & MAC Computers.

Click the button to get your hands on this comprehensive manual.