Stihl 015 015L Chainsaw Service Repair Workshop Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

T-

i

.c

STTHL AI5

ti}

C

o

PREFACE

The

power

cirain saws STIHL 015

and015L havebeenfirst introduced

at the beginning of July 1973. This

service shop manual is ment to

serve you as a guide book for pro-

per and skilled repair works on both

of thesemachines.

Moreover,we suggest to use the

illustrated spare parts list in our

instruction manuals as a help when

repairing. Technical modifications

which should be necessary after

publication of this repairinstruction

will be brought to your attention by

our

"Technical

lnformations".

This service shop manual as well as

all Technical Informations being

subject to modifications shall only

be given to personellwhich is in

charge of service and repair.

Handing over or lending this manual

to otherpersons is prohibited.

CONTENTS

Specifications

Engrne

Fuelsystem

lgnition system

Torques for screwsand nuts

Cutting attachment

ChainDrive and Clutch

Function

Troublin g

Disassembly

Repair

Reassembly

Engine

Construction

Trou b lin g

Exposing the cylinder

Cylinder

Disassem b ly-cran kcase

crankshaft and piston

Reassembly-crankcase

Pressure testing of crankcase

Pressure testing with vacuum

pump

lgnition System

Design and operation

Spark plug

Hightension lead

lgnition stop switch

Short circuit wire

Flywheel

Checking the ignition timing

Adjusting the ignition timing

lgnition System 015 L electronic

Design andoperation

Checking the ignition timing

Adjusting the ignition timing

Flywheel

2 lgnition coil

2 Magneto air gap

2 Trigger plate

3 Magneto edge gap

3 Checking the magneto edge gap

3 Contact plate

lgnition coil

Trouble shooting for ignition

a i'm atu re

Rewind Starter

Design and operation

Troubling

Installation of a new starter rope

8 Installation of rewind spring

B Tensioning the rewind spring

8 Pawls and hook-on spring

9 General repair

10

Oil Pump

Design and operation

Troubl ing

Disassembly of oil pump

Repair

to

Carburetor with Air Filter

17 Design and operation

17 Disassembly of carburetor

18 Repair

18 Pressure testing

19 Carburetoradjustment

19 Troubling

20 Fuelhose

zl

22 SpecialTools

5

q

5

o

6

7

30

JI

JI

22

23

ZJ

25

27

32

3Z

5Z

J4

34

35

35

11

12

36

JO

JO

?1

JI

38

38

39

?o

A'l

al

42

43

43

O STTHI:

Andreas Stihl

Postfach 1760

D -7050 Waiblingen

28

28

29

29

30

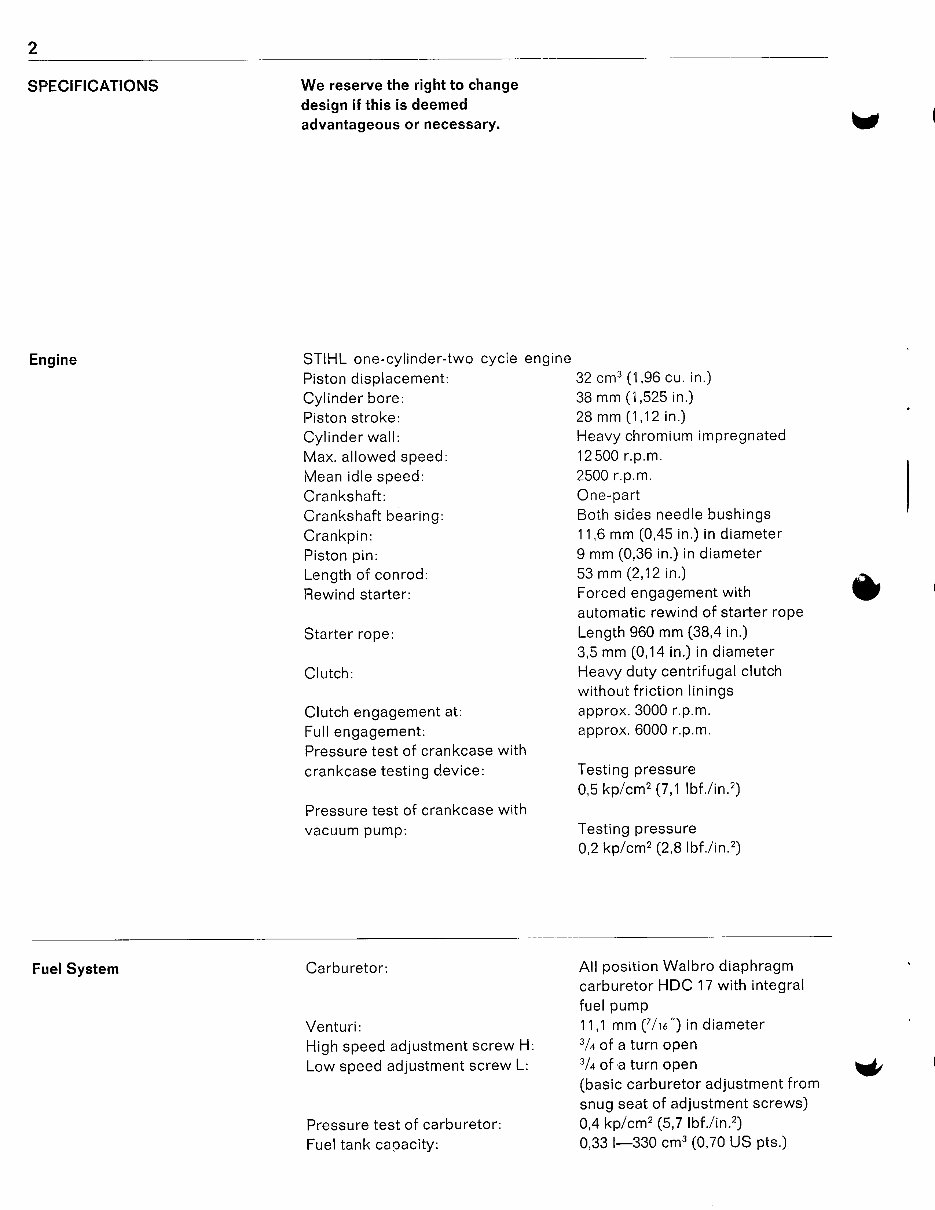

SPECIFICATIONS

We reservethe right to change

design if this is deemed

advantageous or necessary.

Engine STIHL one-cylinder-two cycle engine

Piston displacement: 32 cm3 (1,96 cu. in.)

Cylinder bore:

38 mm (1,525 in.)

Piston stroke:

28 mm (1,12 in.)

Cylinder wall: Heavy chromium impregnated

Max.allowed speed: 12500 r.P.m.

Mean idle speed: 2500 r.P.m.

Crankshaft: One-Part

Crankshaft bearing: Both sidesneedle bushings

Crankpin:

11,6 mm (0,a5 in.)in diameter

Piston pin: 9 mm (0,36 in.)in diameter

Length of conrod:

53 mm (2,12 in.)

Rewind starter:

Forced engagement with

automatic rewindof starter roPe

Starter rope: Length 960 mm (38'ain.)

3,5mm (0,1a in.)in diameter

Clutch:

Heavy duty centrifugal clutch

without friction linings

Clutch engagement at: approx' 3000 r.p.m.

Fullengagement:

approx. 6000 r.p.m'

Pressure test of crankcase with

crankcase testing device: Testing pressure

0,5 kp/cm2 (7,1lbf ./in.2)

Pressure test of crankcase with

vacuum pump: Testing pressure

0,2 kp/ cm2 (2,8lbf./ in.2)

Fuelsystem Carburetor:

All position Walbrodiaphragm

carburetor HDC 17 with integral

fuel pump

Venturi: 11,1 mm (7/rc") in diameter

Highspeedadjustment screw H:

slt

of a turn open

Low speedadjustment screw L:

3lt

of a turn open

(basic carburetor adjustment from

snugseat of adjustment screws)

Pressure test of carburetor: 0,4 kp/cm2 (5,7lbf./in.2)

Fuel tank capacity: 0,33

l-330 cms(0,70 US pts')

U'l

tr

v

3

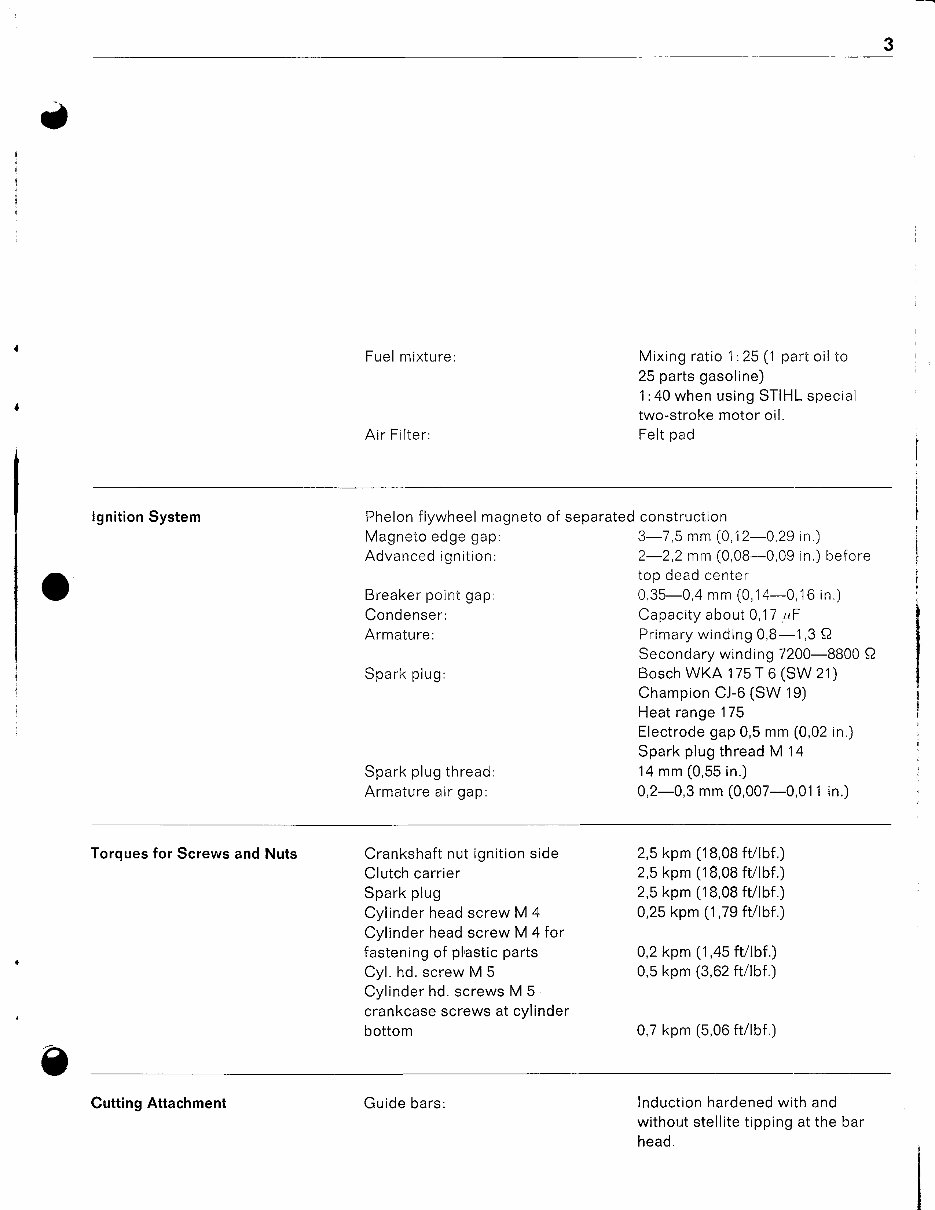

Fuelmixture:

Air Filter:

Mixingratio 1:25 (1 part oil to

25 partsgasoline)

1:40 when usingSTIHL special

two-stroke motoroil.

Feltpad

lgnition Systern Phelon flywheel magneto of separated construction

Magneto edge gap:

Advanced ignition:

Breaker pointgap:

Condenser:

Armature:

Spark plug:

3-7,5 mm (0,12-0,29in.)

2-2.2 mm (0,08-0.09in.)before

tnn do:ri aantar

0,35-0,4 mm (0,14-0,16in.)

Capacity about 0,17

,rF

Primary winding 0,8-1,3 f2

Secondary wlnding 7200-8800 Q

Bosch WKA 175 T 6 (SW 21)

Champion CJ-6 (SW 19)

Heatrange1 75

Electrode gap 0,5 mm (0,02 in.)

Sparkplug threadM 14

14 mm (0,55 in.)

0,2-0,3 mm (0,007-0,011 in.)

Spark plugthread:

Armature air gap:

Torques for Screwsand Nuts Crankshaft nut ignition side

Clutch carrier

Spark plug

Cylinder headscrew M 4

Cylinder headscrew M 4 for

fastening of plastic parts

Cyl. hd. screw M 5

Cylinder hd. screwsM 5

crankcase screwsat cvlinder

bottom

2,5kpm (18,08 ftllbf.)

2,5 kpm (18,08 fvlbf.)

2,5 kpm (18,08 ftllbf.)

0,25 kpm (1,79 ft/lbf .)

0,2 kpm (1,45 fVlbf.)

0,5 kpm (3,62 ftllbf.)

0,7 kpm (5,06 ftllbf.)

e

lnduction hardened with and

without stellite tipping at the bar

head.

Cutting Attachment Guidebars:

4

v !

Bar lengths:

Chain:

Chainspeed:

Chainlubrication:

Oil tank capacitY:

Chainsprocket:

25 cm (10 in.) guidebar without

stellite tipping at the bar head

30 cm

(12 in.) Duromatic

Auide

bar

with stellite tipping at the bar head

30 cm (12 in.) Rollomatic guidebar

with star shaped rollernose

r/a

"-oilomatic

chiPPer chain

STIHL chain model 3831

t/+ "-oilomatic-S-safetY

chain

STIHL chain model 3849

r/+ "-micromatic-semi-chisel chain

STIHL chain model3856

r/+ "-micromatic-S'safetY

chai n

STIHL chain model 3855

approx. 14,2

m/sek (46,58 ftlsec.)

at 8500 r.P.m.

Oil

pumpwith pumP

Plunger

governed by engine speed,

PUmPS

only when chain is rotating

0,18 l-180 cm3 (0,38 US

Pts.)

8 teeth lor

1/+"

chain

(

v

wiih 25 cm (10 in.)

bar and chain

015

015L,

4,2k9(9,2a

p)

Weight of Saw

01 5 L electron ic 4,4 kg (9,68

P.)

Extras

STIHL emergencY kit

Special muffler,

handguard

(

v

5

SAW CHAIN DRIVE AND CLUTCH

I

O

Function

'

I

{

"l

I

t

l

I

!

fhe power from the engine is trans- With increasing speed- at approx. Note:

a

mittedto the saw chainby a centri- 3000r.p.m. the clutch shoes held by The carburetorhas to be adjusted

fugalclutch. Thisclutch iscomposed the clutchspring are forced to the in such a way (see

"carburetor ad-

of clutch carrier,two clutch shoes outside.They are pressed against

justment")

that the chain does not

and one clutch spring.The washer the clutch drum thus transmitting rotate when engine is idling.

which is positioned behind the the enginepower to the saw chain.

clutch for the guidance of the clutch The chain sprocketalso drives the

shoes as well as the chainsprocket oil pump at engaged clutch, as the

with clutchdrum rivetedonto it are tooth profileengages in a provided

also partof the clutch assembly. recess at the small spur gear for

the

pump.

O

Troublins

The clutch is maintenancef ree.

Normal wear, however, cannot be

avoided. Therefore, the clutch and

chainsprocket must be checked on

propercondition periodically.

Troubles

Causes How to correct

Extraneous noises Engine is running too highwhen Adjustidle speedregulating screw

idlino

O

Saw chain does not stop running Springstretched or fatigued Replace spring

when idling Springhooksdamaged

Extreme chain wear Worn chain sorocket Replace chain sprocket

Disassembly

Starter rooe coiled around handle frame

A fouled or improperly operating

clutch as well as'a worn chain

sprocket must be disassembled and

repaired respectively replaced.

For disassembly first take off chain

sprocket cover and cutting attach-

ment. Carefully

pull of spark plug

terminal and screw out spark plug.

Thereafter pull out starter rope and

wind it three to four times around

the handle frame. This prevents

possible breakage of the starter

rope when reinstalling the clutch.

Now insertlocking screw into spark

plug thread by hand until its snug

seat to lock the crankshaft. Then

unscrew clutch with combination

wrench (SW 13) from the crank-

shaft.

Note! Clutch carrier has left hand

thread! Therefore unscrewing is

done in clockwise direction.

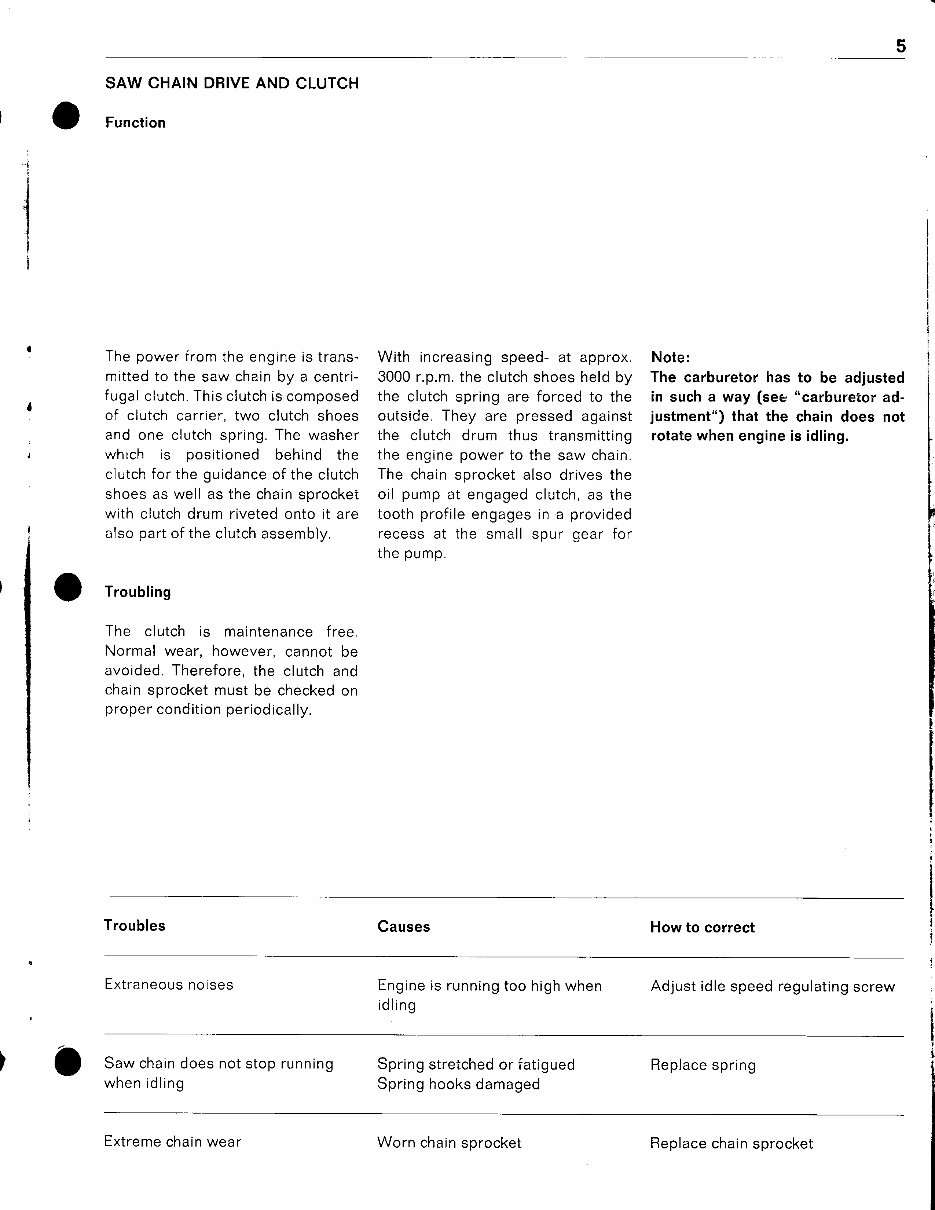

Top:

Inserting locking screw

Bottom:

Looseningthe clutch

Repair

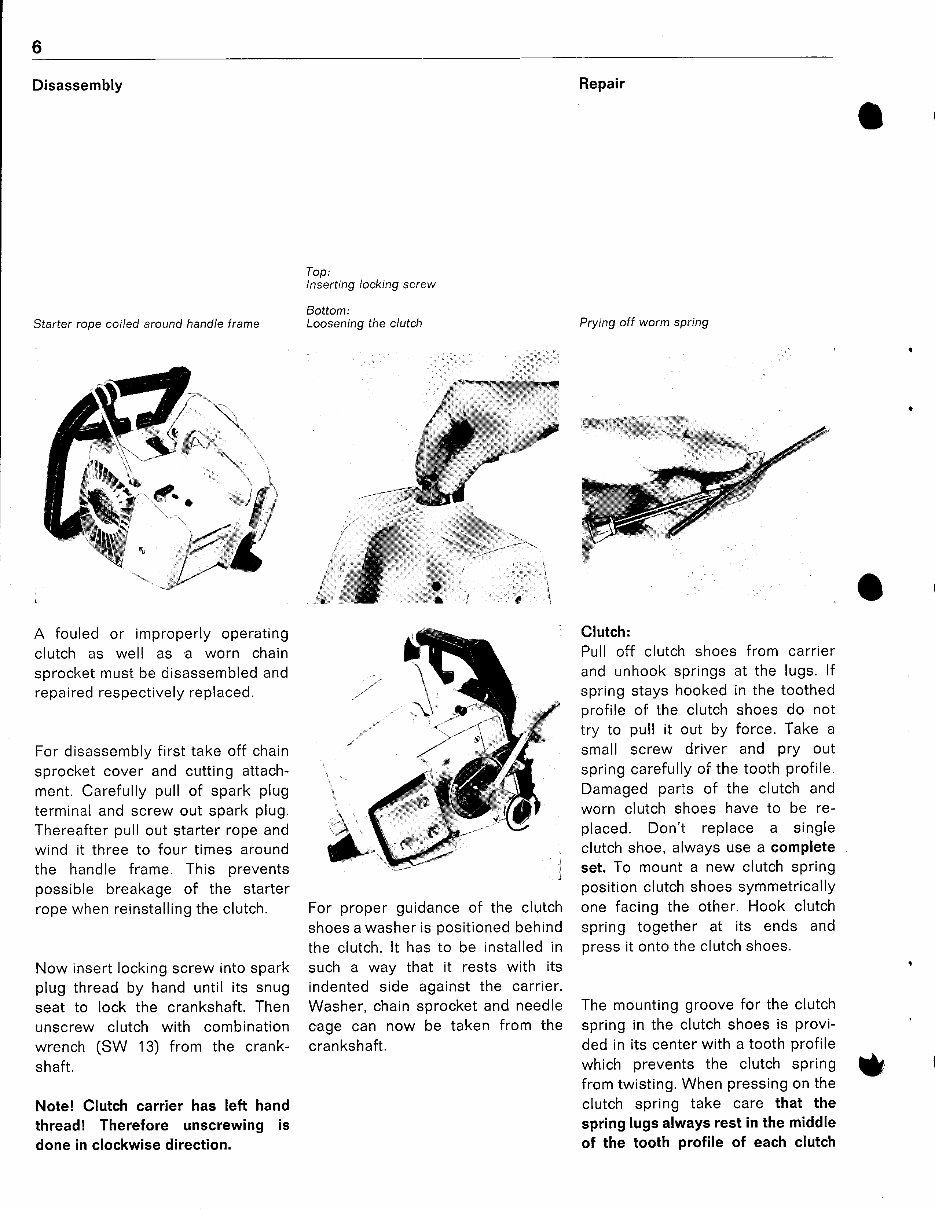

Prying off worm spring

Clutch:

Pull off clutch shoes from carrier

and unhook springs at the lugs. lf

spring stays hooked in the toothed

profile of the clutch shoes do not

try to pull it out by force. Take a

small screw driver and pry out

springcarefully

of the tooth profile.

Damaged parts of the clutch and

worn clutch shoes have to be re-

placed. Don't replace a single

clutch shoe, alwaysuse a comPlete

set. To mount a new clutch sPring

position clutchshoes symmetrically

one facing the other. Hook clutch

spring together at its ends and

oress it onto the clutch shoes.

The mounting groove for the clutch

spring

in the clutchshoes is provi-

ded in its center

with a tooth profile

which prevents the clutch spring

from twisting.

When pressing on the

clutch spring take care that the

spring lugs alwaysrest in the middle

of the tooth profile of each clutch

'l>

-

-''

\

rf1

..

,. -i

i.. ;

r'l

For proper guidanceof the clutch

shoes a washer is

positioned

behind

the clutch.lt has to be installed in

such a way that it rests with its

indented side against the carrier.

Washer,chainsprocketand needle

cage can now be taken from the

crankshaft.

F.y 'g o" c ;ctt sboes

shoe.Moreover, it is very important

that the clutch spring always rests

completely in the groove of the

clutch shoe-this is true also for the

areaof the toothprofile. lf the clutch

springis protruding it is undergoing

an unnecessary wearing

Process

at

engaged clutch- as a result of clutch

drum friction. lf the spring lugs are

placed outside of a clutch shoe a

breakage of the springmightoccur.

Then slide clutchshoes with clutch

springsonto carrier. With a screw-

driver pry on the clutch shoesto the

carrier. Therebypress clutchshoes

with one handto the carrier in order

to avoid its jump-backcaused bY

the pretensioning of the clutch

spri ng.

Chainsprocket:

The stress on the chainsprocket is

extremelyhigh. lf it shows visible

wear at the teeth it has to be ex-

changed. This wear should not ex-

ceed a depthof 0,5 mm (0,019 in.).

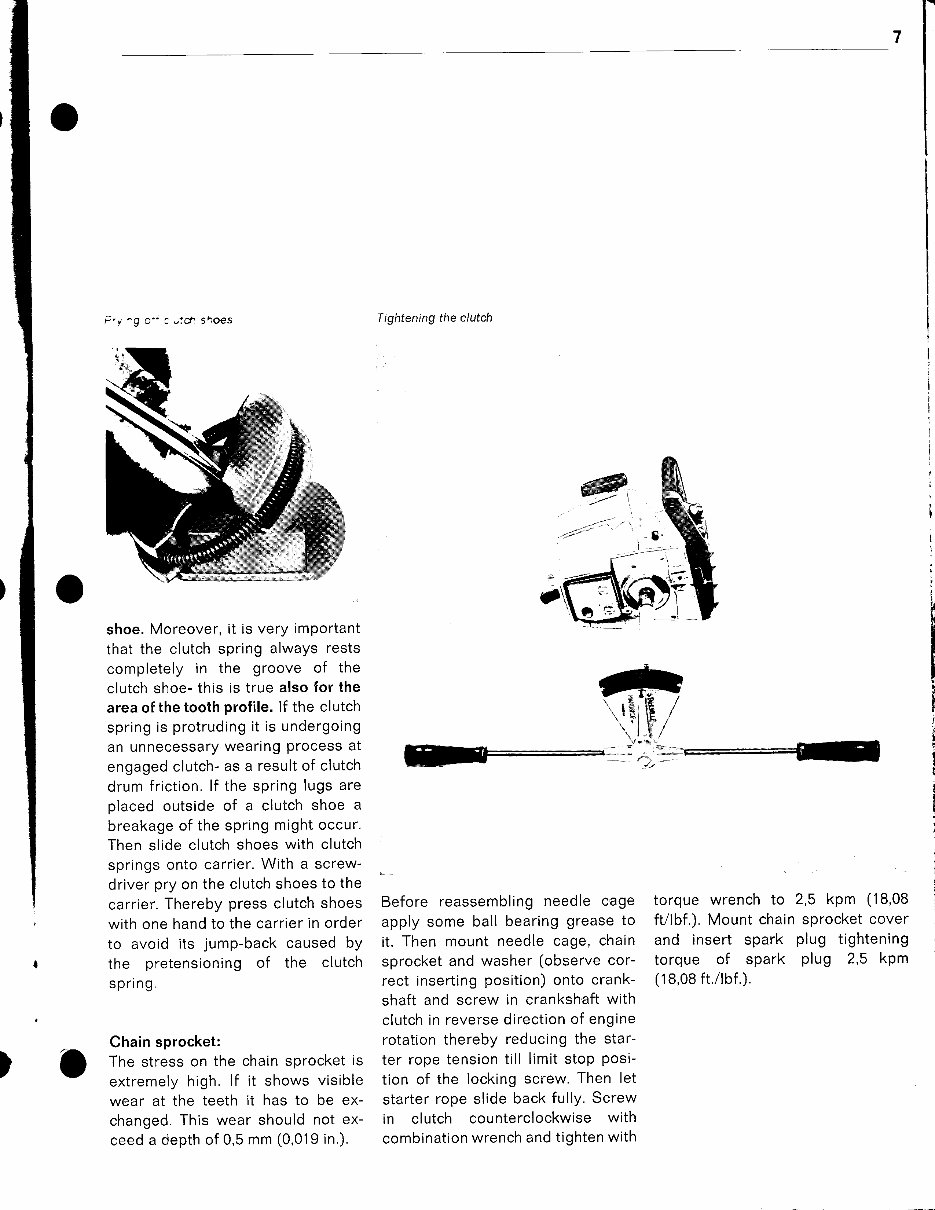

Tightening the clutch

Before reassembling needle cage

apply some ball bearing greaseto

it. Then mount needle cage, chain

sprocketand washer (observe cor-

rect inserting position) onto crank-

shaft and screw in crankshaft with

clutch in reverse direction of engine

rotationthereby reducingthe star-

ter rope tensiontill limit stop

posi-

tion of the locking screw. Then let

starter rope slide back fully. Screw

in clutch counterclockwisewith

combination wrench and tighten with

torque wrench to 2,5 kpm (18,08

ftllbf.).Mount chain sprocket cover

and insert spark plug tightening

torque of spark plug 2,5 kpm

(18,08 ft./rbf.).

@

-tt"

''

t'.'t9,8

,

,,,

jf

/

FrTZ

)

t-

t-

ENGINE

Construction O(

The power chain saws are driven 2 heavy duty needle bushings. At The crankshaft at the ignitionside

I

by an aircooledone-cylinder two- the bearing seats

of the crankcase is providedwith a cam to activate

cycle engine.The crankcasecon- the crankshaft is sealedby separate the breaker point set.The conrod is

sists of two housing parts; as a oil sealson both sides. The bearing made of a special tempered case '

specialconstruction feature the cy- support between crankshaft and hardened steel.

linder at the same time serves as conrod is achieved by 12 cylindrical

crankcase half.Cylinder and piston rollers which are individually posi-

are made of a special aluminum tioned in a grease layer on the

alloy. Thecrankshaft

is drop forged. crankshaft and are kept in the

It is a onepart crankshaftand is guide groove on the crankshaft by

supported in the crankcase with the connecting rod.

O(

Troubling Causes

How to correct

Engine stopswhen idling, however, Sealing ring of crankshaft leaks Replace sealing rings

ooerates normal at full throttle

Crankcase defective (cracks) Replace crankcase

Motor doesnot reach full Air filterclogged Clean

performance or runs irregularly

Engine gets by-pass air by badly Mountcarburetor correctly if

fittedcarburetor necessary replace flangegasket

Piston ring leaky or broken Replace piston ring

Engine overheated lnsufficient cylinder cooling. Air Cleancooling air by passes.

intake openings at handle shroud

clogged or cooling fins fouled

Engine all right Trouble sourcemustbe looked for

in fuel system resPectivelY

carburetor or ignition system, see

respective paragraPh.

tl

9

o

Exposing the Cylinder

Tap

U^scret ^g :-9' !e. Cover

Solo-

I coso'

5'' -

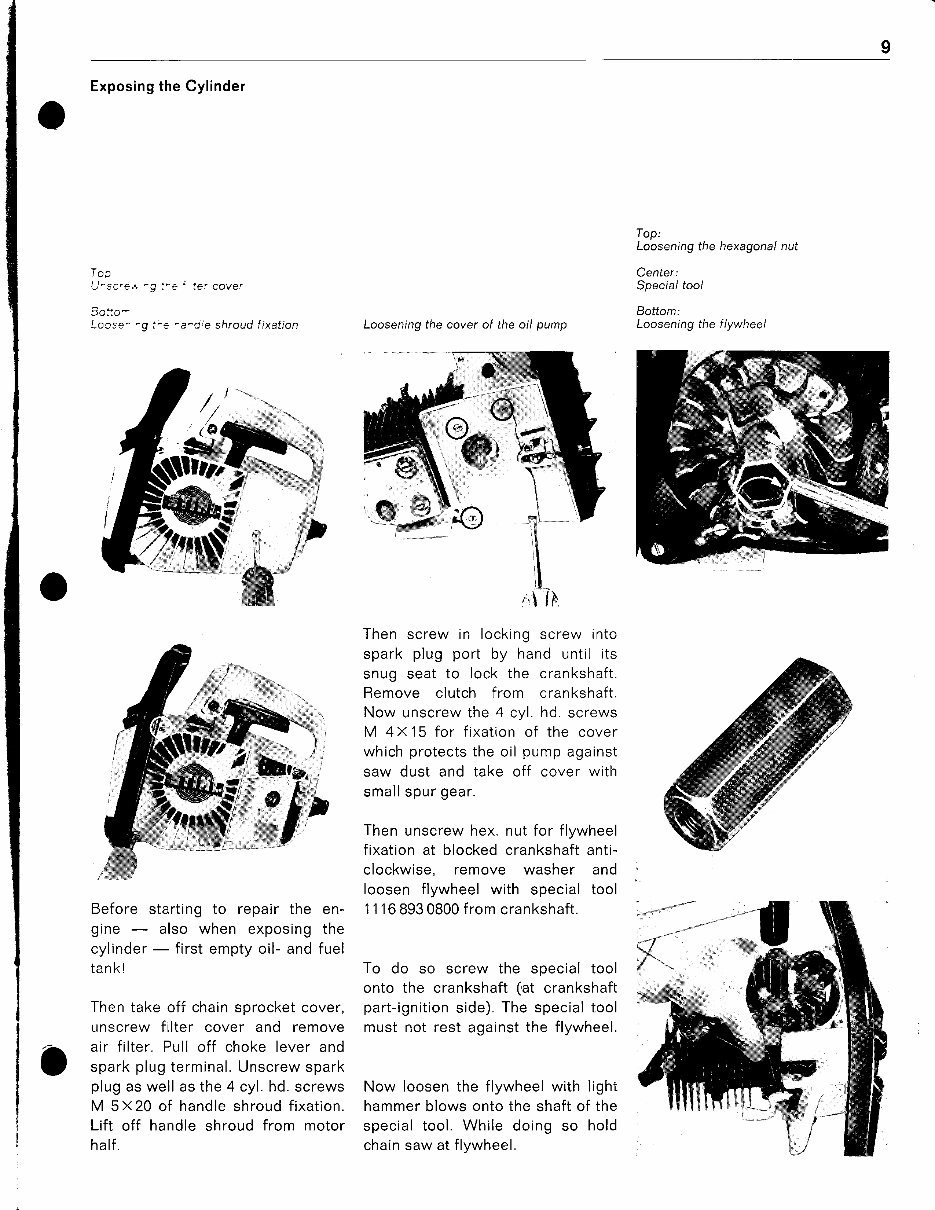

Before starting to repair the en-

gine - also when exposing the

cylinder - first empty oil- and fuel

tankl

Then take off chainsprocket cover,

unscrew f ilter cover and remove

air filter. Pull off choke lever and

spark plug terminal. Unscrew spark

plug as well as the 4 cyl. hd. screws

M 5X20 of handleshroud fixation.

Lift off handle shroud from motor

half .

Top:

Looseningthe hexagonal nut

Center:

Special tool

Bottom:

Loosenlngthe flywheel

o

Loosening the cover of the oil pump

Then screw in locking screw into

spark plug port by hand until its

snug seat to lock the crankshaft.

Remove clutch f rom crankshaft.

Now unscrew the 4 cyl. hd. screws

M 4X15 for fixation of the cover

which protects the oil pump against

saw dust and take off cover with

small spur gear.

Then unscrewhex. nut for flywheel

fixation at blocked crankshaft anti-

clockwise, remove washer and

loosen flywheel with special tool

111 6 893 0800 from crankshaft.

To do so screw the special tool

onto the crankshaft(at crankshaft

part-ignition side).The specialtool

must not rest againstthe flywheel.

Now loosen the flywheelwith light

hammer blows onto the shaft of the

special tool. While doing so hold

chain saw at flywhee,.

ffi3

i:l f&

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 11 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

This Service Manual for the STIHL 015 015L CHAINSAW is a comprehensive resource for immediate repairs. It contains detailed technical data, diagrams, and a complete list of parts. Whether you are a professional mechanic or a DIY enthusiast, this manual is a valuable tool.

- Introduction

- Specifications

- Clutch, Chain Drive, Chain Brake And Chain Tensioner

- Engine

- Ignition System

- Rewind Starter

- AV Handle System

- Master Control / Handle System

- Chain Lubrication

- Fuel System

- Special Servicing Tools And Aids

This Service Repair Manual is available in PDF format and is compatible with all versions of Windows and Mac. It is written in English and requires Adobe Reader for access. The manual provides step-by-step instructions, making it suitable for all skill levels, and can be easily accessed in the garage or workshop.