Stihl MS 271, MS 291 Brushcutters Service Repair Manual INSTANT

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

STIH)

STIHL MS 271, 291

2010-06

1 MS 271 C, MS 291 C

q

© ANDREAS STIHL AG & Co. KG, 2010

RA_574_00_01_01

1. Introduction and

Safety Precautions 3

1.1 Introduction 3

1.2 Safety Precautions 4

2. Specifications 5

2.1 Engine 5

2.2 Fuel System 5

2.3 Ignition System 5

2.4 Chain Lubrication 5

2.5 Tightening Torques 6

3. Troubleshooting 8

3.1 Clutch 8

3.2 Chain Drive,

Chain Brake,

Chain Tensioner 9

3.3 Chain Lubrication 11

3.4 Rewind Starter 12

3.5 Ignition System 14

3.6 Carburetor 15

3.7 Engine 18

4. Clutch 19

4.1 Clutch Drum 19

4.2 Clutch 19

5. Chain Brake 20

5.1 Checking Operation 20

5.2 Brake Band 20

5.3 Brake Lever 22

5.4 Brake lever on

machines with

QuickStop Super 24

5.4.1 Adjusting the

brake cable 26

5.4.2 Brake cable

Removing and

Installing 27

5.5 Cam Lever 29

5.6 Pins 30

5.7 Chain Tensioner 31

5.7.1 Quick chain tensioner 31

5.8 Bar Mounting Studs 32

6. Engine 33

6.1 Muffler 33

6.2 Leakage Test 34

6.2.1 Preparations 34

6.2.2 Vacuum Test 35

6.2.3 Pressure Test 35

6.3 Oil Seals 36

6.4 Shroud 37

6.5 Cylinder / Crankshaft 38

6.6 Crankshaft / Bearings 41

6.7 Piston 42

6.8 Piston Rings 44

7. Ignition System 45

7.1 Ignition Timing 45

7.2 Preseparator 45

7.3 Install new

ignition module 45

7.4 Testing the

Ignition Module 47

7.5 Spark Plug Boot /

Ignition Lead 48

7.6 Flywheel 48

7.7 Short Circuit Wire 49

7.7.1 Testing 49

7.7.2 Removing and

Installing 50

7.7.3 Ground Wire 52

7.7.4 Contact Spring 52

7.8 Ignition System

Troubleshooting 54

8. Rewind Starter 57

8.1 General 57

8.2 Fan housing 57

8.3 Pawls 58

8.4 ErgoStart 59

8.5 Rope Rotor 60

8.6 Starter Rope / Grip 60

8.7 Tensioning the

Rewind Spring 62

8.8 Replacing the

Rewind Spring 62

9. Servicing the

AV System 65

9.1 Annular Buffer and AV

Spring on Oil Tank 65

9.2 AV Spring on

Fuel Tank 65

9.3 AV Spring on

Handlebar 66

9.4 Stop Buffer at

Clutch Side 67

9.4.1 Stop Buffer at

Ignition Side 67

9.4.2 Buffers on Filter Base 68

9.5 Install new handlebar 68

10. Control Levers 70

10.1 Master Control Lever 70

10.1.1 Removing and

Installing 70

10.2 Throttle Trigger/

Lockout Lever 70

10.3 Throttle Trigger/

Lockout Lever –

QuickStop Super 72

10.3.1 Switch Lever –

QuickStop Super 73

10.3.2 Lockout Lever –

QuickStop Super 74

10.3.3 Choke Rod 75

10.3.4 Throttle Rod 75

11. Chain Lubrication 77

11.1 Pickup Body 77

11.2 Oil Suction Hose 77

11.3 Oil Pump 77

11.4 Valve 79

Contents

2 MS 271 C, MS 291 C

Contents

12. Fuel System 80

12.1 Air Filter 80

12.2 Baffle 80

12.3 Filter Base 80

12.4 Air Guide Shroud 82

12.4.1 Air Guide Shroud –

Models with

Manual Fuel Pump 82

12.5 Carburetor 84

12.5.1 Leakage Test 85

12.6 Servicing the

Carburetor 86

12.6.1 Metering Diaphragm 86

12.6.2 Inlet Needle 86

12.6.3 Pump Diaphragm 87

12.6.4 Levers on

Throttle Shaft 88

12.6.5 Adjusting Screws 89

12.7 Adjusting the

Carburetor 90

12.7.1 Basic Setting 90

12.7.2 Standard setting 92

12.8 Carburetor Carrier 92

12.9 Intake Manifold 94

12.10 Tank Vent 95

12.10.1 Testing 95

12.10.2 Removing and

Installing 95

12.11 Fuel Intake 96

12.11.1 Pickup Body 96

12.11.2 Fuel Hose 96

12.11.3 Fuel Hose –

Models with Manual

Fuel Pump 99

12.11.4 Manual Fuel Pump 102

12.11.5 Tank Housing 103

13. Special Servicing

Tools 106

14. Servicing Aids 108

3 MS 271 C, MS 291 C

1. Introduction and Safety Precautions

1.1 Introduction

This service manual contains

detailed descriptions of all the repair

and servicing procedures specific to

this power tool.

You should make use of the

illustrated parts lists while carrying

out repair work. They show the

installed positions of the individual

components and assemblies.

Refer to the latest edition of the

relevant parts list to check the part

numbers of any replacement parts.

A fault on the machine may have

several causes. To help locate the

fault, consult the chapter on

"Troubleshooting" and the

"STIHL Service Training System"

for all assemblies.

Refer to the “Technical Information”

bulletins for engineering changes

which have been introduced since

publication of this service manual.

Technical information bulletins also

supplement the parts list until a

revised edition is issued.

The special tools mentioned in the

descriptions are listed in the chapter

on "Special Servicing Tools" in this

manual. Use the part numbers to

identify the tools in the

"STIHL Special Tools" manual. The

manual lists all special servicing

tools currently available from

STIHL.

Symbols are included in the text and

pictures for greater clarity.

The meanings are as follows:

In the descriptions:

N Action to be taken as shown in

the illustration above the text

– Action to be taken that is not

shown in the illustration above

the text

In the illustrations:

A Pointer

a Direction of movement

@ 4.2 =Reference to another

chapter, i.e. chapter 4.2

in this example.

Service manuals and all technical

information bulletins are intended

exclusively for the use of properly

equipped repair shops. They must

not be passed to third parties.

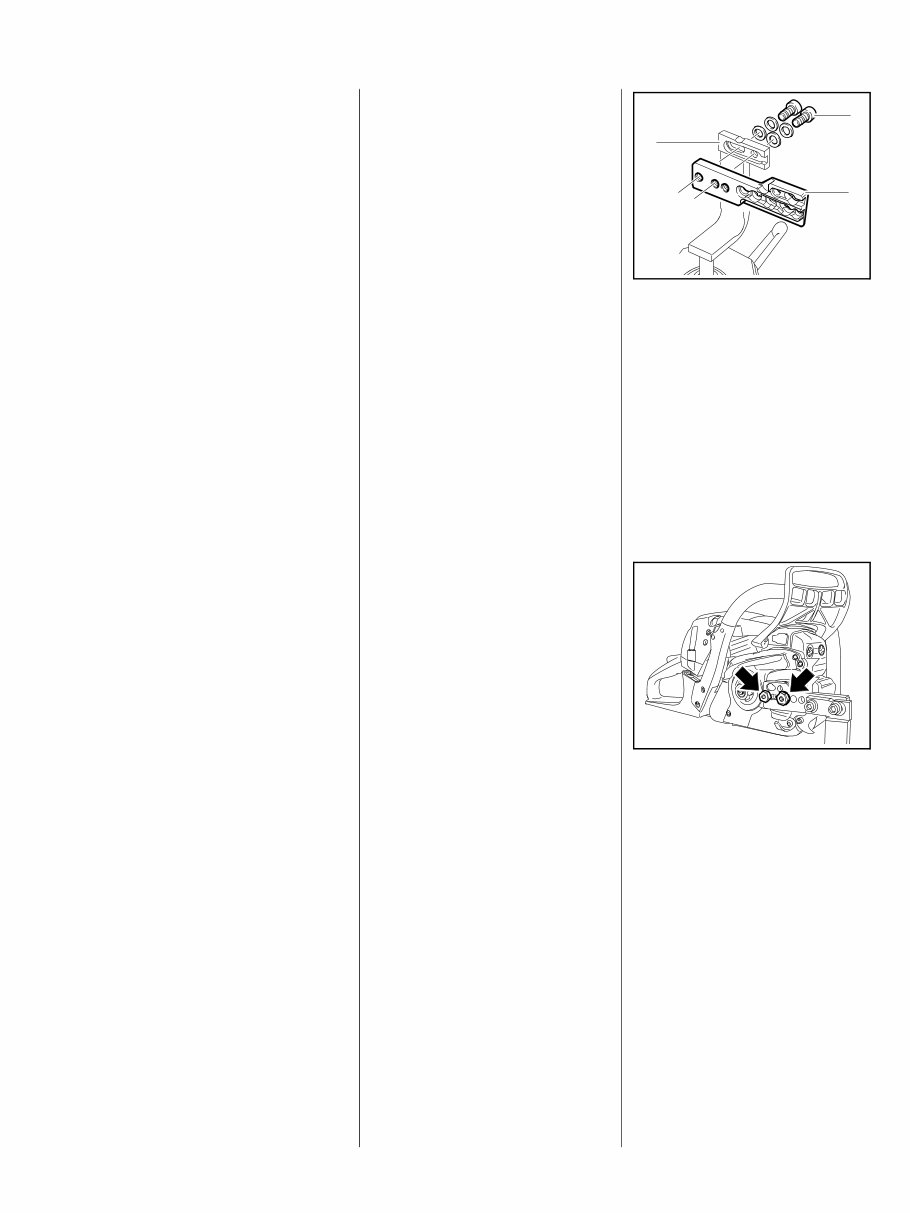

Servicing and repairs are made

considerably easier if the machine

is mounted to assembly stand (3)

5910 890 3101. To do this, secure

the mounting plate (2)

5910 850 1650 to the assembly

stand with two screws (1) and

washers.

The screws must not project since

they, depending on the machine,

may damage housings when the

machine is clamped in position.

Engage the bar mounting studs in

the outer bores in the mounting

plate and secure the machine in

position with the M 8 nuts (arrows).

2710RA320 TG

2

3

1

2710RA000 TG

4 MS 271 C, MS 291 C

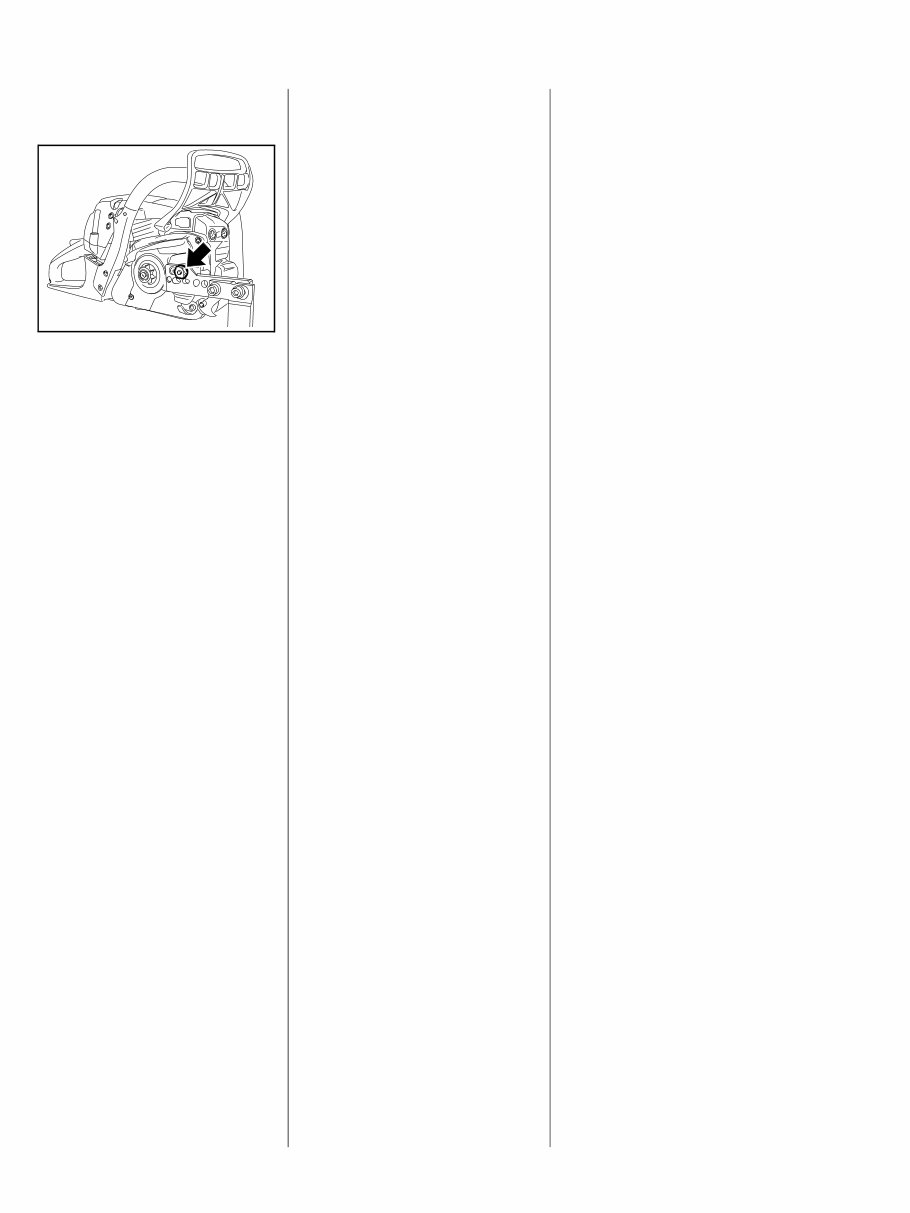

Machines with Quick Chain

Tensioner

Engage the bar mounting stud in the

upper bore in the mounting plate

and secure the machine in position

with the M 8 nut (arrow).

The machine is held in position on

the mounting plate by the screw

heads on the engine housing.

Preparations for servicing

Remove the chain sprocket cover,

saw chain and guide bar before

carrying out repairs or mounting the

machine to the assembly stand.

Always use original STIHL

replacement parts.

They can be identified by the STIHL

part number,

the { logo and the

STIHL parts symbol K

This symbol may appear alone on

small parts.

Storing and disposing of oils and

fuels

Collect fuel or lubricating oil in a

clean container and dispose of it

properly in accordance with local

environmental regulations.

2710RA001 TG

1.2 Safety Precautions

If the machine is started up in the

course of repairs or maintenance

work, observe all local and country-

specific safety regulations as well

as the safety precautions and

warnings in the instruction manual.

Gasoline is an extremely flammable

fuel and can be explosive in certain

conditions.

Do not smoke or bring any fire,

flame or other source of heat near

the fuel. All work with fuel must be

performed outdoors only. Spilled

fuel must be wiped away

immediately.

Always perform leakage test after

working on the fuel system and the

engine.

Exercise extreme caution while

carrying out maintenance and repair

work on the ignition system. The

high voltages which occur can

cause serious or fatal accidents.

Always wear suitable protective

gloves for operations in which

components are heated for

assembly or disassembly.

Improper handling may result in

burns or other serious injuries.

Always replace damaged parts.

Check disassembled parts for wear

or damage before re-installing –

replace as necessary.

Run the machine only with the

shroud mounted in position – there

is otherwise a risk of injury from the

fanwheel and a risk of engine

damage due to overheating.

The chapter on tightening torques

lists all machine components that

have to be tightened to a specific

torque or coated with threadlocking

adhesive. The specifications must

be maintained when tightening

down screws, nuts and other

fasteners in all the procedures

described in this service manual.

Fuel system – hose barb

connectors

Pull off or push on fuel hoses in line

with the connector, preferably by

hand, to ensure the tightness of the

fuel system.

Avoid damaging the hose barb

– do not use sharp-edged pliers,

screwdrivers, etc.

Do not cut open fuel hoses with a

knife or similar tool.

Do not re-use fuel hoses after

removal. Always install new hoses

– fuel hoses can be overstretched

during removal.

Install new fuel hoses either dry or

with the aid of STIHL press fluid,

b 14.

Other press fluids are not approved

and may result in damage to the fuel

hoses.

Coat the ends of the hoses and the

connectors with STIHL press fluid

and then push the new hoses on to

the hose barbs, b 14.

5 MS 271 C, MS 291 C

2. Specifications

2.1 Engine

MS 271 MS 291

Displacement: 50.2 cm

3

55.5 cm

3

Bore: 44.7 mm 47.0 mm

Stroke: 32.0 mm 32.0 mm

Engine power to ISO 7293: 2.6 kW (3.5 bhp)

at 9,500 rpm

2.8 kW (3.8 bhp)

at 9,500 rpm

Maximum permissible engine speed

with bar and chain: 13,000 rpm 13,000 rpm

Idle speed: 2,800 rpm 2,800 rpm

Clutch: Centrifugal clutch without

linings

Centrifugal clutch without

linings

Clutch engages at: 3,600 rpm 3,600 rpm

Crankcase leakage test

at gauge pressure: 0.5 bar

under vacuum: 0.5 bar

2.2 Fuel System

Carburetor leakage test at

gauge pressure: 0.8 bar

Operation of tank vent at

gauge pressure: 0.5 bar

Fuel: as specified in instruction

manual

2.3 Ignition System

Air gap between ignition

module and fanwheel: 0.20 (+ 0.1/- 0.05) mm

Spark plug (resistor type): NGK BPMR 7 A

Electrode gap: 0.5 mm

2.4 Chain Lubrication

Speed-controlled oil pump with reciprocating piston

Oil delivery rate: 8.0 (+/2.0) cm

3

/min

at 10,000 rpm

6 MS 271 C, MS 291 C

2.5 Tightening Torques

DG and P (Plastoform) screws are used in polymer and light metal components. These screws form a

permanent thread when they are installed for the first time. They can be removed and installed as often as

necessary without impairing the strength of the screwed assembly, providing the specified tightening torque is

observed.

For this reason it is essential to use a torque wrench.

Fastener Thread size For component Torque

Nm

Remarks

Screw P 4x12 Cover plate/chain sprocket cover 2.5 B

Screw P 4x12 Chain tensioner cover/engine housing 1.5

Screw P 4x14 Antivibration spring/engine housing 2.0

Screw P 5x16 Antivibration spring/tank housing 3.0

Screw P 4x12 Brake band/engine housing 2.0

Screw P 4x10 Brake cable retainer/ tank housing 2.0 Q

Collar screw M 8 Collar screw/collar bushing 30.0 1)

Collar screw M 8/M 10 Collar stud for bar / engine housing 16.0 3)

Collar screw M 8/ D 8 Collar screw/engine housing 16.0 B

Collar screw M 8/ D 9 Collar stud for bar / engine housing

(repair solution)

16.0

Screw P 4x12 Cover, chain brake / engine housing 1.5

Screw M 4x9.6 Spark arresting screen/muffler 1.0

Screw P 6x32.5 Handlebar/tank housing 7.0

Screw P 5x20 Hand guard/fan housing/engine housing 4.0

Screw M 5x20 Hand guard/fan housing/engine housing 8.0

Screw M 5x14 Shroud / engine housing 5.0

Screw P 6x28 Chain catcher/engine housing/bearing plug 6.0

Screw P 5x20 Spiked bumper / engine housing, top 4.0

Screw P 5x20 Spiked bumper / engine housing, bottom 4.0

Screw M 4x12 Manifold/cylinder 3.0 2)

Screw D 5x18 Bearing plug/cylinder 9.0 2)

Screw P 5x20 Fan housing / engine housing 4.0

Screw P 4x12 Air baffle / engine housing 2.0

Carrier M 12x1 L Carrier / crankshaft 50.0

Screw D 4x18 Oil pump/engine pan 4.0 2)

Screw D 5x18 Muffler / cylinder 9.0 2)

Nut M 8x1 Flywheel/crankshaft 28.0 4)

Screw P 4x12 Side plate/engine housing 2.0

Collar nut M 5 Carburetor / collar screw, 1st stage, fan side 2.0

Collar nut M 5 Carburetor / collar screw, 2nd stage, sprocket

side

3.5

Collar nut M 5 Carburetor / collar screw, 3rd stage, fan side 3.5

7 MS 271 C, MS 291 C

Fastener Thread size For component Torque

Nm

Remarks

Screw P 5x16 Pre-separator / engine housing 3.0

M 14x1.25 Spark plug/cylinder 25.0

Screw D 4x18 Ignition module/engine pan 4.0 2)

Screw D 6x50 Cylinder/engine pan 11.0

Screw D 6x35 Cylinder/engine pan 11.0

Remarks:

1) Loctite 270, high strength

2) Screws with binding head

3) Micro-encapsulated screws

4) Degrease crankshaft/flywheel and mount oil-free

Q) QuickStop Super

B) Quick chain adjuster

Use the following procedure when refitting a DG or P screw in an existing thread:

Place the screw in the hole and rotate it counterclockwise until it drops down slightly.

Tighten the screw clockwise to the specified torque.

This procedure ensures that the screw engages properly in the existing thread and does not form a new thread

and weaken the assembly.

Coat micro-encapsulated screws with medium strength Loctite 242 or 243 before reinstalling.

Power screwdriver setting for polymer: DG and P screws max. 500 rpm

Do not use an impact wrench for releasing or tightening screws.

Do not mix up screws with and without binding heads.

8 MS 271 C, MS 291 C

3. Troubleshooting

3.1 Clutch

Condition Cause Remedy

Saw chain stops under full load Clutch shoes badly worn Install new clutch

Clutch drum badly worn Install new clutch drum

Saw chain rotates at idle speed Engine idle speed too high Readjust idle speed screw LA

Clutch springs stretched Replace the clutch springs or install

new clutch

Clutch springs broken Replace the clutch springs

Loud noises Clutch springs stretched Replace all clutch springs

Needle cage damaged Fit new needle cage

Clutch shoe retainer broken Install new retainer or clutch

Clutch shoes and carrier worn Install new clutch

9 MS 271 C, MS 291 C

3.2 Chain Drive, Chain Brake, Chain Tensioner

Condition Cause Remedy

Chain sprocket wears rapidly Chain not properly tensioned Tension chain as specified

Wrong chain pitch Fit chain of correct pitch

Insufficient chain lubrication Check chain lubrication

Saw chain stops under full load Clutch shoes badly worn Install new clutch

Clutch drum badly worn Install new clutch drum

Brake band blocked Check freedom of movement and

operation of brake band

Saw chain rotates at idle speed Engine idle speed too high Readjust idle speed screw LA

Clutch springs stretched Replace the clutch springs or install

new clutch

Clutch springs broken Replace the clutch springs

Saw chain does not stop

immediately when brake is

activated

Brake spring stretched or broken Fit new brake spring

Brake band stretched or worn Fit new brake band

Clutch drum worn Install new clutch drum

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

$41.99

Viewed 91 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

$41.99

This comprehensive Service Manual is essential for immediate repairs to your STIHL MS 271 and MS 291 BRUSHCUTTERS. It contains detailed technical data, diagrams, and a complete list of parts, making it indispensable for professional mechanics and DIY enthusiasts alike.

- Models Covered:

- Stihl MS 271

- Stihl MS 291

The manual covers:

- Introduction

- Safety Precautions

- Specifications

- Troubleshooting

- Clutch

- Chain Brake

- Engine

- Ignition System

- Rewind Starter

- Servicing the AV System

- Control Levers

- Chain Lubrication

- Fuel System

- Special Servicing Tools

- Servicing Aids

File Format: PDF

Compatibility: All Versions of Windows & Mac

Language: English

Requirements: Adobe Reader

This manual provides step-by-step instructions, making it easy for any skill level to perform their own repairs and save money. Take it with you into the garage for quick access to the information you need.