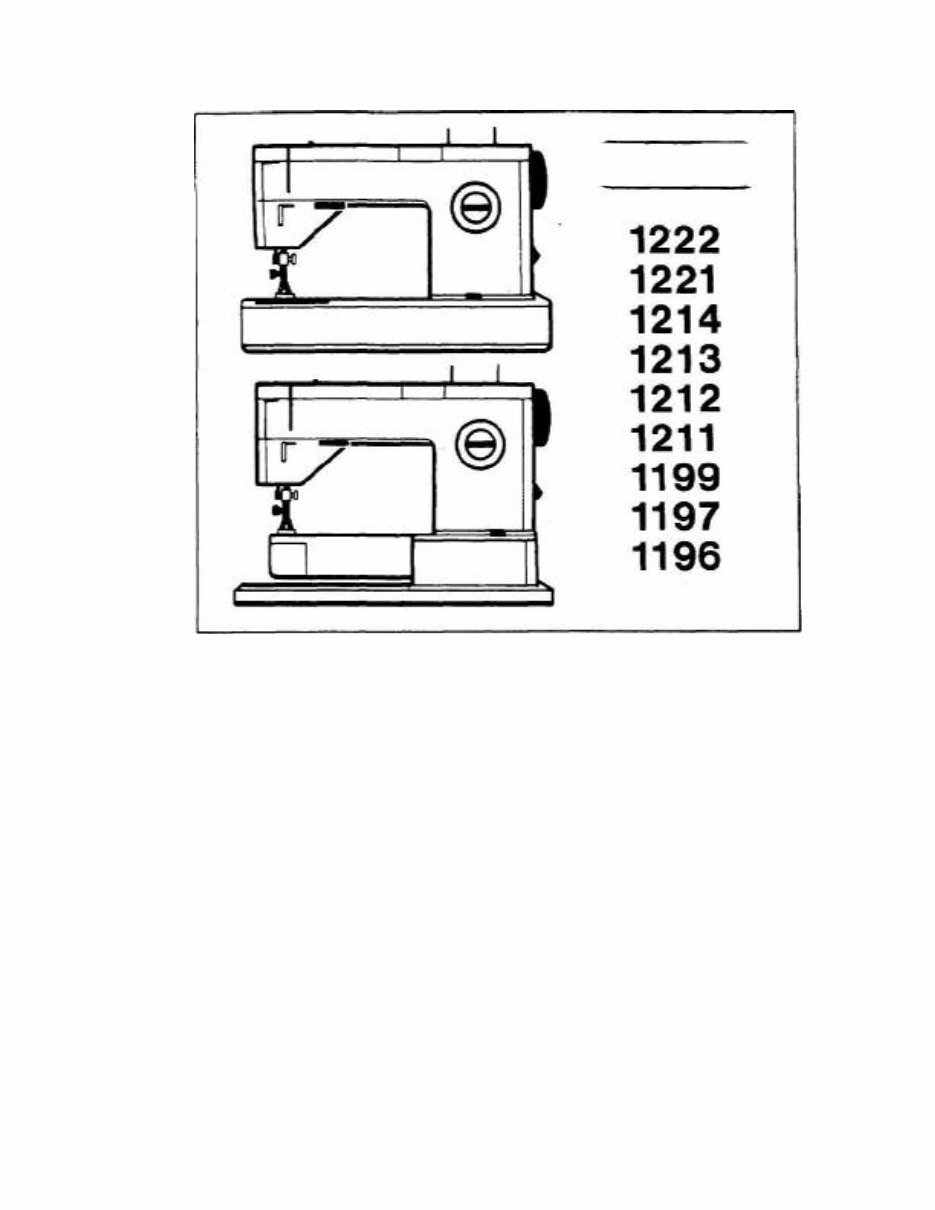

PFAFF Sewing Machine Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

How to Repair

PFAFF

How to Repair Sewing machine PFAFF

C PFAFT)

Foreword

This provisional Service Manual has been compiled in order to enable our service

personnel to carry out all repairs on these machines quickly and satisfactorily. It will

be superseded by the final edition when it is published.

Before you carry out any adjustments, acquaint yourself with the settings discussed

in this Manual and check whether the machine is actually out of adjustment. Since,

apart from a few minor details, the mechanical setup of Pfaff machines 1222, 1221,

1212 and 1211 is the same, the instructions contained in this Manual apply to all of

them. Variations in the adjustment procedure which are necessitated by differences

in design are discussed separately.

For checking up or adjusting a machine, it is best to follow the procedure outlined in

the Manual. When re-assembling machines which have been dismantled completely,

roughly adjust all parts in order to facilitate final adjustment. When ordering spare

parts, please refer to the Spare Parts Catalogue and state the following:

1. Machine class

2. Complete ten-digit

3. Part name

4. Color of finish, if part is lacquered.

5. Old or new version, if applicable.

When making electrical repairs, be sure to comply with the safety regulations in

effect in your country. Since part of the electrical system of these machines must

only be tested at low tension, proceed in strict compliance with the instructions given

in the chapter on the "Electrical System". For this reason, all electrical repairs must

be performed by an expert.

Adjustment of the machine is greatly facilitated by the following tools and

gauges:

Needle rise gauge 87O 136-01

C-clamp for above gauge 87O 137-00

Bobbin case position slot gauge 7*501.00-201

Machine feed gauge 63-112 120-08

Special spanner 106 300-306

Combination spanner, 5«5 nun 43-111 010-04

Combination spanner, 7«0 mm 43-111 010-05

Combination spanner, 8 mm 43-111 010-06

Circlip pliers, ZA 21 07-438 000-40

Circlip pliers, A 1 07-438 000-50

Clip washer pliers, 1.9 kz 07-437 003-10

Clip washer pliers, 2.3 kz 07-437 003-20

Clip washer pliers, 3.2 kz 07-437 003-30

Clip washer pliers, 4.0 kz 07-437 003-40

Clip washer pliers, 5.0 kz 07-437 003-50

Clip washer pliers, 6.0 kz 07-437 003-60

Clip washer pliers, 7.0 kz 07-437 003-70

Contents

Page

Foreword 1

Technical Data 5

Stop Matic Mechanism

Operation

1. Adjusting the Clutch Lever 7

2. Sotting the Roller in Relation to the

Roller Clutch Pin 9

Zigzag Mechanism

3. Dismantling the Automatic Mechanism 10

Relative Adjustment of Worm Gears and

of Drive Lever 11

6. Adjusting the Needle Position Knob 12

7. Basic Position of Eccentric Stud in

Needle Bar Frame 13

8. Zeroing the Needle for Straight Stitching 14

9. Adjusting the Needle Vibration Controlled

by the Zigzag Mechanism 15

10. Adjusting the Needle Position 17

11. Centering-The Needle Throw in the

Needle Plate Slot l8

Buttonhole MechanismM 12.

Op

eration of Buttonhole Mechanism 20

13. Basic Position of Buttonhole Control Stop 22

lk. Adjusting the Relative Position of Driving

Pawl and Ratchet Wheel 23

15. Timing the Pawl Stroke 2k

16. Final Adjustment of the Buttonhole

Control Stop 26

17 Timing the Buttonhole Forward-Reverse Feed 28

Feed Mechanism

18. Lateral Adjustment of Feed Dog 29

19. Setting the Feed Dog Parallel to the

Needle Plate 31

20. Setting the Feed Dog at the Correct Height 32

21. Adjusting the Feed Eccentric Clutch Sleeve 33

22. Adjusting the Feed Eccentric Endwise 35

23. Adjusting the Link-Type Feed Regulator

Endwise 36

2k. Zeroing the Feed Regulator 37

25. Timing the Top and Bottom Feed Strokes 38

Page

26. Adjusting the Drop Feed Mechanism 40

27. Setting the Presser Bar at the Correct Height 4l

28. Adjusting the Pressure on the Material 43

29. Lateral Adjustment of Feeding Foot in

Relation to Sewing Foot 44

30. Adjusting the Feeding Foot in Sewing

Direction 46

31. Adjusting the Feeding Foot Vertically 47

32. Adjusting the Vibrator 48

33. Timing the Buttonhole Forward-Reverse Feed 50

Sewing Mechanism

34. Adjusting the Position of the Needle in the

Needle Plate Slot 52

35. Basic Position of Hook Bearing 52

36. Timing the Sewing Hook 53

37. Setting the Needle Bar at the Correct Height 54

38. Setting the Hook-to-Needle Clearance 57

39. Adjusting the Bobbin Case Position Finger 58

Automatic Mechanism

40. Operation 60

41. Fitting the Automatic Mechanism 63

Fixed-Ratio Automatic Mechanism

42. Setting the Clearance between Worm and

Worm Wheel 65

43. Setting the Feeler Fingers Close to the

Cam Stack 66

44. Adjusting the Needle Vibrating Controlled

by the Fixed-Ratio Automatic Mechanism 67

45. Centering the Needle Throw in the Needle

Plate Slot for Functional Stitching 69

46. Adjusting the Length of Forward and Backward

Stitches for Hemstitching 70

..... Variable-Ratio Automatic Mechanism

47. Setting the Feeler Fingers Close to the

Cam Stack 72

48. Zeroing the Pattern Length Wheel 73

49. Close Setting of Feeler Finger for Scallops 74

Electrical System

50. Description of Electrical Equipment 75

51. Setting the Maximum Speed and the Speed for

The Stop matic Control 79

52. Setting the Maximum Speed of Machine and Stop

matic Mechanism on Machines Equipped with

Dual-Voltage-Range Motors (110 and 220 V) 8l

53. Adjusting the Cleaned Belt Tension 8j>

54. Test Procedure and Trouble Shooting in the

Electrical System 84

Page

Sewing Off

5^. Adjusting the Dobbin Winder 85

55. Operation of Needle Threaded 86

56. Adjusting the Threaded Bar Collar 86

57» Adjusting the Needle Threaded Head 87

58. Tension Regulation 88

59* Adjusting the Bobbin Thread Tension 88

60. Adjusting the Needle Thread Tension 89

61. Adjusting the Tension Release Mechanism 90

62. Adjusting the Stroke of the Thread

Check Spring 91

63. Adjusting the Length of Forward and

Backward Stitches for Hemstitching 92

64a. Sitting the Household Overlook Stitch 92 a

6k. Adjusting the Length of Forward and

Backward Stitches for Triple-Stitch Seams 93

65. Making a Sample Various repair jobs Swatch 94

66. Changing the motor and the carbon brushes 95

67. Changing the pressure spring in the

balance-wheel realize Icon 99

Technical Data

Pfaff 1222 free-arm sewing machine with additional top feed

And combined automatic unit consisting of a fixed-ratio functional-stitch

mechanism and a variable-ratio ornamental-stitch mechanism.

Pfaff 1221 flatbed sewing machine with additional top feed

And combined automatic unit consisting of a fixed-ratio functional-stitch

mechanism and a variable-ratio ornamental-stitch mechanism.

Pfaff 1212 free-arm sewing machine with fixed-ratio automatic functional-stitch

mechanism.

Pfaff 1211 flatbed sewing machine with fixed-ratio automatic functional-stitch

mechanism.

Fixed-ratio automatic unit with forward-reverse feed control, reduction ratio 12:1.

Five functional stitches which can be varied by different zigzag settings or combined.

Variable-ratio automatic unit with intermittent drive and stitch number regulation.

Five ornamental stitches which can be varied by different needle position and pattern

length settings or combined. Zigzag mechanism with needle vibration control and

needle position adjustment (left, center, right).

Stitch length and stitch width settings are combined in fixed relationship.

Semi-automatic buttonhole unit with forward-reverse feed control.

Feed eccentric clutch (for reverse sewing and buttonholing). Top and bottom feeds, 1:1

feed ratio, upper feeding foot can be disengaged.

Electronic speed control by thyristor control. Master switch for

electrical system.

Stop matic control with roller clutch for controlling needle position at end of sewing

action.

Drop feed mechanism combined with vibrator for operating the presser bar.

Power is transmitted from the arm shaft to the hook drive shaft by a clip belt at a ratio of

1:2.

Power is transmitted from the motor to the shaft by a cleared belt.

Link take-up.

Vibrating needle bar frame.

Transverse, double-revolution rotary hook. Needle system

130. Light-metal casting.

Weight of machines with motor, but without accessories:

Pfaff 1222 10.20 kg (22.4 lbs)

Pfaff 1221 9.00 kg (19.8 lbs)

Pfaff 1212 9.50 kg (20.9 lbs)

Pfaff 1211 8.35 kg (18.3 lbs)

Stitch length approx. 4 mm (6 s.p.i.) Stitch width

approx. 4.5 mm (11/64")

Clear work space: 225 x 120 mm (9" x 4 3/4") Bedplate dimensions: 421 x 178

mm (15 1/2" x 7") Base plate dimensions on free-arm machines: 421 x 178 mm

(15 1/2" x 7") Motor:

Type GE 270, 220 or 110 V, 0-60 c/s, 40/80 W,

7000 r.p.m. + 10 % Type GE 271,

dual-voltage-range motor for 220 or

110 V connection, 0-60 c/s, 40/80 W,

7000 r.p.m. + 10 % Fully radio and TV

suppressed. Suppression class: FN Sewing head: insulation class

2 Motor alone: insulation class 1 Glare-free sewing light, 15 W.

Finish: light grey (No. 6) Subject to alterations in design and

dimensions.

Various Data

Needle bar rise Hook-to-needle clearance Needle

bar height (top of needle eye to lower edge of

hook point), set with machine set for widest

zigzag stitch and needle on left of its throw.

Clearance between bobbin case position

finger and position slot Feed dog height Foot

lift

Maximum feeding foot rise Final

phase of feed stroke

Lowest position of darning foot

above needle plate level

Maximum sewing speed

Maximum speed of Stop matic mechanism

2.0 mm (.08") 0.1

mm (.004") 0.5 mm

(.02")

0.7 mm (.027") 0.9

mm (.035") 6.5 mm

(.25") 1.2 mm (.05")

0.6 - 0.7 mm (.023"

- .027")

0 - 0.1 mm (.004") 900 -

1000 r.p.m. 120 r.p.m.

STOPMATIC MECHANISM

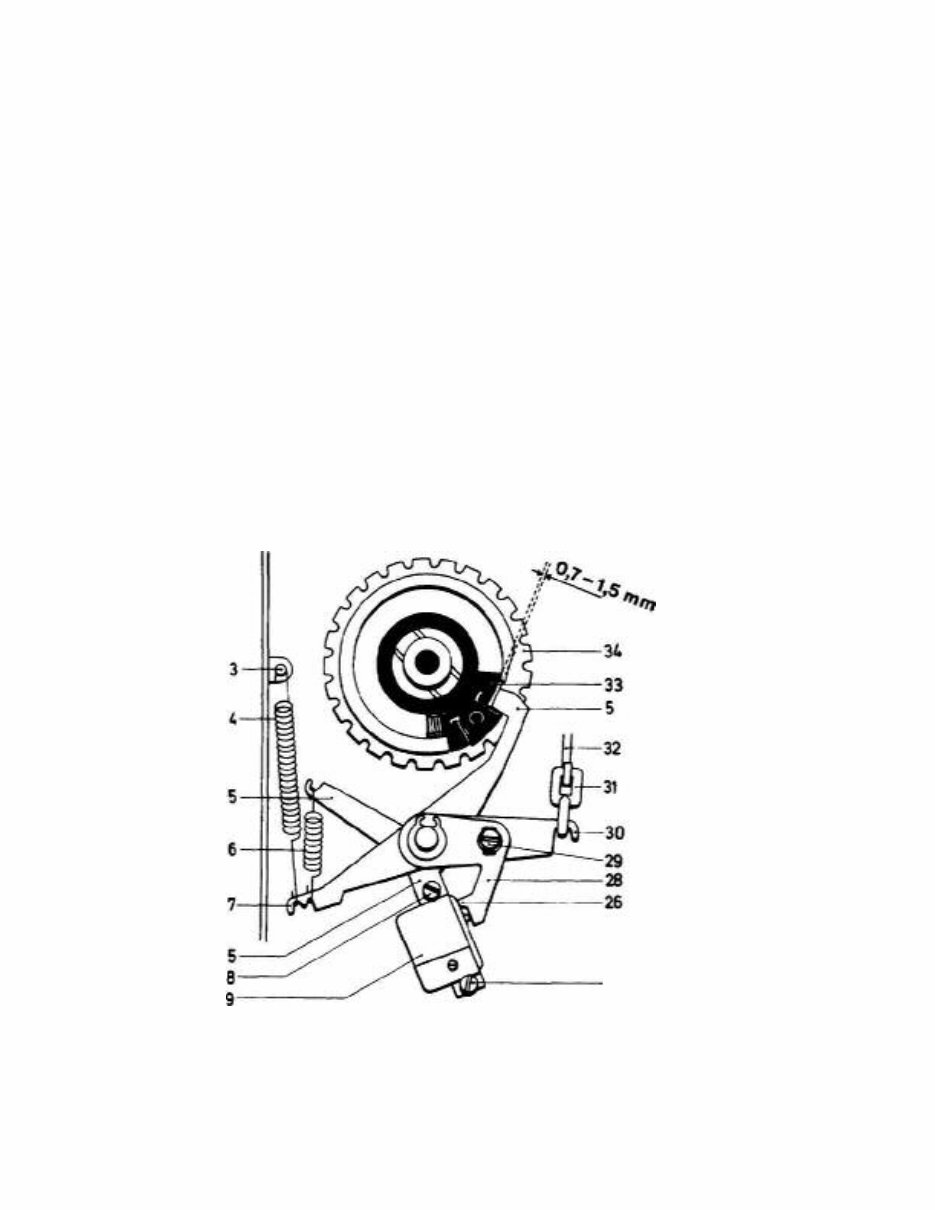

Operation

The Stopmatic mechanism is engaged when the presser bar lifter is at its top or

bottom-most position. When this lever is operated, this motion is transmitted to

clutch lever 5 via connecting rod 32 (Fig. l). The clutch lever in turn engages and

disengages a roller clutch. The machine is stopped by the Stopmatic mechanism

when the take-up lever is roughly at its highest point. At this point, clutch lever 5

drops into a cutout in belt sprocket "}k and pushes against slide 33 (with pin).This

slide, in turn, pushes against a roller and thus disengages the roller clutch. Micro

switch 9 is switched off simultaneously.

1. Adjusting the Clutch Lever

Rule:

With the presser bar lifter up in Stopmatic position, there should be a

clearance of 0.7 to 1.5 mm between slide 33 and clutch lever 5, so that when

the presser bar lifter is pushed right down there is a minimum clearance of

0.1 mm. Also, lug 26 of lever 28 (Fig.l) must be in contact with micro switch 9

in both of the above positions of the presser bar lifter.

Check:

Remove the arm standard cover and the balance wheel. Take out the three

screws 37 (Fig.2) and remove cover disc 36. Bring the presser bar lifter to

the upper Stopmatic position and turn the arm shaft in sewing direction

until clutch lever 5 (Fig.la) has dropped into the cutout of upper sprocket 34.

Check the clearance of 0.7 to 1.5 mm (varies on individual machines)

between slide 33 and clutch lever 5. Push the presser bar lifter down as far

as it will go and check the minimum clearance of 0.1 mm, too.

Adjustment:

Push the presser bar lifter back up to the Stopmatic position. Loosen screw

29 and press lever 23 tc the left until the clearance of 0.7 to 1.5 mm is

correct. Fully tighten screw 29.

Verification:

Push the presser bar lifter up beyond its Stop matic position and watch the clearance

while doing so. Push the presser bar lifter down as far as it will go and check the

clearance again. During the longest stroke, there must be a safety clearance of 0.1

mm so that the micro switch is not operated.

Note:

If clutch lever 5 strikes slide 33 when the presser bar lifter is pushed up or down, the

clearance must be repeatedly altered with the presser bar lifter up, until the lever no

longer strikes the slide in the up or down position. It must not be possible for clutch

lever 5 to snap out of the cutout in the upper sprocket when the arm shaft is turned

backwards.

Fig. 1

10

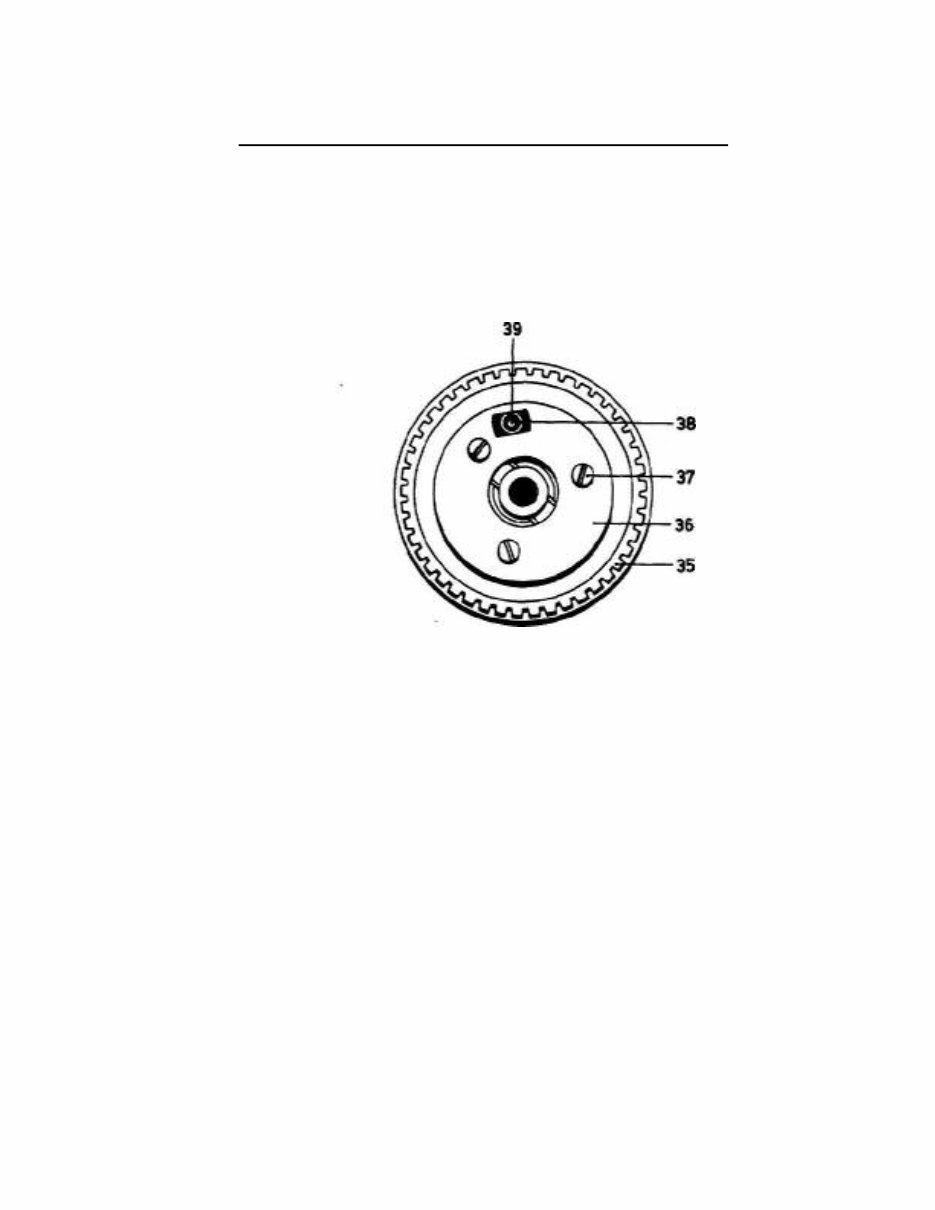

2. Setting the Roller in Relation to the Roller

Clutch Pin ______________________________________

Rule:

Pin 39 on the slide (Fig. 2) should be positioned slightly to the left of the

middle of roller 38.

Check:

Lower the presser bar lifter and turn the balance wheel until roller 38 is

at the top. Make a visual inspection (see Fig. 2).

Fig. 2

Adjustment:

Loosen the three screws 37 and turn the complete roller clutch 35 until

the above setting is correct. Then tighten the three screws 37 securely

again.

Verification:

Operate the Stop matic mechanism several times by flicking the presser

bar lifter to its top and bottom-most positions.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

$41.99

Viewed 94 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

$41.99

PFAFF Repair Manual

Models Covered

- 1222

- 1221

- 1214

- 1213

- 1212

- 1211

- 1199

- 1197

- 1196