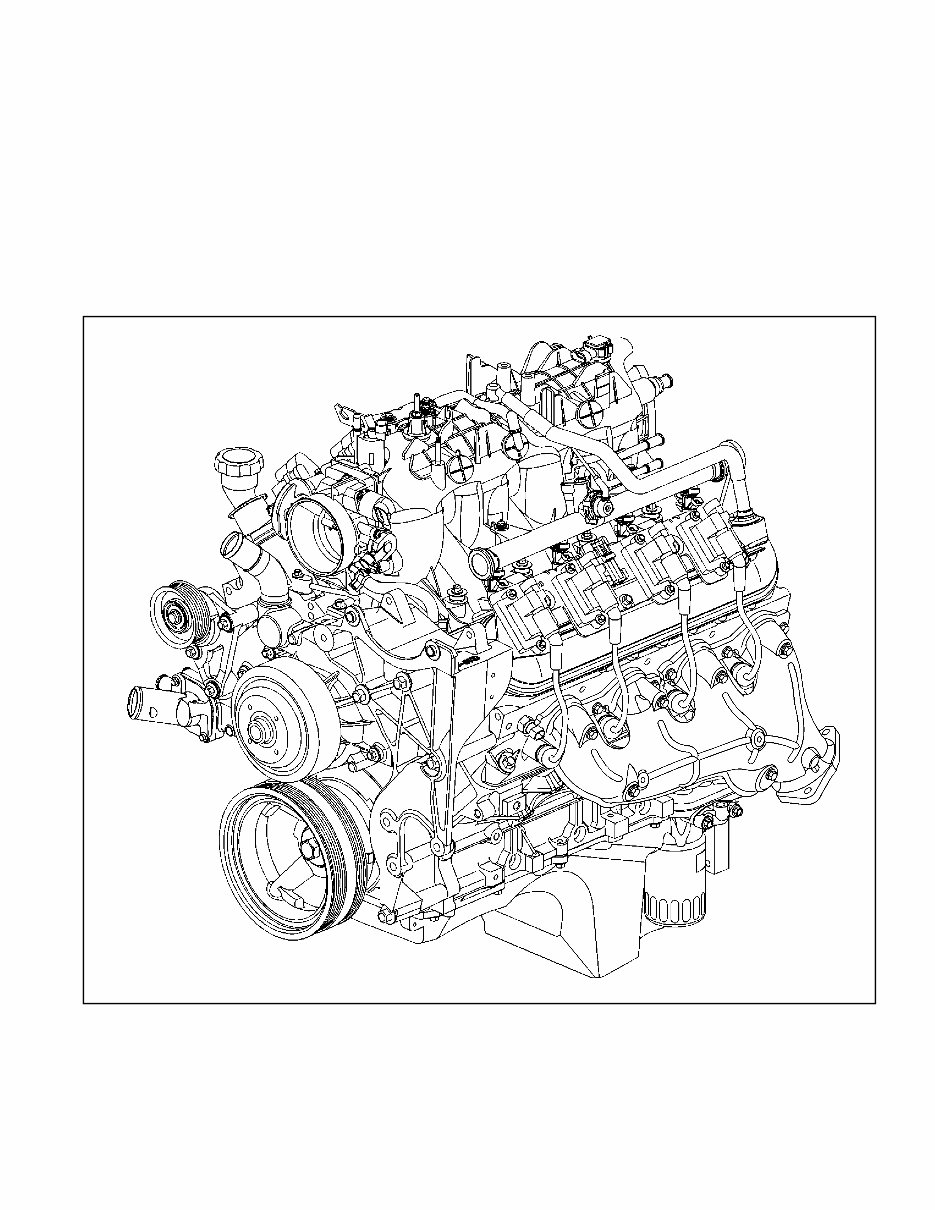

VORTEC LQ4,LQ9 6L MASTER Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Engine Mechanical

Service Manual

6.0L

(LQ4, LQ9)

6-2 Engine Mechanical - 6.0L Engine

2002

This Page Was

Intentionally Left

Blank

Engine Engine Mechanical - 6.0L 6-3

2002

Contents

Engine Mechanical - 6.0L

Specifications ............................................................................................................................... 7

Fastener Tightening Specifications ............................................................................................ 7

Engine Mechanical Specifications ............................................................................................ 10

Engine Mechanical Specifications (cont’d) .............................................................................. 11

Engine Mechanical Specifications (cont’d) .............................................................................. 12

GM SPO Group Numbers ........................................................................................................... 13

Sealers, Adhesives and Lubricants .......................................................................................... 14

Thread Repair Specifications ................................................. 15

Engine Block-Front View ........................................................................................................... 15

Engine Block-Rear View ............................................................................................................ 16

Engine Block-Left Side View ...................................................................................................... 17

Engine Block-Right Side View ................................................................................................... 18

Engine Block-Bottom View ........................................................................................................ 19

Engine Block-Top View .............................................................................................................. 21

Cylinder Head-Top View ............................................................................................................. 22

Cylinder Head-End View ............................................................................................................ 22

Cylinder Head-Exhaust Manifold Deck View ............................................................................ 23

Cylinder Head-Intake Manifold Deck View ................................................................................ 24

Component Locator ................................................................................................................... 25

Disassembled Views .................................................................................................................. 25

Intake Manifold/Upper Engine ................................................................................................... 25

Cylinder Head/Upper Engine ..................................................................................................... 27

Lower Front of Engine ............................................................................................................... 28

Lower Engine Assembly ............................................................................................................ 29

Cylinder Head Assembly (Aluminum) ....................................................................................... 31

Oil Pump Assembly ................................................................................................................... 32

Engine Identification .................................................................................................................. 32

Repair Instructions ................................................................. 34

Draining Fluids and Oil Filter Removal ..................................................................................... 34

Crankshaft Balancer Removal .................................................................................................. 36

Tools Required ........................................................................................................................... 36

Engine Flywheel Removal ......................................................................................................... 37

Clutch Pilot Bearing Removal ................................................................................................... 38

Oil Level Indicator and Tube Removal ....................................................................................... 39

Exhaust Manifold Removal-Left ................................................................................................ 40

Exhaust Manifold Removal-Right ............................................................................................. 40

Water Pump Removal ................................................................................................................. 41

Throttle Body Removal .............................................................................................................. 41

Fuel Rail and Injectors Removal ............................................................................................... 42

Intake Manifold Removal ............................................................................................................ 43

Coolant Air Bleed Pipe Removal ............................................................................................... 45

Engine Valley Cover Removal ................................................................................................... 46

6-4 Engine Mechanical - 6.0L Engine

2002

Valve Rocker Arm Cover Removal (Left Side) .......................................................................... 47

Valve Rocker Arm Cover Removal (Right Side) ....................................................................... 48

Valve Rocker Arm and Push Rod Removal .............................................................................. 50

Cylinder Head Removal - Left Side ........................................................................................... 51

Cylinder Head Removal - Right Side ......................................................................................... 51

Valve Lifter Removal .................................................................................................................. 52

Oil Filter, Adapter and Pan Cover Removal .............................................................................. 53

Oil Pan Removal ......................................................................................................................... 54

Engine Front Cover Removal .................................................................................................... 56

Engine Rear Cover Removal .........................................................................................................

57

Oil Pump, Pump Screen and Deflector Removal ..................................................................... 58

Timing Chain and Sprockets Removal ..................................................................................... 59

Camshaft Removal ..................................................................................................................... 60

Piston, Connecting Rod and Bearing Removal ....................................................................... 61

Crankshaft and Bearings Removal ........................................................................................... 63

Engine Block Plug Removal ...................................................................................................... 65

Engine Block Clean and Inspect ............................................................................................... 69

Cylinder Boring and Honing ...................................................................................................... 70

Boring Procedure ...................................................................................................................................................... 70

Honing Procedure ..................................................................................................................................................... 70

Deglazing Procedure ................................................................................................................................................ 71

Crankshaft and Bearings Clean and Inspect ........................................................................... 72

Cleaning Procedure .................................................................................................................................................. 72

Inspection procedure ................................................................................................................................................ 72

Measuring Main Bearing Clearance .......................................................................................... 76

Measuring Connecting Rod Bearing Clearance ....................................................................................................... 80

Crankshaft Balancer Clean and Inspect .................................................................................. 81

Engine Flywheel Clean and Inspect .......................................................................................... 82

Piston and Connecting Rod Disassemble ............................................................................... 83

Press Fit Piston Pin .................................................................................................................................................. 83

Full-Floating Piston Pin ........................................................................................................................................... 85

Piston, Connecting Rod and Bearings Clean and Inspect ..................................................... 86

Piston and Pin .......................................................................................................................................................... 86

Connecting Rod and Bearings ................................................................................................................................. 89

Measuring Piston Ring End Gap .............................................................................................................................. 91

Piston and Connecting Rod Assemble .................................................................................... 91

Press Fit Piston Pin .................................................................................................................................................. 91

Full-Floating Piston Pin ........................................................................................................................................... 95

Camshaft Bearing Removal ....................................................................................................... 96

Tool Usage Information .............................................................................................................. 97

Bearing, Expander and Expander Driver Information ............................................................................................. 97

Tool Assembly and Operation .................................................................................................................................. 98

Camshaft and Bearings Clean and Inspect .............................................................................. 99

Camshaft Bearing Installation ................................................................................................. 101

Measuring Camshaft Lobe Lift ............................................................................................................................... 101

Timing Chain and Sprockets Clean and Inspect ................................................................... 102

Valve Rocker Arm and Push Rods Clean and Inspect .......................................................... 103

Valve Lifters and Guides Clean and Inspect .......................................................................... 105

Cylinder Head Disassemble .................................................................................................... 106

Engine Engine Mechanical - 6.0L 6-5

2002

Cylinder Head Clean and Inspect ........................................................................................... 108

Valve Guide Reaming/Valve and Seat Grinding ..................................................................... 110

Valve Guide Reaming .............................................................................................................................................. 110

Valve and Seat Grinding ......................................................................................................................................... 112

Cylinder Head Assemble ......................................................................................................... 115

Oil Pump Disassemble ............................................................................................................. 118

Oil Pump Clean and Inspect .................................................................................................... 121

Oil Pump Assemble .................................................................................................................. 123

Engine Front Cover Clean and Inspect .................................................................................. 125

Engine Rear Cover Clean and Inspect ................................................................................... 126

Engine Valley Cover Clean and Inspect .................................................................................. 126

Valve Rocker Arm Cover Clean and Inspect .......................................................................... 127

Oil Pan Clean and Inspect ........................................................................................................ 128

Intake Manifold Clean and Inspect .......................................................................................... 131

Cleaning Procedure ................................................................................................................................................ 131

Inspection Procedure .............................................................................................................................................. 132

Exhaust Manifold Clean and Inspect ...................................................................................... 134

Coolant Air Bleed Pipe Clean and Inspect ............................................................................. 135

Water Pump Clean and Inspect ............................................................................................... 136

Thread Repair ........................................................................................................................... 137

General Thread Repair ............................................................................................................................................ 137

Cylinder Head Bolt Hole Thread Repair ................................................................................................................. 140

Main Cap Bolt Hole Thread Repair .......................................................................................... 144

Service Prior to Assembly ....................................................................................................... 148

Engine Block Plug Installation ................................................................................................ 150

Crankshaft and Bearings Installation ..................................................................................... 153

Piston, Connecting Rod and Bearing Installation ................................................................. 156

Piston Selection ...................................................................................................................................................... 156

Installation Procedure ............................................................................................................................................ 158

Camshaft Installation ............................................................................................................... 161

Timing Chain and Sprockets Installation ............................................................................... 162

Oil Pump, Pump Screen and Deflector Installation ................................................................ 164

Engine Rear Cover Installation ............................................................................................... 165

Crankshaft Rear Oil Seal Installation ...................................................................................... 168

Engine Front Cover Installation .............................................................................................. 168

Crankshaft Front Cover Oil Seal Installation .......................................................................... 170

Oil Pan Installation .................................................................................................................... 171

Oil Filter, Adapter and Pan Cover Installation ......................................................................... 174

Valve Lifter Installation ............................................................................................................. 175

Cylinder Head Installation (Left Side) ..................................................................................... 176

Cylinder Head Installation (Right Side) ................................................................................... 178

Valve Rocker Arm and Push Rod Installation ........................................................................ 180

Valve Rocker Arm Cover Installation - Left ............................................................................. 181

Valve Rocker Arm Cover Installation - Right .......................................................................... 182

Engine Valley Cover Installation .............................................................................................. 184

Coolant Air Bleed Pipe Installation ......................................................................................... 185

Intake Manifold Installation ...................................................................................................... 187

Fuel Rail and Injectors Installation .......................................................................................... 190

Water Pump Installation ........................................................................................................... 191

6-6 Engine Mechanical - 6.0L Engine

2002

Throttle Body Installation ........................................................................................................ 191

Exhaust Manifold Installation - Left ......................................................................................... 192

Exhaust Manifold Installation - Right ...................................................................................... 193

Clutch Pilot Bearing Installation .............................................................................................. 194

Oil Level Indicator and Tube Installation ................................................................................. 194

Engine Flywheel Installation .................................................................................................... 195

Crankshaft Balancer Installation ............................................................................................. 197

Description and Operation ................................................... 200

Engine Component Description ............................................................................................. 200

Camshaft and Drive System ................................................................................................................................... 200

Crankshaft ............................................................................................................................................................... 200

Cylinder Heads ........................................................................................................................................................ 200

Engine Block ........................................................................................................................................................... 201

Exhaust Manifolds .................................................................................................................................................. 201

Intake Manifold ........................................................................................................................................................ 201

Oil Pan ..................................................................................................................................................................... 201

Piston and Connecting Rod Assembly .................................................................................................................. 201

Valve Rocker Arm Cover Assemblies ..................................................................................................................... 201

Valve Train ............................................................................................................................................................... 201

Product Information ................................................................................................................. 201

Torque Values and/or Fastener Tightening Strategies .......................................................................................... 201

Disassembly and Assembly Procedure Revisions ................................................................................................ 201

Engine Mechanical Diagnostic Procedure Revisions ........................................................................................... 201

Lubrication Description ........................................................ 202

Lubrication Flow Schematic .................................................................................................... 202

Lower Front of Engine ............................................................................................................. 203

Separating Parts ....................................................................................................................... 204

Cleanliness and Care ............................................................................................................... 204

Replacing Engine Gaskets ...................................................................................................... 204

Gasket Reuse and Applying Sealant ...................................................................................................................... 204

Separating Components ......................................................................................................................................... 204

Cleaning Gasket Surfaces ....................................................................................................................................... 204

Assembling Components ....................................................................................................................................... 204

Use of RTV and Anaerobic Sealer .......................................................................................... 205

Sealant Types .......................................................................................................................................................... 205

Aerobic Type Room Temperature Vulcanizing (RTV) Sealant ............................................................................... 205

Anaerobic Type Gasket Eliminator Sealant ........................................................................................................... 205

Anaerobic Type Threadlock Sealant ....................................................................................................................... 206

Anaerobic Type Pipe Sealant .................................................................................................................................. 206

Tools and Equipment ............................................................................................................... 206

Special Tools ......................................................................... 207

Engine Engine Mechanical - 6.0L 6-7

2002

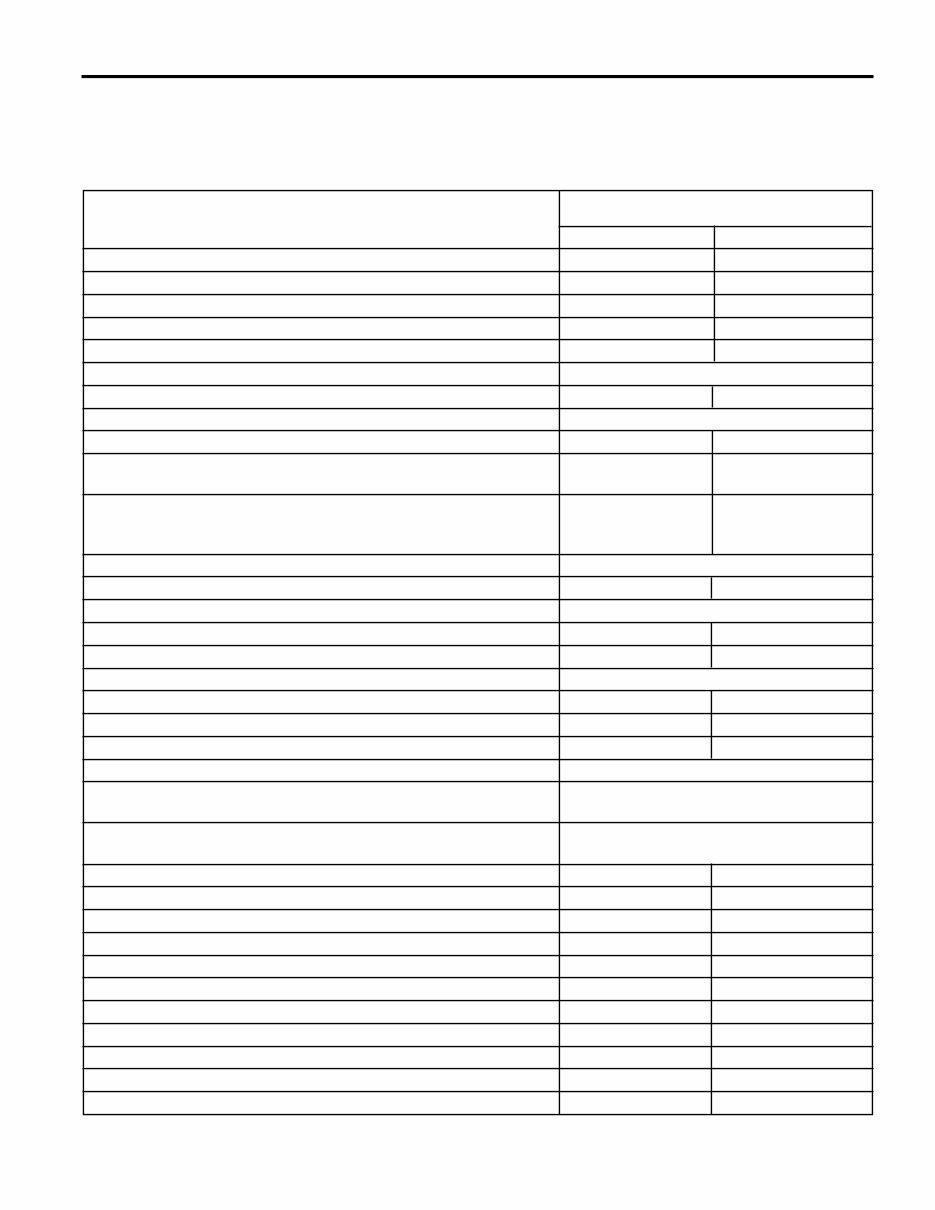

Engine Mechanical - 6.0L

Specifications

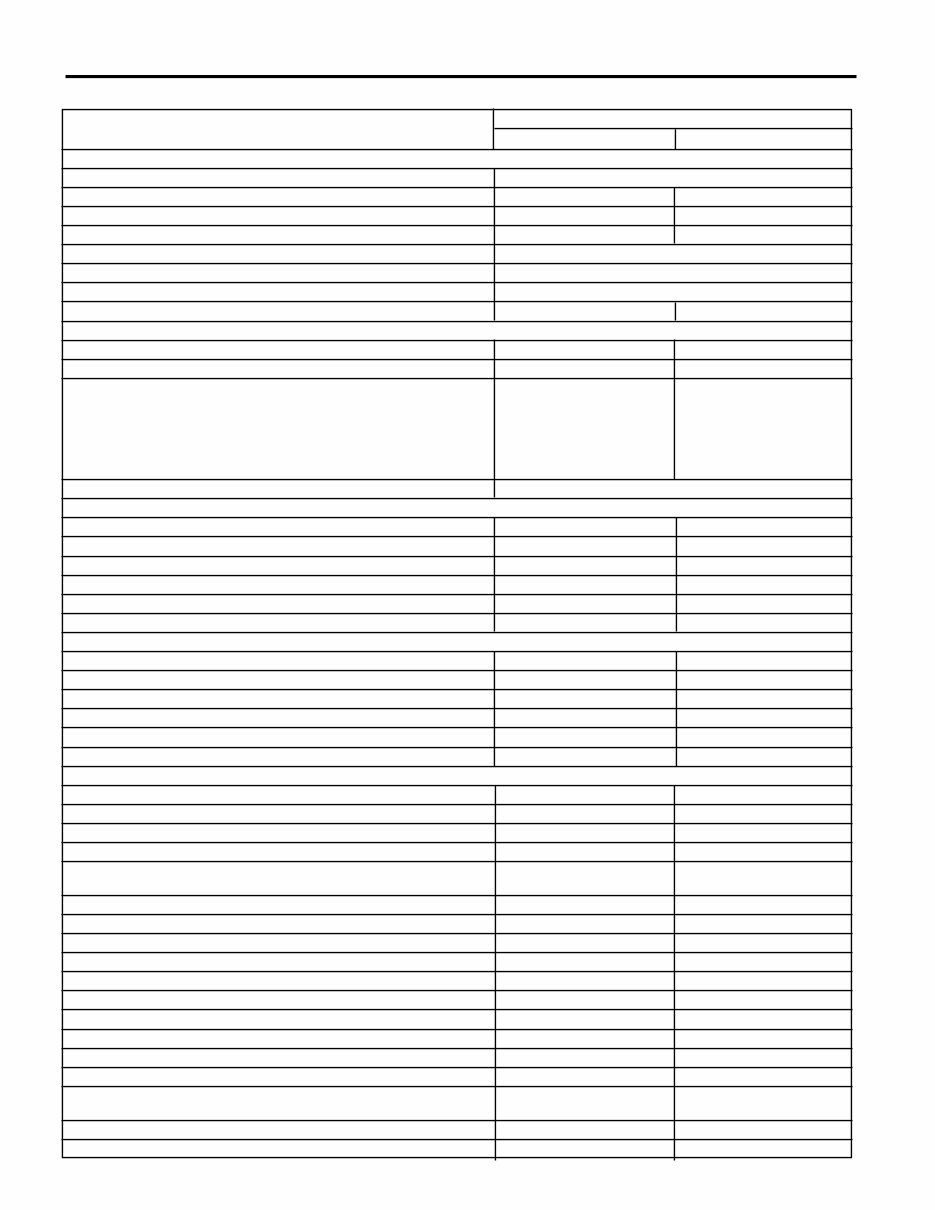

Fastener Tightening Specifications

Specification

Application Metric English

Accelerator Control Cable Bracket Bolts 10 N•m 89 lb in

Camshaft Retainer Bolts 25 N•m 18 lb ft

Camshaft Sensor Bolt 25 N•m 18 lb ft

Camshaft Sprocket Bolts 35 N•m 26 lb ft

Connecting Rod Bolts-First Design (First Pass) 20 N•m 15 lb ft

Connecting Rod Bolts-First Design (Final Pass) 60 degrees

Connecting Rod Bolts-Second Design (First Pass) 20 N•m 15 lb ft

Connecting Rod Bolts-Second Design (Final Pass) 75 degrees

Coolant Temperature Gauge Sensor 20 N•m 15 lb ft

Crankshaft Balancer Bolt (Installation Pass-to Ensure the Balancer is

Completely Installed 330 N•m 240 lb ft

Crankshaft Balancer Bolt (First Pass-Install a NEW Bolt After the

Installation Pass and Tighten as Described in the First and Final

Passes) 50 N•m 37 lb ft

Crankshaft Balancer Bolt (Final Pass) 140 degrees

Crankshaft Bearing Cap Bolts (Inner Bolts-First Pass in Sequence) 20 N•m 15 lb ft

Crankshaft Bearing Cap Bolts (Inner Bolts-Final Pass in Sequence) 80 degrees

Crankshaft Bearing Cap Side Bolts 25 N•m 18 lb ft

Crankshaft Bearing Cap Bolts (Outer Studs-First Pass in Sequence) 20 N•m 15 lb ft

Crankshaft Bearing Cap Bolts (Outer Studs-Final Pass in Sequence) 51 degrees

Crankshaft Oil Deflector Nuts 25 N•m 18 lb ft

Crankshaft Position Sensor Bolt 25 N•m 18 lb ft

Cylinder Head Bolts (First Pass-all M11 Bolts in Sequence) 30 N•m 22 lb ft

Cylinder Head Bolts (Second Pass-all M11 Bolts in Sequence) 90 degrees

Cylinder Head Bolts (Final Pass-all M11 Bolts in Sequence-Excluding

the Medium Length Bolts at the Front and Rear of Each Cylinder Head) 90 degrees

Cylinder Head Bolts (Final Pass-all M11 Medium Length Bolts at the

Front and Rear of Each Cylinder Head in Sequence) 50 degrees

Cylinder Head Bolts (M8 Inner Bolts in Sequence) 30 N•m 22 lb ft

Cylinder Head Coolant Plug 20 N•m 15 lb ft

Engine Block Coolant Drain Plugs 60 N•m 44 lb ft

Engine Block Heater 40 N•m 30 lb ft

Engine Block Oil Gallery Plugs 60 N•m 44 lb ft

Engine Coolant Air Bleed Pipe Bolts 12 N•m 106 lb in

Engine Flywheel Bolts (First Pass) 20 N•m 15 lb ft

Engine Flywheel Bolts (Second Pass) 50 N•m 37 lb ft

Engine Flywheel Bolts (Final Pass) 100 N•m 74 lb ft

Engine Front Cover Bolts 25 N•m 18 lb ft

Engine Rear Cover Bolts 25 N•m 18 lb ft

6-8 Engine Mechanical - 6.0L Engine

2002

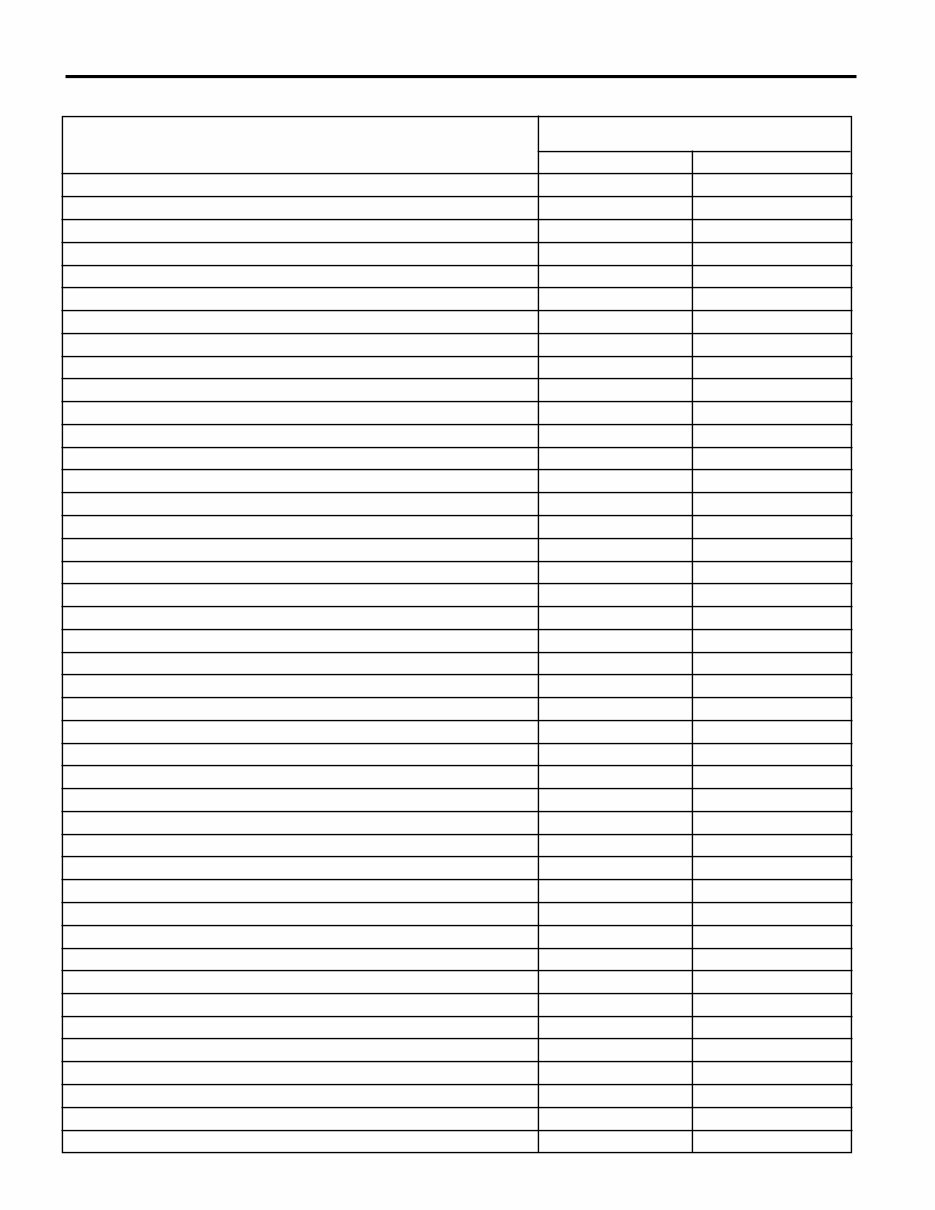

Fastener Tightening Specifications (cont’d)

Specification

Application Metric English

Engine Service Lift Bracket M10 Bolts 50 N•m 37 lb ft

Engine Service Lift Bracket M8 Bolt 25 N•m 18 lb ft

Engine Sight Shield Bolts 10 N•m 89 lb in

Engine Sight Shield Bracket Bolts 5 N•m 45 lb in

Engine Valley Cover Bolts 25 N•m 18 lb ft

Exhaust Manifold Bolts (First Pass) 15 N•m 11 lb ft

Exhaust Manifold Bolts (Final Pass) 25 N•m 18 lb ft

Exhaust Manifold Heat Shield Bolts 9 N•m 80 lb in

Fuel Rail Bolts 10 N•m 89 lb in

Fuel Rail Crossover Tube Bolts 3.8 N•m 34 lb in

Fuel Rail Stop Bracket Bolt 50 N•m 37 lb ft

Ignition Coil-to-Bracket Bolts 8 N•m 71 lb in

Ignition Coil Bracket-to-Valve Rocker Arm Cover Studs 12 N•m 106 lb in

Intake Manifold Bolts (First Pass in Sequence) 5 N•m 44 lb in

Intake Manifold Bolts (Final Pass in Sequence) 10 N•m 89 lb in

Intake Manifold Wiring Harness Stud 10 N•m 89 lb in

Knock Sensors 20 N•m 15 lb ft

Oil Filter 30 N•m 22 lb ft

Oil Filter Fitting 55 N•m 40 lb ft

Oil Level Indicator Tube Bolt 25 N•m 18 lb ft

Oil Level Sensor 13 N•m 115 lb in

Oil Pan Baffle Bolts 12 N•m 106 lb in

Oil Pan Closeout Cover Bolt (Left Side) 9 N•m 80 lb in

Oil Pan Closeout Cover Bolt (Right Side) 9 N•m 80 lb in

Oil Pan Cover Bolts 12 N•m 106 lb in

Oil Pan Drain Plug 25 N•m 18 lb ft

Oil Pan M8 Bolts (Oil Pan-to-Engine Block and Oil Pan-to-Front Cover) 25 N•m 18 lb ft

Oil Pan M6 Bolts (Oil Pan-to-Rear Cover) 12 N•m 106 lb in

Oil Pressure Sensor 20 N•m 15 lb ft

Oil Pump-to-Engine Block Bolts 25 N•m 18 lb ft

Oil Pump Cover Bolts 12 N•m 106 lb in

Oil Pump Relief Valve Plug 12 N•m 106 lb in

Oil Pump Screen Nuts 25 N•m 18 lb ft

Oil Pump Screen-to-Oil Pump Bolt 12 N•m 106 lb in

Spark Plugs-New 20 N•m 15 lb ft

Spark Plugs-All Subsequent Installations 15 N•m 11 lb ft

Throttle Body Nuts 10 N•m 89 lb in

Throttle Body Studs 6 N•m 53 lb in

Valve Lifter Guide Bolts 12 N•m 106 lb in

Valve Rocker Arm Bolts 30 N•m 22 lb ft

Valve Rocker Arm Cover Bolts 12 N•m 106 lb in

Water Inlet Housing Bolts 15 N•m 11 lb ft

Water Pump Bolts (First Pass) 15 N•m 11 lb ft

Engine Engine Mechanical - 6.0L 6-9

2002

Fastener Tightening Specifications (cont’d)

Specification

Application Metric English

Water Pump Bolts (Final Pass) 30 N•m 22 lb ft

Water Pump Cover Bolts 15 N•m 11 lb ft

6-10 Engine Mechanical - 6.0L Engine

2002

Engine Mechanical Specifications

Specification

Application Metric English

General Data

Engine Type V8

Displacement 6.0L 364 CID

Bore 101.618-101.636 mm 4.0007-4.0014 in

Stroke 92.0 mm 3.622 in

Compression Ratio - LQ4 9.40:1

Compression Ratio - LQ9 10.0:1

Firing Order 1-8-7-2-6-5-4-3

Spark Plug Gap 1.524 mm 0.060 in

Lubrication System

Oil Capacity (without Oil Filter Change) 4.73 Liters 5.0 Quarts

Oil Capacity (with Oil Filter Change) 5.68 Liters 6.0 Quarts

41 kPa at 6.0 psig at

1,000 engine rpm 1,000 engine rpm

Oil Pressure (Minimum-Hot) 124 kPa at 18.0 psig at

2,000 engine rpm 2,000 engine rpm

165 kPa at 24.0 psig at

4,000 engine rpm 4,000 engine rpm

Oil Type 5W-30

Camshaft

End Play 0.025-0.305 mm 0.001-0.012 in

Journal Diameter 54.99-55.04 mm 2.164-2.166 in

Journal Diameter Out-of-Round 0.025 mm 0.001 in

Lobe Lift (Exhaust) 7.13 mm 0.281 in

Lobe Lift (Intake) 6.96 mm 0.274 in

Runout (Measured at the Intermediate Journals) 0.05 mm 0.002 in

Connecting Rod

Connecting Rod Bearing Bore Diameter 56.505-56.525 mm 2.224-2.225 in

Connecting Rod Bearing Bore Out-of-Round - LQ4 0.004-0.008 mm 0.00015-0.0003 in

Connecting Rod Bearing Bore Out-of-Round - LQ9 0.006 mm 0.00023 in

Connecting Rod Bearing Clearance (Production) 0.023-0.065 mm 0.0009-0.0025 in

Connecting Rod Bearing Clearance (Service Limit) 0.023-0.076 mm 0.0009-0.003 in

Connecting Rod Side Clearance 0.11-0.51 mm 0.00433-0.02 in

Crankshaft

Crankshaft Bearing Clearance (Production) 0.020-0.052 mm 0.0008-0.0021 in

Crankshaft Bearing Clearance (Service Limit) 0.020-0.065 mm 0.0008-0.0025 in

Crankshaft Connecting Rod Journal Diameter (Production) 53.318-53.338 mm 2.0991-2.0999 in

Crankshaft Connecting Rod Journal Diameter (Service Limit) 53.308 mm (Minimum) 2.0987 in (Minimum)

Crankshaft Connecting Rod Journal Taper (Production) 0.005 mm (Maximum for 1/2 0.0002 in (Maximum for 1/2

of the Journal Length) of the Journal Length)

Crankshaft Connecting Rod Journal Taper (Service Limit) 0.02 mm (Maximum) 0.00078 in (Maximum)

Crankshaft Connecting Rod Journal Out-of-Round (Production) 0.005 mm 0.0002 in

Crankshaft Connecting Rod Journal Out-of-Round (Service Limit) 0.01 mm 0.0004 in

Crankshaft End Play 0.04-0.2 mm 0.0015-0.0078 in

Crankshaft Main Journal Diameter (Production) 64.993-65.007 mm 2.558-2.559 in

Crankshaft Main Journal Diameter (Service Limit) 64.993 mm 2.558 in

Crankshaft Main Journal Out-of-Round (Production) 0.003 mm 0.0001 in

Crankshaft Main Journal Out-of-Round (Service Limit) 0.008 mm 0.0003 in

Crankshaft Main Journal Taper (Production) 0.01 mm 0.0004 in

Crankshaft Main Journal Taper (Service Limit) 0.02 mm 0.00078 in

Crankshaft Reluctor Ring Runout (Measured 1.0 mm (0.04 in) Below

the Tooth Diameter) 0.7 mm (Maximum) 0.028 in (Maximum)

Crankshaft Runout (at Rear Flange) 0.05 mm (Maximum) 0.002 in (Maximum)

Crankshaft Thrust Wall Runout 0.025 mm 0.001 in

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

Viewed 76 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

The Vortec LQ4 and LQ9 6L Master Service Repair Manual is a comprehensive resource for professional mechanics and DIY enthusiasts. This full/complete version provides crystal clear viewing, making it an invaluable tool for anyone working on these engines.