TECUMSEH TVT691 V TWIN Engine Full Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

V-TWIN

ENGINE

TECUMSEH

i

TABLE OF CONTENTS

CHAPTER 1. GENERAL INFORMATION

CHAPTER 2. AIR CLEANERS

CHAPTER 3. CARBURETORS AND FUEL SYSTEMS

CHAPTER 4. GOVERNORS AND LINKAGE

CHAPTER 5. ELECTRICAL SYSTEMS

CHAPTER 6. IGNITION

CHAPTER 7. INTERNAL ENGINE AND DISASSEMBLY

CHAPTER 8. ENGINE ASSEMBLY

CHAPTER 9. TROUBLESHOOTING AND TESTING

CHAPTER 10. ENGINE SPECIFICATIONS

Copyright © 2000 by Tecumseh Products Company

All rights reserved. No part of this book may be reproduced or transmitted, in any form or by any

means, electronic or mechanical, including photocopying, recording or by any information storage and

retrieval system, without permission in writing from Tecumseh Products Company Training Department

Manager.

ii

TABLE OF CONTENTS

(by subject)

GENERAL INFORMATION

Page

Engine Identification ................................................................................................ 1-1

Interpretation of Engine Identification ...................................................................... 1-1

Short Blocks ............................................................................................................ 1-2

Fuels ........................................................................................................................ 1-2

Engine Oil ................................................................................................................ 1-3

Basic Tune-Up Procedure ....................................................................................... 1-4

Storage .................................................................................................................... 1-4

AIR CLEANERS

General Information ................................................................................................. 2-1

Operation ................................................................................................................. 2-1

Components ............................................................................................................ 2-1

Troubleshooting and Testing .................................................................................... 2-1

Service ..................................................................................................................... 2-2

CARBURETORS AND FUEL SYSTEMS

General Information ................................................................................................. 3-1

Float Style Carburetors ............................................................................................ 3-1

Operational Circuits Series 7 Carburetor ................................................................. 3-1

Testing ..................................................................................................................... 3-3

Carburetor Disassembly Procedure ........................................................................ 3-5

Inspection ................................................................................................................ 3-7

Carburetor Re-Assembly ......................................................................................... 3-7

Throttle Shaft and Plate ................................................................................... 3-7

Choke Shaft and Plate ..................................................................................... 3-8

Fuel Bowl Assembly ........................................................................................ 3-8

Impulse Fuel Pumps ................................................................................................ 3-9

Impulse Fuel Pump Service ........................................................................... 3-10

GOVERNORS AND LINKAGE

General Information ................................................................................................. 4-1

Operation ................................................................................................................. 4-1

Troubleshooting ....................................................................................................... 4-1

Engine Speed Adjustments ..................................................................................... 4-1

Engine Overspeed ........................................................................................... 4-2

Engine Surging ................................................................................................ 4-2

Governor Service

Static Adjustment - Governor .......................................................................... 4-2

Governor Gear and Shaft Service ................................................................... 4-3

Governor Shaft Replacement .......................................................................... 4-3

iii

Page

Speed Controls and Linkage ................................................................................... 4-3

Synchronizing the Carburetors ................................................................................ 4-4

Choke Synchronization ............................................................................................ 4-5

ELECTRICAL SYSTEMS

General Information ................................................................................................. 5-1

Operation ................................................................................................................. 5-1

Converting Alternating Current to Direct Current ..................................................... 5-2

Components

Battery ............................................................................................................ 5-2

Wiring .............................................................................................................. 5-2

Condition ......................................................................................................... 5-2

Wire Gauge ..................................................................................................... 5-2

Electrical Terms ....................................................................................................... 5-3

Basic Checks ........................................................................................................... 5-3

Charging Circuit ....................................................................................................... 5-4

3 Amp D.C. 5 Amp A.C. Alternator ......................................................................... 5-4

Diode Replacement ........................................................................................ 5-4

Checking the System ...................................................................................... 5-5

16 Amp Alternator System with External Regulator ................................................. 5-5

Troubleshooting Electrical Charging Circuit Flow Chart .......................................... 5-6

Voltage Regulators .................................................................................................. 5-7

Fuel Shut-Down Solenoids ...................................................................................... 5-7

Low Oil Pressure Sensor Testing ............................................................................. 5-7

Starting Circuit ......................................................................................................... 5-8

Testing Procedure Starting Circuit .................................................................. 5-8

Troubleshooting Electrical Starter Circuit Flow Chart ..................................... 5-9

Electric Starter Service .......................................................................................... 5-10

12 Volt Electric Starter .................................................................................. 5-10

Inspection and Repair ................................................................................... 5-11

Brush Holder ................................................................................................. 5-12

Brush Replacement ...................................................................................... 5-12

IGNITION

General Information ................................................................................................. 6-1

Operation

Solid State Ignition System (CDI) ............................................................................ 6-1

Components .................................................................................................... 6-1

Testing Procedure ............................................................................................ 6-2

Service

Spark Plug Service .......................................................................................... 6-3

Conditions Causing Frequent Spark Plug Fouling ........................................... 6-3

Ignition Timing ......................................................................................................... 6-3

Service Tips ............................................................................................................. 6-4

TABLE OF CONTENTS (continued)

iv

INTERNAL ENGINE AND DISASSEMBLY

General Information ................................................................................................. 7-1

Lubrication Systems ................................................................................................ 7-1

Disassembly Procedure ........................................................................................... 7-1

Disassembly of Cylinder Heads ............................................................................... 7-4

Valves .............................................................................................................. 7-5

Valve Guides ................................................................................................... 7-5

Valve Springs ................................................................................................... 7-6

Push Rods ....................................................................................................... 7-6

Valve Seats ...................................................................................................... 7-6

Internal Engine Component Inspection

Cylinders .......................................................................................................... 7-7

Pistons ............................................................................................................. 7-8

Rings ............................................................................................................... 7-9

Connecting Rods ........................................................................................... 7-10

Crankshafts and Camshafts .......................................................................... 7-11

Mechanical Compression Release ................................................................ 7-12

Valve Lifters ................................................................................................... 7-13

Crankcase Breather ....................................................................................... 7-13

Cylinder Cover ............................................................................................... 7-13

ENGINE ASSEMBLY

Engine Assembly ..................................................................................................... 8-1

TROUBLESHOOTING AND TESTING

Engine Knocks ......................................................................................................... 9-1

Engine Overheats .................................................................................................... 9-1

Surges or Runs Unevenly ........................................................................................ 9-1

Engine Misfires ........................................................................................................ 9-1

Engine Vibrates Excessively .................................................................................... 9-2

Breather Passing Oil ................................................................................................ 9-2

Excessive Oil Consumption ..................................................................................... 9-2

Lack Power .............................................................................................................. 9-2

ENGINE SPECIFICATIONS

TVT691 Engine Specifications ............................................................................... 10-1

Torque Specifications ............................................................................................ 10-3

Service Tool List .................................................................................................... 10-4

TABLE OF CONTENTS (continued)

Page

1-1

1-1

CHAPTER 1. GENERAL INFORMATION

ENGINE IDENTIFICATION

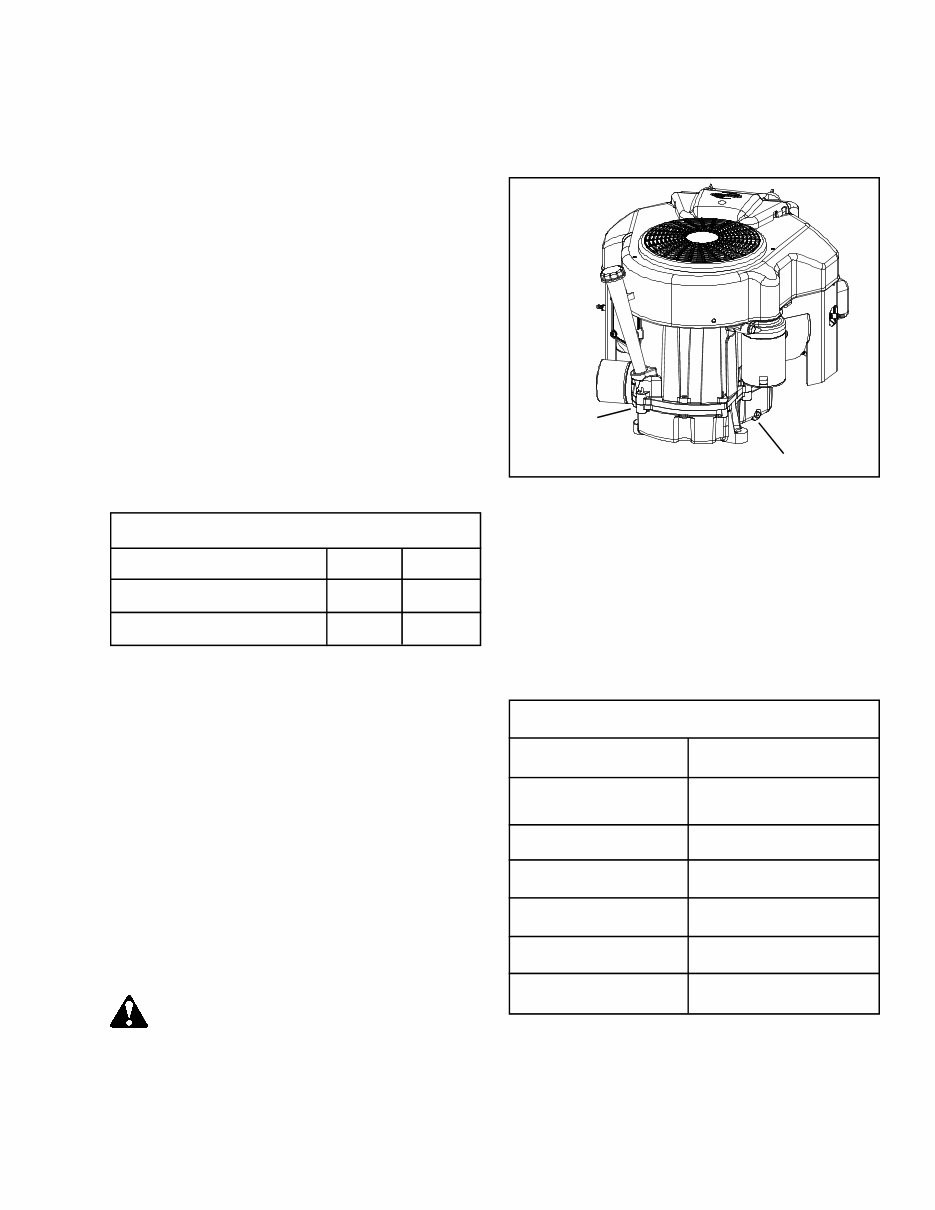

Tecumseh engine model, specification, and date of

manufacture (D.O.M.) are located on decals attached to

the blower housing of the engine. The engine

identification decal also provides the applicable warranty

code, oil and fuel recommendations, EPA (Environmental

Protection Agency) and C.A.R.B. (California Air Resource

Board) Emission Compliance Information. (Illust. 1-1)

The group of numbers following the model number is

the specification number. The last three numbers

indicate a variation to the basic engine specification.

(Illust. 1-3)

INTERPRETATION OF ENGINE

IDENTIFICATION

The letter designations (TVT) in a model number

indicate the basic type of engine.

The number designations following the letters (691)

indicate the basic engine model displacement in CC’s

(cubic centimeters). (Illust. 1-2)

1-2

The letter in parenthesis on the engine information decal

is the warranty code identification number. This letter

designates the length of time the engine is under

warranty. A cross-reference may be found in the service

warranty policy of the master repair manual or the engine

operator’s manual. (Illust. 1-4)

1-3

1-4

ENGINE

MODEL

NUMBER

SPECIFICATION

NUMBER

WARRANTY

IDENTIFICATION

NUMBER

1-2

The D.O.M. (date of manufacture) indicates the

production date of the engine by year and numerical day.

(Illust. 1-5)

This symbol points out important safety

INSTRUCTIONS, WHICH IF NOT FOLLOWED,

could endanger the personal safety of YOU and

others. Follow all instructions.

SHORT BLOCKS

New short blocks are identified by a tag marked S.B.V.

(Short Block Vertical) located on the engine block. When

a short block repair is made, it is vital both the original

engine and short block numbers are present on the

repaired product for correct future parts identification.

(Illust. 1-6)

1-5

1-6

Using model TVT691-600401A D.O.M. 9146 as an

example, the interpretation is as follows:

TVT691- Is the model number.

60041A Represents the specification number used for

properly identifying the parts of the engine.

TVT Tecumseh Vertical Twin.

691 Indicates the displacement in cubic

centimeters.

9146 Is the D.O.M. (Date of Manufacture) formerly

serial number.

9 Is the last digit in the year of manufacture

(1999).

146 Indicates the calendar day of that year (146th

day or May 26

th

of 1999).

A,B,C A letter following the D.O.M. number

represents the line, shift and plant in which

the engine was built.

Emissionized engines that meet the California Air

Resource Board (C.A.R.B.) or the Environmental

Protection Agency (EPA) standards will include additional

required engine information on the engine decal.

NOTE: To maintain the best possible emission

performance, use only Genuine Tecumseh Parts.

FUELS

Tecumseh Products Company strongly recommends the

use of fresh, clean, unleaded regular gasoline in all

Tecumseh engines. Unleaded gasoline burns cleaner,

extends engine life, and promotes good starting by

reducing the build up of combustion chamber deposits.

Unleaded regular, unleaded premium or reformulated

gasoline containing no more than 10% Ethanol, 15%

MTBE or 15% ETBE may be used.

Leaded fuel is not available in the United States and

should not be used if any of the above options are

available.

Never use gasoline, fuel conditioners, additives or

stabilizers containing methanol, white gas, or fuel blends,

which exceed the limits, specified above for Ethanol,

MTBE, or ETBE because engine/fuel system damage

could result.

CAUTION: THE USE OF SOME ANTI-ICING

ADDITIVES MAY CREATE A METHANOL FUEL

BLEND. DO NOT USE ADDITIVES THAT

CONTAIN METHANOL. FUEL CONDITIONERS

THAT CONTAIN ISOPROPYL ALCOHOL CAN

BE USED IN CORRECT MIXTURE RATIOS.

Regardless of which of the approved fuels are used, fuel

quality is critical to engine performance. Fuel should

not be stored in an engine or container more than 30

days prior to use. Time may be extended with the use of

a fuel stabilizer like TECUMSEH, part number 730245.

See “STORAGE” instructions in this Manual, Operators

Manual, or Bulletin 111.

DATE OF

MANUFACTURE

(D.O.M.)

SBV OR SBH IDENTIFICATION NUMBER

SHORT BLOCK IDENTIFICATION TAG

SERIAL NUMBER

SBV- 564A

SER 5107

1-3

Change oil and filter after the first two operating hours.

Standard oil change intervals are every 50 hours. Oil

filter changes are recommended every 100 operating

hours.

Oil Change Intervals: Change the oil and filter after

the first 2 hours of operation. Thereafter oil change

intervals are every 50 hours. Oil and oil filter changes

are requested every 100 operating hours. Service should

be performed more often if operated under extremely

dusty or dirty conditions. The oil and filter (if equipped)

should be changed yearly if operated less than 100 hours.

Oil Check: Check the oil each time the equipment is

used or every five-(5) hours of operation. Position the

equipment so the engine is level when checking the oil

level.

CAUTION: A TWIN CYLINDER ENGINE MAY

START AND RUN ON ONLY ONE CYLINDER.

ALWAYS DISCONNECT BOTH SPARK PLUG

WIRES FROM THE SPARK PLUGS AND

GROUND TO THE DEDICATED RETAINING

POSTS LOCATED ON THE VALVE COVER

BOXES BEFORE ATTEMPTING ANY SERVICE

OR MAINTENANCE WORK ON THE ENGINE OR

EQUIPMENT.

ENGINE OIL

TECUMSEH FOUR-CYCLE ENGINES REQUIRE THE

USE OF CLEAN, HIGH QUALITY DETERGENT OIL.

Be sure original container is marked: A.P.I. service “SF”

thru “SJ” or “CD”.

TECUMSEH RECOMMENDS USING ONE OF THE

FOLLOWING FOUR CYCLE OILS THAT ARE

SPECIALLY FORMULATED TO TECUMSEH

SPECIFICATIONS.

DO NOT USE SAE 10W40 OIL.

FOR SUMMER (Above 32

0

F) (0

o

C) USE SAE 30 OIL.

PART 730225

Use SAE 30 oil in high temperature, high load

applications. Using multigrade oil may increase oil

consumption.

FOR WINTER (Below 32

0

F) (0

o

C) USE SAE 5W30 OIL.

PART 730226

(SAE 10W is an acceptable substitute.)

(BELOW 0

0

F (-18

o

C) ONLY): SAE 0W30 is an

acceptable substitute.

Oil Capacity

Engine Model oz. ml.

TVT691 with Filter 80 2366

TVT691 Oil Only 72 2129

Oil Change Procedure: Locate the oil drain plug in the

mounting flange. The drain plug or cap on most units is

located above the frame in one of the locations shown.

(Illust. 1-7) The oil filter if equipped, can be removed

with a commercially available filter wrench.

NOTE: An oil change is best performed after the engine

is warm.

Remove the oil plug or cap and allow the oil to drain into

a proper receptacle. Always make sure that drain oil and

filter are disposed of properly. Contact your local

governing authorities to find a waste oil disposal site.

Once the oil is drained, reinstall the drain plug and fill the

engine with new oil to the proper capacity.

BASIC MAINTENANCE CHART

Pre-filter (Dry Poly) Clean every 25 hours

Air filter (Paper Element) Replace every 100 hours of

operation

Oil change Every 50 hours or annually

Oil filter Every 100 hours or

annually

Spark plug replacement Every 100 hours or

annually

Clean cooling fins Every 200 hours or

annually

Fuel Filter (Replace) Every 100 hours or

annually

1-7 STANDARD OIL DRAIN PLUG LOCATION

ALTERNATE

LOCATION

1-4

1-8

BASIC TUNE-UP PROCEDURE:

NOTE: Today’s fuels can cause many problems in an

engines performance due to the fuel quality and short

shelf life (as little as 30 days). Always check fuel as a

primary cause of poor engine performance before

performing any other service.

The following is a minor tune-up procedure. When this

procedure is completed, the engine should operate

properly. Further repairs may be necessary if the engine’s

performance remains poor.

CAUTION: REMOVE THE SPARK PLUG WIRES

AND ATTACH TO THE DEDICATED RETAINING

POSTS BEFORE DOING ANY SERVICE WORK

ON THE ENGINE.

1. Service or replace the air cleaner. See Chapter 2

under “Service”.

2. Inspect the level and condition of the oil, change or

add oil as required.

3. Remove the blower housing and clean all dirt, grass

or debris from the intake screen, Cylinder head,

cooling fins, carburetor, governor levers and linkage.

4. Check that the fuel filter, fuel tank, and fuel line are

clean. We recommend replacing the fuel filter every

100 hours or annually.

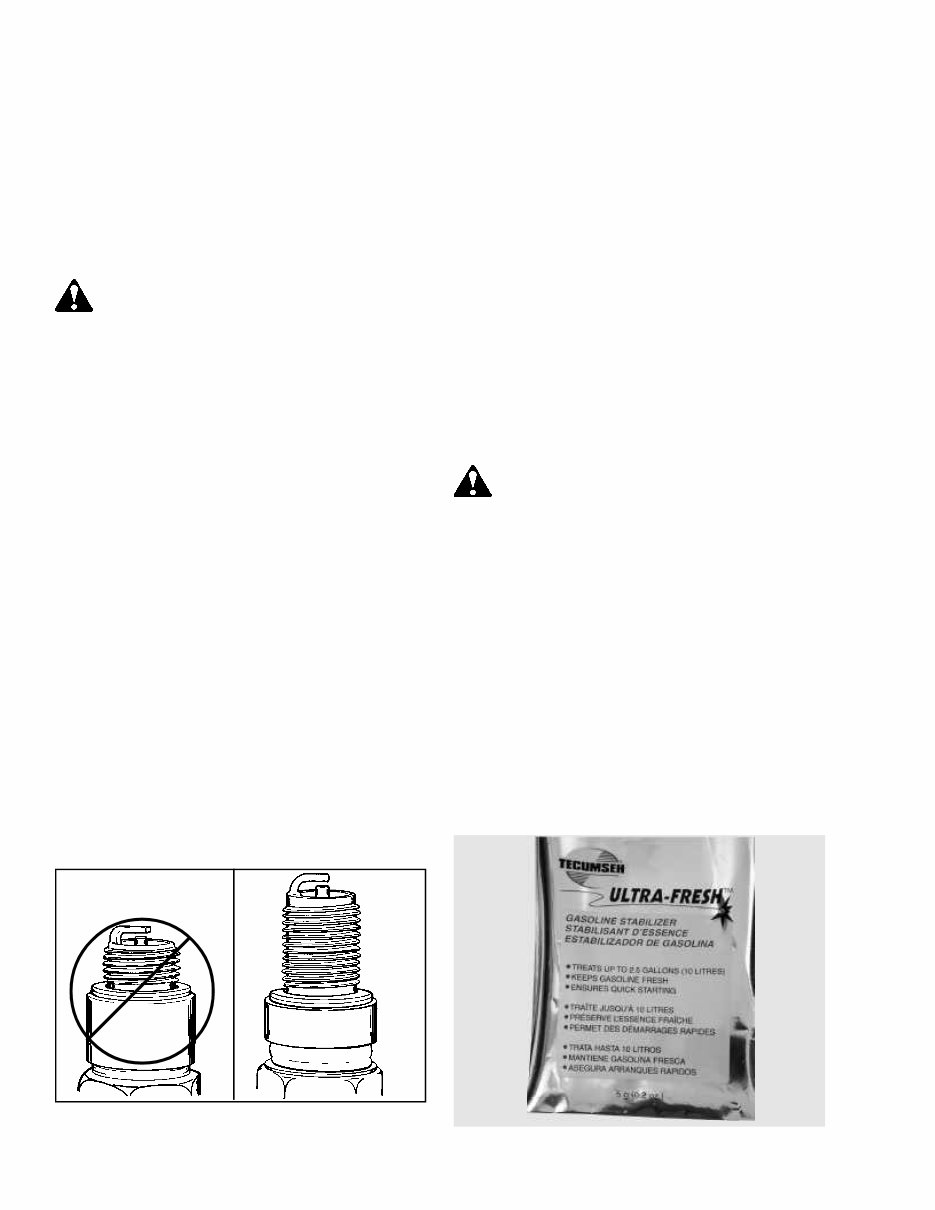

5. Replace the spark plugs every 100 hours or annually,

consult the parts breakdown for the correct spark

plug to be used. Set the spark plug gap (.030") (.762

mm) and install the plug, being careful not to cross

thread. Tighten the spark plug to 21 foot pounds

(28 Nm) of torque. If a torque wrench is not

available, turn the spark plug in as far as possible

by hand, then use a spark plug wrench to turn the

plug 1/2 turn further. If installing a used plug, only

1/8 to 1/4 turn after seat is needed. Note: The correct

plug reach must be used see (Illust. 1-8).

6. Make sure all ignition wires are free of abrasions or

breaks and are properly routed so they will not rub

on the flywheel.

7. Completely clean the cooling fins, intake screen and

linkages of all dirt and debris. Reinstall the blower

housing, fuel tank, fuel line, and air cleaner assembly

if removed. Be careful not to pinch any of the

wires upon re-assembly.

8. Make sure all remote cables are correctly routed and

adjusted for proper operation. See Chapter 4, under

“Speed Controls and Linkage”.

9. Reinstall the spark plug wires, add fuel and oil as

necessary, start the engine.

STORAGE

(IF THE ENGINE IS TO BE UNUSED FOR 30 DAYS

OR MORE)

CAUTION: NEVER STORE THE ENGINE WITH

FUEL IN THE TANK INDOORS OR IN

ENCLOSED, POORLY VENTILATED AREAS,

WHERE FUEL FUMES MAY REACH AN OPEN

FLAME, SPARK OR PILOT LIGHT AS ON A

FURNACE, WATER HEATER, CLOTHES

DRYER OR OTHER GAS APPLIANCE.

Gasoline can become stale in less than 30 days and

form deposits that can impede proper fuel flow and engine

operation. To prevent deposits from forming, all gasoline

must be removed from the fuel tank and the carburetor.

An acceptable alternative to removing all gasoline, is by

adding Tecumseh fuel stabilizer, part number 730245,

to the gasoline. Fuel stabilizer is added to the fuel tank

or storage container. Always follow the mix ratio found

on the stabilizer container. Run the engine at least 10

minutes after adding the fuel stabilizer to allow it to

reach the carburetor. (Illust. 1-9)

1-9

STANDARD

PLUG

OHV

2-1

2-1

CHAPTER 2. AIR CLEANERS

GENERAL INFORMATION

The air cleaner is the device used to eliminate dust and

dirt from the air supply. Filtered air is necessary to assure

that abrasive particles are removed before entering the

combustion chamber. Dirt allowed into the engine will

quickly wear the internal components and shorten engine

life.

The TVT series engine uses a paper-type air filter system

and also has a dry foam pre-filter.

Extremely dirty conditions require more frequent pre-filter

cleaning or paper element replacement.

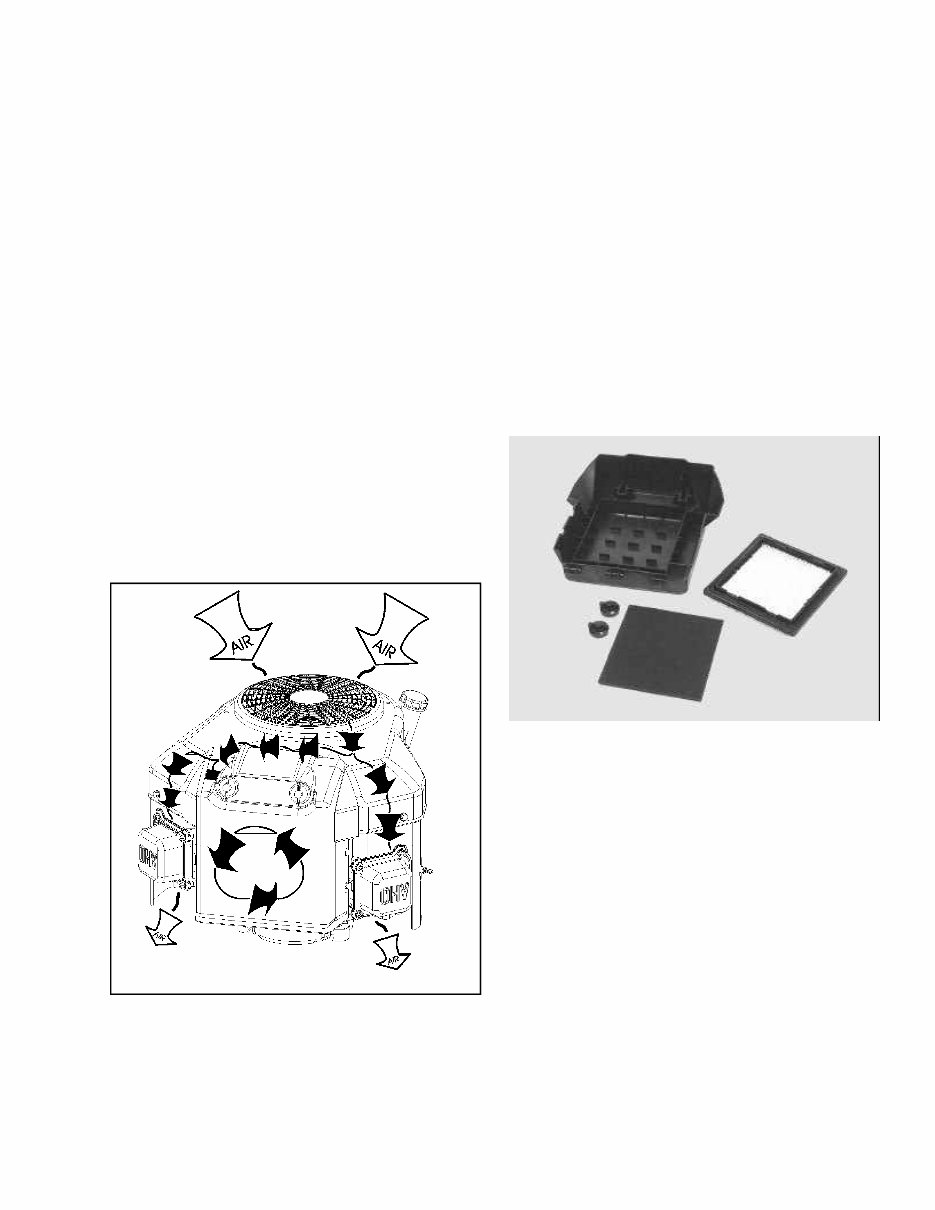

OPERATION

The air filter cover secures and seals the paper filter

element in place. The cover also prevents large particles

from entering the filter body and completes the Kleen-

Aire

®

circuit. The air is first filtered through the flywheel

and blower housing then enters the air filter cover. It

travels through the pre-filter then the paper filter element.

Pre-filters typically extend the paper filter life.

(Illust. 2-1)

COMPONENTS

The cover holds the poly pre-cleaner and clamps the

paper filter in place, creating a dirt tight seal. The cover

also prevents large debris from entering the filter body.

The pre-cleaner is made of a polyurethane foam and

designed to pre-filter the air prior to it passing through

the paper filter. This added stage, assures the operator

of maximum air filtering and extends paper filter life.

The paper filter element is the main filter to stop

impurities from entering the engine. This dry-type element

is pleated paper for increased surface area maximizing

its life. The filter has rubberized edges to assure sealing.

(Illust. 2-2)

TROUBLESHOOTING AND TESTING

If the engine’s performance is unsatisfactory (runs

unevenly, starts smoking abnormally or loses power),

the first engine component(s) to be checked are the air

filter(s). A dirt restricted or oil soaked filter will cause

noticeable performance problems. Polyurethane pre-filter

can be cleaned following the service procedure listed

under “Service” in this chapter. A paper-type air filter can

only be replaced NEVER attempt to clean a paper filter.

The paper-type filter must not have any oil film or residue

present. Should the paper have a brown tint it may have

been damaged by an excessively oiled pre-filter or

crankcase breather problems. Follow the procedure listed

in the “Service” section of this chapter for filter

replacement or cleaning.

2-2

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 17 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

- This complete factory service repair workshop manual is available for instant access on your computer, tablet, or smartphone.

- It covers all repairs, servicing, and troubleshooting procedures with detailed photos and diagrams.

- Professional mechanics and technicians use this manual, which contains step-by-step instructions and highly detailed exploded diagrams and pictures.

- You have the option to print out a single page or the entire manual.

- This manual can be used on multiple computers without any limitations or trial periods.

- There is no expiry date or renewal fee; you can use this manual for life.

- It is fully compatible with Windows and MAC computers.

For more information, please click the button below.