Tecumseh 8 to 18 hp Technician / Service Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

T E C H N I C I A N ' S H A N D B O O K

TECUMSEH

8 TO 18 HP

CAST IRON

FOUR CYCLE

ENGINES

This manual covers the following models:

VH80, VH100, HH80, HH100, HH120, OH120-180

Model numbers are located on the engine shroud.

Other illustrated Tecumseh 2-Cycle Engine, 4-Cycle Engine

and Transmission manuals; booklets; and wall charts are

available through Tecumseh.

For complete listing write or call

Contents

Page

CHAPTER 1. GENERAL INFORMATION ................................................................................................................................... 1

SECTION 1. ENGINE IDENTIFICATION ............................................................................................................................. 1

SECTION 2. ENGINE CARE ............................................................................................................................................... 2

CHAPTER 2. AIR CLEANERS, CARBURETORS, GOVERNORS AND LINKAGE ................................................................... 4

SECTION 1. AIR CLEANERS .............................................................................................................................................. 4

SECTION 2. GENERAL CARBURETOR INFORMATION .................................................................................................. 5

SECTION 3. TECUMSEH CARBURETORS ....................................................................................................................... 6

SECTION 4. WALBRO CARBURETORS .......................................................................................................................... 10

HH80 - 120, VH80 - 100 .............................................................................................................................................. 10

SECTION 5. OVERHEAD VALVE ENGINE CARBURETORS .......................................................................................... 13

SECTION 6. GOVERNORS ............................................................................................................................................... 16

SECTION 7. IMPULSE FUEL PUMP ................................................................................................................................. 19

CHAPTER 3. REWIND STARTERS, ELECTRIC STARTERS, TROUBLESHOOTING AND GENERATORS ......................... 20

SECTION 1. REWIND STARTERS .................................................................................................................................... 20

SECTION 2. ELECTRIC STARTERS ................................................................................................................................ 22

SECTION 3. 12 VOLT STARTER TROUBLE SHOOTING CHART ................................................................................... 25

CHAPTER 4. GENERAL VALVE INFORMATION, CYLINDER HEAD AND BREATHER ASSEMBLY ................................... 27

SECTION 1. GENERAL VALVE INFORMATION ............................................................................................................... 27

SECTION 2. CYLINDER HEAD ......................................................................................................................................... 31

SECTION 3. BREATHER ASSEMBLIES ........................................................................................................................... 32

CHAPTER 5. PISTON AND RINGS, CONNECTING RODS AND CRANKSHAFTS ................................................................ 33

SECTION 1. PISTON AND RINGS .................................................................................................................................... 33

SECTION 2. CONNECTING RODS ................................................................................................................................... 35

SECTION 3. CRANKSHAFTS ........................................................................................................................................... 36

CHAPTER 6. CAMSHAFT, BEARINGS AND SEALS ............................................................................................................... 37

SECTION 1. CAMSHAFT .................................................................................................................................................. 37

SECTION 2. BEARINGS .................................................................................................................................................... 38

SECTION 3. SEALS ........................................................................................................................................................... 42

CHAPTER 7. DYNA-STATIC

®

BALANCING SYSTEM ............................................................................................................. 43

CHAPTER 8. IGNITION SYSTEMS, CHARGING SYSTEMS BATTERY SERVICE and

ELECTRICAL CONTROL PANELS .......................................................................................................................................... 45

SECTION 1. IGNITION SYSTEMS .................................................................................................................................... 45

SECTION 2. CHARGING SYSTEMS ................................................................................................................................. 48

SECTION 3. BATTERY SERVICE ..................................................................................................................................... 53

SECTION 4. ELECTRICAL CONTROL PANELS .............................................................................................................. 56

CHAPTER 9. TROUBLESHOOTING ........................................................................................................................................ 61

CHAPTER 10. 8 H.P. & LARGER ENGINE SPECIFICATIONS AND TORQUES .................................................................... 66

SECTION 1. CROSS REFERENCE LIST FOR TABLE OF SPECIFICATIONS ................................................................ 66

SECTION 2. TORQUE SPECIFICATIONS ........................................................................................................................ 70

8 H.P. & LARGER ENGINES (EXCEPT VALVE-IN-HEAD) ......................................................................................... 70

SECTION 3. VALVE-IN-HEAD ENGINE SPECIFICATIONS ............................................................................................. 71

SECTION 4. TORQUE SPECIFICATIONS ........................................................................................................................ 73

VALVE-IN-HEAD .......................................................................................................................................................... 73

CHAPTER 11. EDUCATIONAL MATERIALS AND TOOLS ...................................................................................................... 74

i

C Tecumseh Products Company

1998

1

CHAPTER 1. GENERAL INFORMATION

SECTION 1. ENGINE IDENTIFICATION

Tecumseh engine model numbers are stamped into

the blower housing, or are located on a nameplate

or tag on the engine in locations as illustrated.

INTERPRETATION OF MODEL NUMBER. The first

letter designations in a model number indicate the

basic type of engine.

HH - Horizontal-Heavy Duty (Cast Iron)

VH - Vertical-Heavy Duty (Cast Iron)

OH - Overhead Valve-Heavy Duty (Cast Iron)

The number designations following the letter indicates

the horsepower of the engine.

The number following the model number is the

specification number. The last three numbers of the

specification number indicate a variation to the basic

engine specification.

The serial number indicates the production data.

Using model number OH160-170033, Serial 8044C

as an example, interpretation is as follows:

OH160-170033 - is the model and specification number.

OH - Overhead Valve-Heavy Duty (Cast Iron)

160 - Indicates 16 horsepower.

170033 - is the specification number used for properly

identifying the parts of the engine.

8044C - is the serial number.

8 - first digit is the year of manufacture (1998)

044 - indicates calendar day of that year (044 day

or February 13, 1998).

C - represents the line, shift or plant in which the

engine was built at the factory.

SHORT BLOCKS. New short blocks are identified

by a tag marked SBH (Short Block Horizontal) or

SBV (Short Block Vertical). Original model tags of

engines should always be transferred to a short block

for correct parts identification.

OH160-170033 SER 8044C

2

SECTION 2. ENGINE CARE

FUELS. Use clean, fresh unleaded automotive gasoline

in all Tecumseh four-cycle engines. (Leaded “regular”

gasoline is an acceptable substitute.)

NOTE: Do Not use gasoline containing methanol

(wood alcohol). Gasoline containing a maximum of

10 ethanol or grain alcohol (sometimes called “gasohol”)

may be used but requires special care when engine

is unused for extended periods.

See “STORAGE” instructions.

ENGINE OIL, ALL FOUR CYCLE ENGINES:

USE A CLEAN, HIGH QUALITY, DETERGENT OIL.

Be sure original container is marked with engine

service classification “SF - SJ.”

DO NOT USE SAE10W40 OIL.

FOR SUMMER (ABOVE 32°F, 0°C) USE SAE 30 OIL

(SAE10W30 is an acceptable substitute.)

FOR WINTER (BELOW 32°F, 0°C) USE SAE 5W20

OR 5W30 OIL.

(SAE10W is an acceptable substitute.)

(BELOW 0°F, -18°C ONLY) Use 0W30 oil or SAE10W

oil diluted with 10% kerosene is acceptable.

NOTE: For severe, prolonged, winter operation of

HH120 model, SAE10W oil is recommended.

OIL CHANGE INTERVALS. Change oil after first two

(2) hours of operation and every 25 hours thereafter,

or more often if operated under dusty or dirty conditions.

OIL CHECK. Check oil every 5 hours or each time

the equipment is used. Position equipment so the

engine is level when checking the oil.

BREAK-IN PROCEDURE. Proper break-in procedure

is important for proper seating of rings, on a new

engine or newly overhauled engine.

Do normal work with the unit, running the engine

under load. Vary the load on the engine frequently

to aid in seating of the rings.

The engine should not be allowed to idle or run at

part throttle for extended periods during break-in.

Work the engine but do not abuse it.

TUNE-UP PROCEDURE. The following is a minor

tune-up procedure. When this procedure is completed,

the engine will operate properly or you may discover

that further repairs may have to be performed.

NOTE: It is recommended to use only factory parts

in a Tecumseh engine. This is especially important

with an air filter, since the use of any other than the

specified part number may result in serious damage

to the engine.

CAUTION: Remove spark plug wire before doing

any service work on engine.

1. Service or replace air cleaner as necessary.

2. Inspect level and condition of oil; drain oil.

3. Remove blower housing, clean all dirt, grass or

debris from intake screen, head and cylinder cooling

fins and carburetor governor levers and linkage.

4. Remove cylinder head, remove carbon, inspect

valves and cylinder bore. Replace head using

a new head gasket. Torque to specifications.

5. Remove carburetor, clean and install carburetor

kit, make adjustment pre-sets where needed.

Make sure fuel tank, fuel filters and fuel lines

are clean. Reinstall carburetor, replacing any worn

or damaged governor springs or linkage. Make

proper governor adjustment.

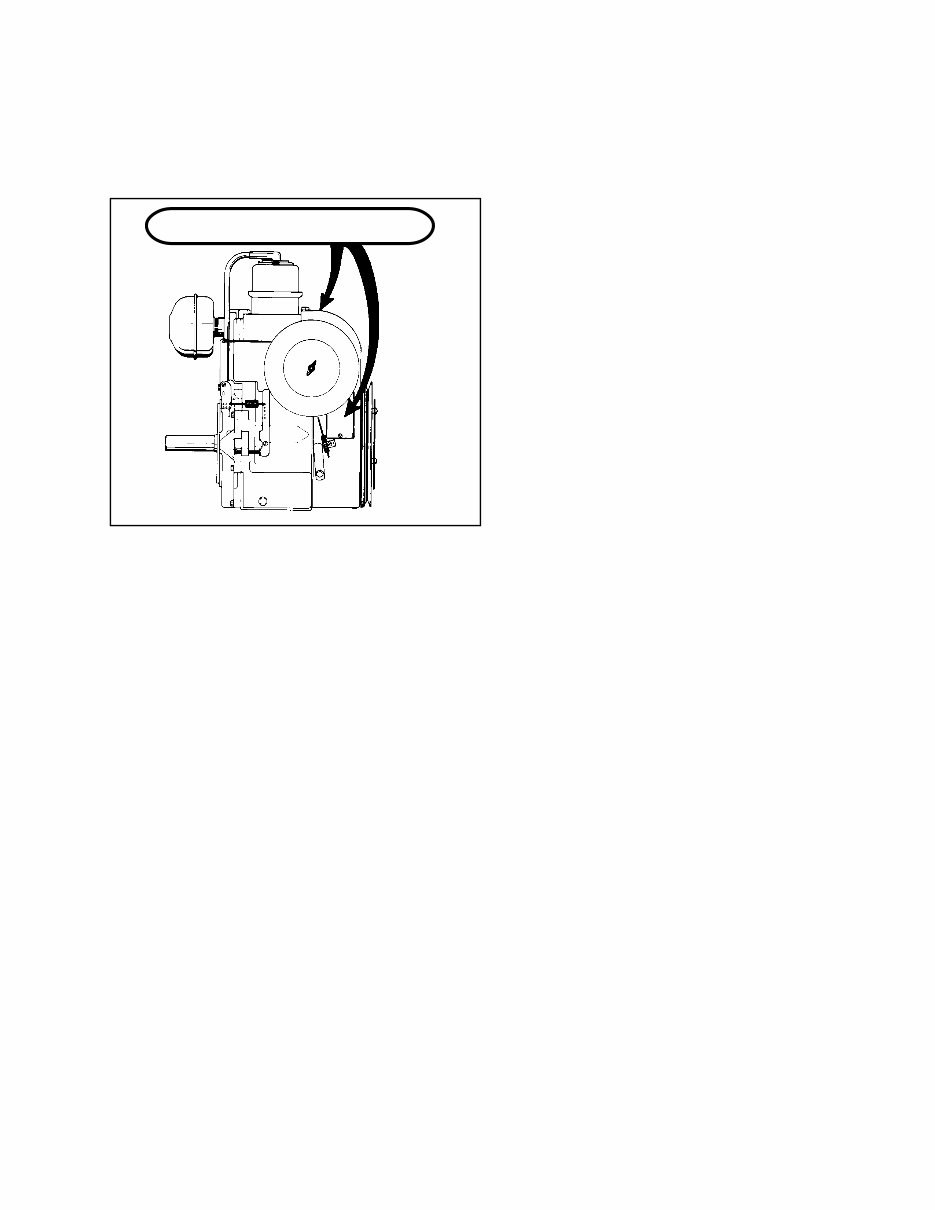

6. Remove flywheel, check for leaks in oil seals,

check flywheel key and reinstall flywheel. Replace

spark plug and check for spark.

7. Make sure all remote linkage is properly adjusted

for proper operation.

8. Replace fuel and oil.

9. Run engine and adjust carburetor and set R.P.M.

to specifications found on Microfiche or computer

parts lookup.

STORAGE: (IF THE ENGINE IS TO BE UNUSED

FOR 30 DAYS OR MORE)

CAUTION: NEVER STORE THE ENGINE WITH

FUEL IN THE TANK INDOORS , IN ENCLOSED

POORLY VENTILATED AREAS WHERE FUEL

FUMES MAY REACH AN OPEN FLAME, SPARK

OR PILOT LIGHT AS ON A FURNACE, WATER

HEATER, CLOTHES DRYER OR OTHER GAS

APPLIANCE.

Gasoline can become unstable in less than 30 days

and form deposits that can impede proper fuel flow

and engine operation. To prevent deposits from forming,

all gasoline must be removed from the fuel tank and

the carburetor. An acceptable alternative to removing

all gasoline is adding a fuel stabilizer to the gasoline.

Fuel stabilizer (such as Tecumseh’s Part No. 730245)

is added to the fuel tank or storage container. Always

follow the mix ratio found on the stabilizer container.

Run the engine at least 10 minutes after adding the

stabilizer to allow it to reach the carburetor.

3

DRAINING THE FUEL SYSTEM:

CAUTION: DRAIN THE FUEL INTO AN

APPROVED CONTAINER OUTDOORS, AND

AWAY FROM ANY OPEN FLAME OR

COMBUSTION SOURCE. BE SURE THE

ENGINE IS COOL.

1. Remove all gasoline from the fuel tank by running

the engine until the engine stops, or by draining

the fuel tank by removing the fuel line at the

carburetor or fuel tank. Be careful not to damage

the fuel line, fittings, or fuel tank.

2. Drain the carburetor by pressing upward on the

bowl drain (if equipped) which is located on the

bottom of the carburetor bowl. On carburetors

without a bowl drain, the carburetor may be drained

by loosening the bowl nut on the bottom carburetor

one full turn. Allow to completely drain and retighten

the bowl nut being careful not to damage the

bowl gasket when tightening.

3. If "Gasohol" has been used, complete the above

procedure and then put one half pint of unleaded

gasoline into the fuel tank and repeat the above

procedure. If Gasohol is allowed to remain in

the fuel system during storage, the alcohol content

will cause rubber gaskets and seals to deteriorate.

Change Oil: If the oil has not been changed recently,

this is a good time to do it.

Oil Cylinder Bore:

1. Disconnect the spark plug wire and ground the

wire to the engine. Remove the spark plug and

put 1/2 ounce (14 ml) of clean engine oil into

the spark plug hole.

2. Cover the spark plug hole with a shop towel.

3. Crank the engine over slowly several times.

CAUTION: AVOID SPRAY FROM SPARK PLUG

HOLE WHEN SLOWLY CRANKING ENGINE

OVER.

4. Install the spark plug and connect the spark plug

wire.

Clean Engine: Remove the blower housing and clean

all dirt, grass or debris from the intake screen, cylinder

head, cylinder cooling fins, carburetor, governor levers

and linkage.

4

CHAPTER 2. AIR CLEANERS, CARBURETORS,

GOVERNORS AND LINKAGE

SECTION 1. AIR CLEANERS

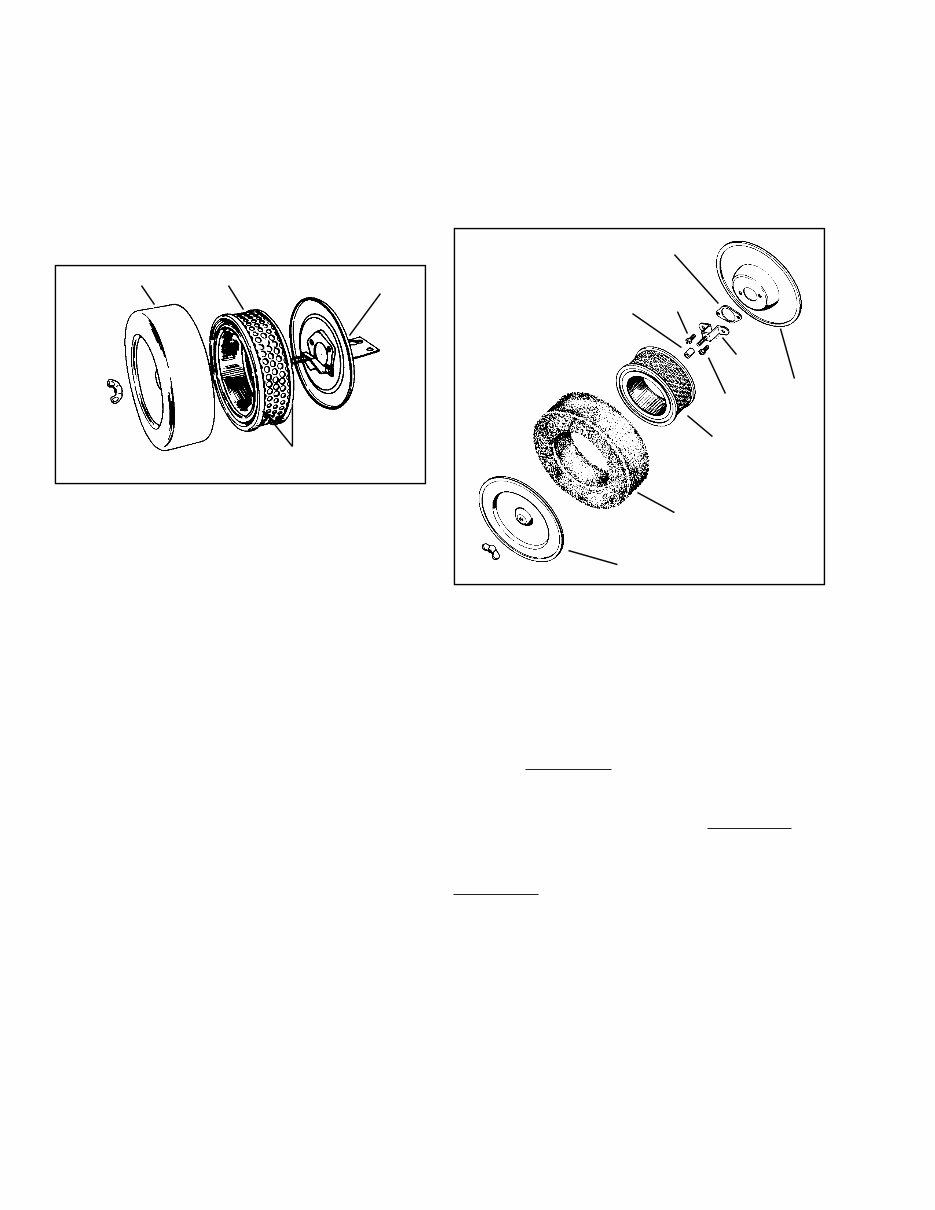

PAPER-TYPE AIR CLEANER SERVICE. Dry type

paper air cleaners are utilized on all Tecumseh Large

Frame engines. These air cleaners have treated paper

elements with rubberlike sealing edges. These edges

must seal properly to prevent dirt leakage.

PAPER-TYPE AIR CLEANER SERVICE. Replace

air filter once a year or more often in extremely dusty

or dirty conditions.

DO NOT ATTEMPT TO CLEAN OR OIL FILTER.

Be sure to clean base and cover thoroughly before

installing new paper filter.

NEVER RUN THE ENGINE WITHOUT THE COMPLETE

AIR CLEANER INSTALLED ON THE ENGINE.

NOTE: Serious damage to the engine may result in

using other than the specified part number filter.

Use factory recommended parts only.

POLYURETHANE-TYPE AIR CLEANER. Some

Tecumseh Large Frame engines may use a polyurethane

air filter in conjunction with a paper filter.

POLY-TYPE AIR CLEANER SERVICE. Clean and

re-oil every 3 months or every 25 operating hours,

whichever comes first. Clean daily if used in extremely

dusty or dirty conditions. Proceed as follows:

Remove wing nut and cover.

Slide foam filter off paper filter.

Wash foam filter in water and detergent solution and

squeeze, Don’t twist until all dirt is removed.

Rinse thoroughly in clear water.

Wrap in a clean cloth and squeeze, Don’t twist until

completely dry.

Saturate foam filter with engine oil and squeeze,

Don’t twist to distribute oil and remove excess oil.

Clean top side of base and inside of cover thoroughly.

Replace foam filter, cover and wing nut. Tighten wing

nut securely.

NEVER RUN ENGINE WITHOUT COMPLETE AIR

CLEANER INSTALLED ON ENGINE.

COVER ELEMENT

BASE

SEALING EDGES

GASKET

BOLT

SPACER

BRACKET

BOLT

BACK

COVER

PAPER

ELEMENT

POLY

OUTER ELEMENT

FRONT COVER

5

SECTION 2. GENERAL CARBURETOR INFORMATION

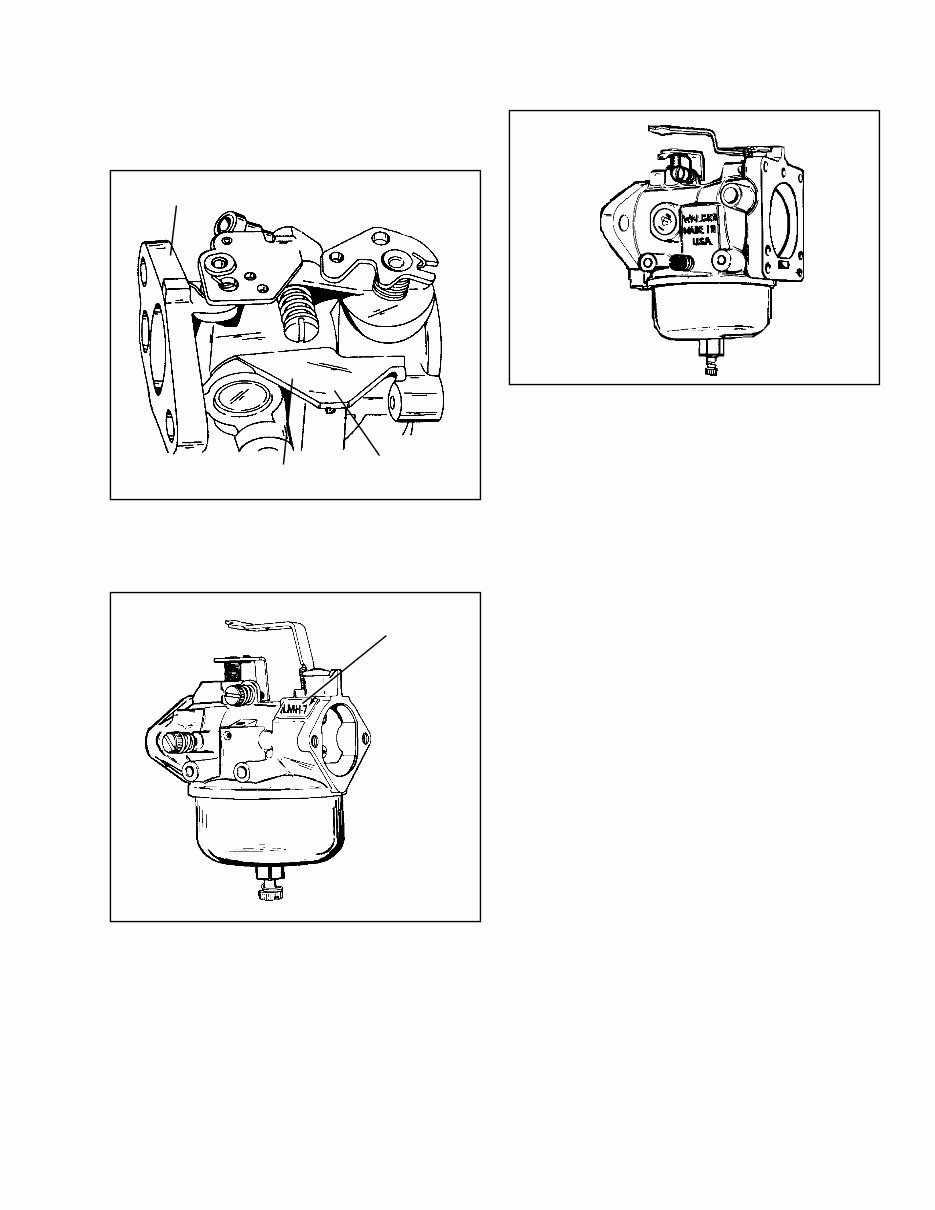

CARBURETOR IDENTIFICATION . Tecumseh

carburetors are identified by a model number and

code date stamping on the carburetor as illustrated.

When servicing carburetors, use the engine model

number or the model number on the carburetor and

proper section in the Master Parts Manual or Microfiche

Catalog for proper service information.

These carburetors are used on some HH80-100-

120 and VH80-100 engines.

This carburetor is used on the Overhead Valve engine

12, 14, 16 & 18 horsepower.

FLOAT-FEED CARBURETORS. Float-feed carburetors

use a hollow metal float to maintain the operating

level of fuel in the carburetor. As the fuel is used,

the fuel level in the carburetor bowl drops and the

float moves downward. This actuates the inlet needle

valve, to allow fuel to flow by gravity into the fuel

bowl. As the fuel level in the bowl again rises, it

raises the float. This float motion adjusts the fuel

flow at the proper rate and keeps the fuel at the

proper mixture level.

CARBURETOR

CODE DATE

CARBURETOR

MODEL NUMBER

ALTERNATE LOCATION

FOR MODEL NUMBER

89 3 F 5

89 3 F

CARBURETOR

MODEL NUMBER

6

SECTION 3. TECUMSEH CARBURETORS

Following are initial carburetor adjustments to be

used to start the engine. After the engine has reached

operating temperature make final adjustments.

Main Adjustment HH80-100-120

Screw VH100, 1-3/4 turns.

Idle Adjustment HH80-100-120

Screw VH100, 1-1/4 turns

The Master Parts Manual or Microfiche has a direct

engine-to carburetor reference list. Further identification

of the carburetor is stamped on the carburetor body

as shown. Refer to the standard service part number

and the identification number on the carburetor body,

in any correspondence.

CARBURETOR DISASSEMBLY, INSPECTION AND

ASSEMBLY. Carefully disassemble carburetor, removing

all non-metallic parts, i.e., gaskets, viton seats and

needles, “O” rings, fuel pump valve, etc.

THROTTLE. Examine the throttle lever shaft and

shutter prior to disassembly. Replace any worn parts.

1. Remove the screw in the center of the throttle

shutter and pull out the throttle shaft lever assembly.

2. When reassembling, replace the throttle shutter

with identifying marks as positioned prior to

disassembly. The throttle shaft must be held in

tight to the bottom bearing to prevent the throttle

shutter from riding on the throttle bore of the

body, causing excessive throttle shutter wear

and governor hunting.

CHOKE. Examine the choke lever, shaft and shutter

prior to disassembly. Replace any worn parts.

1. Remove the screw in the center of the choke

shutter and pull out the choke shaft lever assembly.

2. When reassembling, replace the choke shutter

with identifying marks as positioned prior to

disassembly. Hold the choke shaft securely into

the bearing bore when replacing the choke shutter.

IDLE ADJUSTMENT SCREW. Remove the idle screw

from the carburetor body and examine the point for

damage to the seating surface of the taper. Replace

any damaged parts.

CARBURETOR

MODEL NUMBER

WELCH PLUG

CHOKE LEVER

THROTTLE

LEVER

NOTE: IDENTIFYING MARK WILL BE

FOUND IN THE 3 O’CLOCK POSITION THROTTLE

SHUTTER

CHOKE SHUTTER CUT

OUT CLEARANCE FOR

INTERNAL VENT TUBE

GOOD BAD

7

HIGH SPEED ADJUSTMENT SCREW. For service,

examine the taper of the high speed adjustment screw.

If the taper is damaged at the area where it seats,

replace the screw and fuel bowl retainer nut as an

assembly.

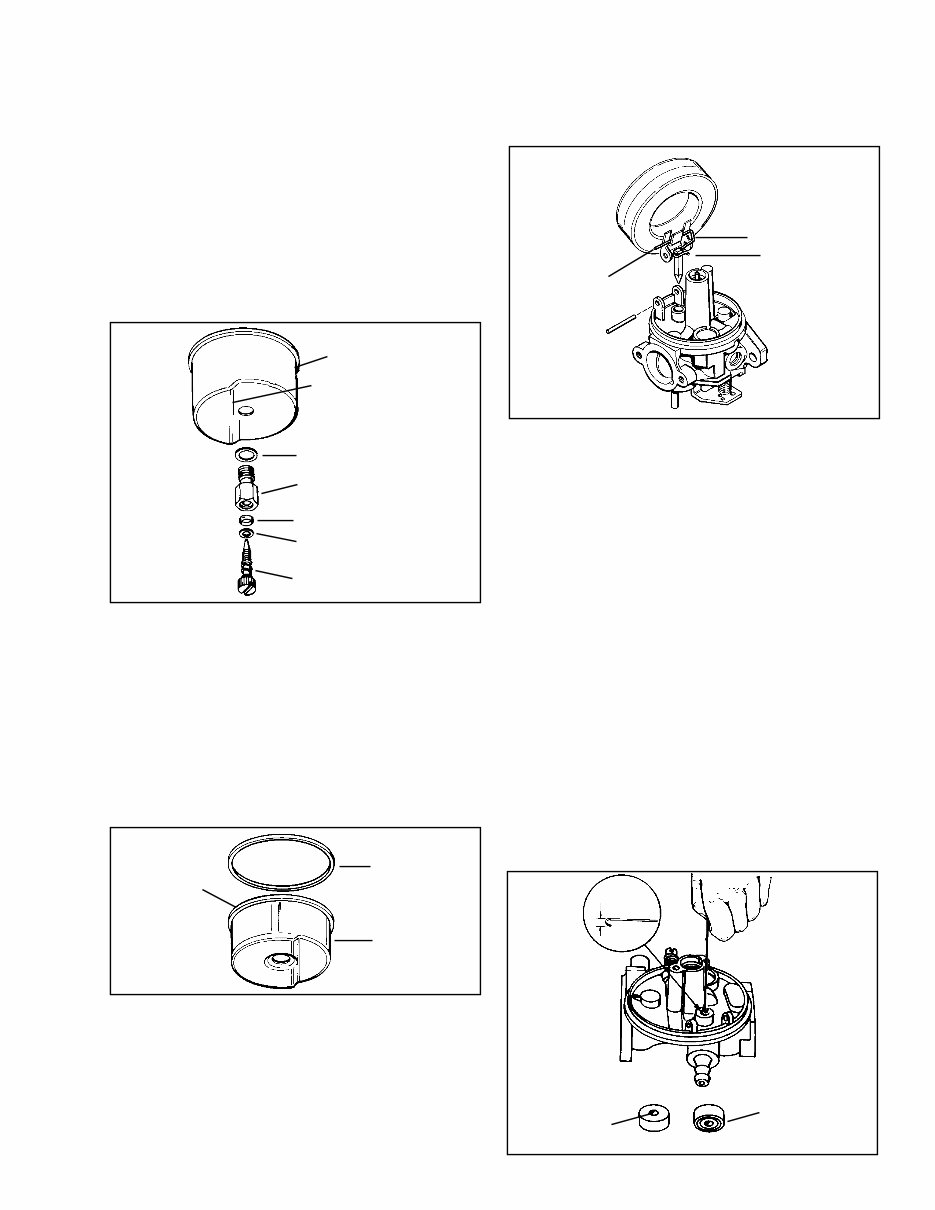

FUEL BOWL RETAINING NUT. Remove the fuel bowl

retaining nut including fiber washer.

Examine the small fuel passage in the annular groove

in the retaining nut. This passage must be clean

for the proper transfer of fuel into the idle metering

system. Replace any worn parts.

When replacing, torque the fuel bowl nut to 50-60

inch pounds.

INLET NEEDLE. The inlet needle is anchored to

the float tab by a clip, to assure proper movement

of the inlet needle off of the seat when the float

drops. The inlet needle clip must be positioned as

shown during reassembly.

FUEL BOWL. Check the bowl for corrosion or dirt.

Replace if necessary.

The fuel bowl must be free of dirt and corrosion.

When tearing down carburetor for repair, replace

fuel bowl “O” ring. Before installation lubricate the

“O” ring with a small amount of oil for easier installation.

The fuel bowl flat surface must be positioned on

the same side of the carburetor as the fuel inlet fitting

or same side as the float hinge pin to assure full

travel of the float.

FLOAT. Remove the float. Examine the float for crushing

or holes. Examine the float hinge bearing surfaces

through which the float hinge pin passes and replace

if worn.

Examine the inlet needle. If any wear is evident, or

any of the corners show signs of rounding, the needle

should be replaced.

The inlet needle hooks onto the float tab by means

of a spring clip. To prevent binding, the long, straight

end of the clip should face the choke end of the

carburetor as shown.

SERVICING THE VITON SEAT.

a. REMOVAL. If the seat is to be replaced use the

bent end of a paper clip or wire with a 3/32'’

(.24 mm) hook. Push the hook through the Viton

seat hole. Then with the hook, pull the Viton seat

out. Replace with a new seat.

NOTE: A #4 crochet hook can also be used for removal.

b. INSTALLATION.

NOTE: After thoroughly cleaning the cavity, moisten

the viton seat with oil.

Insert the seat with the grooved side into the

cup. Press the viton seat squarely into the base

with a punch.

FUEL BOWL

FLAT OF FUEL BOWL

TOWARD FUEL INLET

FITTING

FIBER WASHER

FUEL BOWL

RETAINING NUT

“O” RING

BRASS WASHER

HIGH SPEED ADJUSTMENT

SPRING AND SCREW

TORQUE TO

50 - 60 INCH

POUNDS

“O” RING

FUEL BOWL

CHECK FOR

CORROSION

AND DIRT

CLIP

LONG END

OF CLIP

OPEN END

OF CLIP

THROTTLE END

CHOKE END

3/32”

(.24 mm)

INLET NEEDLE

SEATS AT THIS

POINT

INSERT THIS

FACE FIRST

REMOVAL OF VITON SEAT

INSTALLATION OF VITON SEAT

HOOK END

8

HIGH SPEED NOZZLE. The carburetor body contains

a main nozzle emulsion tube pressed into the carburetor

body to a predetermined depth and positioned within

the venturi of the carburetor. Do not attempt to remove

this main nozzle. Repositioning of this nozzle will

seriously affect the metering characteristics of the

carburetor and will require replacement of the entire

carburetor.

FUEL INLET FITTING. If necessary, this fitting can

be removed by pulling and twisting. Be sure to install

the fitting in the same position as the original. When

installing the fitting, insert tip into the carburetor

body, then coat the exposed portion of the shank

with Loctite grade A; then press it in until the shoulder

contacts the carburetor body.

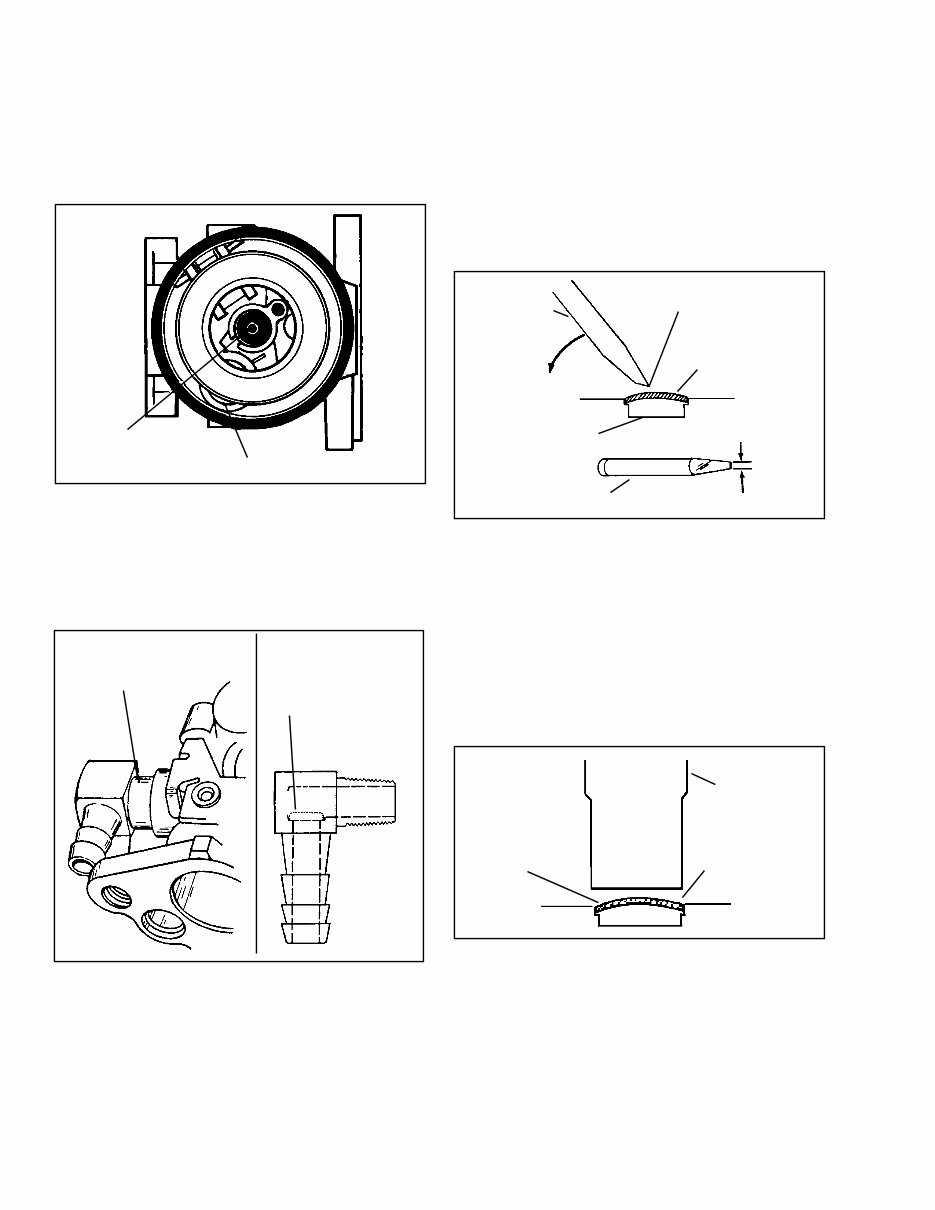

CARBURETOR BODY. When removing the choke

and throttle shafts, check shafts and bearings in

carburetor body for wear. Any looseness in these

areas can cause dirt to enter the engine and cause

premature wear. If dust seals are present, these should

be positioned next to the carburetor body.

To do a proper cleaning job, welch plugs should be

removed to expose drilled passages. To remove the

welch plug, sharpen a small chisel to a sharp wedge

point. Drive the chisel into the welch plug, push down

on chisel and pry plug out of position.

When all accessories and shafts have been removed,

soak the carburetor in carburetor cleaner for a maximum

of 30 minutes. Blow out all passages with compressed

air in the opposite direction of normal fuel flow or

use a soft tag wire. Clean all metallic parts with solvent.

To install a new welch plug after cleaning, place

the welch plug into receptacle with raised portion

up. With a punch equal, or greater than the size of

the plug, merely flatten the plug. Do not dent or drive

the center of the plug below the top surface of the

carburetor.

WELCH PLUG

MAIN NOZZLE

EMULSION TUBE

DO NOT REMOVE

PRESS IN PARTIALLY

THEN APPLY LOCTITE

GRADE A

SOME INLET FITTINGS

UTILIZED A STRAINER

SMALL CHISEL

PRY OUT PLUG

PIERCE PLUG WITH TIP

WELCH PLUG TO BE

REMOVED

DO NOT ALLOW

CHISEL POINT TO

STRIKE CARBURETOR

BODY

ABOUT 1/8” (3.2 MM)

WIDE

SMALL CHISEL

FLAT-END PUNCH

NEW WELCH

PLUG

SAME OR LARGER

DIAMETER OF PLUG

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

$36.99

Viewed 76 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

$36.99

Whether you're a professional mechanic or a DIY enthusiast, this 78-page Service/Technicians Manual for Tecumseh 8 to 18 hp Cast Iron 4-Cycle Engines is an invaluable resource. It covers models VH80, VH100, HH80, HH100, HH120, and OH120-180. This manual provides the technical information you need to troubleshoot and repair your Tecumseh engine.

Get your hands on this comprehensive manual to gain insights into maintaining and servicing your engine. It's a must-have for anyone looking to ensure their engine runs smoothly and efficiently.