Subaru Engine EX35 and EX40 Technician / Service Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. PERFORMANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3. FEATURES (EX35, 40 series) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4. GENERAL DESCRIPTION OF ENGINE COMPONENTS . . . . . . . . . . . . . . . . 6

5. DISASSEMBLY AND REASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5-1 PREPARATIONS AND PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5-2 SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5-3 DISASSEMBLY PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5-4 REASSEMBLY PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6. ENGINE OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7. MAGNETO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8. IGNITION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9. WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

10. ELECTRIC STARTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

11. OIL SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

12. AUTOMATIC DECOMPRESSION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . 53

13. CARBURETOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

14. RECOIL STARTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

15. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

16.TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

17. STANDARD REPAIR TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

17-1 STANDARD DIMENSIONS AND LIMITS OF USE . . . . . . . . . . . . . . . . . . 72

17-2 SERVICE DATA (The following are only for your reference.) . . . . . . . . . . . 77

17-3 TIGHTENING TORQUE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

17-4 AIR GAP AND CLEARANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

18.MAINTENANCE AND STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

CONTENTS

Section Title Page

- 1 -

1. SPECIFICATIONS

*Specifications are subject to change without notice.

Model EX35D EX40D

Type

Air-Cooled, 4-Cycle, Slant Single-Cylinder,

Horizontal P.T.O. Shaft, OHC Gasoline Engine

Bore & Stroke mm (in.) 89 × 65 (3.50 × 2.56)

Piston Displacement ml (cu.in.) 404 (24.65)

Compression Ratio 8.3

Continuous Output kW(HP)/r.p.m.

5.5(7.5)/3000

6.3(8.5)/3600

6.3(8.5)/3000

7.0(9.5)/3600

Maximum Output kW(HP)/r.p.m. 7.4(10.0)/3600 8.8(12.0)/3600

Maximum Torque

N ・ m / r.p.m.

(kgf ・ m / r.p.m.)

(ft ・ lb. / r.p.m.)

26/2400

(2.6/2400)

(19.18/2400)

27/2400

(2.7/2400)

(19.91/2400)

Direction of Rotation Counterclockwise as viewed from the P.T.O. shaft side

Valve Arrangement Overhead cam system

Cooling System Forced air cooling system

Lubrication System Splash lubrication system

Lubricant

Automobile engine oil ; Grade SE or higher (SG,SH or SJ in recomended)

SAE 10W-30-----Under ordinary atmospheric temperatures

SAE 5W-30-------In cold areas

Capacity of Lubricant L 1.2

Carburetor Horizontal draft, Float type

Fuel Automobile unleaded gasoline

Fuel Consumption Rate g/kW ・ h (g/HP ・ h) 381 (280)

Fuel Supply System Gravity type

Fuel Tank Capacity L 7.0

Ignition System Transistorized magneto

Spark Plug NGK BR-6HS

Charging Capacity (Option) V-A 12-1A, 3A, 16.7A (Option)

Starting System Recoil starter / Electric starter (Option)

Governor System Centrifugal flyweight system

Dry Weight kg (lb.) 33 (72.75)

Dimensions (L x W x H) mm (in.) 389 x 450 x 443 (15.31 x 17.72 x 17.44)

- 2 -

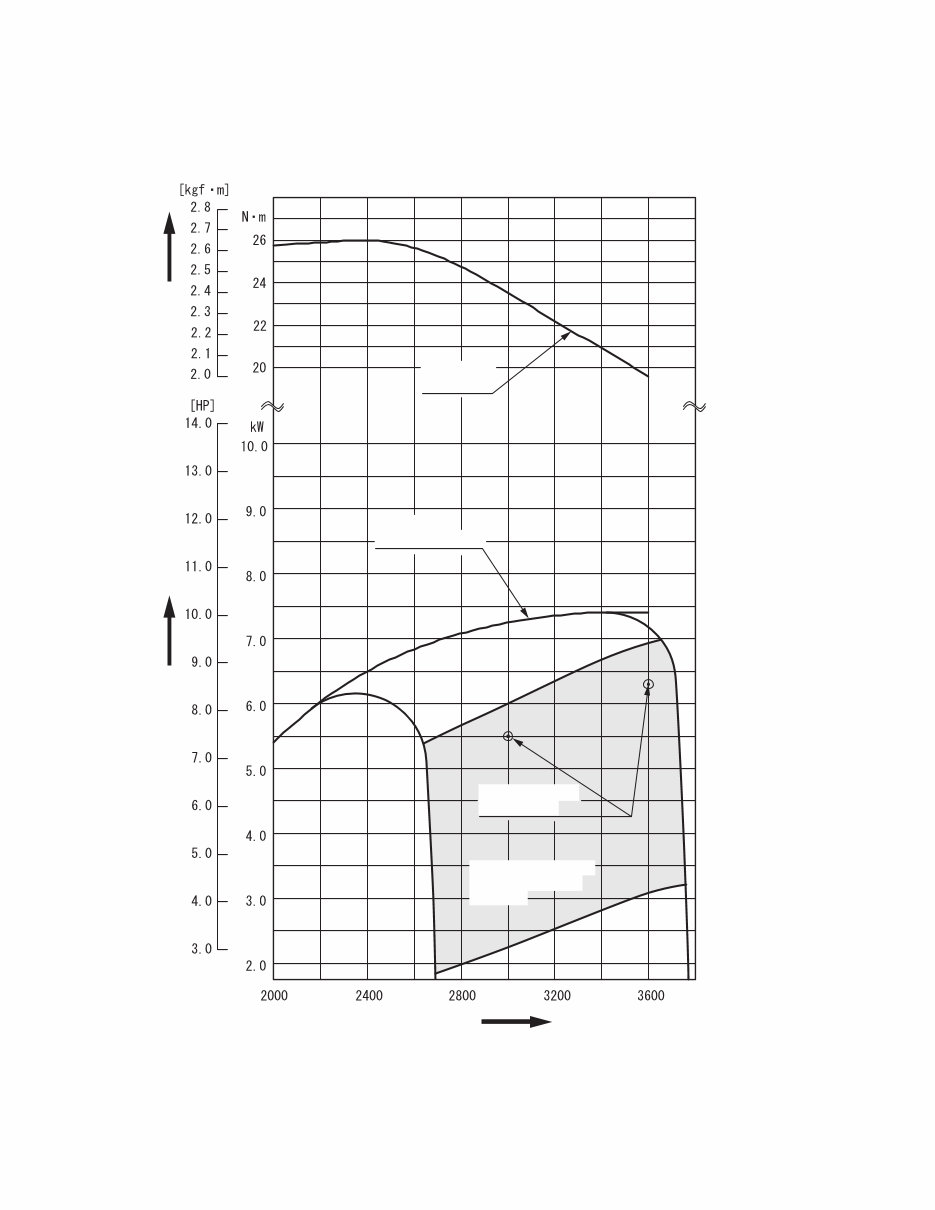

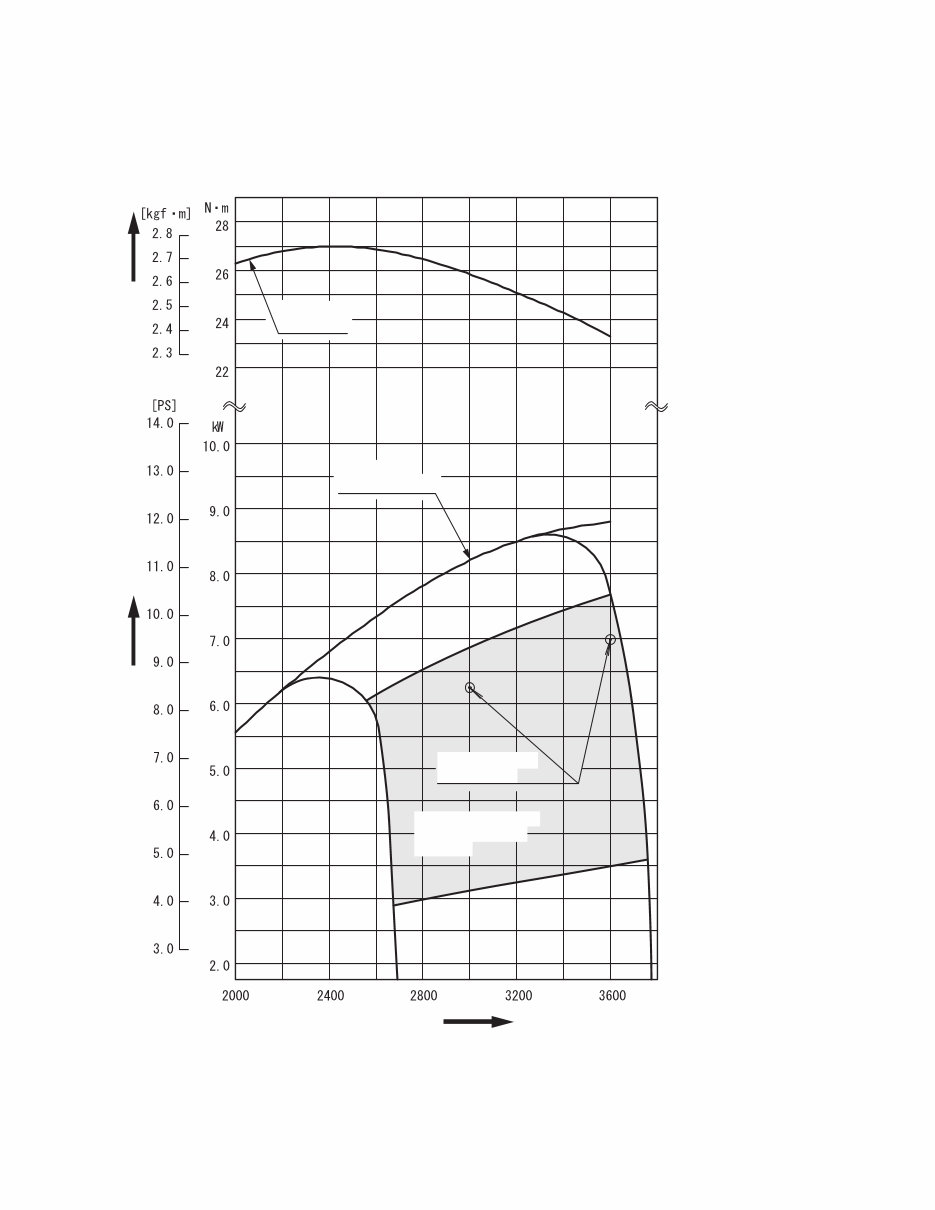

2. PERFORMANCE

2-1 MAXIMUM OUTPUT

The Maximum output is the output of an engine with its throttle valve fully opened and considering that all the

moving parts are properly broken in.

A new engine may not produce full maximum output while its moving parts are still not broken-in.

NOTE :

Power curves shown in the following charts are made in conformity with SAE internal combustion engine

standard test code J1349.

2-2 CONTINUOUS RATED OUTPUT

The continuous rated output is the output of an engine at optimum governed speed which is most favorable

from the view point of engin’s life and fuel consumption.

When the engine is installed on a certain equipment, it is recommended that the continuous output required

from the equipment to be kept below this continuous rated output.

2-3 MAXIMUM TORQUE

The maximum torque is the torque at the output shaft when the engine is producing maximum output at a

specific r.p.m..

- 3 -

EX35D

MAXIMUM

TORQUE

MAXIMUM

HORSEPOWER

r.p.m. REVOLUTION

TORQUE

OUTPUT

CONTINUOUS

RATED HP

RECOMMENDED

HORSEPOWER

RANGE

2-4 PERFORMANCE CURVES

- 4 -

EX40D

MAXIMUM

TORQUE

MAXIMUM

HORSEPOWER

r.p.m. REVOLUTION

TORQUE

OUTPUT

CONTINUOUS

RATED HP

RECOMMENDED

HORSEPOWER

RANGE

- 5 -

3. FEATURES (EX35, 40 series)

3-1 HIGH OUTPUT

Thanks to the adoption of a cam profile exclusively for intake and exhaust and the optimization of the shape

of the intake/exhaust port and the shape of the combustion chamber, the top-of-the-class-level maximum

output is achieved.

3-2 EXTREMELY SILENT - SOFT TONE QUALITY

EX engines are 2dBA quieter and softer in tone than other engines in the same class.

This quiet and soft tone is achieved by:

- Resin blower housing reduce noise leakage of mechanical noise.

- Employment of an optimized capacity Rigid Muffler.

3-3 EXTREMELY EASY START

Reliable Starting and Less Pulling Force are achieved by:

Sophisticated Mechanical Compression Release System as well as newly designed Combustion Chamber.

3-4 EXTREMELY EASY MAINTENANCE

Extreme ease of maintenance is realized by:

- High Parts Commonality

simplifies maintenance & lowers repair cost due to fewer parts for service.

- Only with ordinary tools, routine maintenance, assembly and disassembly can be performed.

3-5 EXTREMELY ADVANCED TECHNOLOGY

Extreme reliability and durability are achieved by:

- Heavy Duty Chain Driven OHC System

Oval type case-hardened steel links enhance performance and resist stretching, which result in extended

maintenance free operation.

- Completely New Main Bearing Cover’s Design

Flush-mounted main bearing cover with lower moment of deformation significantly increases reliability and

engine life.

- Superior Cooling and Lubrication System

Heat reduction is achieved by more efficient, larger and more numerous cooling fins on crankcase, cylinder

and mounting base, as well as by outstanding oil delivery system.

- Large Ball Bearings on both ends of crankshaft for maximum stability under demanding loads.

- Cast Iron Cylinder Liner resists wear

3-6 EXTREME POWER AND PERFORMANCE

Extremely Higher Power and Lower Fuel Consumption are realized by:

- High speed and homogeneous combustion achieved by sophisticated Pentroof Combustion Chamber which

includes Intake and Exhaust Valves located at optimum angle.

- Straight Intake Port with minimal air flow resistance.

Environmentally friendly

EX engines comply with EPA Phase 2 and CARB Tier III Emission Regulations in the USA.

Extreme application compatibility

With four versatile models, existing slant-cylinder engines can be easily replaced.

- 6 -

4. GENERAL DESCRIPTION OF ENGINE COMPONENTS

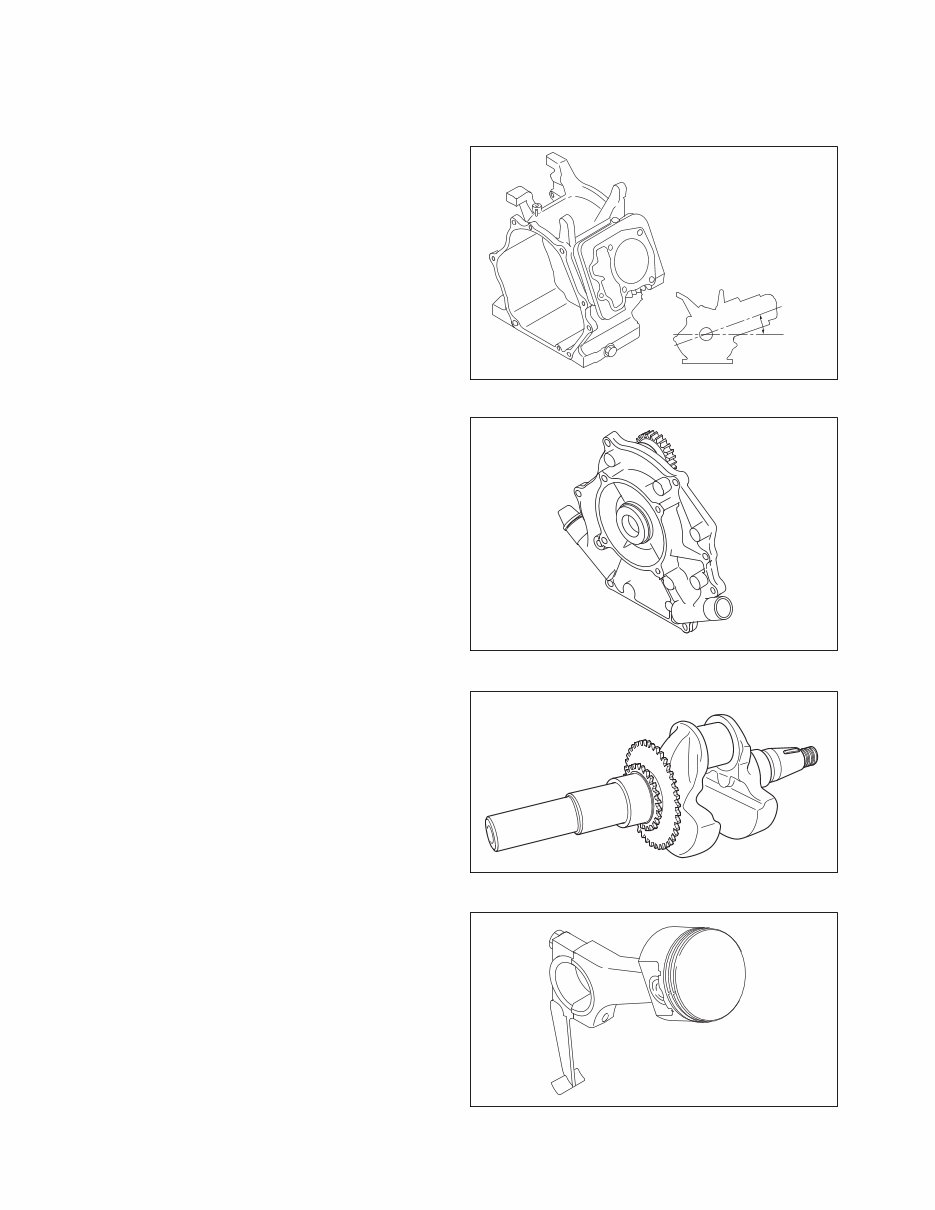

4-1 CYLINDER AND CRANKCASE

The cylinder and crankcase are aluminum die-casting

as a single piece. A special cast iron cylinder liner is

molded into the aluminum die-casting.

The crankcase has a mounting surface on the output

shaft side to which the main bearing cover is attached.

The cylinder is inclined to the right at an angle of 25

degrees from the horizontal as viewed from the output

shaft side.

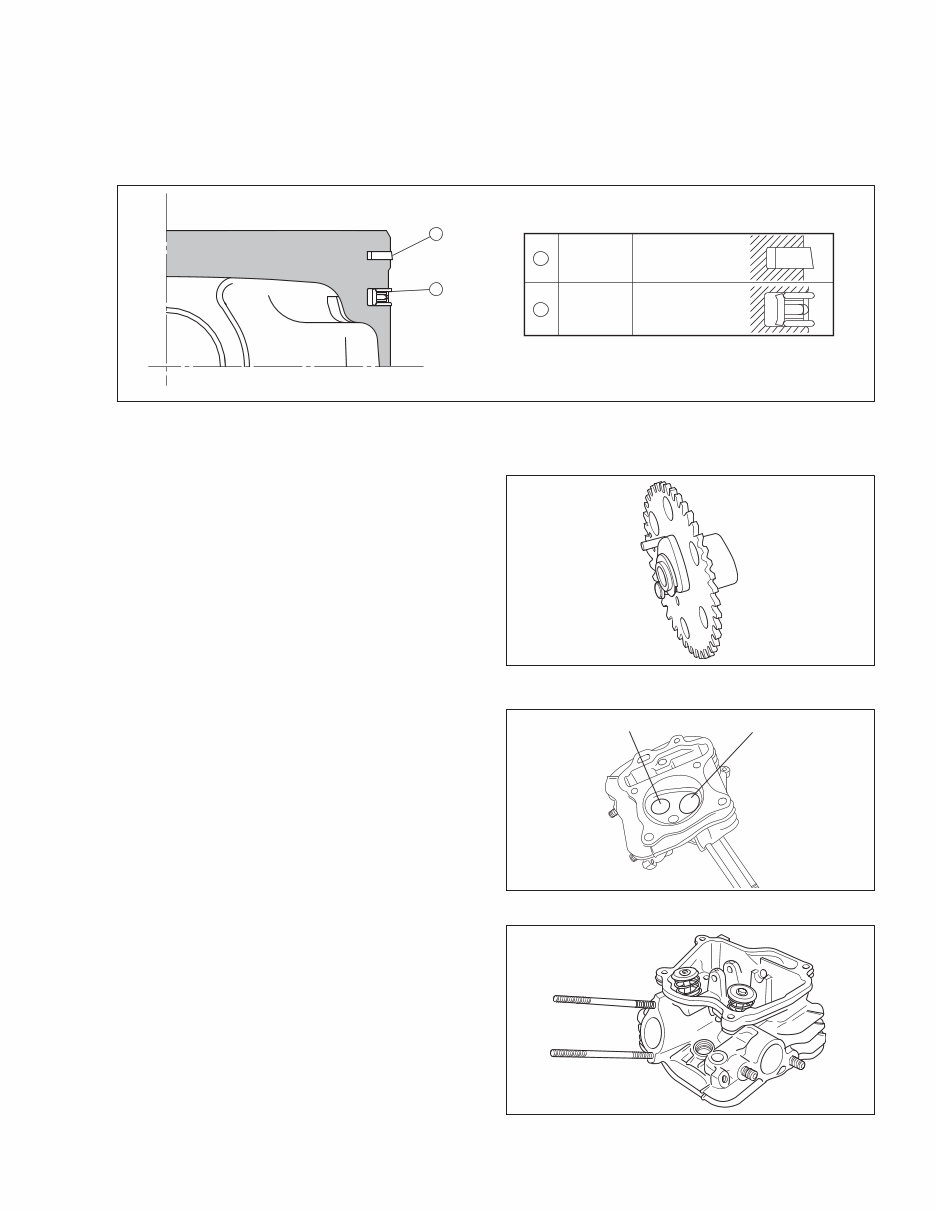

4-2 MAIN BEARING COVER

The main bearing cover is an aluminum die-casting,

which is mounted on the output shaft side of the

crankcase. By removing the main bearing cover, the

inside of the engine can be inspected with ease.

Pilots and bosses are machined into the cover

to facilitate the direct coupling of the engine with

machines such as generators and pumps.

Oil gauges (fillers) are on both sides of the cover for

easy maintenance.

4-3 CRANKSHAFT

The crankshaft is forged carbon steel, and the crank

pin is high-frequency inductionhardened.

The crank sprocket used to drive the chain and the

gear used to drive the governor gear are pressed into

the output end of the shaft.

4-4 CONNECTING ROD AND PISTON

The connecting rod is a specially heat-treated

aluminum alloy die-casting. Its large and small ends

function as bearings. A splasher built into the

connecting rod lubricates by splashing engine oil.

The piston is an aluminum alloy casting with grooves

for mounting one compression ring and one oil ring.

Fig.4-1

Fig.4-2

Fig.4-3

25°

Fig.4-4

- 7 -

Fig.4-6

Fig.4-5

4-7 VALVE ARRANGEMENT

This engine has a chain-driven overhead cam and

overhead valve construction, with a single cam which

has individual profile for intake and exhaust to

perform high output.

Fig.4-7

EXHAUST VALVE

INTAKE VALVE

Fig.4-8

4-8 CYLINDER HEAD

The cylinder head is on aluminum die-casting with a

dome-shaped combustion chamber. The intake and

exhaust ports are arranged in a cross direction to

improve combustion efficiency.

TOP

RING

OIL

RING

1

2

TAPER

THREE-PIECE

CONSTRUCTION

1

2

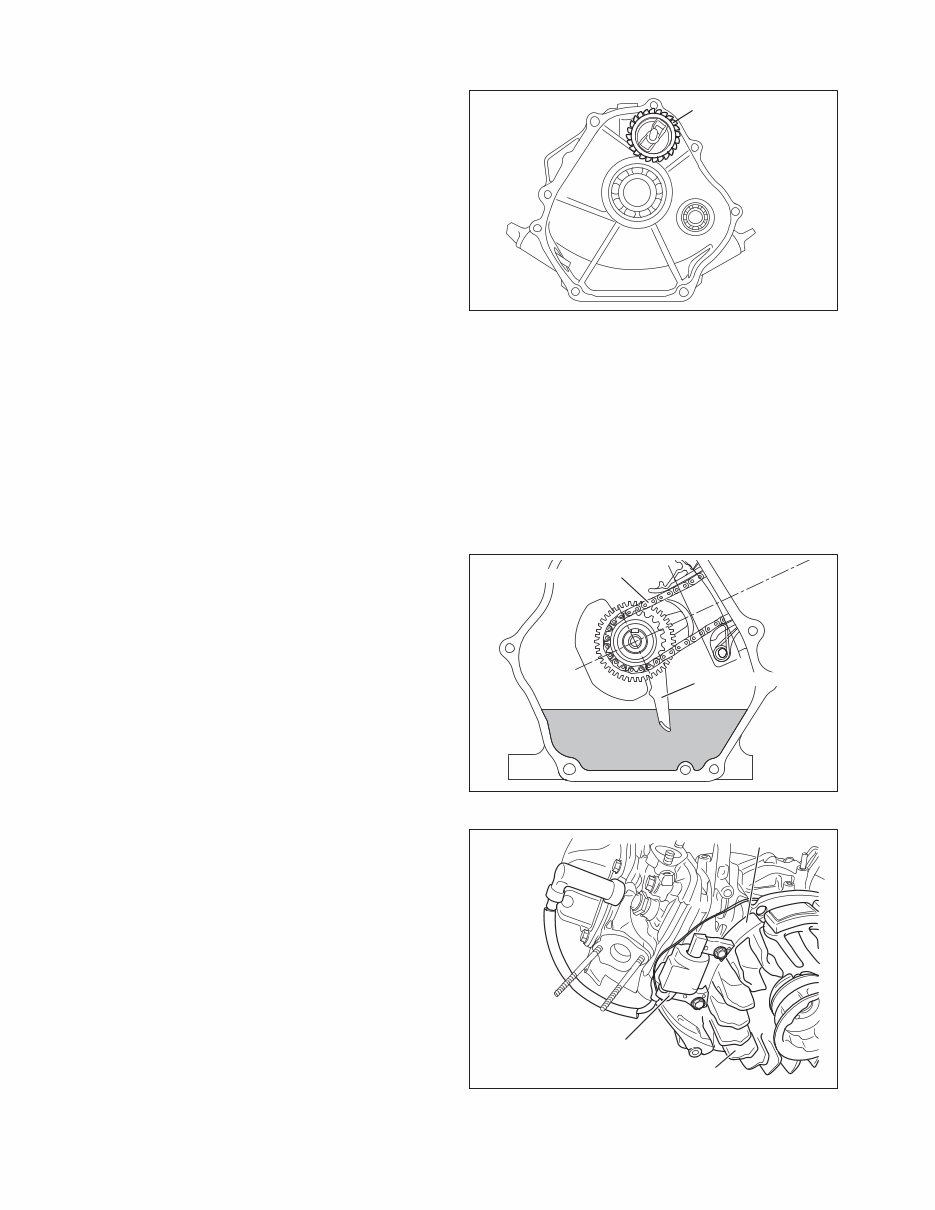

4-6 CAMSHAFT

The camshaft and the sprocket are made of special

sintered alloy. They are constructed as a single

piece. The camshaft is provided with intake and

exhaust cam, and the decompression release lever is

mounted on the sprocket shaft end side.

4-5 PISTON RINGS

The piston rings are made of special cast iron. The profile of the top ring is a tapered face.

The oil ring is designed for better sealing and less oil consumption, in combination with 3 pieces.

- 8 -

4-12 TIMING CHAIN

Timing chain system is adopted and designed for

lubricating for the upper portion of cylinder head.

The timing chain is engaged between the sprocket

portion of integrated camshaft in the cylinder head and

the crankshaft gear sprocket.

The sprocket teeth in particular shape are adopted to

enhance the durability and to realize low noise level.

4-13 IGNITION SYSTEM

The ignition system is a transistor controlled magneto

system with the ignition timing set at 24 degrees

before the top dead center. The magneto consists of

a flywheel and ignition coil. The flywheel (cooling fan

is separete from the flywheel) is directly mounted on

the crankshaft and the ignition coil is directly

mounted on the crankcase.

* Model EX35 and 40 has a smooth advanced

ignition timing system to improve starting

performance. (For further details, refer to page

46, section “7. MAGNETO”.)

Fig.4-10

Fig.4-11

4-11 LUBRICATION SYSTEM

The rotating parts, sliding parts and valves of the engine are lubricated with oil in the crankcase.

The oil is splashed onto the parts by the oil splasher on the connecting rod.

4-10 COOLING SYSTEM

The engine uses a forced air-cooling system in which a synthetic resin cooling fan (which is separate from the

flywheel), reduce noise and forces cooling air into the cylinder and cylinder head.

Baffles are provided to guide the flow of cooling air. (As for with starting motor, baffle 1 is not mounted.)

4-9 GOVERNOR SYSTEM

This engine is equipped with a centrifugal flyweight

type governor that makes it possible to operate the

engine at a constant speed, even with load

variations. (The governor flyweights are mounted on

a governor gear.)

Fig.4-9

GOVERNOR GEAR

TIMING CHAIN

OIL SPLASHER

IGNITION COIL

FAN

FLYWHEEL

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

Viewed 48 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

Need help with your Subaru Engine? Look no further than this 84-page Service/Technicians Manual for Subaru Engines EX35 and EX40. This manual covers models EX35 and EX40, making it a valuable resource for both professional mechanics and DIY enthusiasts. Whether you're tackling repairs or maintenance, this manual provides the technical information you need. Trust in a reliable seller and feel free to reach out with any questions you may have.