Robin EY14, EY18-3,EY23, Ey25-2, EY27-2 service manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

ROBIN AMERICA, mc.

ROBIN TO WISCONSIN ROBIN

ENGINE MODEL CROSS REFERENCE LIST

ROBIN WISCONSIN ROBIN

-

EY08

EYl5

EY 15V

EY20

EY2OV

EY23

EY28

EY35

EY40

EY45V

EY2 1

EY44

EY25

EY27

EY 18-3

EHl 1

EH12

EH15

EH17

EH21

EH25

EH30

EH3OV

EH34

EH34V

EH43V

EC13V

DY23

DY27

DY30

DY35

DY4 1

W1-080

W1-145

W1-145V

w1-185

W1-185V

Wl-230

W 1-280

W1-340

W1-390

W1-450V

EY21W

EY44W

EY 18-3W

EY25W

EY27W

TWO CYCLE

WOl-115

WOl-120

WO1-150

WO1-170

wo1-210

WO1-250

WO 1-300

WO 1 -300v

WO 1-340

WO 1 -340V

WO 1 -430V

WT1-125V

WRD 1-230

WRD 1-270

WRD 1-300

WRD1-350

wRDl-410

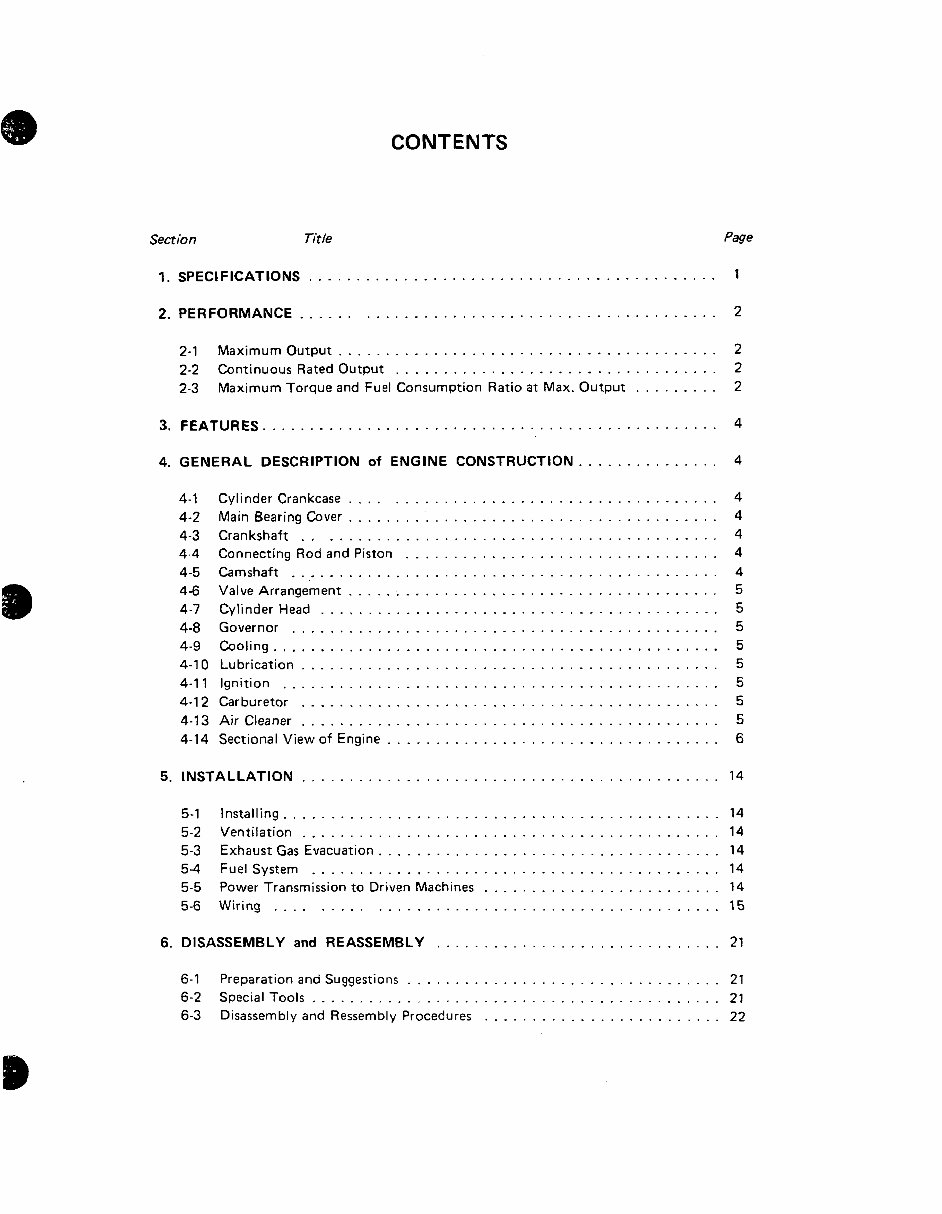

CONTENTS

Section Title Page

...........................................

1 . SPECIFICATIONS 1

2 . PERFORMANCE ........................................... 2

2-1 Maximum Output ........................................ 2

2-2 Continuous Rated Output .................................. 2

2-3 MaximumTorque and Fuel Consumption Ratio at Max . Output ......... 2

3 . FEATURES ................................................ 4

4 . GENERAL DESCRIPTION of ENGINE CONSTRUCTION ............... 4

4-1 Cylinder Crankcase ...................................... 4

4-2 Main Bearing Cover ....................................... 4

4-3 Crankshaft ........................................... 4

4-5 Camshaft ............................................. 4

4-7 Cylinder Head .......................................... 5

4-8 Governor ............................................. 5

4-9 Cooling ............................................... 5

4-10 Lubrication ............................................ 5

4-11 Ignition .............................................. 5

4-13 Air Cleaner ............................................ 5

4-14 Sectional View of Engine ................................... 6

4.4 Connecting Rod and Piston ................................. 4

4-6 Valve Arrangement ....................................... 5

4-12 Carburetor ............................................ 5

5.lNSTALLATlON ............................................ 14

5-1 Installing .............................................. 14

5-2 Ventilation ............................................ 14

5-3 Exhaust Gas Evacuation .................................... 14

5-4 Fuel System ........................................... 14

5-5 Power Transmission to Driven Machines ......................... 14

5-6 Wiring ............................................. 15

6 . DISASSEMBLY and REASSEMBLY .............................. 21

6-1 Preparation and Suggestions ................................. 21

6-2 Special Tools ........................................... 21

6-3 Disassembly and Ressembly Procedures ......................... 22

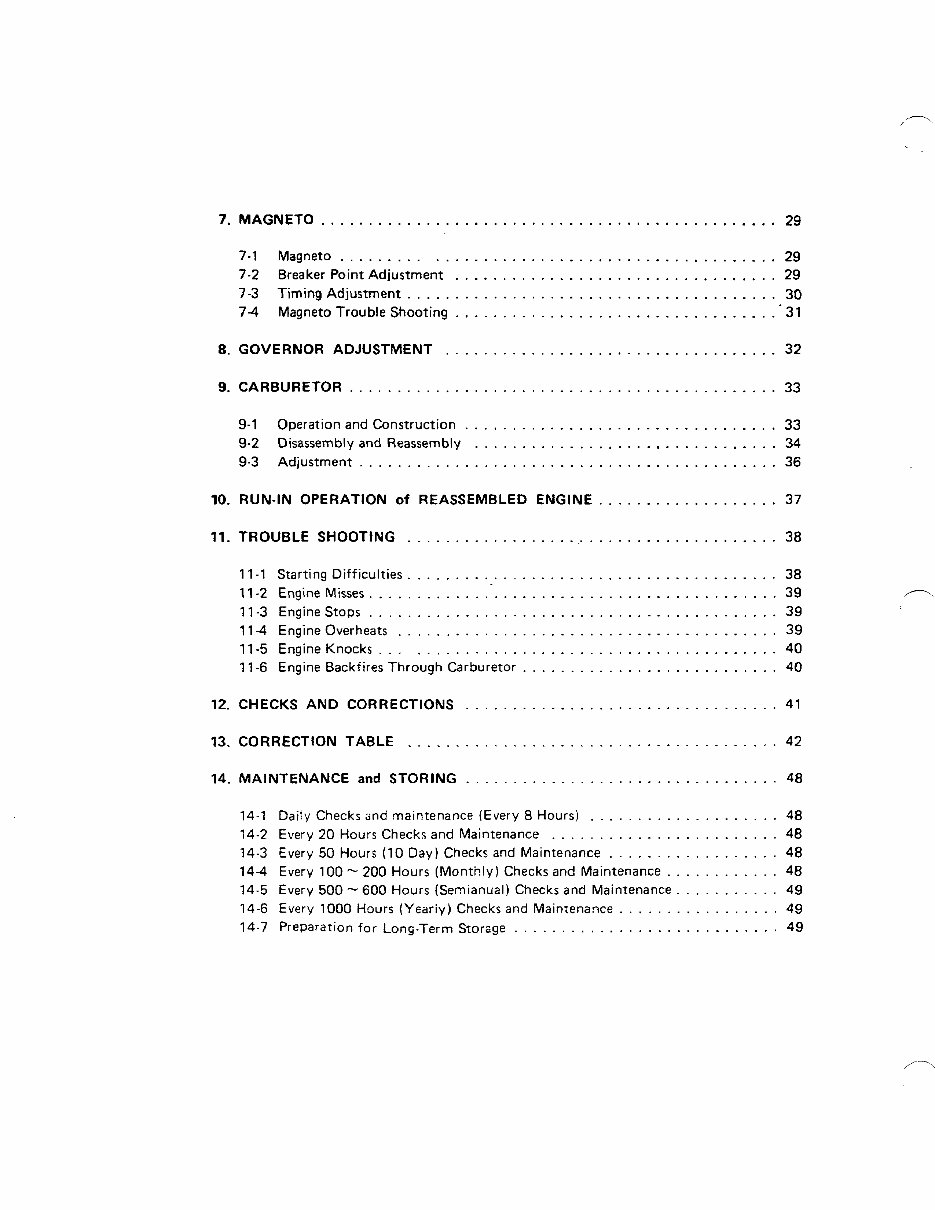

7.MAGNETO ................................................ 29

7-1 Magneto ............................................. 29

7-2 Breaker Point Adjustment .................................. 29

74 Magneto Trouble Shooting ................................... 31

7-3 Timing Adjustment ....................................... 30

8 . GOVERNOR ADJUSTMENT ................................... 32

9. CARBURETOR ............................................. 33

9-1 Operation and Construction ................................. 33

9-2 Disassembly and Reassembly ................................ 34

9-3 Adjustment ............................................ 36

10 . RUN-INOPERATION of REASSEMBLED ENGINE ................... 37

11 . TROUBLE SHOOTtNG ....................................... 38

11 -1 Starting Difficulties ....................................... 38

11 -2 Engine Misses ........................................... 39

11-3 Engine Stops ........................................... 39

114 Engine Overheats ........................................ 39

11-5 Engine Knocks ......................................... 40

11-6 Engine BackfiresThroughCarburetor ........................... 40

12 . CHECKS AND CORRECTIONS ................................. 41

13 . CORRECTION TABLE ....................................... 42

14 . MAINTENANCE and STORING ................................. 48

14-1Daily Checks and maintenance(Every 8 Hours) .................... 48

14-2 Every 20 Hours Checks and Maintenance ........................ 48

14-3 Every 50 Hours (10 Day) ChecksandMaintenance .................. 48

14-4 Every 100 . 200 Hours (Monthly) Checks and Maintenance ............ 48

14-5 Every 500 . 600 Hours (Semianual) Checksand Maintenance ........... 49

14-6 Every 1000 Hours (Yearly) Checks and Maintenance ................. 49

14-7 Preparation forLong-Term Storage ............................ 49

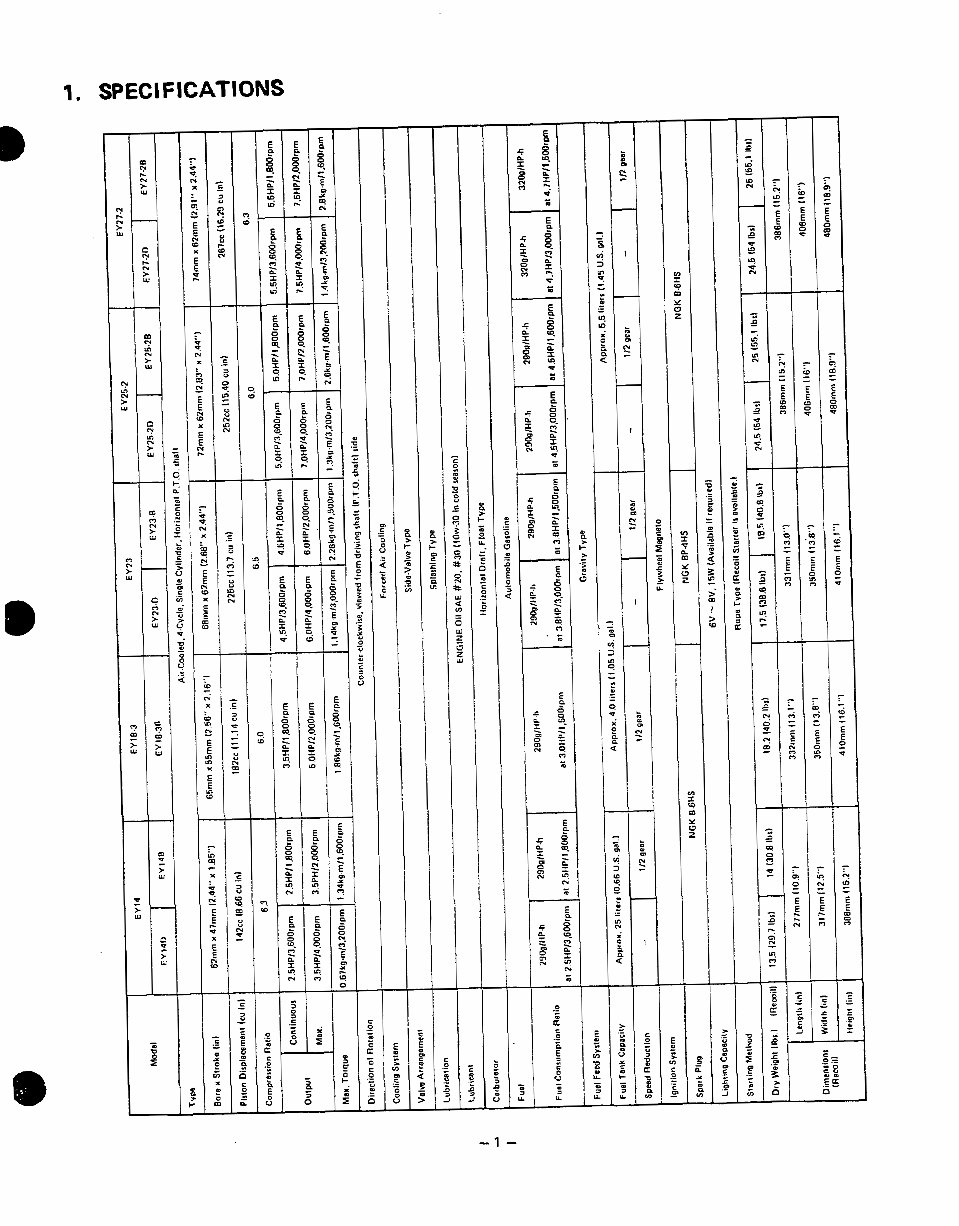

1. SPEC1 FICATIONS

[ N

m

p 5 2 0

n

0 "

V

t

1

c

t

I

I

i

-1 -

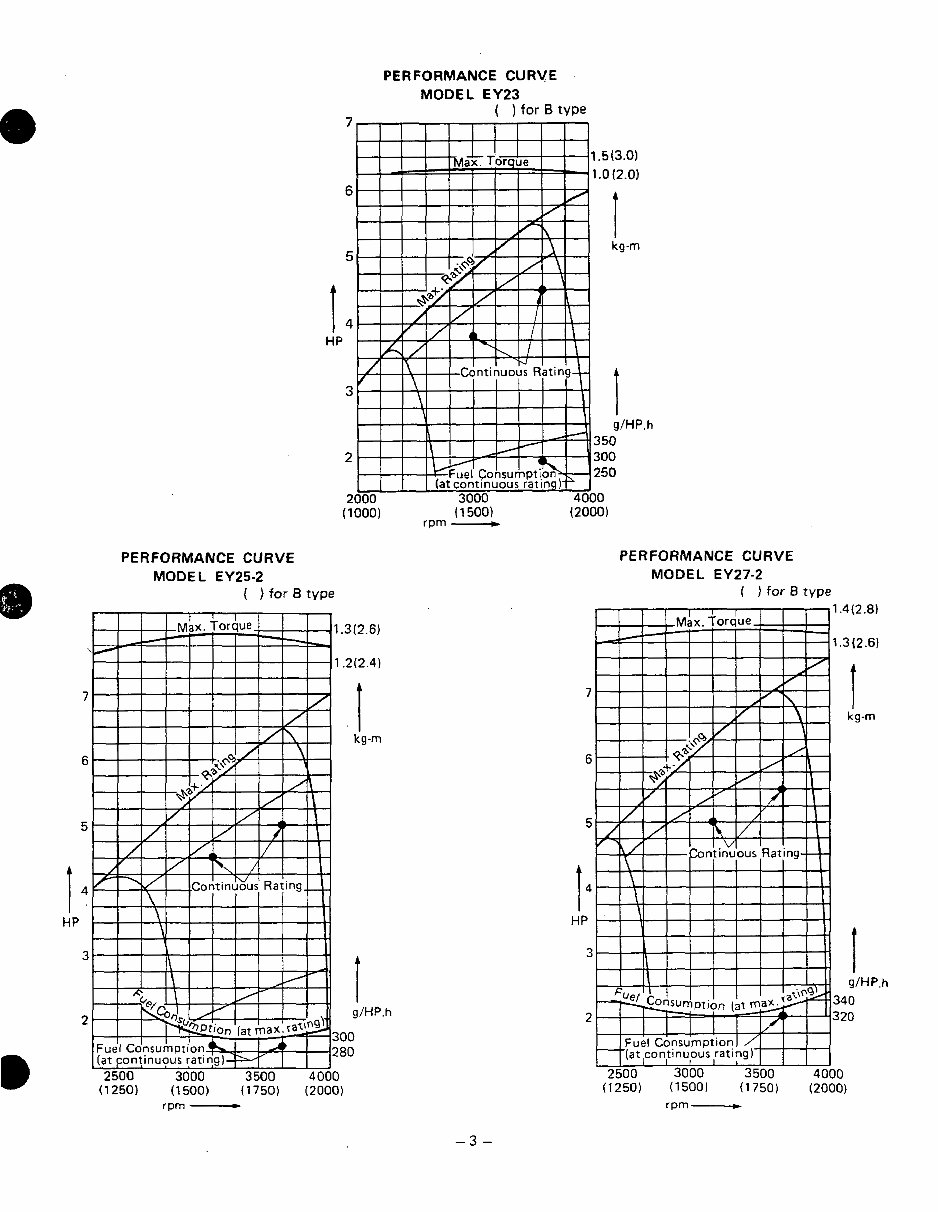

2. PERFORMANCE

2-1 MAXIMUM OUTPUT n

The Maximum output of an engine is such standard power as developed by that engine, after its

initial run-in period with all the moving parts properly worn-in, when operating with the fully

openthrottlevalve.Therefore,it follows that a newenginemaynotdevelopthismaximum

output in the beginning, because moving parts are not in a properly worn-in condition.

2-2 CONTINUOUS RATED OUTPUT

The continuous rated output of an engine is such power as developed by that engine when

running at anoptimumspeedmostfavorablefromthepointofviewofenginelifeandfuel

consumption ratio. Therefore, it follows that when designing a driving system for any

mechanism, with a model EY14, EY18-3, EY23, EY25-2 and EY27-2 engine, as a prime mover,

the continuous power requirement of that mechanism must be kept below the continuous rated

output specified.

2-3 MAXIMUM TORQUE and FUEL CONSUMPTION RATIO AT MAX. OUTPUT

The maximum torque of an engine is that driving torque of the driving shaft at which the engine

is driving an external load, while the engine is developing its max. output. The fuel

consumption ratio at max. output is that fuel consumption ratio of an engine while that engine

is running at the rnax. output.

PERFORMANCE CURVE PERFORMANCE CURVE

MODEL EY18-38

-2-

PERFORMANCE CURVE

MODEL EY23

7

( ) for B type

1.5(3.0)

1.0 (2.0)

6

I

5

kg-m

HP I 4

3

I

g1HP.h

3 50

2 300

250

2000 3000 4000

(1 000) (1 500) (2000)

rpm __c

PERFORMANCE CURVE

MODEL EY25-2

( ) for B type

.h

PERFORMANCE CURVE

MODEL EY27-2

( ) for 8 type

1.4(2.8)

1.3(2.6)

7 I

kg-m

6

5

HP I4

3

I

g1HP.h

340

2 320

2500 3000 3500 4000

(1250) (1500)

(1750) (2000)

rpm -

-3 -

FEATURES

A compact, lightweight and durable 4-cycle air-cooled engine with high power output,

embodying ingenious design technique and advanced production skill. n

Simple construction, smart appearance, easy start.

Reliable power for wide. variety of purposes, with smooth speed controll by a governor,

under varying load conditions.

Economical advantage through low fuel consumption.

Great versatility in installation through a 360° belt extension possibility and a two side oil

fill and drain arrangement.

GENERAL DESCRIPTJON of ENGINE CONSTRUCTION

CYLINDER, CRANKCASE

The cylinder and the crankcase are die-cast as a compact aluminium mono-block piece. The

cylinder liner and the valve seats are made of special alloy cast iron and are imbedded in the

aluminium casting as inserts. The intake and exhaust ports are located at one side of the

cylinder and are also made of inserted pieces in the casting.

The crankcase is separable at the driving shaft side and this separable piece constitutes the

main bearing cover.

4-2 MAIN BEARING COVER

As the aluminium die-cast main bearing cover is built onto the crankcase on the driving shaft

side, the engine 'inside are reached for inspection, easily by simply removing it. It is also

provided with a flange and boss for directly mounting operating machines such as generators

and pumps.

There are two oil filters serving also as oil gauges provided at two locations.

(However, in EY18-3 or EY23 engine, at one location in the carburetor side.)

4-3 CRANKSHAFT

The crankshaft is machined from a carbon steel forging with an induction hardened crank pin.

On the fan side, the breaker cam is provided and on the driving side, the crankshaft gear is

force-fit.

44 CONNECTING ROD and PISTON

The connecting rod is machined from an aluminium alloy forging in which the forged alloy itself

serves as the bearing metal at both ends. On the large end, an oil scraper for splashing the

lubricating oil is provided.

The piston is machined from an aluminium alloy casting and is provided with two grooves for

compression rings and one groove for the oil ring.

4-5 CAMSHAFT

The camshaft is machined from a carbon steel forging with integral intake and exhaust cams

and is provided with a force-fit cam gear. In the model B engine, the camshaft serves also as

the driving shaft, being driven at half the crankshaft speed. In the EY14D, EY23D, EY25-2D

and EY27-2D engines, the camshaft is machined from a special alloy cast iron with an integral

camshaft gear, and is supported by aluminium bearing metals machined integral with the

crankcase at both ends. (no ball bearing is used)

n

-4 -

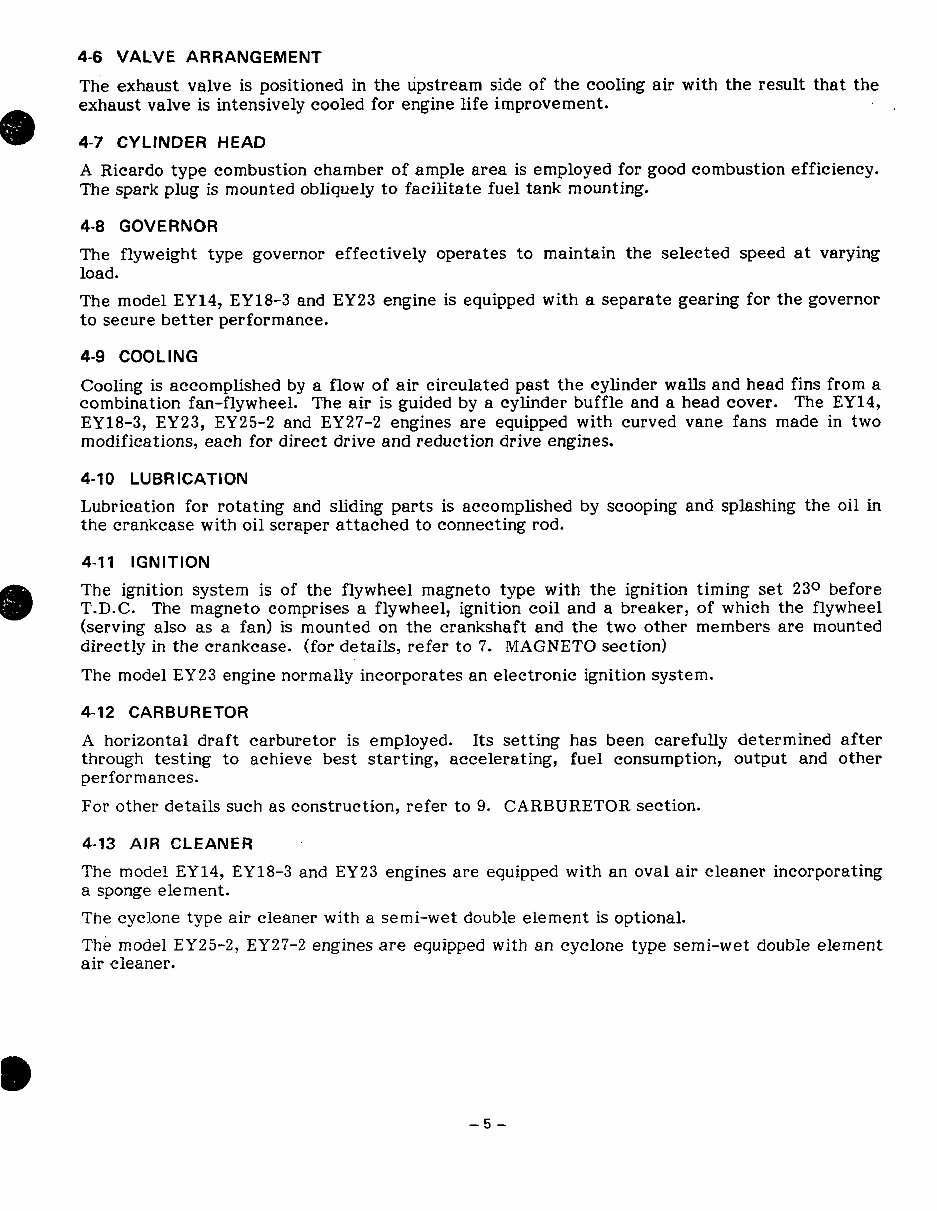

4-6 VALVE ARRANGEMENT

The exhaust valve is positioned in the upstream side of the cooling air with the result that the

exhaust valve is intensively cooled for engine life improvement.

-

4-7 CYLINDER HEAD

A Ricardo type combustion chamber of ample area is employed for good combustion efficiency.

The spark plug is mounted obliquely to facilitate fuel tank mounting.

4-8 GOVERNOR

The flyweight type governor effectivelyoperatesto maintain the selected speed at varying

load.

The model EY14, EY18-3 and EY23 engine is equipped with a separate gearing for the governor

to secure better performance.

4-9 COOLING

Cooling is accomplished by a flow of air circulated past the cylinder walls and head fins from a

combination fan-flywheel. The air is guided by a cylinder buffle and a head cover. The EY14,

EY18-3, EY23, EY25-2 and EY27-2 engines are equipped with curved vane fans made in two

modifications, each for direct drive and reduction drive engines.

4-10 LUBRICATION

Lubrication for rotating and sliding parts is accomplished by scooping and splashing the oil in

the crankcase with oil scraper attached to connecting rod.

4-11 IGNITION

The ignition system is of the flywheel magneto type with the ignition timing set 230 before

T.D.C. The magneto comprises a flywheel, ignition coil and a breaker, of which the flywheel

(serving also as a fan) is mounted on the crankshaft and the two other members are mounted

directly in the crankcase. (for details, refer to 7. MAGNETO section)

The model EY23 engine normally incorporates an electronic ignition system.

4-12 CARBURETOR

A horizontal draft carburetor is employed. Its setting has been carefully determined after

through testing to achieve best starting, accelerating, fuel consumption, output and other

performances.

For other details such as construction, refer to 9. CARBURETOR section.

4-13 AIR CLEANER

The model EY 14, EY18-3 and EY23 engines are equipped with an oval air cleaner incorporating

8 sponge element.

The cycl.one type air cleaner with a semi-wet double element is optional.

The model EY25-2, EY27-2 engines are equipped with an cyclone type semi-wet double element

air cleaner.

-5-

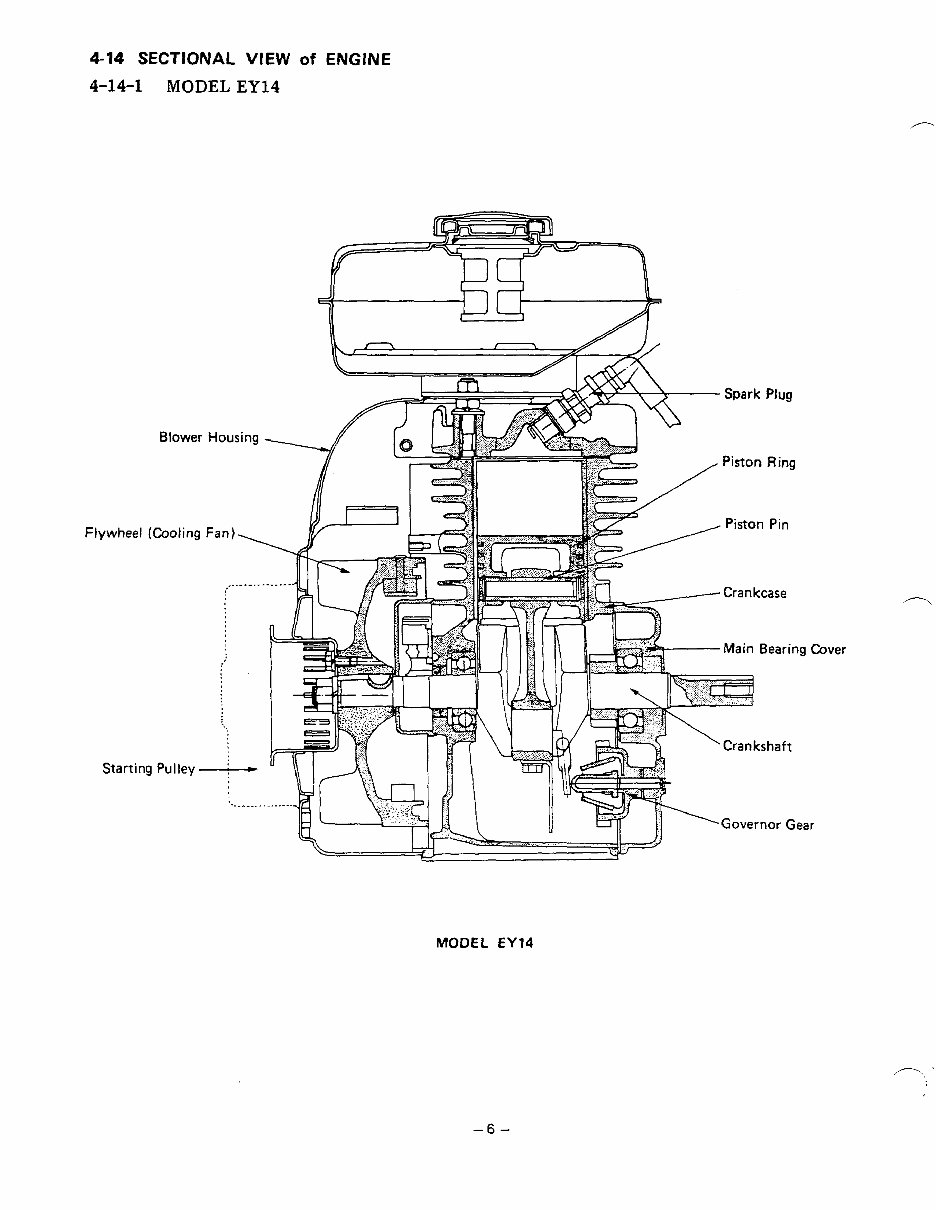

4-14 SECTIONAL VIEW of ENGINE

4-14-1 MODEL EY14

FI

Blower

ywheel (Cooling

Housing

Starting Pulley-

MODEL EY14

ver

-6-

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

Viewed 67 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

This is the complete factory service repair workshop manual for the Robin EY14, EY18-3, EY23, EY25-2, EY27-2. This Service Manual has easy-to-read text sections with top quality diagrams and instructions. It provides step-by-step instructions based on the complete disassembly of the machine, including highly detailed exploded pictures and diagrams to show you how to complete the required job correctly and efficiently.

Service Repair Manual Covers:

- SPECIFICATIONS

- PERFORMANCE

- FEATURE

- GENERAL DESCRIPTION

- INSTALLATION

- DISASSEMBLY AND REASSEMBLY

- ENGINE OIL

- MAGNETO

- GOVERNOR ADJUSTMENT

- CARBURETOR

- BREAK IN OPERATION

- TROUBLESHOOTING

- INSTALLATION

- CHECKS AND CORRECTIONS

- TABLE OF CORRECTION STANDARD

- MAINTENANCE AND STORAGE

- And More......

File Format: .PDF manual