Scania DSC9 DSC 9 Engine Workshop Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

DSC 9 Engine Workshop

SCANIA Manual

This manual covers the following engines up to 1996

3 Series Trucks

DSC 9 10 (220Hp)

DSC 9 07 (250Hp)

DSC 9 09 (250Hp)

DSC 9 08 (280Hp)

4 Series Trucks

DSC 9 11 (220Hp)

DSC 9 12 (260Hp)

DSC 9 13 (310Hp)

Manual Contents:

Description of Operation .....

Engine Overhaul Description

C M0

from the library of Barrington Diesel Club

2

18

SCANIA

service

Contents

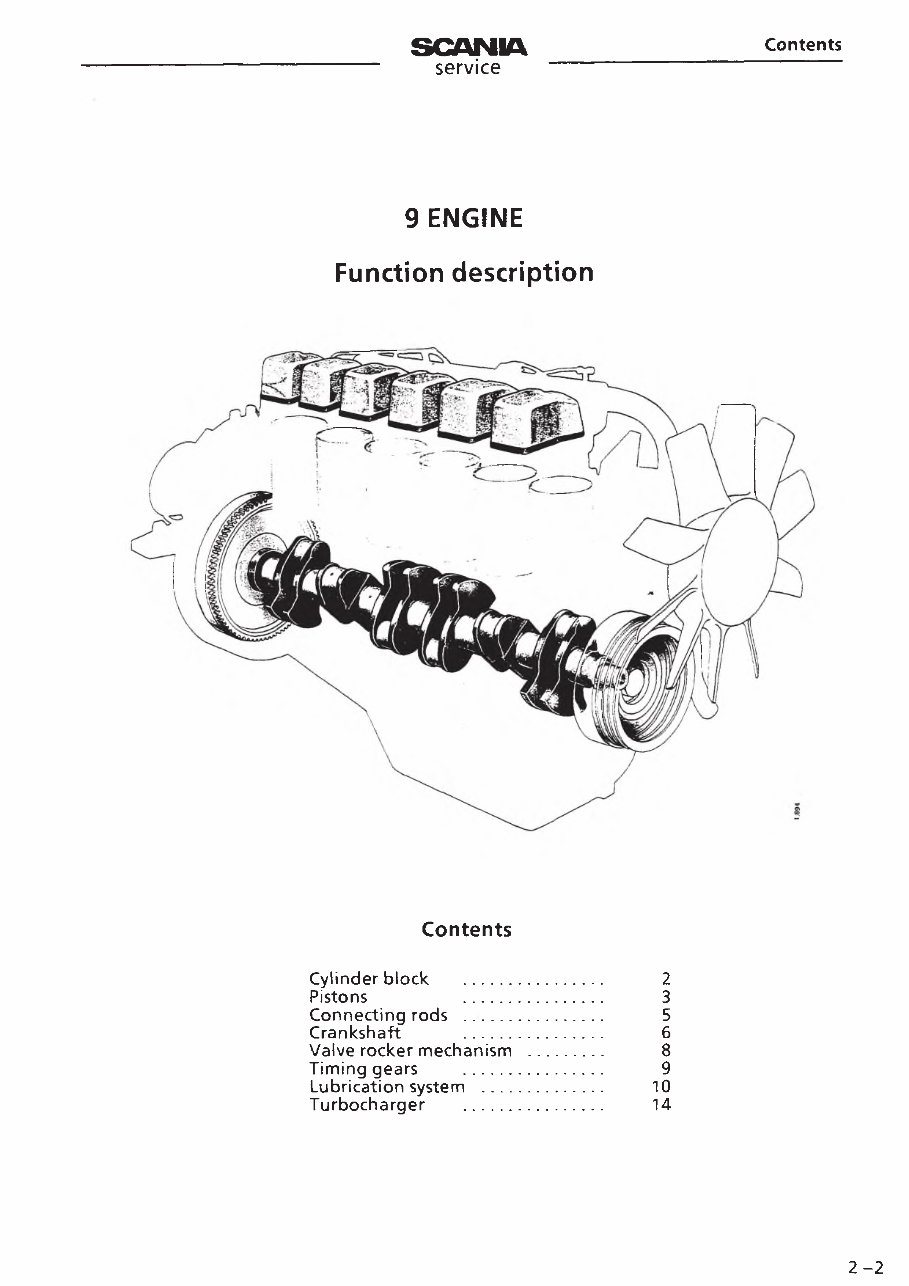

9 ENGINE

Function description

Contents

Cylinder block ...................................... 2

Pistons 3

Connecting rods ................................. 5

Crankshaft 6

Valve rocker mechanism ..................... 8

Timing gears ...................................... 9

Lubrication system ................................. 10

Turbocharger ...................................... 14

2-2

from the library of Barrington Diesel Club

Cylinder block

SCANIA

service

Cylinder block

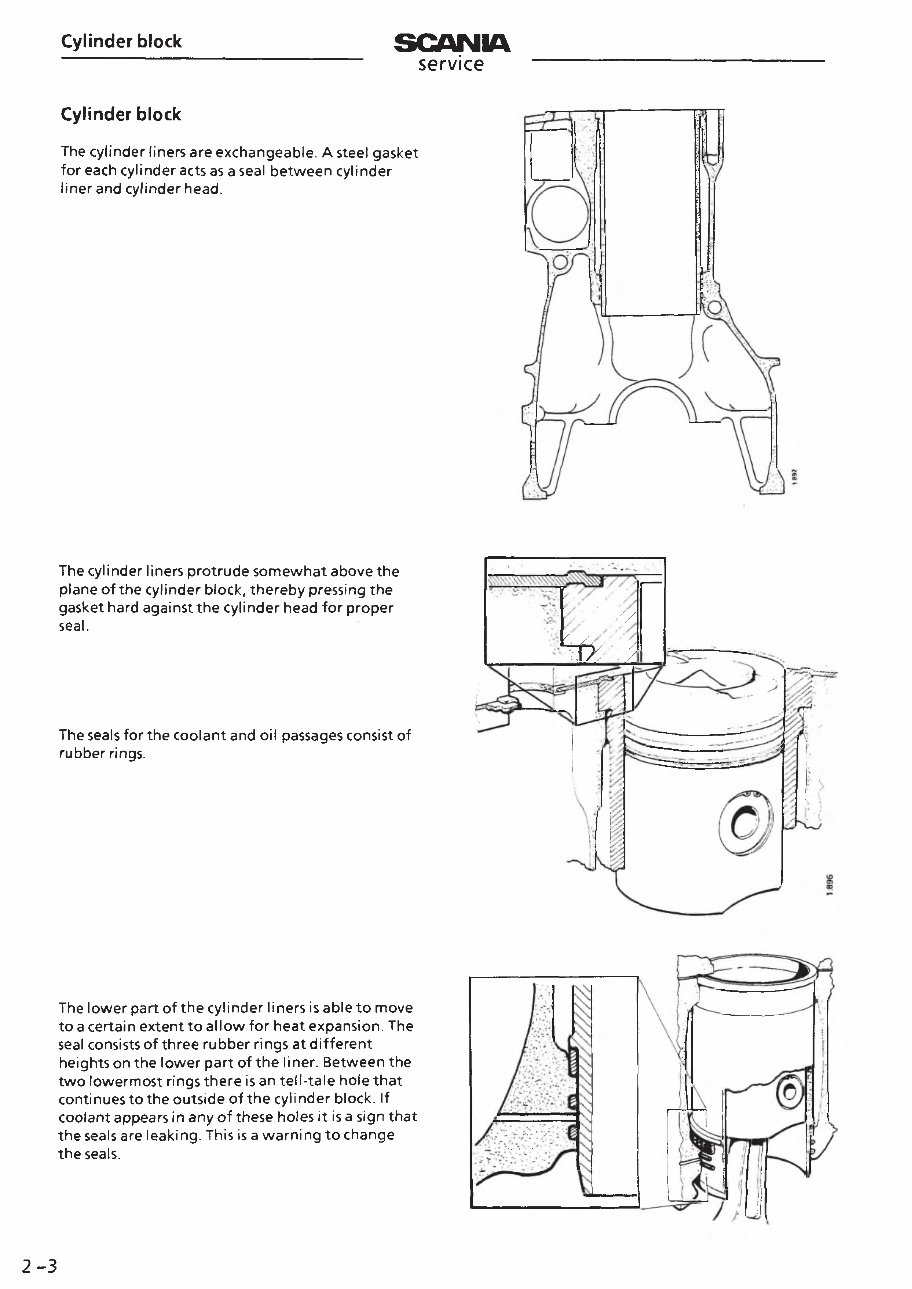

The cylinder liners are exchangeable. A steel gasket

for each cylinder acts as a seal between cylinder

liner and cylinder head.

The cylinder liners protrude somewhat above the

plane of the cylinder block, thereby pressing the

gasket hard against the cylinder head for proper

seal.

The seals for the coolant and oil passages consist of

rubber rings.

'' •//

H y /./,

The lower part of the cylinder liners is able to move

to a certain extent to allow for heat expansion. The

seal consists of three rubber rings atdifferent

heights on the lower part of the liner. Between the

two lowermost rings there is an tell-tale hole that

continues to the outside of the cylinder block. If

coolant appears in any of these holes it is a sign that

the seals are leaking. This is a warning to change

the seals.

2-3

from the library of Barrington Diesel Club

SCANIA

service

Pistons

Pistons

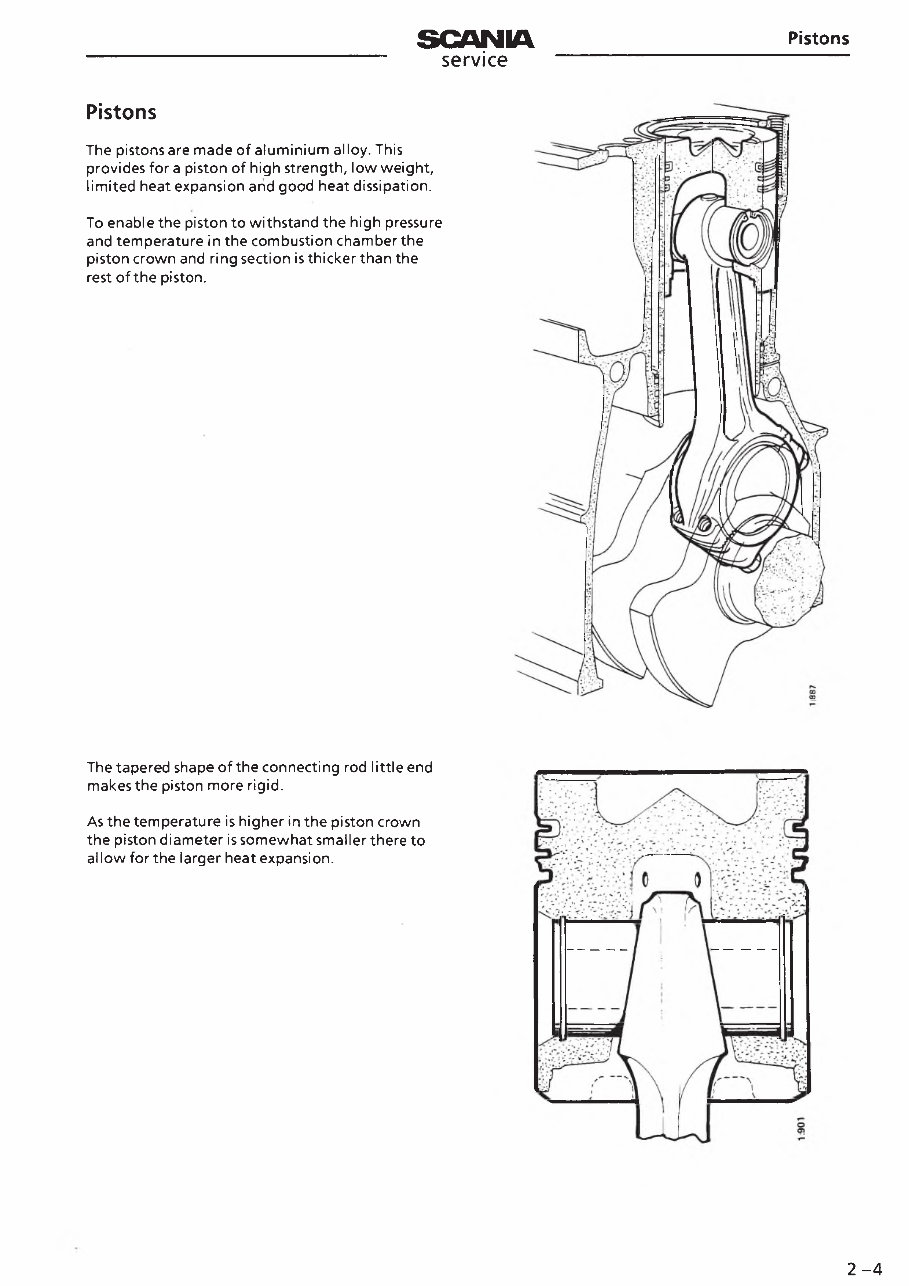

The pistonsare made of aluminium alloy. This

provides for a piston of high strength, low weight,

limited heat expansion and good heat dissipation.

To enable the piston to withstand the high pressure

and temperature in the combustion chamber the

piston crown and ring section is thicker than the

rest of the piston.

The tapered shape of the connecting rod little end

makes the piston more rigid.

As the temperature is higher in the piston crown

the piston diameter is somewhat smaller there to

allow for the larger heat expansion.

2-4

from the library of Barrington Diesel Club

Pistons

SCANIA

service

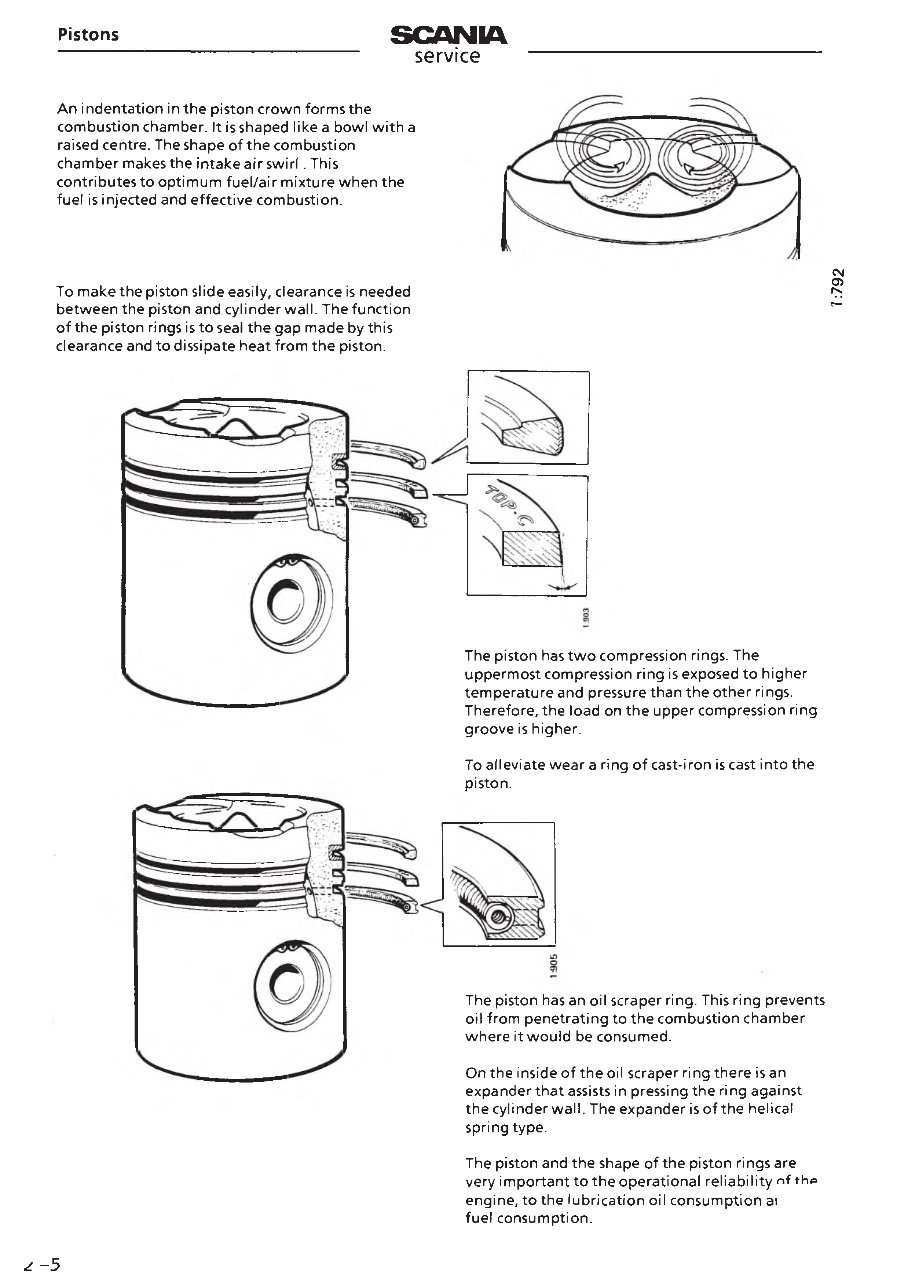

An indentation inthe piston crown forms the

combustion chamber. It is shaped like a bowl with a

raised centre. The shape of the combustion

chamber makes the intake air sw irl. This

contributes to optimum fuel/air mixture when the

fuel is injected and effective combustion.

To make the piston slide easily, clearance is needed

between the piston and cylinder wall. The function

of the piston rings is to seal the gap made by this

clearance and to dissipate heat from the piston.

The piston has two compression rings. The

uppermost compression ring is exposed to higher

temperature and pressure than the other rings.

Therefore, the load on the upper compression ring

groove is higher.

To alleviate wear a ring of cast-iron is cast into the

piston.

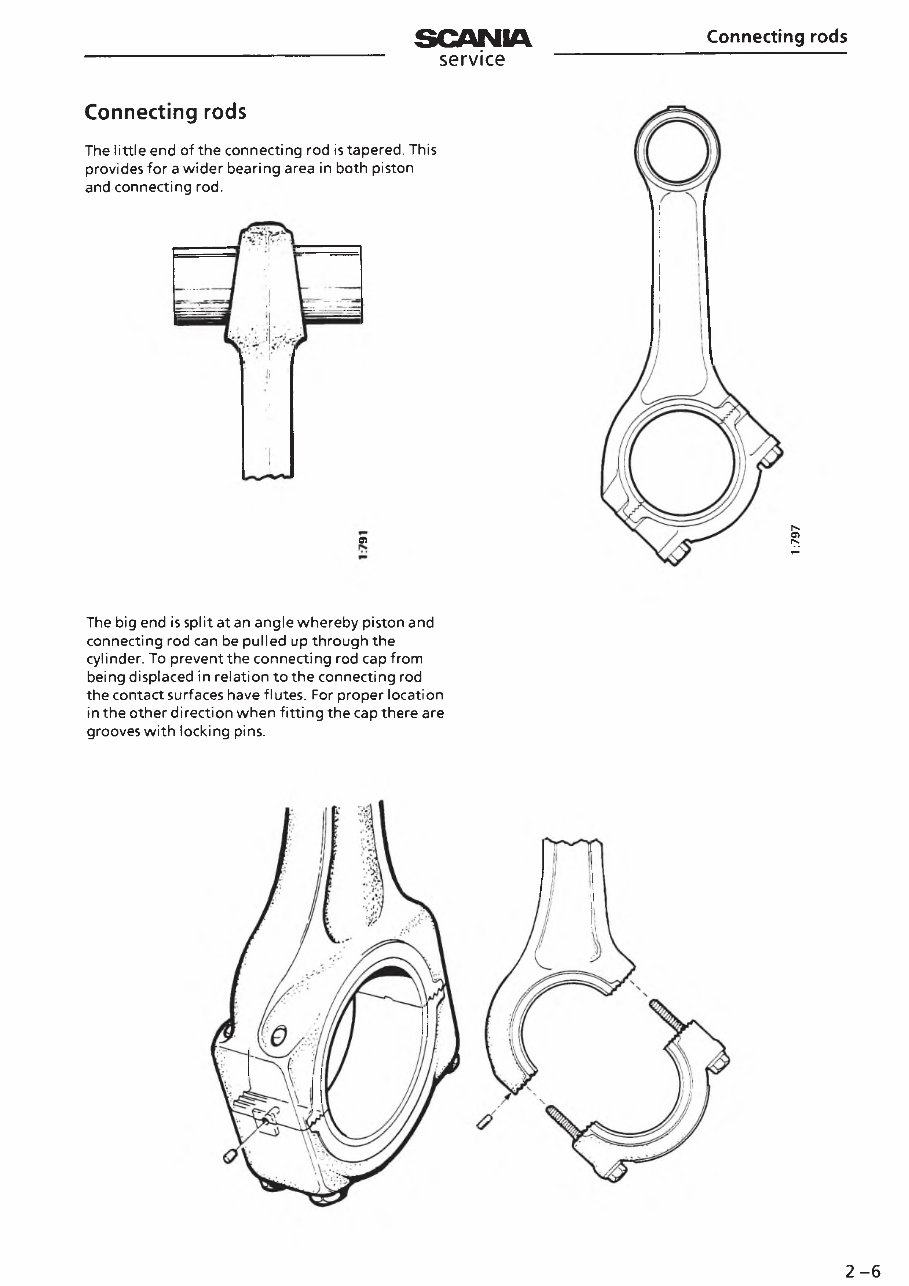

The piston has an oil scraper ring. This ring prevents

oil from penetrating to the combustion chamber

where it would be consumed.

On the inside of the oil scraper ring there is an

expanderthat assists in pressing the ring against

the cylinder wall. The expander is of the helical

spring type.

The piston and the shape of the piston rings are

very important to the operational reliability of the

engine, to the lubrication oil consumption and the

fuel consumption.

^ -5

1:792

from the library of Barrington Diesel Club

SCANIA

service

Connecting rods

Connecting rods

The little end of the connecting rod is tapered. This

provides for a wider bearing area in both piston

and connecting rod.

0)

The big end is split at an angle whereby piston and

connecting rod can be pulled up through the

cylinder. To prevent the connecting rod cap from

being displaced in relation to the connecting rod

the contact surfaces have flutes. For proper location

in the other direction when fitting the cap there are

grooves with locking pins.

2-6

1:797

from the library of Barrington Diesel Club

Crankshaft

SCANIA

service

Crankshaft

Each compressions stroke acts as a brake on the

crankshaft and each combustion stroke strives to

increase the crankshaft rotation speed.

Twice in each revolution the pistons and connecting

rods change direction of movement.

Thereby the crankshaft is subjected to frequent

force impulses in each revolution.

The quality of the metal is important to the service

life of the crankshaft. Very high demands are also

made on shape and surface treatment.

The hardening of the crankshaft journals is

sufficiently deep to enable regrinding several times.

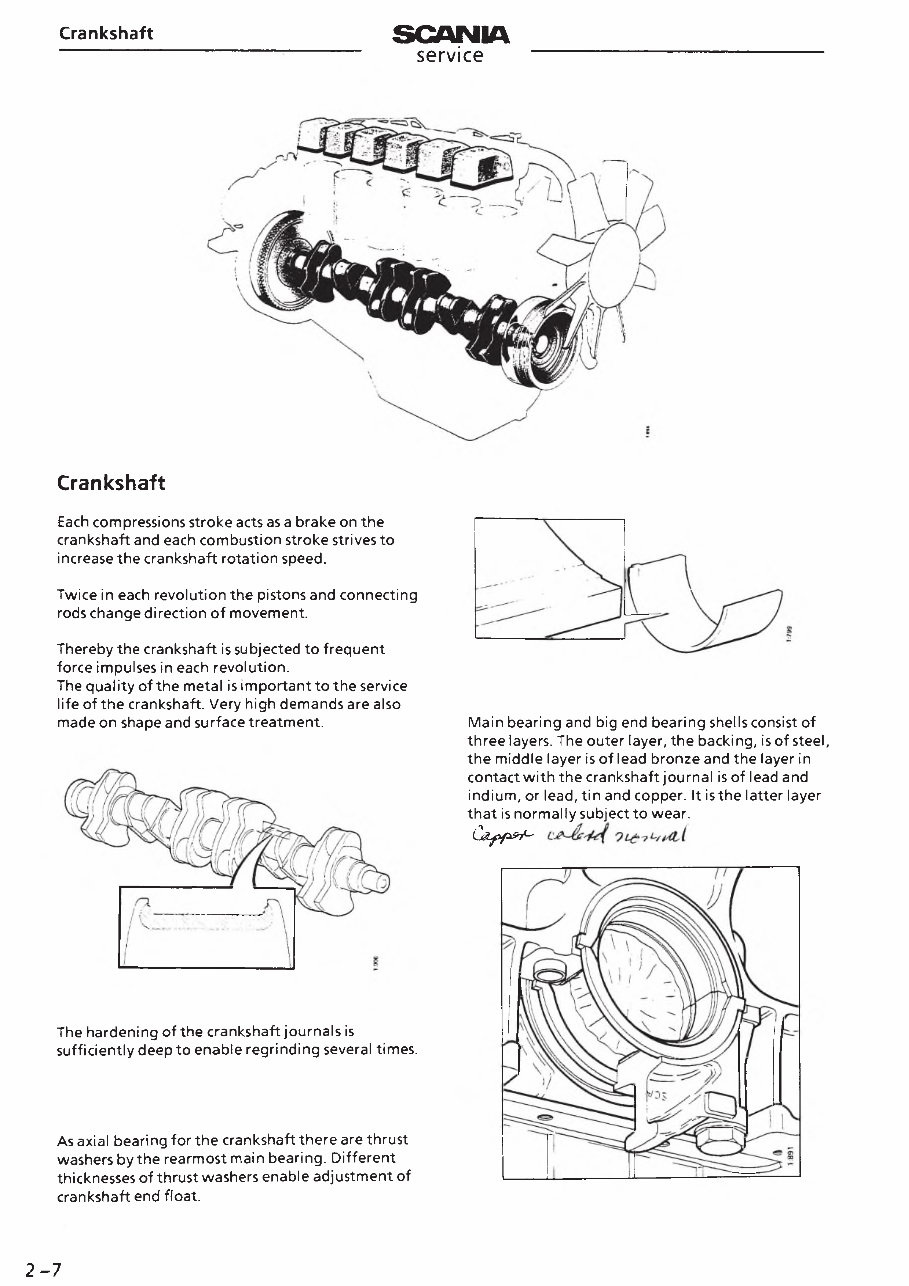

As axial bearing for the crankshaft there are thrust

washers by the rearmost main bearing. Different

thicknesses of thrust washers enable adjustment of

crankshaft end float.

Main bearing and big end bearing shells consist of

three layers. The outer layer, the backing, is of steel,

the middle layer is of lead bronze and the layer in

contact with the crankshaft journal is of lead and

indium, or lead, tin and copper. It isthe latter layer

that is normally subject to wear.

CjjLpf&i-'

2-7

from the library of Barrington Diesel Club

SCANIA

service

Crankshaft

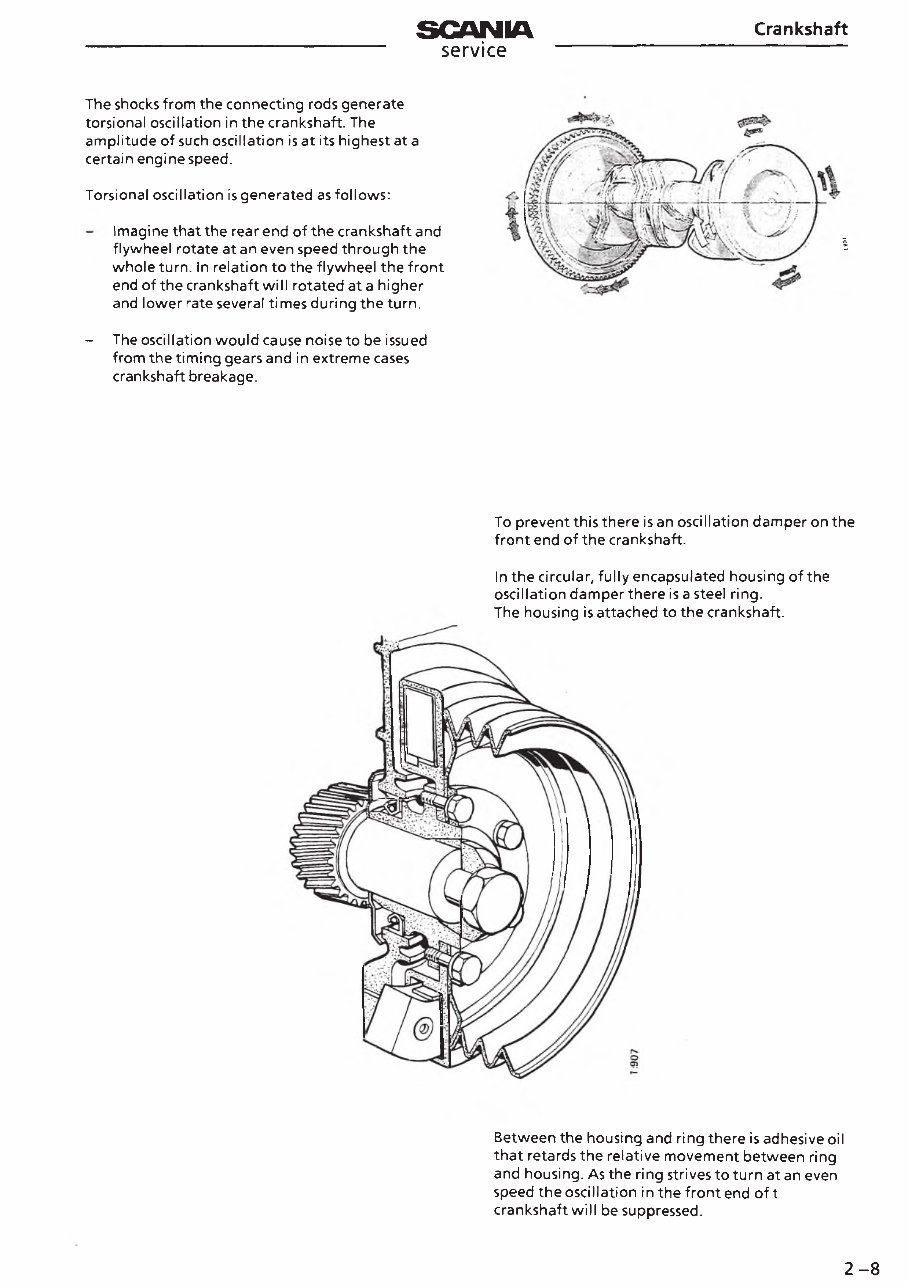

The shocks from the connecting rods generate

torsional oscillation in the crankshaft. The

amplitude of such oscillation is at its highest at a

certain engine speed.

Torsional oscillation is generated as follows:

Imagine that the rear end of the crankshaft and

flywheel rotate at an even speed through the

whole turn. In relation to the flywheel the front

end of the crankshaft will rotated at a higher

and lower rate several times during the turn.

- The oscillation would cause noise to be issued

from the timing gears and in extreme cases

crankshaft breakage.

To prevent this there is an oscillation damper on the

front end of the crankshaft.

In the circular, fully encapsulated housing of the

oscillation damper there is a steel ring.

The housing is attached to the crankshaft.

Between the housing and ring there is adhesive oil

that retards the relative movement between ring

and housing. As the ring strives to turn at an even

speed the oscillation in the front end of the

crankshaft will be suppressed.

2-8

t.«ol

from the library of Barrington Diesel Club

Valve rocker mechanism

SCANIA

service

Valve rocker mechanism

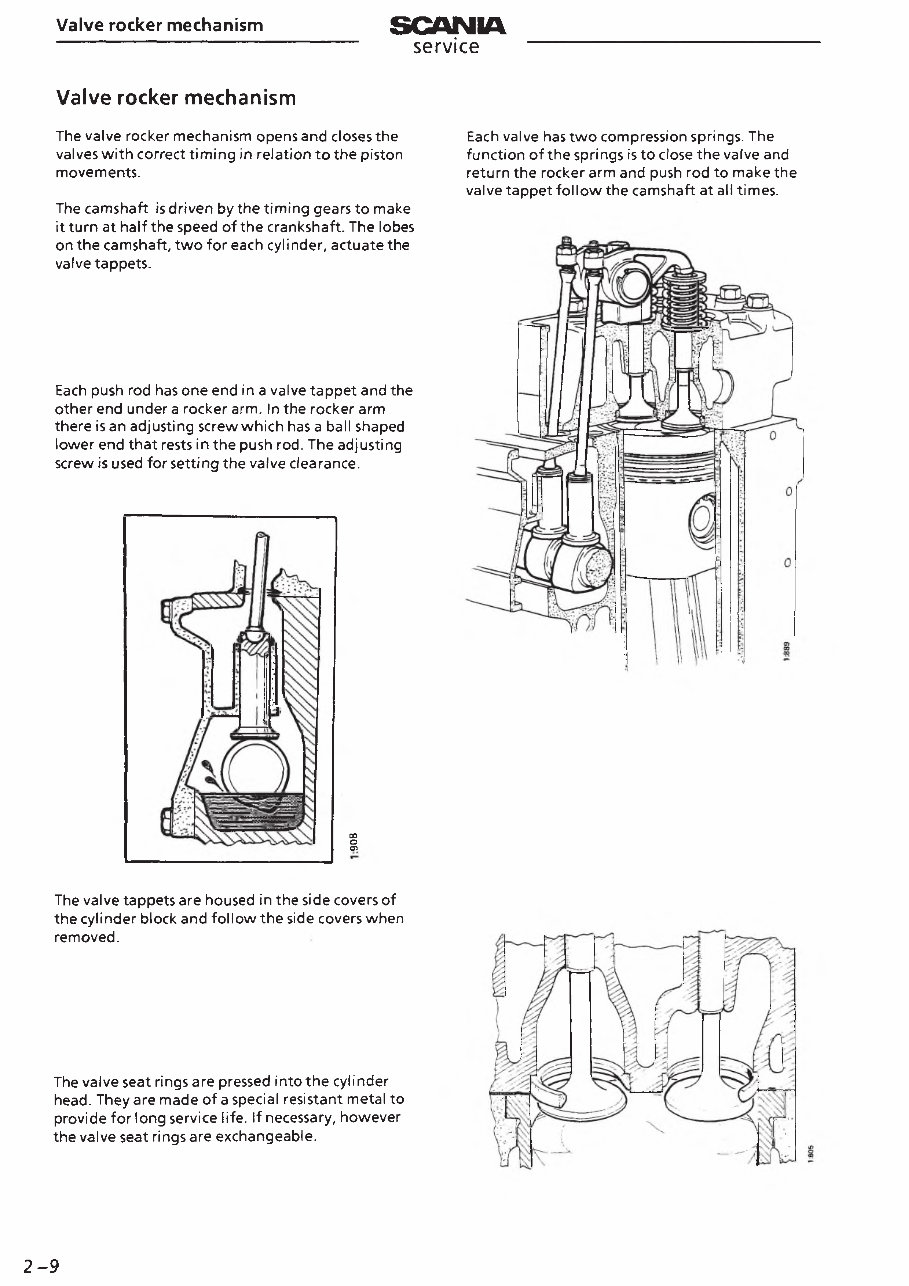

The valve rocker mechanism opens and closes the

valves with correct timing in relation to the piston

movements.

The camshaft is driven by the timing gears to make

it turn at half the speed of the crankshaft. The lobes

on the camshaft, two for each cylinder, actuate the

valve tappets.

Each push rod has one end in a valve tappet and the

other end under a rocker arm. In the rocker arm

there is an adjusting screw which has a ball shaped

lower end that rests in the push rod. The adjusting

screw is used for setting the valve clearance.

Each valve has two compression springs. The

function of the springs is to close the valve and

return the rocker arm and push rod to make the

valve tappet follow the camshaft at all times.

00

O

CT>

The valve tappets are housed in the side covers of

the cylinder block and follow the side covers when

removed.

The valve seat rings are pressed into the cylinder

head. They are made of a special resistant metal to

provide for long service life. If necessary, however

the valve seat rings are exchangeable.

2-9

from the library of Barrington Diesel Club

SCANIA

service

Timing gears

Timing gears

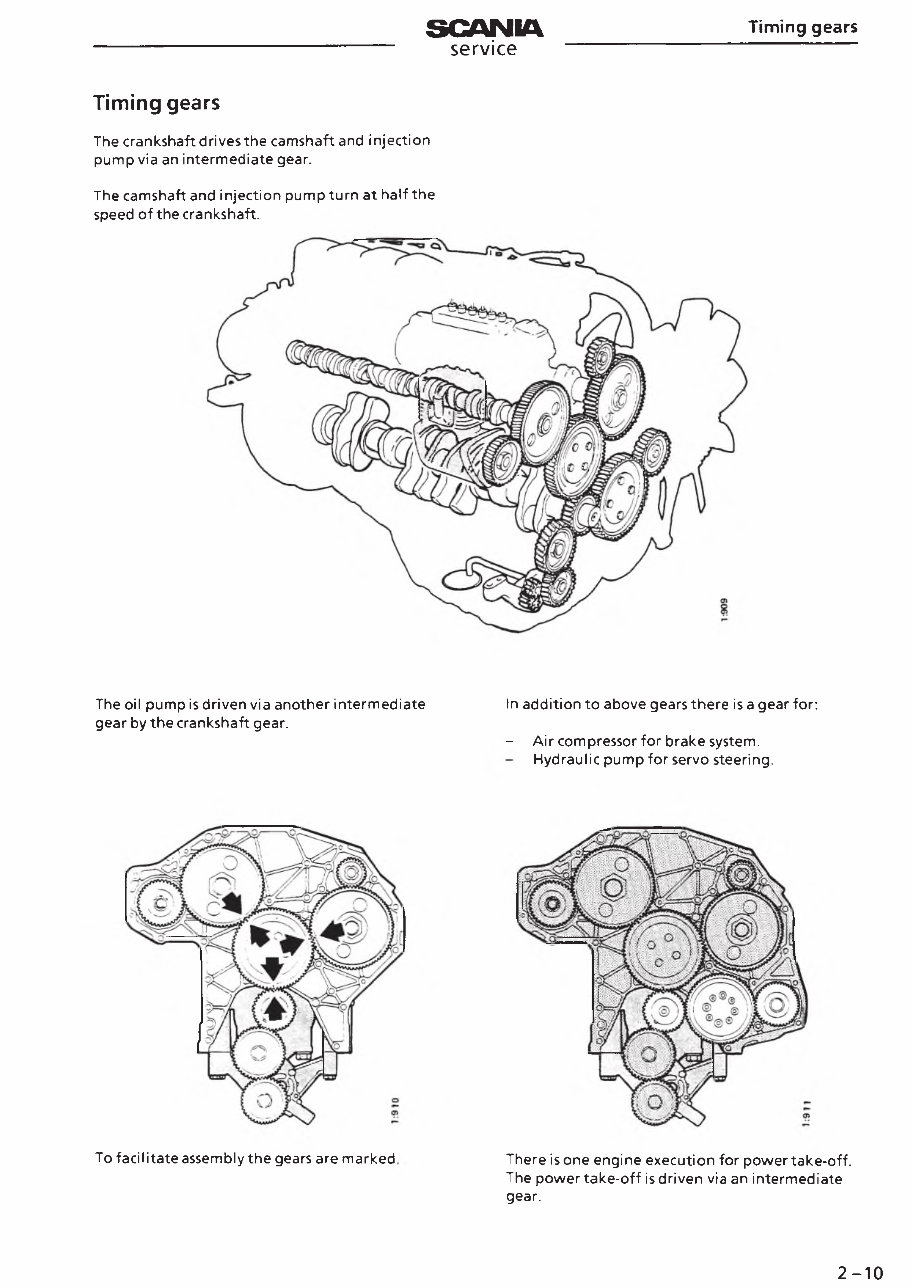

The crankshaft drives the camshaft and injection

pump via an intermediate gear.

The camshaft and injection pump turn at half the

speed of the crankshaft.

The oil pump is driven via another intermediate

gear by the crankshaft gear.

In addition to above gears there is a gear for:

- Air compressor for brake system.

Hydraulic pump for servo steering.

To facilitate assembly the gears are marked

There is one engine execution for power take-off.

The power take-off is driven via an intermediate

gear.

2-10

from the library of Barrington Diesel Club

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

$54.99

Viewed 99 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

$54.99

DSC 9 Engine Workshop Manual

This manual provides comprehensive coverage for the following engines up to 1996:

- 3 Series Trucks: DSC 9 10 (220Hp), DSC 9 07 (250Hp), DSC 9 09 (250Hp), DSC 9 08 (280Hp)

- 4 Series Trucks: DSC 9 11 (220Hp), DSC 9 12 (260Hp), DSC 9 13 (310Hp)

Manual Contents:

- Description of Operation

- Engine Overhaul Description