02:01 Issue 7.0 en-GB

© Scania CV AB 2018, Sweden

Installation manual

Engine

Marine engines

DI09, DI13, DI16

393 926

INSTALLATION

MANUAL

© Scania CV AB 2018, Sweden

02:01 Issue 7.0 en-GB 2

Changes from the previous issue ............................................................................ 3

Engine suspension .................................................................................................... 4

Suspension design requirements ......................................................................... 4

Rigid engine suspension ...................................................................................... 6

Flexible engine suspension .................................................................................. 6

Suspension of reverse gear .................................................................................. 8

Tightening torque for engine suspension ............................................................ 9

Permissible installation and operating angles ................................................... 10

Flywheel housing .............................................................................................. 11

Lifting the engine .............................................................................................. 12

Engine bed ......................................................................................................... 15

Accessibility for maintenance and repairs .......................................................... 16

Installation requirements ................................................................................... 16

Clearances ......................................................................................................... 17

Engine alignment ................................................................................................... 18

Aligning engine and shafts ................................................................................ 19

Power transmission ............................................................................................... 24

Flexible coupling ............................................................................................... 24

Friction clutch ................................................................................................... 24

Transmission types ................................................................................................ 25

Mechanical transmissions ................................................................................. 25

Belt transmissions ............................................................................................. 25

Power take-off ........................................................................................................ 27

Front-mounted power take-offs ......................................................................... 28

Side-mounted power take-offs .......................................................................... 30

Calculation example for torque take-off from power take-off .......................... 37

Connection of sensors for external monitoring systems .................................... 37

DI09 and DI13 .................................................................................................. 38

DI16 .................................................................................................................. 40

Torsional oscillations ............................................................................................ 42

Data for torsional oscillation calculation .......................................................... 42

Torsional oscillation calculations from Scania ................................................. 43

General tightening torques for screw joints ....................................................... 44

Specification of normal tightening torques ....................................................... 44

Tightening torques ............................................................................................ 45

INSTALLATION

MANUAL

© Scania CV AB 2018, Sweden

Changes from the previous issue

02:01 Issue 7.0 en-GB 3

Changes from the previous issue

The changes made in this document compared with the previous issue are marked

with a black line in the left-hand margin. The changes are also described below.

• In section Suspension design requirements there is a clarification that the suspen-

sion should be as rigid as possible. In addition, example illustrations of suspen-

sion for engines with marine transmission have been added.

• In section Insulators , maximum and minimum loads and dimensions for Scania

insulators have been added.

• In section Tightening torque for engine suspension , a tightening sequence for the

engine brackets has been added.

• The conditions for propeller installation without a separate thrust bearing have

been clarified in section Flywheel housing .

• Working procedures for Lifting the engine have been added.

• Section Flexible coupling has been made clearer.

• In section Power take-off , a text and illustration has been added, informing the

reader that components from other manufacturers cannot be used in the belt trans-

mission.

• Hydraulic diagram for hydraulic pump has been added.

• Calculation example for torque take-off from power take-off has been added.

• In section Data for torsional oscillation calculation , information has been added

on what values Scania needs in order to approve an external torsional oscillation

calculation.

INSTALLATION

MANUAL

© Scania CV AB 2018, Sweden

Engine suspension

02:01 Issue 7.0 en-GB 4

Engine suspension

Suspension design requirements

The type of engine suspension that is appropriate varies for different engine installa-

tions. In general, the following applies:

• The engine suspension should be designed for the forces it is exposed to, both

continuously and momentarily during operation. Such forces are reaction forces

from the transmitted torque and in some cases longitudinal acceleration, retarda-

tion and reaction forces in the engine.

• Both the engine suspension and the engine bed should be designed so that there

are no resonant oscillations within the engine speed range. They should also be

designed so that annoying vibrations from the engine are not transmitted to the

surroundings.

• The engine suspension and engine bed should be designed in a way which allows

access for maintenance and repairs.

• The suspension should be as rigid as possible. Use all 4 screw holes in the cylinder

block and flywheel housing for the respective engine bracket. See illustration.

• The engine bed location and the engine suspension must be designed so that the

permissible angles of inclination for the engine are not exceeded. See Permissible

installation and operating angles .

393 929

INSTALLATION

MANUAL

© Scania CV AB 2018, Sweden

Engine suspension

02:01 Issue 7.0 en-GB 5

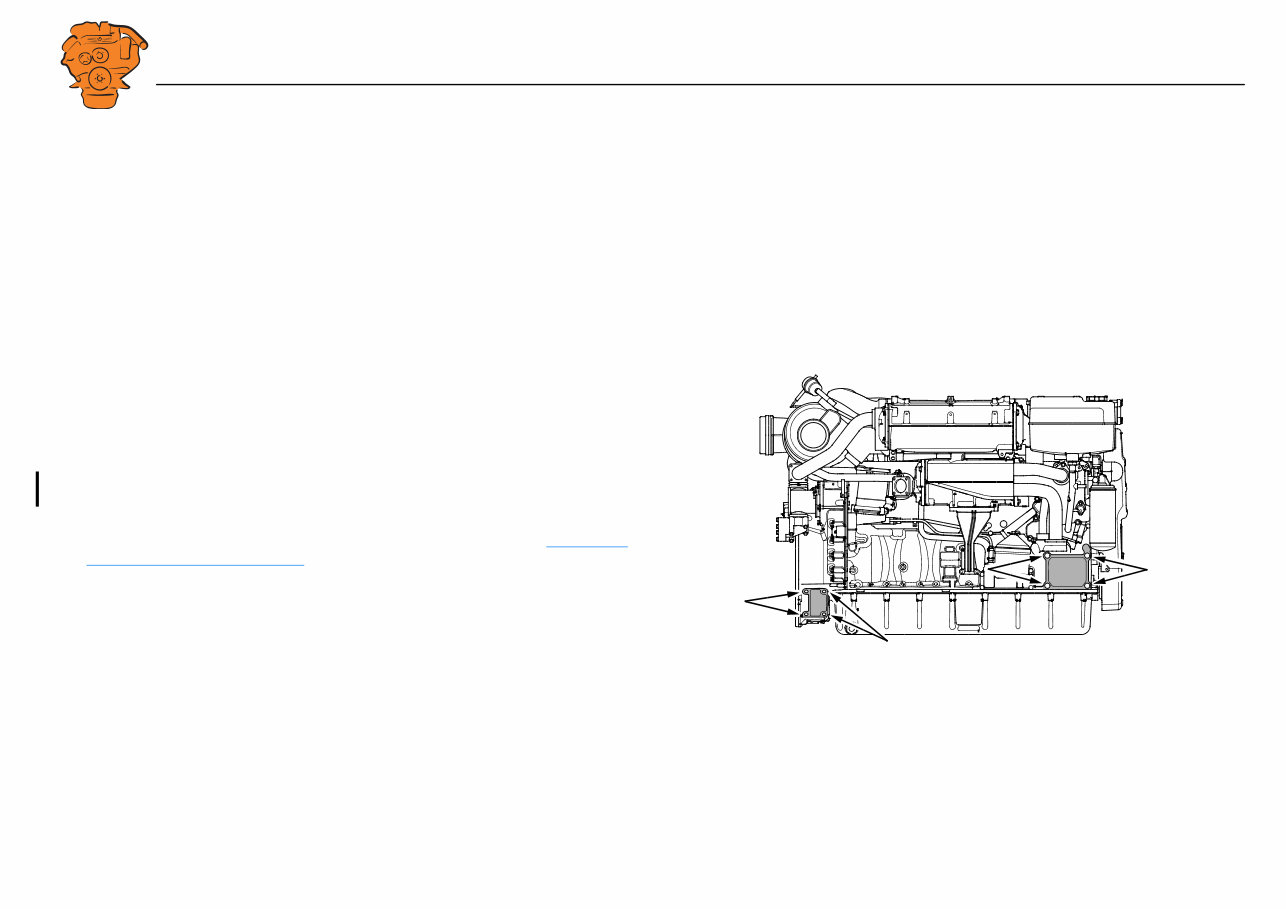

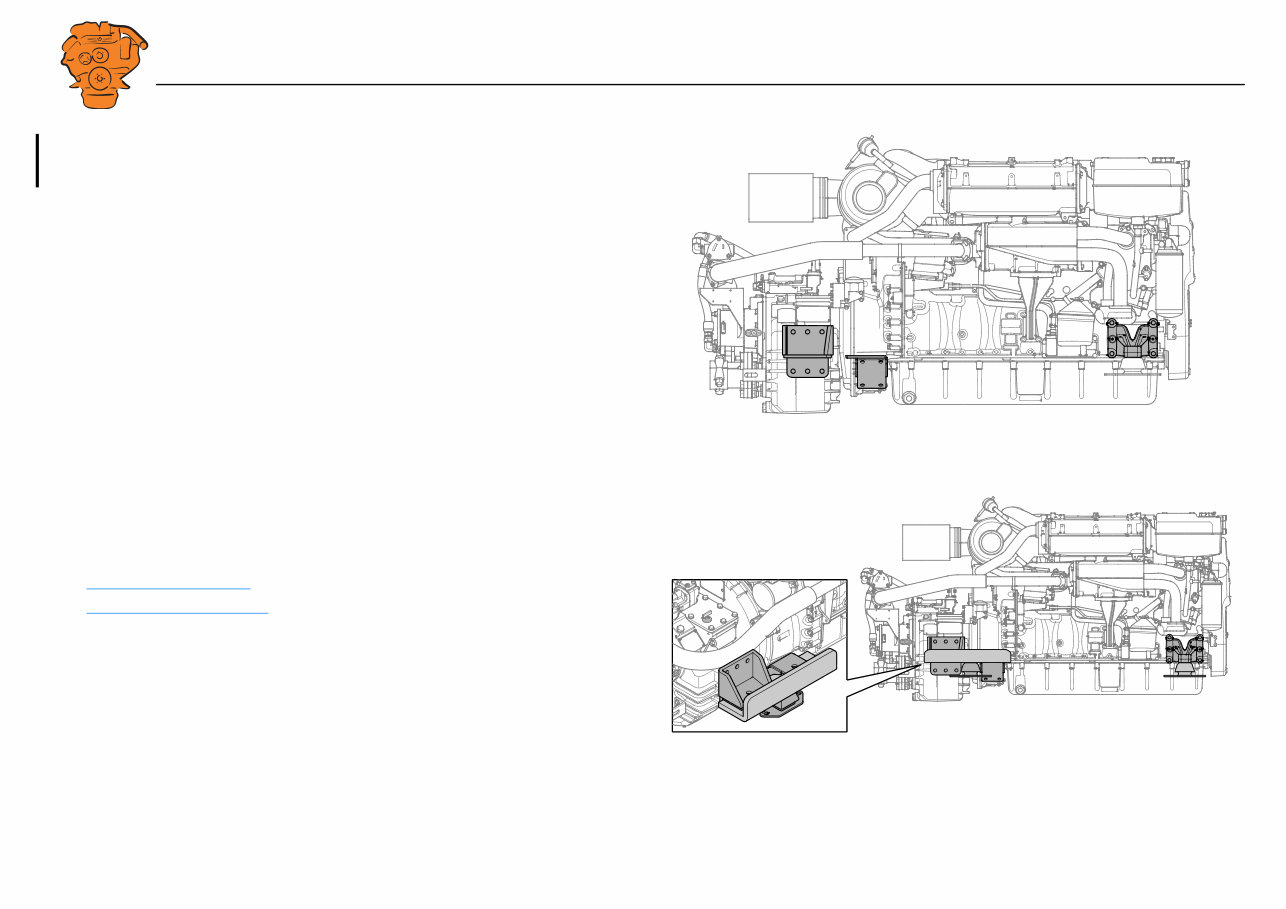

• For engines with marine transmission, Scania recommends a six-point suspension

or four-point suspension with a common rear bracket for pipes, transmission and

engine. See the illustrations.

There are two standard engine suspension designs:

• Rigid engine suspension

• Flexible engine suspension

393 925

Example of six-point suspension.

393 927

Example of four-point suspension with common rear bracket.

INSTALLATION

MANUAL

© Scania CV AB 2018, Sweden

Engine suspension

02:01 Issue 7.0 en-GB 6

Rigid engine suspension

A rigid engine suspension can absorb greater forces in all directions than flexible en-

gine suspension. It requires highly accurate alignment of the engine in relation to the

driven unit. On the other hand, it requires no special flexibility in the hoses, pipes and

controls connected to the engine.

A rigid engine suspension can be used in engine installations where vibration causes

no significant problems and where other characteristics make it desirable.

Even with a rigid engine suspension, the transmission of vibration to the engine bed

can be kept low if the masses of the engine bed and connected parts are large in re-

lation to the mass of the engine.

It is also possible to construct flexible engine suspension between the frame and the

engine bed to reduce the transmission of vibration to the engine bed.

Flexible engine suspension

Flexible engine suspension dampens vibrations more effectively than rigid engine

suspension. It prevents extreme movement between engine and engine bed during vi-

olent ship movement. Flexible engine suspension can also absorb some level of re-

action force from the propeller. Flexible engine suspension does not require such

careful alignment of the engine as rigid engine suspension.

However, flexible engine suspension does not absorb longitudinal and lateral forces

in the engine to the same extent as rigid engine suspension.

344 281

Examples of rigid engine suspension.

334 280

Examples of flexible engine suspension.

INSTALLATION

MANUAL

© Scania CV AB 2018, Sweden

Engine suspension

02:01 Issue 7.0 en-GB 7

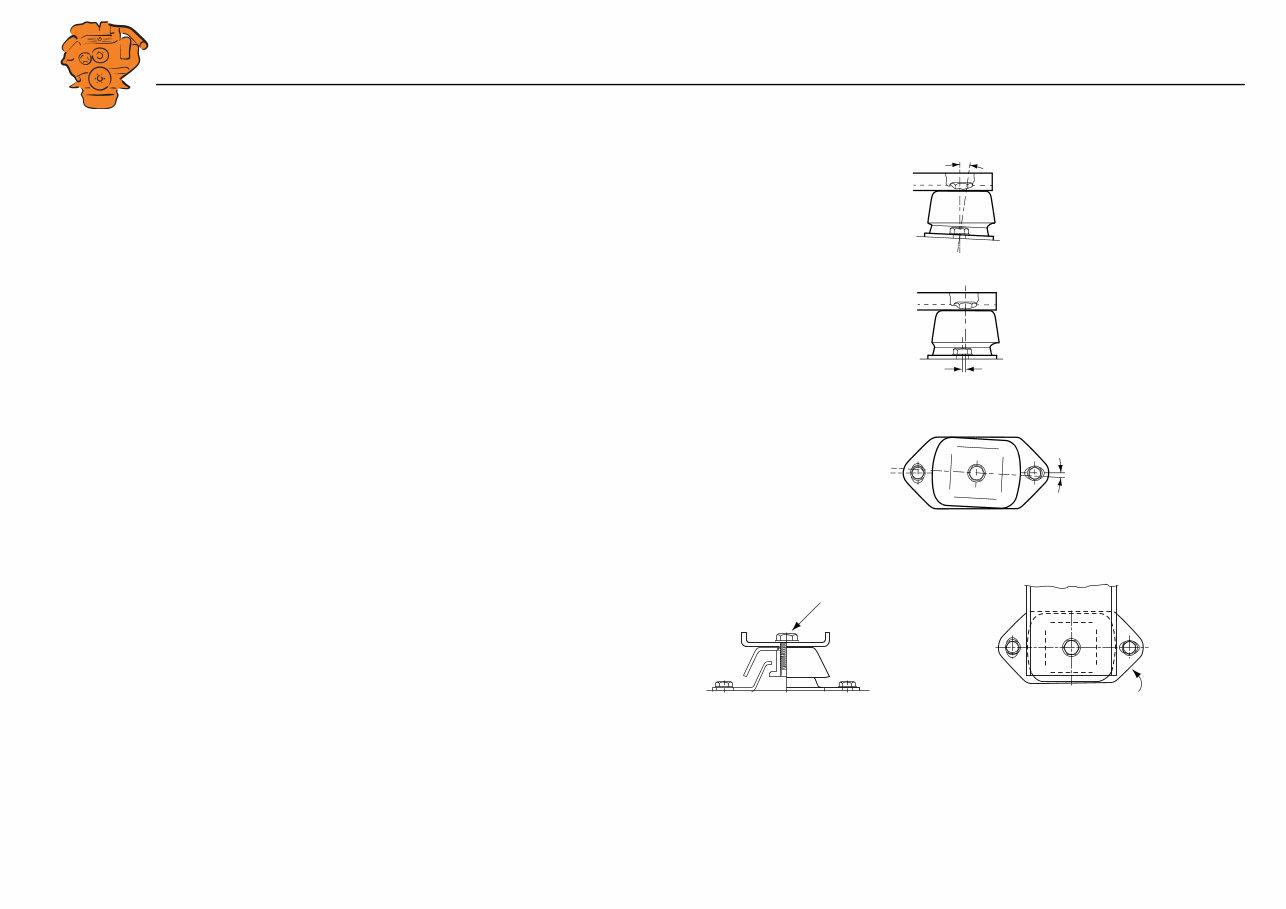

Insulators

Cushyfloat insulators with hardness 55 or 65 Shore can be ordered as option. The fol-

lowing applies for these parts:

• The engine bracket and frame or engine bed should be parallel.

• The vertical centre lines should coincide laterally.

• The upper and lower parts of the insulators should be parallel longitudinally.

Tightening torque. Hardness marking.

max 1°

396 084

0

396 085

55

0°

396 086

310 404

160±10 Nm

310 405

55

55

alt. 65

INSTALLATION

MANUAL

© Scania CV AB 2018, Sweden

Engine suspension

02:01 Issue 7.0 en-GB 8

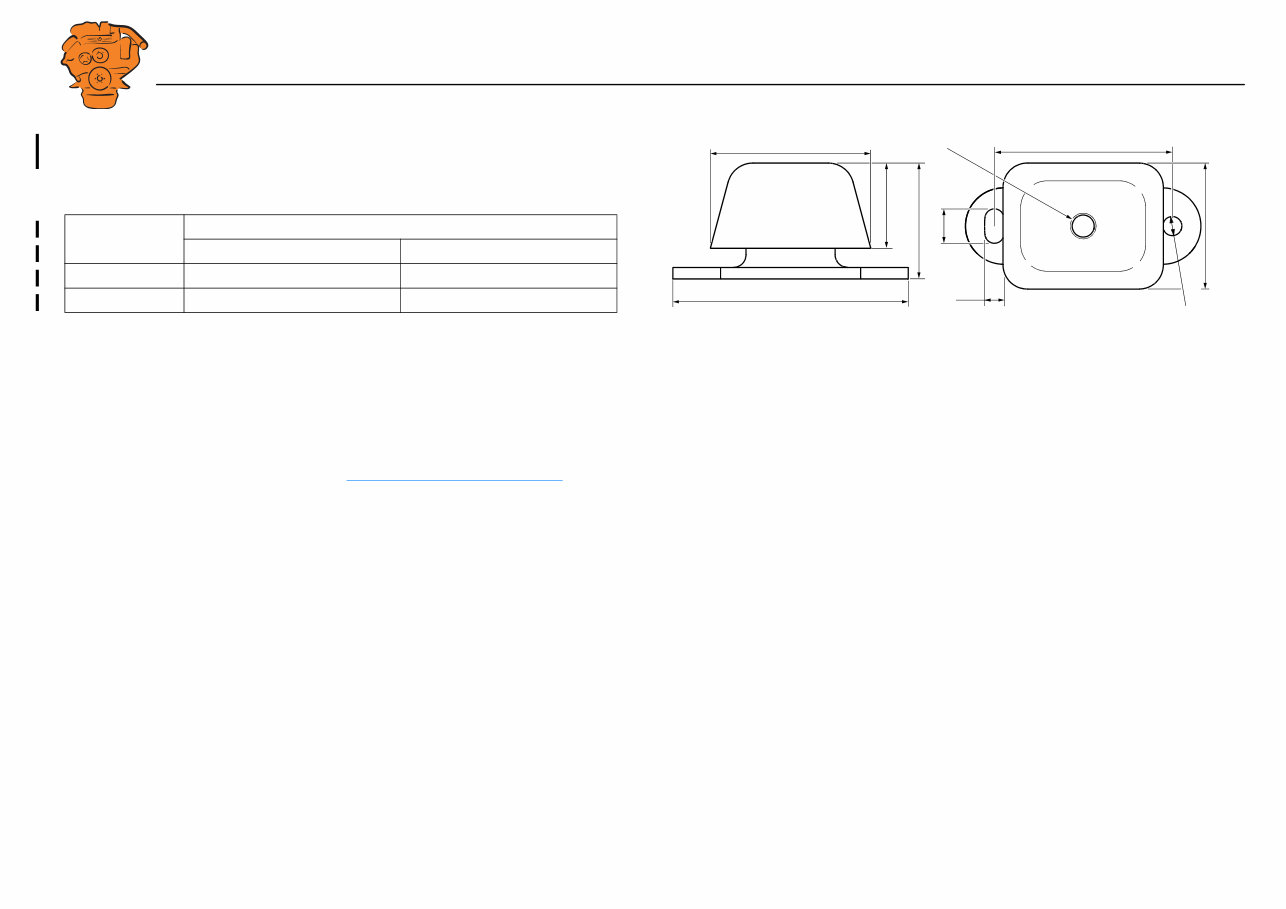

The illustration shows the dimensions of the insulators. The illustration applies to

both 55 and 65 Shore.

Suspension of reverse gear

Built-on reverse gear can either have separate brackets or suspension attachments

which are integrated with the engine. See Suspension design requirements .

Contact Scania or the supplier of the reverse gear about approved type of suspension

for reverse gear.

Shore

Vertical load (kg), DI09, DI13, DI16

Min. Max.

55 205 340

65 300 500

140

185

67

15

27

126

A

99

Ø 15

M20

394 807

Insulators 55 and 65 Shore.

Dimension A: Without load = 91 mm. With load = 86 mm.

INSTALLATION

MANUAL

© Scania CV AB 2018, Sweden

Engine suspension

02:01 Issue 7.0 en-GB 9

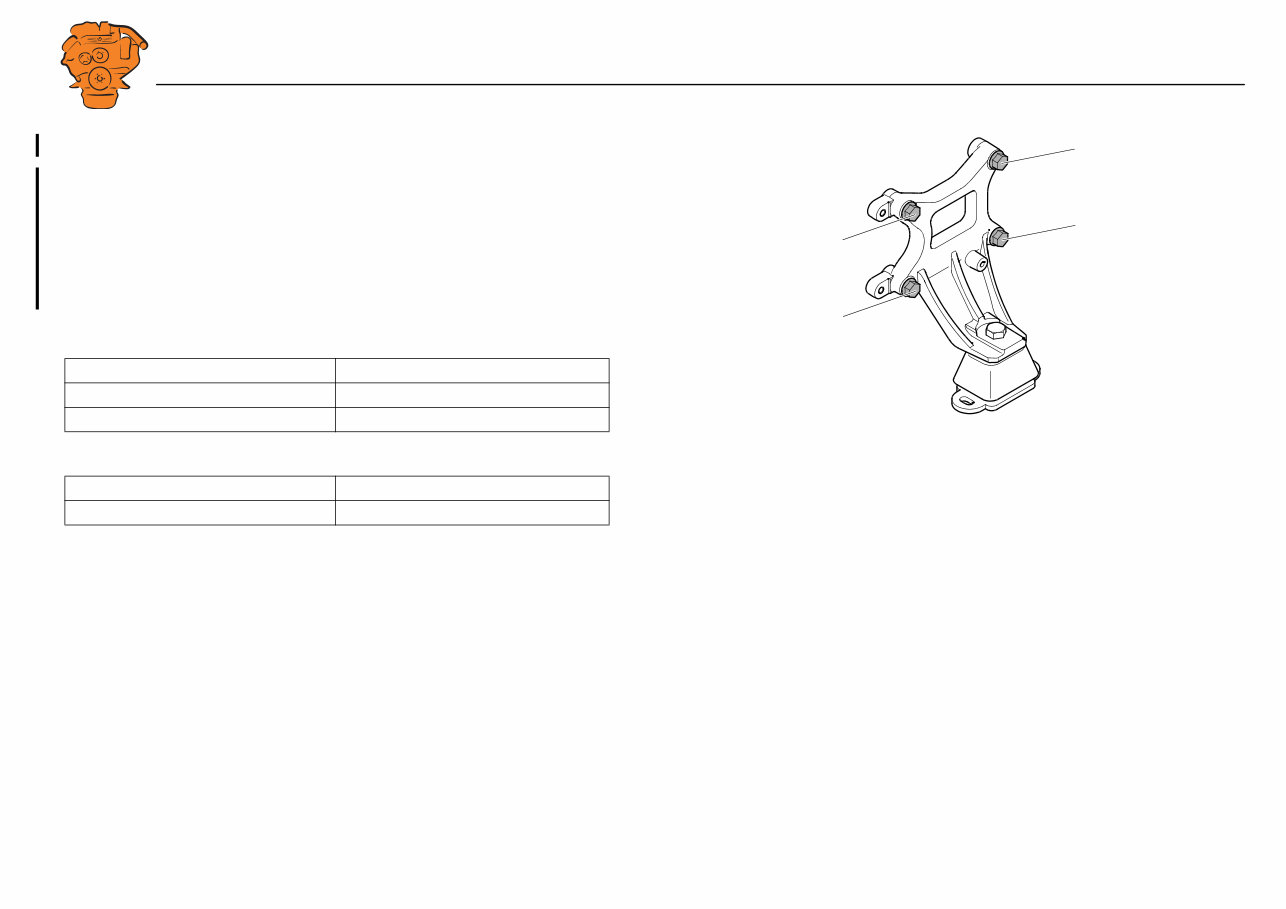

Tightening torque for engine suspension

The engine brackets can look different on different engine types, but all types of en-

gine bracket are tightened crosswise.

1. Torque tighten screws 1 and 2.

2. Torque tighten screws 3 and 4.

3. Angle-tighten screws 1 and 2.

4. Angle-tighten screws 3 and 4.

Front engine suspension

Rear engine suspension

Type of screw Tightening torques

25 mm clamping length, M16, 10.9 130 Nm, 90°

50 mm clamping length, M16, 10.9 130 Nm, 135°

Type of screw Tightening torques

M14, 8.8 149 Nm

1

3

4

2

394 815

Example of engine bracket.

INSTALLATION

MANUAL

© Scania CV AB 2018, Sweden

Engine suspension

02:01 Issue 7.0 en-GB 10

Permissible installation and operating angles

IMPORTANT!

If the angles of inclination are exceeded, lubrication system performance will deteri-

orate, which can cause damage to the engine or reduce its service life.

Maximum installation angle means maximum permissible installation angle for an

engine relative to the horizontal plane. The angle indicates the limit for engine incli-

nation during continuous operation.

Maximum operating angle means maximum permissible angle of inclination for an

engine in operation and with minimum oil level. The angle may only be used for

short periods. The maximum forward or rearward operating angles are not applicable

to their full extent if the engine is inclined laterally at the same time.

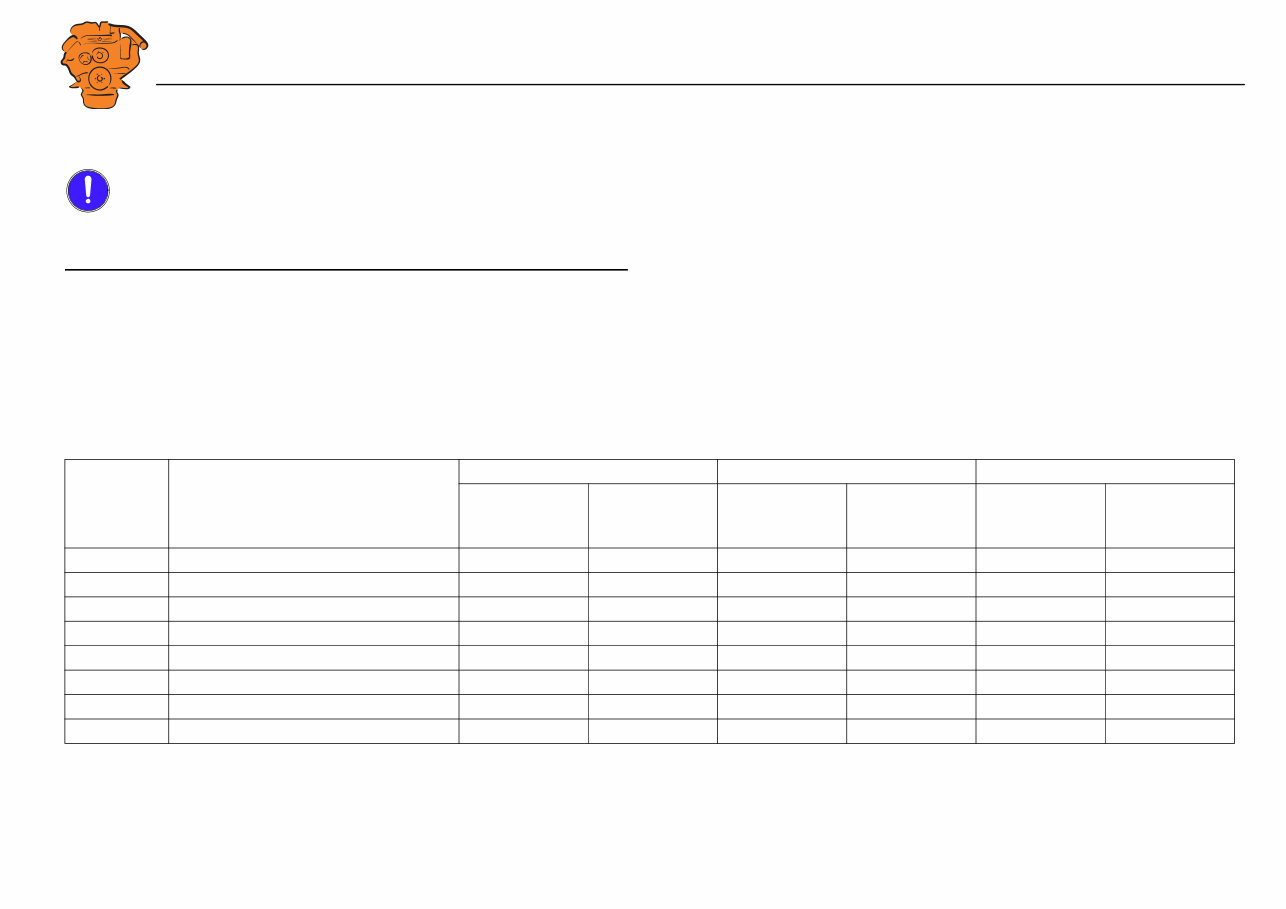

Engine type Type of oil sump Max. installation angle Max. operating angle Oil capacity (litres)

Inclination rear-

wards and for-

wards

Inclination lat-

erally

Inclination rear-

wards and for-

wards

Inclination lat-

erally

Min. Max.

DI09 Deep front, without ladder frame 12° 12° 30° 30° 32 38

DI09 Low, without ladder frame 12° 12° 20° 30° 25 32

DI13 Deep front, with ladder frame 12° 12° 30° 30° 39 45

DI13 Deep front, without ladder frame 12° 12° 30° 30° 30 36

DI13 Low, with ladder frame 12° 12° 25° 30° 28 34

DI13 Extra low, without ladder frame 12° 12° 25° 30° 25 30

DI16 Deep front, with ladder frame 12° 10° 25° 30° 40 48

DI16 Low, with ladder frame 12° 10° 25° 30° 29 37

You're Reading a Preview

What's Included?

Lifetime Access

Access PDF Contents & Bookmarks

Print one or all pages of your manual