Scania DI09, DI13, DI16 Marine engines - Instrumentation 2.0

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

03:03 Issue 5.0 en-GB

© Scania CV AB 2016, Sweden

Installation manual

Instrumentation 2.0

Marine engines

DI09, DI13, DI16

344 457

Downloaded from www.Manualslib.com manuals search engine

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

03:03 Issue 5.0 en-GB 2

System overview ...................................................................................................... 3

List of abbreviations ............................................................................................ 3

System overview ................................................................................................. 3

Positioning of the displays .................................................................................. 5

Connection ............................................................................................................... 7

Electrical cables................................................................................................... 7

Junction box, connection ..................................................................................... 8

Junction box, components ................................................................................. 11

Main display (DCU), junction blocks ............................................................... 12

Auxiliary display (RP), junction blocks ............................................................ 19

Safety module (SDU), connection .................................................................... 22

Gateway – overview.......................................................................................... 22

Position of the monitors on the engine .............................................................. 23

Connecting emergency stop .............................................................................. 25

Engine shutdown override in systems with safety device unit (SDU) .............. 26

Using the main display .......................................................................................... 27

First start............................................................................................................ 27

Navigation ......................................................................................................... 30

Administration in the main display ................................................................... 33

Configuring and upgrading software with USB memory stick......................... 37

Configuring the main display with a USB memory stick ................................. 38

Upgrading the main display or auxiliary display software ............................... 39

Copying one configuration file in the main display .......................................... 39

Configuring the main display via a web browser ............................................... 40

Connecting a computer to the main display ...................................................... 40

General information about the IP address ......................................................... 42

Homepage.......................................................................................................... 43

Logging in to the main display.......................................................................... 44

Important system settings: dcu / Miscellaneous / System Type........................ 44

Password: dcu > Password................................................................................ 45

File management: dcu > File ............................................................................ 46

Configuring input signals: dcu > I/O Configuration > Config Inputs .............. 47

Configure output signals: dcu > I/O Configuration / Config Outputs .............. 63

Designing instrument pages: dcu > Interface Design ....................................... 67

Set the sequences for starting, stopping and for lubrication: dcu > Start/Stop/Pre-

lube ................................................................................................................... 69

Settings for the user interface: dcu > User Interface ........................................ 72

Changing the engine designation: dcu > Engine Model ................................... 73

Setting the maintenance interval: dcu > Service Interval ................................. 74

Network settings: dcu > Communication ......................................................... 75

Other functions: dcu > Miscellaneous .............................................................. 77

SDU .................................................................................................................. 82

Auxiliary display ................................................................................................... 83

First start ........................................................................................................... 83

Administration in the auxiliary display ............................................................ 85

Examples of connection of sensors and monitors .............................................. 92

Connection of 4-20 mA, e.g. oil pressure sensor for the reverse gear .............. 92

Connection of PT100, e.g. coolant temperature sensor .................................... 94

Connection of switch input, e.g. low engine oil pressure monitor ................... 96

Downloaded from www.Manualslib.com manuals search engine

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

System overview

03:03 Issue 5.0 en-GB 3

System overview

List of abbreviations

The abbreviations in the list below are used in this manual. DCU, RP och SDU ap-

pear in the display interface and in the configuration interface.

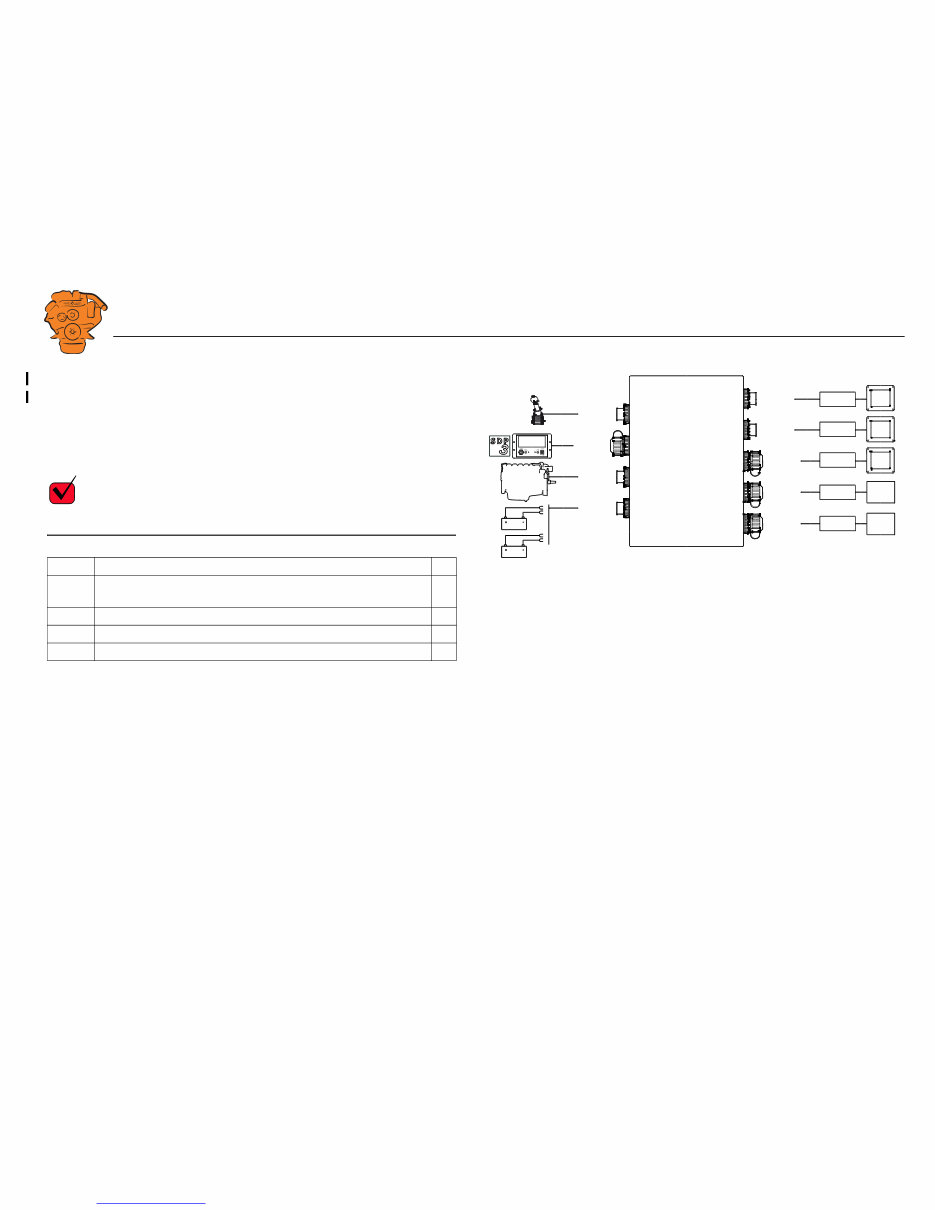

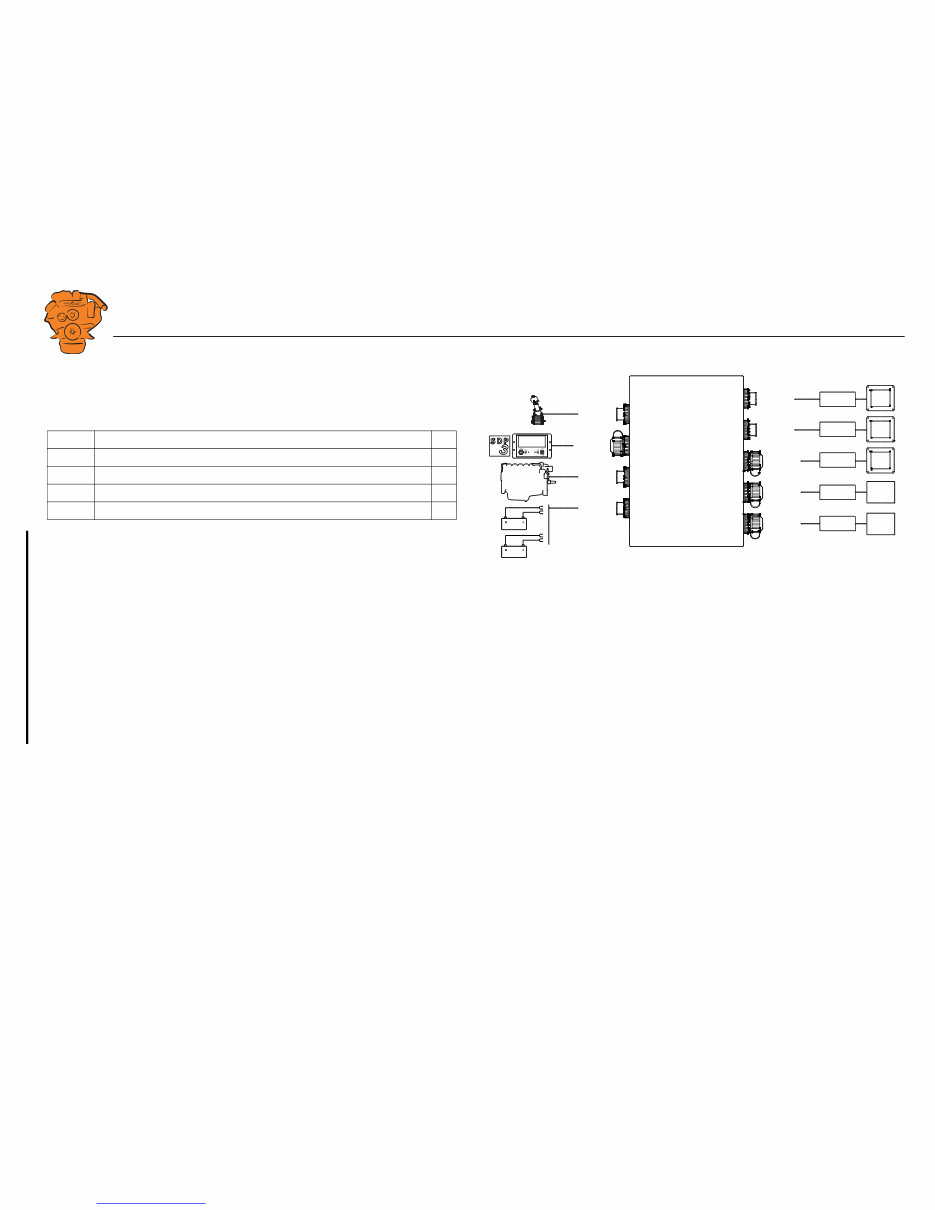

System overview

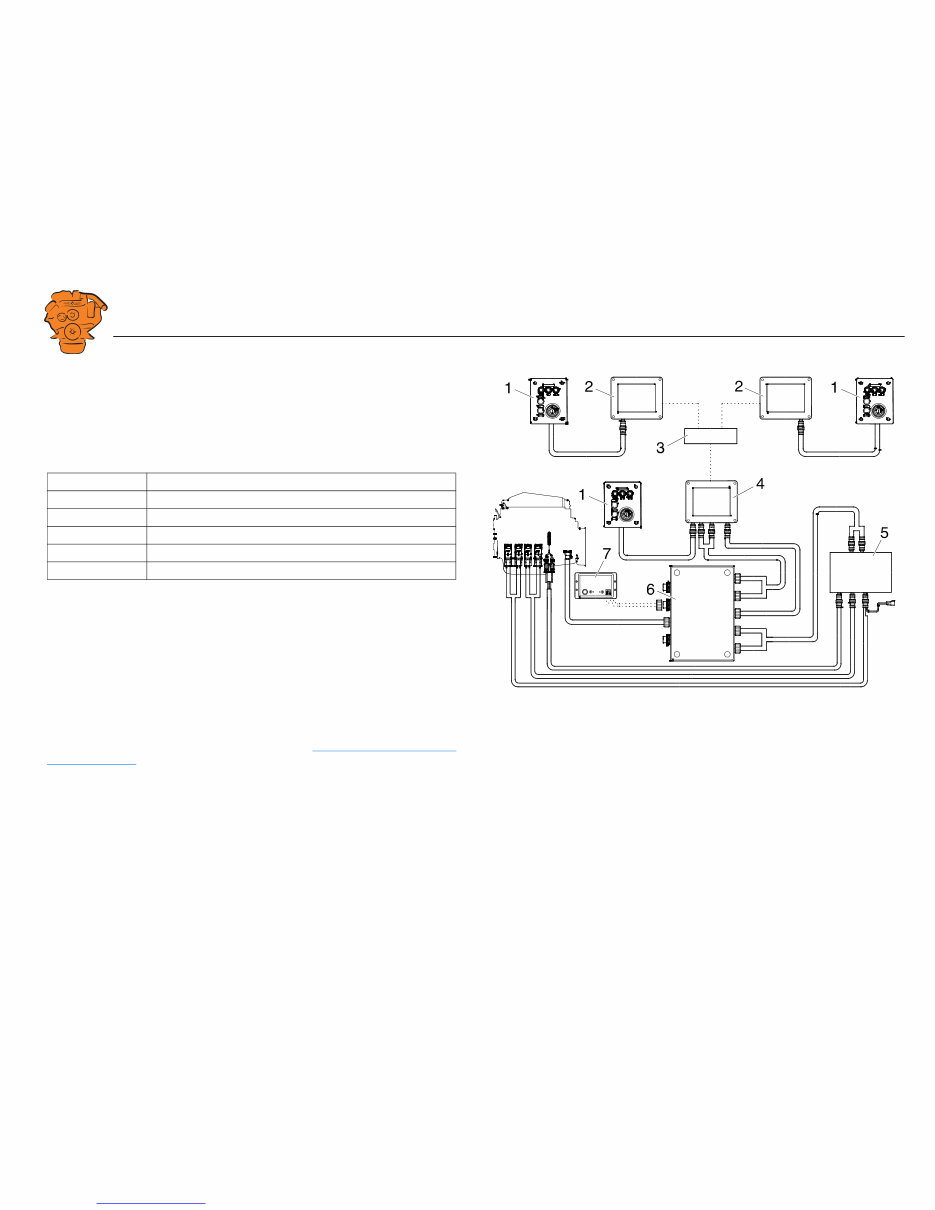

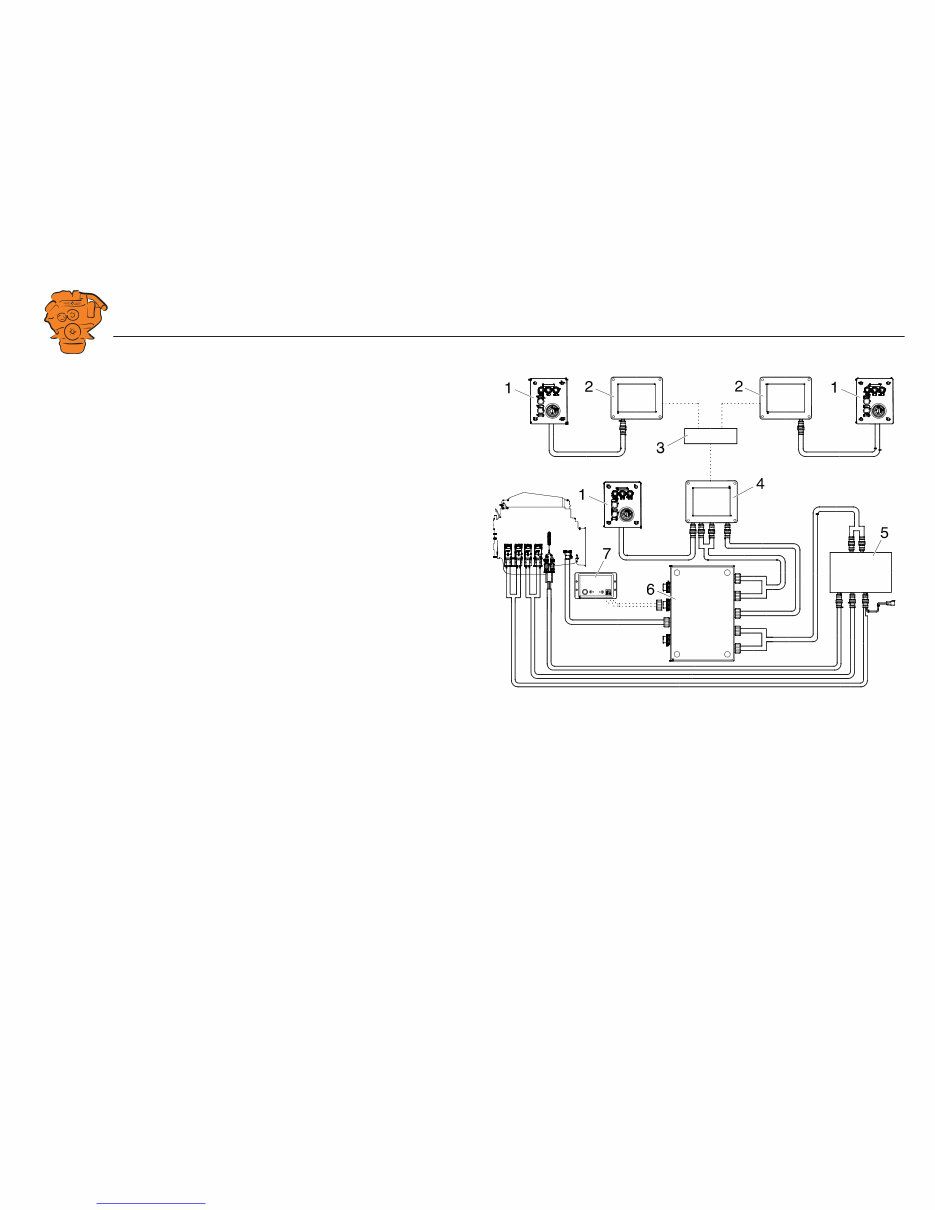

The illustration shows an overview of component parts in a marine engine manage-

ment system prepared for classification.

Main display (DCU)

The main display is the basic unit of the engine management system. Different sensor

values are displayed on the main display touch screen, and different commands are

also carried out there.

The main display is configured using a computer with a web browser via the built in

web server of the main display. This is described in the Configuring the main display

via a web browser section.

Abbreviation Description

DCU Main display

RP Auxiliary display

SDU Safety device unit

FMI Failure Mode Identifier

SPN Suspect Parameter Number

361 900

Example of the layout of a type approved marine engine management system.

1. Control panel.

2. Auxiliary display (RP).

3. Network switch.

4. Main display (DCU).

5. Safety module (SDU).

6. Junction box.

7. Gateway.

Downloaded from www.Manualslib.com manuals search engine

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

System overview

03:03 Issue 5.0 en-GB 4

Auxiliary display (RP)

The auxiliary display is an option and has the same user interface as the main display.

The auxiliary display reads the configuration from the main display. This makes it

easy to retrofit.

Control panel

The engine can be started and stopped through the control panel. It can also be used

to activate and adjust engine speed settings 1 or 2. The engine installation can be car-

ried out with or without a control panel.

Network switch

A network switch is only required if more than one auxiliary display is connected to

the engine management system. If the system only contains one auxiliary display, it

is connected directly to the main display via a crossover network cable.

Safety module (SDU)

The safety device unit has monitoring and shutdown functions and is a requirement

for classified engine management systems. It should be easily accessible so that

alarms can be acknowledged in an easy way.

Junction box

The junction box is used to connect all the parts of the engine management system to

the engine. The junction box also contains fuses. It should be easily accessible.

Gateway

The gateway reads specific messages about position and speed via NMEA 2000, so

that the instrumentation can calculate fuel consumption per nautical mile. The gate-

way cannot process messages other than these. The gateway requires software ver-

sion 2.11 or later to be installed in the displays.

361 900

Example of the layout of a type approved marine engine management system.

1. Control panel.

2. Auxiliary display (RP).

3. Network switch.

4. Main display (DCU).

5. Safety module (SDU).

6. Junction box.

7. Gateway.

Downloaded from www.Manualslib.com manuals search engine

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

System overview

03:03 Issue 5.0 en-GB 5

Positioning of the displays

Do not position the displays so that they are exposed to direct sunlight. This impairs

the readability of the displays. The user should have full access to the displays. It

must also be easy to access the connections on the rear of the displays.

IMPORTANT!

The displays must not be fitted on vibrating equipment. They may only be positioned

next to the engine bed if either the engine or the display housing has vibration damp-

ing.

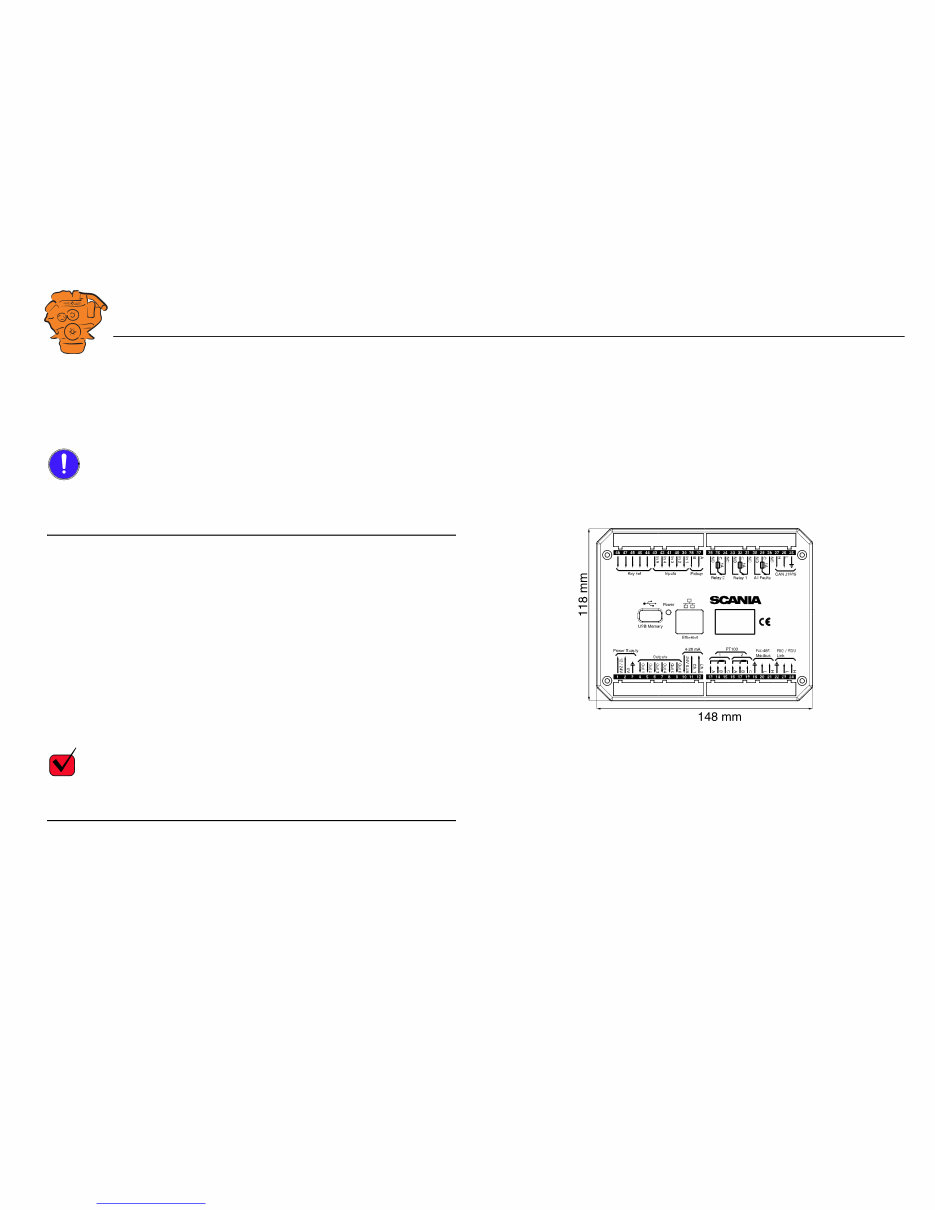

Installation dimensions

Provide a 150 x 120 mm rectangle where the display is to be positioned. There must

be at least 70 mm free space behind the display.

Main display

Scania recommends positioning the main display in the engine compartment for the

following reasons:

• To ensure that operation and monitoring are close to the engine.

• To minimise the lengths of the electrical cables between the sensors and main dis-

play.

• To reduce the risk of electrical interference caused by long electrical cables.

REQUIREMENT!

On a type approved installation, the main display must be located in the engine com-

partment.

361 901

Installation dimensions for the main display and auxiliary display.

Downloaded from www.Manualslib.com manuals search engine

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

System overview

03:03 Issue 5.0 en-GB 6

Auxiliary display

The auxiliary display is normally positioned outside the engine compartment, but can

also be positioned in the engine compartment.

Downloaded from www.Manualslib.com manuals search engine

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 7

Connection

Electrical cables

To protect against electromagnetic interference, Scania recommends that all electri-

cal cables within the system are twisted in pairs with 35-40 turns/m. This only applies

to external signal cables connected to the system.

IMPORTANT!

If a shielded electrical cable is used, the shielding should be connected to ground, not

to 0 V. Only connect the shielding to one end of the electrical cable.

To provide good separation of the electromagnetic interference that can occur, some

of the electrical cables can be routed separately from the others, e.g. the signal cable

from a magnetic pulse sensor.

Electrical cables for electric power supply must have a minimum cross section of

2.5 mm

2

.

Ground

IMPORTANT!

Separate ground and 0 V. In marine installations, ground and 0 V must not be con-

nected. The hull is ground and the battery negative terminal is 0 V.

24 V and 0 V are filtered in the main display in order to reduce electromagnetic in-

terference. If ground and 0 V are connected together, the filters in the main display

will not function.

Downloaded from www.Manualslib.com manuals search engine

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 8

Junction box, connection

Minimum connection

The minimum connection required for the system to function is for the pins on con-

nector C4066 to be connected. If the throttle control is to be controlled via the main

display, then pins 1 and 2 of connector C4068 must also be connected.

Please refer to the electrical system installation manual 03:01 for information on how

to connect the throttle control to the engine control unit. If the throttle control is con-

nected to the engine control unit, secondary throttle control cannot be used.

C4066

Connection of power supply to the engine management system and instrumentation

2.0 (battery).

Note:

If the system has a safety device unit (SDU), 2 separate groups of batteries must be

used.

Pin Description I/O

1 30 voltage, 24 V -

2 Ground (battery negative terminal) -

3 30 voltage, 24 V -

4 Ground (extra battery negative terminal) -

1

2

3

4

DCU

DCU

DCU

SDU

SDU

C4068

C4067

C4052

C4053

C4056

C4058

C4059

C4054

C4055

C4057

C4060

C4061

C4062

C4066

Gat eway

C4001

372 773

Connecting the junction box.

Downloaded from www.Manualslib.com manuals search engine

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 9

C4062

Connection to engine connector C4001.

C4067

Diagnostic socket for connecting e.g. SDP3 and CAN communication. Use connec-

tor 1 508 055 and hand crimping tool 99 494.

REQUIREMENT!

Any equipment connected to the connector must comply with the CAN specification.

Pin Description I/O

1 15 voltage: 24 V after fuse F4005 and relay in the junction box. Con-

trolled by the system being active.

-

2 Ground -

3 CAN high -

4 CAN low -

1

2

3

4

DCU

DCU

DCU

SDU

SDU

C4068

C4067

C4052

C4053

C4056

C4058

C4059

C4054

C4055

C4057

C4060

C4061

C4062

C4066

Gat eway

C4001

372 773

Connecting the junction box.

Downloaded from www.Manualslib.com manuals search engine

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 10

C4068

Connecting the incoming throttle actuation signal. The update frequency is 100 Hz,

with a median filter on 3 readings.

C4052

Connection to main display via C4054.

C4053

Connection to main display via C4055.

C4056

Connection to main display via C4057.

C4058

Connection to safety device unit (SDU) via C4060.

C4059

Connection to safety device unit (SDU) via C4061.

Pin Description I/O

1 24 V (0.2 A), voltage supply to passive throttle control O

2 Input for signal from throttle control, 4-20 mA I

3 Not used -

4 Not used -

1

2

3

4

DCU

DCU

DCU

SDU

SDU

C4068

C4067

C4052

C4053

C4056

C4058

C4059

C4054

C4055

C4057

C4060

C4061

C4062

C4066

Gat eway

C4001

372 773

Connecting the junction box.

Downloaded from www.Manualslib.com manuals search engine

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$26.99

Viewed 65 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$26.99

- This Parts Manual covers all the models of Scania DI09, DI13, and DI16 Marine engines for Instrumentation 2.0. It is an essential reference guide for servicing, maintenance, repairs, troubleshooting, and diagnostics.

- The manual contains detailed drawings and schematics to help identify various components of these engines. It includes all parts names and numbers, contents, and navigation instructions for every model listed.

- Written in English, the manual comprises 140 printable and searchable pages. It can be accessed with smart devices such as laptops, PCs, etc., providing convenience and flexibility.

- Additionally, it includes frequent reference charts, technical data, and clear instructions for easy understanding, helping users save time, money, and effort by providing all necessary information.

- With this Parts Manual, both professional mechanics and DIY enthusiasts can identify and order the correct part for their engine model, ensuring peak performance and reliability.