Technical Documentation

Fluids and Lubricants

Specification

A001061/32E

(all commercial MTU-Series and DDC S60 Marine)

Printed in Germany

© 2007 Copyright MTU Friedrichshafen GmbH

This Publication is protected by copyright and may not be used in any way whether in whole or in part without the

prior written permission of MTU Friedrichshafen GmbH. This restriction also applies to copyright, distribution,

translation, microfilming and storage or processing on electronic systems including data bases and online services.

This handbook is provided for use by maintenance and operating personnel in order to avoid malfunctions or

damage during operation.

Subject to alterations and amendments.

Table of Contents 01

1 Preface ....................................................................... 03

2 Lubricants .................................................................... 05

3 Coolants ..................................................................... 13

4 Fuels ........................................................................ 21

5 Preservatives ................................................................. 31

6 Approved Fluids and Lubricants (except Series 1800 PowerPack) ...................... 33

7 Approved Fluids and Lubricants, Series 1800 PowerPack ............................. 53

8 Preservation Specifications ...................................................... 65

9 Flushing and Cleaning Specifications for Engine Coolant Systems ..................... 85

A001061/32E 07-01 © MTU

02 Table of Contents

A001061/32E 07-01 © MTU

Preface 03

1 Preface

The service life, operational reliability and function of the drive systems are largely dependent on the fluids

and lubricants employed. The correct selection and treatment of these fluids and lubricants are therefore

extremely important. This publication specifies which fluids and lubricants are to be used.

The Fluids and Lubricants Specifications will be amended or supplemented as necessary. Before

using them, make sure you have the latest version. The latest version is also available at:

http://www.mtu-online.com/Dienstleistungen/Dokumentation

If you have further queries, please contact your MTU representative.

Test standards for fluids and lubricants:

DIN Federal German Standards Institute

EN European Standards

ISO International Standards Organisation

ASTM American Society for Testing and Materials

IP Institute of Petroleum

Note:

Use of the approved fluids and lubricants, either under the brand name or in accordance with the

specifications given in this publication, constitutes part of the warranty conditions.

The supplier of the fluids and lubricants is responsible for the world-wide standard quality of the named products.

Fluids and lubricants for drive plants may be hazardous materials. Certain regulations must be

obeyed when handling, storing and disposing of these substances.

These regulations are contained in the manufacturers’ instructions, legal requirements and technical guidelines

valid in the individual countries. Great differences can apply from country to country and a generally valid guide

to applicable regulations for fluids and lubricants is therefore not possible within this publication.

Users of the products named in these specifications are therefore obliged to inform themselves

of the locally valid regulations. MTU accepts no responsibility whatsoever for improper or illegal

use of the fluids and lubricants which it has approved.

A001061/32E 07-01 © MTU

04 Preface

A001061/32E 07-01 © MTU

Lubricants 05

2 Lubricants

Engine oils

Requirements for MTU Approval of Engine Oils (diesel engines)

The MTU requirements for approval of engine oils for diesel engines are contained in the MTU Factory Standards

MTL 5044 and MTL 5051 for first-use oils and corrosion-inhibiting oils. For gas engines, oil approval requirements

are contained in MTU Factory Standard MTL 5074. These standards can be ordered under these reference numbers.

Manufacturers of engine oils are notified in writing if their product is approved.

Approved engine oils are divided into the following MTU Quality Categories:

• Oil category 1: Standard quality / Single and multigrade oils

• Oil category 2: Higher quality / Single and multigrade oils

• Oil category 3: Highest quality / Multigrade oils

• Oil category 3.1: Multigrade oils with a low ash-forming additive content (low SAPS oils)

Low SAPS oils currently provide the highest oil quality category with low sulfur and phosphor

contents and an ash-forming additive content of <1%.

They are only approved if the sulfur content in the fuel does not exceed 350 mg/kg.

Selection of a suitable engine oil is based on fuel quality, projected oil drain interval and on-site climatic conditions.

At present there is no international industrial standard which alone takes into account all these criteria.

Special Features

MTU Engine Oils

One single-grade and one multigrade oil are available from MTU/DDC. These engine oils are marketed

under the name Power Guard DEO SAE 40 and SAE 15W-40. The engine oils are tailored to the

MTU Off-Highway application groups and correspond to Oil Category 2.

Engine Oils for Series 2000, 4000

For Series 2000 and 4000 engines engine oils other than those listed as approved in Section 6 may be used

provided they satisfy all of the specifications and match all of the characteristics listed in Tables 1 and 2.

Performance specifications for engine oils for Series 2000 and 4000 (Table 1)

Oil category 1 Specification min. API CG-4/CH-4 and ACEA E2–96

Oil category 2 Specification ACEA E7–04

Oil category 3 Specification ACEA E4–04

Oil category 3.1 Specification ACEA E4–04, E6–04

Chemical-physical characteristics for engine oils (Table 2)

Test Method Limit Value

Total base number ASTM D 2896

ISO 3771

> 8mgKOH/g

Shear stability ASTM D 3945 or

CEC-L-14-A-88

Limit values of respective

viscosity class

Deposit test

1)

DIN 51535 Max. 120 mg

1)

Required for multi-grade oils used in closed crankcase ventilation.

Note:

Engine oils which comply with only one of the standards API CF, CF-2, CF-4, CG-4, CH-4 or CI-4 or with

a combination of these specifications, do not fully meet performance specifications.

If these oils are intended for use, the oil drain interval is to be shortened by up to 50% after consultation with MTU.

A001061/32E 07-01 © MTU

06 Lubricants

Engine Oils for Series 6H 1800

Only engine oils as specified in Chapter 7 must be used for engine model 6H 1800

( → Page 53).

Where diesel fuel in accordance with EN 590 is in use, the oil must be changed either after

1000 operating hours or after one year, whichever occurs first.

Where biodiesel/FAME in accordance with EN 14214 is in use, the oil change intervals are

reduced ( → Page 21).

Restrictions on Series 595, 1163 and 8000 applications

For fast commercial ferries with Series 595 or 1163 engines, Category 2 or 3 oils are generally

specified.

Oil Category 3.1 may be used if the sulfur content in the fuel does not exceed 350 mg/kg.

For Series 8000, only the following engine oils may be used:

• Exxon Mobil Delvac1630 SAE 30

• Shell Sirius X SAE 30

Engine Oil Requirements for Gas Engines

Viscosity grade SAE 40 is stipulated for gas engines!

The selection of a suitable engine oil for gas engines depends primarily on the type of gas used to power the engine.

Another significant factor is the quality of the gas regarding its purity. This requires that the operator regularly carries

out gas checks. The gas-engine oils to be used feature a low ash content (< 0.6%) and base numbers within a range

of 4-6 mgKOH/g. This prevents increased ash deposits which can lead to reduced catalytic converter performance.

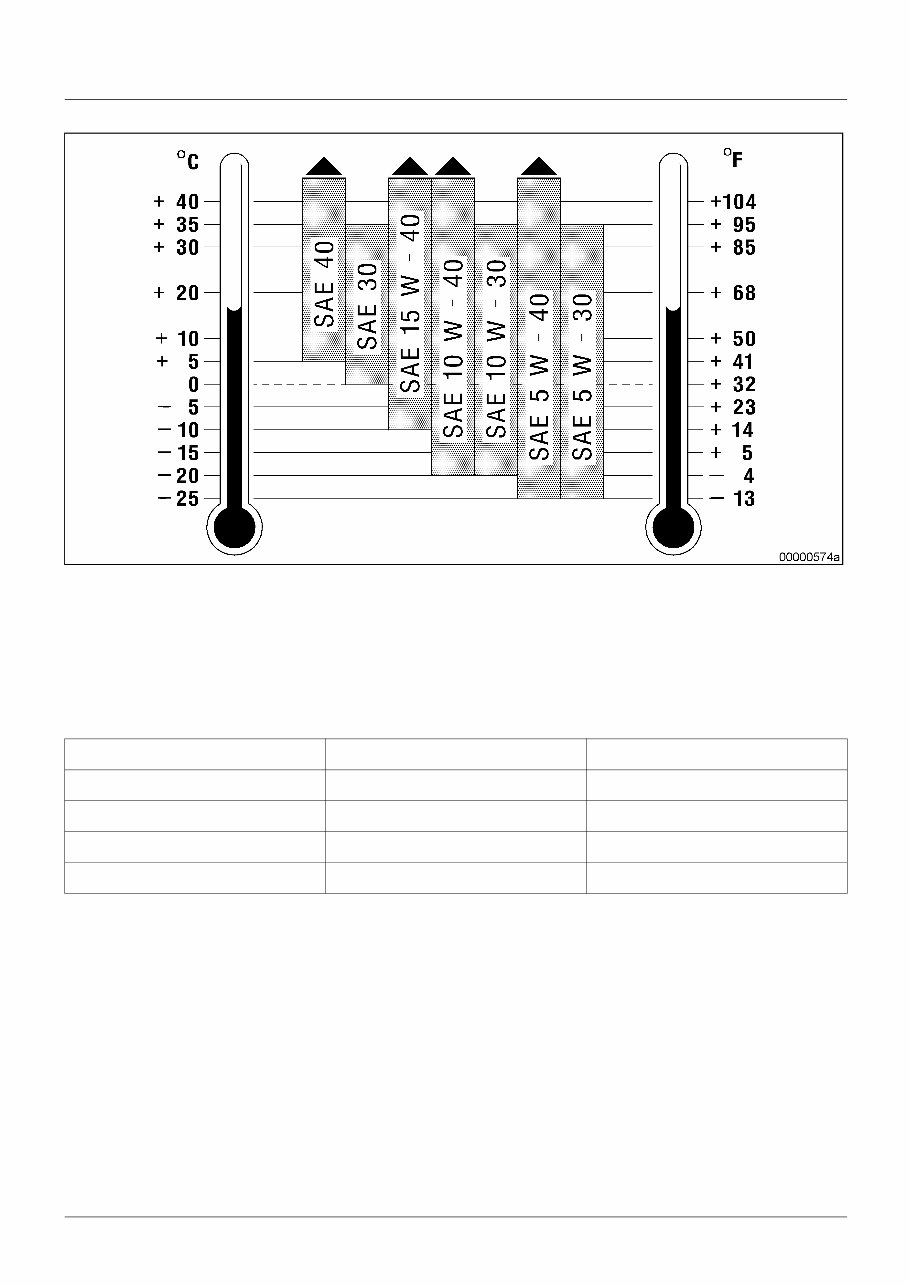

Selection of viscosity grades

Selection of the viscosity grade is based primarily on the ambient temperature at which the engine

is to be started and operated. If the relevant performance criteria are observed the engines can be

operated both with single grade and multigrade oils, depending on the application. Standard values

for the temperature limits in each viscosity grade are shown in Chart 1.

Only where crankcase ventilation to atmosphere is in use as in the case of off-highway vehicles (e.g. tractor

units, earth-moving machines, haul trucks) is it essential that multigrade oils are used.

If the prevailing temperature is too low, the engine oil must be preheated.

A001061/32E 07-01 © MTU

Lubricants 07

Diagram 1

Oil Drain Intervals for Diesel Engines

Engine oil drain intervals depend on the engine-oil quality, its conditioning, the operating conditions and the fuel used.

The intervals quoted (Table 3) are guidelines based on operational experience and are valid

for applications with a standard load profile.

Oil Drain Intervals (Table 3)

Oil category Without centrifugal oil filter With centrifugal oil filter

1 250 operating hours 500 operating hours

2 500 operating hours 1000 operating hours

3 750 operating hours 1500 operating hours

3.11)

750 operating hours 1500 operating hours

1)

= To be used in conjunction with fuels with max. 350 mg/kg sulfur content.

The oil drain intervals in the table are recommended guidelines when using diesel fuels with < 0.5%

sulfur content. The limit values specified in Table 4 for used oil must be complied with. The numbers of

operating hours quoted for oils must be confirmed by means of oil analysis.

The oil drain intervals must be determined by oil analysis if one or more of the following

difficult operating conditions are encountered:

• Extreme climatic conditions

• High engine start-up frequency

• Frequent and prolonged idling or low-load operation

• High sulfur content in the fuel of 0.5 to 1.5 % by weight ( → Page 10)

New oils must be selected which have total base numbers appropriate to the sulfur

content of the fuel in use. ( → Page 08)

For applications involving low runtimes, the engine oil must be changed every two years

at the latest irrespective of its category.

A001061/32E 07-01 © MTU

08 Lubricants

Where engine oils with higher-grade corrosion-inhibiting characteristics are in use, ( → Page 33)

a change must be carried out every 3 years at the latest.

In individual cases the service life of the engine oil can be optimized by regular laboratory analysis and

appropriate engine inspections in consultation with the MTU service point responsible:

The first oil sample should be taken from the engine as a “basic sample” after the engine has

run for approximately 1 hour after being filled with fresh oil.

Further oil samples should be analyzed after engine runtimes which are to be specified. ( → Page 08)

The appropriate engine inspections are to be carried out before and after the oil analyses.

After completion of all analyses, and depending on the findings, special agreements

can be reached for individual cases.

Oil samples must always be taken under the same conditions and at the point provided

for that purpose (see Operating Instructions).

Oil Drain Intervals for Gas Engines 12V 4000 L61

Engine oil drain intervals depend on the engine-oil quality, its conditioning, the operating conditions and the fuel used.

Regular oil analyses are necessary because of the varying gas qualities. At the beginning of the product’s

life cycle, oil samples must be taken and analyzed after every 500 hours of operation.

Given consistent gas quality, an oil drain interval of max. 1,500 hours of operation is recommended.

In individual cases, the oil change intervals can be optimized:

For this purpose, oil samples are analyzed after every 200 -250 hours of operation. ( → Page 08).

The oil samples must always be taken from the extraction point provided and under the same conditions.

Special Additives

Engine oils approved have been specially developed for diesel engines and have all necessary properties.

Further additives are therefore superfluous and may even be harmful.

Laboratory Analysis

General

Orders for engine oil analyses can be placed with MTU.

The oil sample must be taken in accordance with the Operating Instructions.

The following data are required:

• Oil manufacturer

• Brand name with viscosity class

• Oil service life to date

• Serial number of engine from which oil sample was taken

The following must be submitted (for each oil change):

• Min. 0.25 ltr used oil

• Min. 0.25 ltr reference sample (after approx. 1 hour’s operation)

• Min. 0.25 ltr new oil

Spectrometric Oil Analysis

Analysis of the engine oil’s additive-metal content is carried out by the MTU laboratory to determine the brand of oil.

MTU does not generally analyze the oil’s wear-metal contents in order to determine the degree of engine wear.

These content levels are very much dependent on the following factors, among others:

• Individual engine equipment status

• Tolerance scatter

• Operating conditions

• Duty profile

• Fluids and lubricants

• Miscellaneous assembly materials

Unambiguous conclusions as to the wear status of the engine components involved are therefore not

possible. This means that no limit values can be given for wear-metal contents.

Used-oil Analysis

In order to check the used oil, it is recommended that regular oil analyses be carried out. Oil samples should be

taken and analyzed at least once per year and during each oil change and under certain conditions, depending on

application and the engine’s operating conditions, sampling/analysis should take place more frequently.

The test methods and limit values given in Table 4 and Table 5 (Analytical Limit Values for Diesel / Gas Engine

Oils) indicate when the results of an individual oil sample analysis are to be regarded as abnormal.

An abnormal result requires immediate investigation and remedy of the abnormality.

A001061/32E 07-01 © MTU

You're Reading a Preview

What's Included?

Lifetime Access

Access PDF Contents & Bookmarks

Print one or all pages of your manual

Add to Cart

$26.99

$35.99