1963-1990 Mitsubishi Saturn (4G32) Engine OEM Service & Repair Manual

1963-1990 Mitsubishi Saturn (4G32) Engine OEM Service & Repair Manual

Engine covered:

- 1.6L 4G32 Inline-4

The 1963-1990 Mitsubishi Saturn (4G32) Engine OEM Service & Repair Manual provides the original factory procedures for inspection, disassembly, component measurement, and complete overhaul of the 1.6L 4G32 I4 engine. This engine powered a wide range of Mitsubishi passenger vehicles across several decades, and while it is mechanically straightforward, the key to longevity is correct clearances, proper sealing, and maintaining good oiling and cooling performance. This manual breaks down every operation into practical steps, written for technicians who need to understand what to adjust, what to measure, and when parts have reached their limit.

Whether you’re restoring a vintage Mitsubishi, maintaining a daily-driven older model, or rebuilding a 4G32 for long-term reliability, the manual supports both professional mechanics and hands-on enthusiasts. The approach is direct and workshop-ready, without unnecessary theory or filler.

What’s Inside the Saturn 4G32 Service & Repair Manual

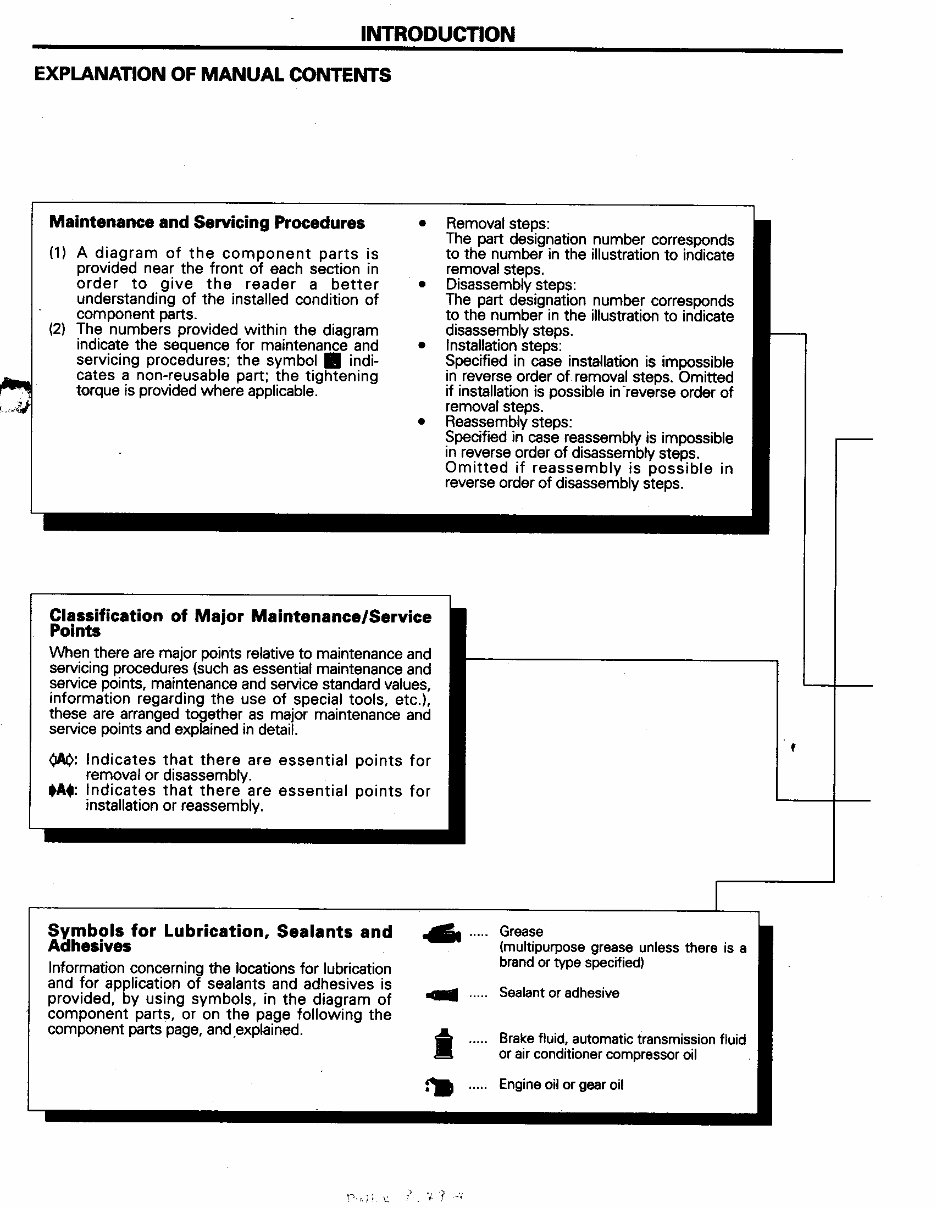

General Information

Factory specifications, engine identification markings, fastener tightening notes, service hints, and maintenance reference data. Helps verify configuration before teardown begins.

Specifications

Torque tables, wear limits, ring end gap measurements, bearing clearances, valve stem height data, compression values, and temperature/tolerance guidelines for inspection and reassembly.

Special Tools

List of specialty pullers, measurement gauges, and installation tools used for correct servicing. Indicates which tools are essential and which can be substituted with standard shop equipment.

Drive Belt & Timing Belt

Belt routing diagrams, tension specifications, camshaft alignment marks, and replacement intervals. Ensures proper valve timing and stable accessory drive performance.

Intake Manifold

Manifold removal and reinstallation procedures, gasket inspection, mating surface checks, and airflow sealing considerations important for smooth idle and throttle response.

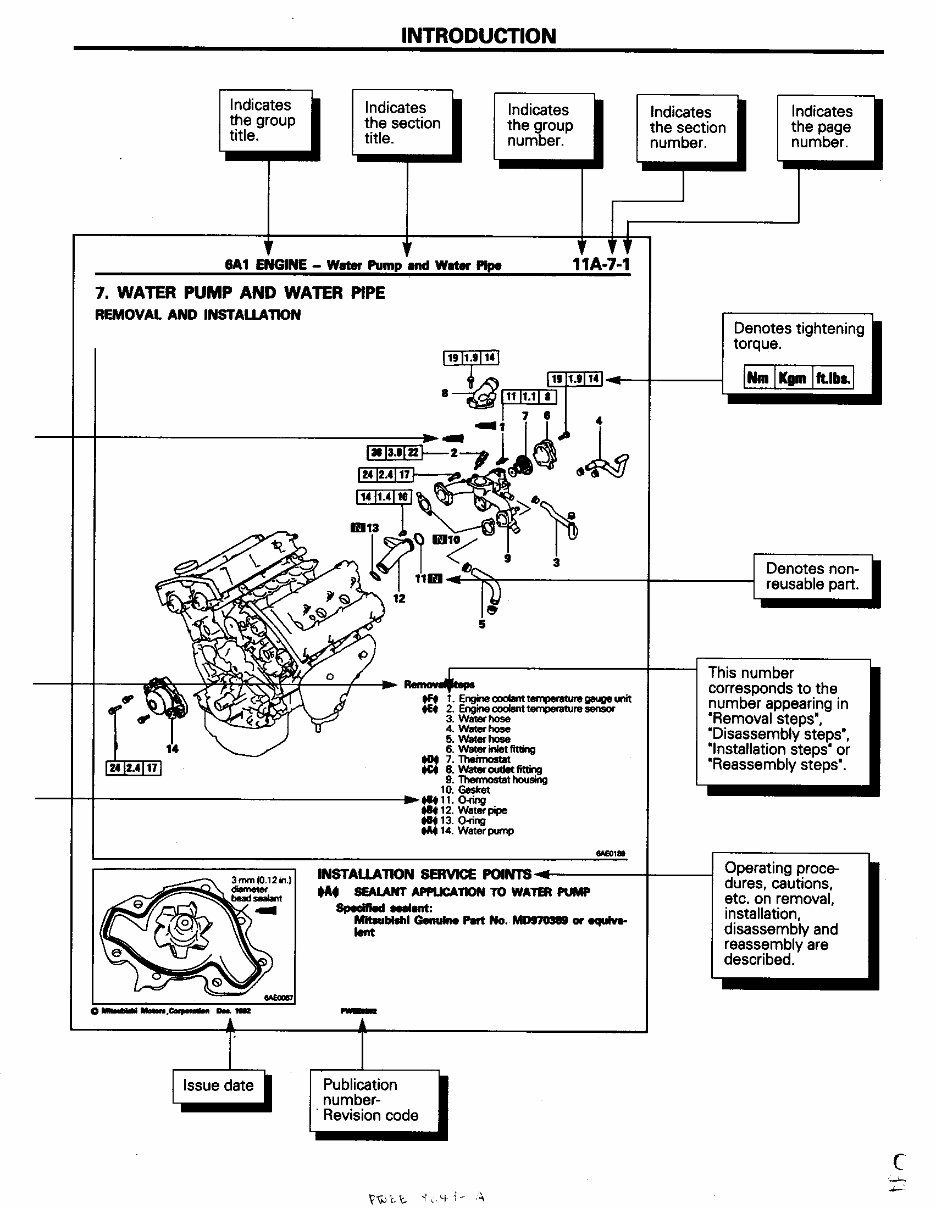

Exhaust Manifold & Water Pump

Exhaust routing and heat shield servicing, manifold fastening techniques, water pump operation checks, impeller clearance evaluation, and coolant circulation service steps.

Rocker Arms & Camshaft

Camshaft lift and wear inspection, rocker arm clearance adjustment, lubrication path checks, and cam journal service points for proper valve operation and noise control.

Rocker Arms & Rocker Shafts

Rocker shaft disassembly, inspection for galling or scoring, re-bushing procedures, lubrication fitment, and reassembly alignment for stable valve train contact geometry.

Cylinder Head & Valves

Valve seat reworking, valve lapping, combustion chamber carbon removal, head gasket servicing, and pressure testing to verify sealing and compression integrity.

Front Case, Oil Pump & Oil Pan

Oil pump disassembly and inspection, rotor to housing clearance checks, oil passage cleaning, oil pan removal and sealing steps to maintain consistent oil pressure throughout the engine.

Piston & Connecting Rod

Piston ring fitting and orientation, ring end gap measurement, wrist pin inspection, connecting rod bearing assessment, and reassembly alignment techniques for stable internal motion.

Crankshaft, Flywheel & Drive Plate

Crankshaft journal measurement, bearing surface evaluation, balancing considerations, flywheel and drive plate installation practices, and torque settings that prevent vibration and premature wear.

Cylinder Block

Block cleaning and inspection, sleeve or bore wear evaluation, honing techniques, deck flatness checks, and sealing strategies to maintain compression and oil containment over long service intervals.

Why This Manual Matters

Older engines like the 4G32 respond very clearly to whether they are serviced correctly. Valve lash off by a hair? It tells you. Oil pump clearance out of spec? You’ll see it in pressure. This manual shows the exact tolerances and adjustment sequences to get the engine back to stable running condition — the way it was designed to operate.

Format & Compatibility

Delivered as a fully searchable PDF for use on laptops, phones, tablets, or printed workbench reference sheets.

Download the 1963–1990 Mitsubishi Saturn 4G32 Engine Service & Repair Manual

A complete, factory-based overhaul and servicing reference for preserving and restoring Mitsubishi’s Saturn-series engines with confidence and mechanical accuracy.

Language: English

Compatibility: Windows, macOS, Linux, iOS, Android

Requirements: PDF Reader (e.g., Adobe Reader)