KOHLER COMMand PRO EFI Model ECV740 27HP Engine Workshop Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

ECV630-ECV749, CV735, CV26, CV745

Service Manual

24 690 02 Rev. L KohlerEngines.com 1

2 Safety

3 Maintenance

5 Specifications

22 Tools and Aids

25 Troubleshooting

29 Air Cleaner/Intake

30 Electronic Fuel Injection (EFI) System-ECV

59 Electronic Fuel Injection (EFI) System-Bosch

89 Governor System

97 Lubrication System

99 Electrical System

104 Starter System

108 Disassembly/Inspection and Service

128 Reassembly

IMPORTANT: Read all safety precautions and instructions carefully before operating equipment. Refer to operating

instruction of equipment that this engine powers.

Ensure engine is stopped and level before performing any maintenance or service.

Safety

2 24 690 02 Rev. L KohlerEngines.com

SAFETY PRECAUTIONS

WARNING: A hazard that could result in death, serious injury, or substantial property damage.

CAUTION: A hazard that could result in minor personal injury or property damage.

NOTE: is used to notify people of important installation, operation, or maintenance information.

WARNING

Explosive Fuel can cause

fires and severe burns.

Do not fill fuel tank while

engine is hot or running.

Gasoline is extremely flammable

and its vapors can explode if

ignited. Store gasoline only in

approved containers, in well

ventilated, unoccupied buildings,

away from sparks or flames.

Spilled fuel could ignite if it comes

in contact with hot parts or sparks

from ignition. Never use gasoline

as a cleaning agent.

WARNING

Rotating Parts can cause

severe injury.

Stay away while engine

is in operation.

Keep hands, feet, hair, and

clothing away from all moving

parts to prevent injury. Never

operate engine with covers,

shrouds, or guards removed.

WARNING

Carbon Monoxide can

cause severe nausea,

fainting or death.

Avoid inhaling exhaust

fumes.

Engine exhaust gases contain

poisonous carbon monoxide.

Carbon monoxide is odorless,

colorless, and can cause death if

inhaled.

WARNING

Accidental Starts can

cause severe injury or

death.

Disconnect and ground

spark plug lead(s) before

servicing.

Before working on engine or

equipment, disable engine as

follows: 1) Disconnect spark plug

lead(s). 2) Disconnect negative (–)

battery cable from battery.

WARNING

Hot Parts can cause

severe burns.

Do not touch engine

while operating or just

after stopping.

Never operate engine with heat

shields or guards removed.

WARNING

Cleaning Solvents can

cause severe injury or

death.

Use only in well

ventilated areas away

from ignition sources.

Carburetor cleaners and solvents

are extremely flammable. Follow

cleaner manufacturer’s warnings

and instructions on its proper and

safe use. Never use gasoline as a

cleaning agent.

CAUTION

Electrical Shock can

cause injury.

Do not touch wires while

engine is running.

CAUTION

Damaging Crankshaft

and Flywheel Can Cause

Personal Injury!

Using improper procedures can

lead to broken fragments. Broken

fragments could be thrown from

engine. Always observe and use

precautions and procedures when

installing flywheel.

WARNING

High Pressure Fluids can

puncture skin and cause

severe injury or death.

Do not work on fuel

system without proper

training or safety

equipment.

Fluid puncture injuries are highly

toxic and hazardous. If an injury

occurs, seek immediate medical

attention.

WARNING

Explosive Fuel can

cause fires and severe

burns.

Fuel system ALWAYS

remains under HIGH

PRESSURE.

Wrap a shop towel completely

around fuel pump module

connector. Press release button(s)

and slowly pull connector away

from fuel pump module allowing

shop towel to absorb any residual

fuel in high pressure fuel line. Any

spilled fuel must be completely

wiped up immediately.

Maintenance

3 24 690 02 Rev. L KohlerEngines.com

MAINTENANCE INSTRUCTIONS

WARNING

Before working on engine or equipment, disable engine as

follows: 1) Disconnect spark plug lead(s). 2) Disconnect

negative (–) battery cable from battery.

Accidental Starts can cause severe injury or

death.

Disconnect and ground spark plug lead(s)

before servicing.

Normal maintenance, replacement or repair of emission control devices and systems may be performed by any repair

establishment or individual; however, warranty repairs must be performed by a Kohler authorized dealer.

MAINTENANCE SCHEDULE

Every 25 Hours or Annually¹

● Service/replace low-profile precleaner (if equipped). Air Cleaner/Intake

Every 100 Hours or Annually¹

● Change oil. Lubrication System

● Replace low-profile air cleaner element. Air Cleaner/Intake

● Remove and clean shrouds and cooling areas. Air Cleaner/Intake

● Check oil cooler fins, clean as necessary (if equipped). Lubrication System

Every 150 Hours

● Check heavy-duty filter minder. Air Cleaner/Intake

● Inspect heavy-duty air filter paper element and inlet screen area. Air Cleaner/Intake

Every 200 Hours¹

● Replace unique Electronic Fuel Injection (EFI) fuel filter.

Every 200 Hours

● Change oil filter. Lubrication System

Every 300 Hours¹

● Replace heavy-duty air cleaner element and check inner element. Air Cleaner/Intake

Every 500 Hours or Annually¹

● Replace spark plugs and set gap. Electrical System

Every 600 Hours¹

● Replace heavy-duty air cleaner inner element. Air Cleaner/Intake

1

Perform these procedures more frequently under severe, dusty, dirty conditions.

REPAIRS/SERVICE PARTS

Kohler genuine service parts can be purchased from Kohler authorized dealers. To find a local Kohler authorized

dealer visit KohlerEngines.com or call 1-800-544-2444 (U.S. and Canada).

Maintenance

4 24 690 02 Rev. L KohlerEngines.com

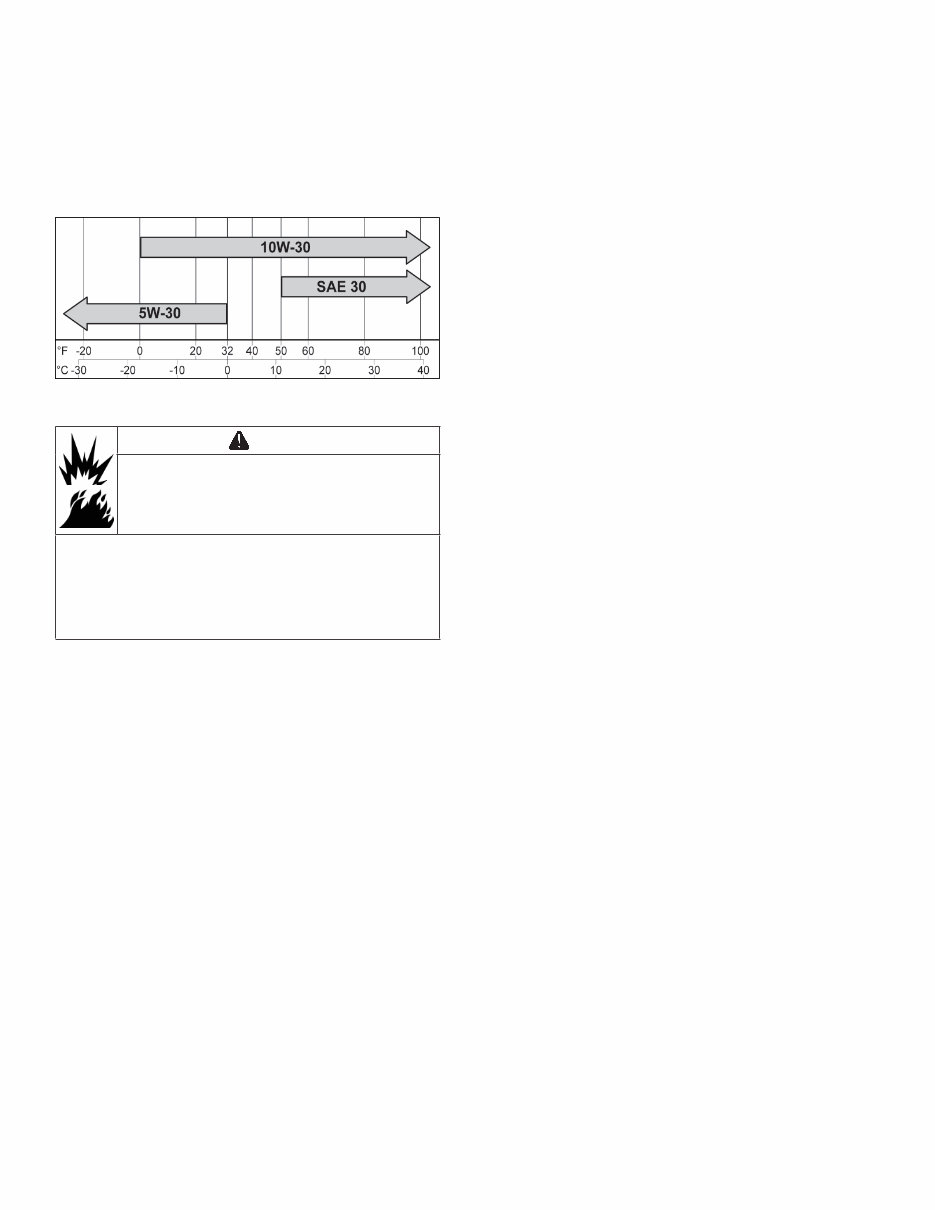

OIL RECOMMENDATIONS

We recommend use of Kohler oils for best performance.

Other high-quality detergent oils (including synthetic)

of API (American Petroleum Institute) service class SJ

or higher are acceptable. Select viscosity based on

air temperature at time of operation as shown in table

below.

FUEL RECOMMENDATIONS

WARNING

Explosive Fuel can cause fires and severe

burns.

Do not fill fuel tank while engine is hot or

running.

Gasoline is extremely flammable and its vapors can

explode if ignited. Store gasoline only in approved

containers, in well ventilated, unoccupied buildings,

away from sparks or flames. Spilled fuel could ignite

if it comes in contact with hot parts or sparks from

ignition. Never use gasoline as a cleaning agent.

NOTE: E15, E20 and E85 are NOT approved and

should NOT be used; effects of old, stale or

contaminated fuel are not warrantable.

Fuel must meet these requirements:

● Clean, fresh, unleaded gasoline.

● Octane rating of 87 (R+M)/2 or higher.

● Research Octane Number (RON) 90 octane minimum.

● Gasoline up to 10% ethyl alcohol, 90% unleaded is

acceptable.

● Methyl Tertiary Butyl Ether (MTBE) and unleaded

gasoline blend (max 15% MTBE by volume) are

approved.

● Do not add oil to gasoline.

● Do not overfill fuel tank.

● Do not use gasoline older than 30 days.

STORAGE

If engine will be out of service for 2 months or more

follow procedure below.

1. Add Kohler PRO Series fuel treatment or equivalent

to fuel tank. Run engine 2-3 minutes to get stabilized

fuel into fuel system (failures due to untreated fuel

are not warrantable).

2. Change oil while engine is still warm from operation.

Remove spark plug(s) and pour about 1 oz. of

engine oil into cylinder(s). Replace spark plug(s) and

crank engine slowly to distribute oil.

3. Disconnect negative (–) battery cable.

4. Store engine in a clean, dry place.

Specifications

5 24 690 02 Rev. L KohlerEngines.com

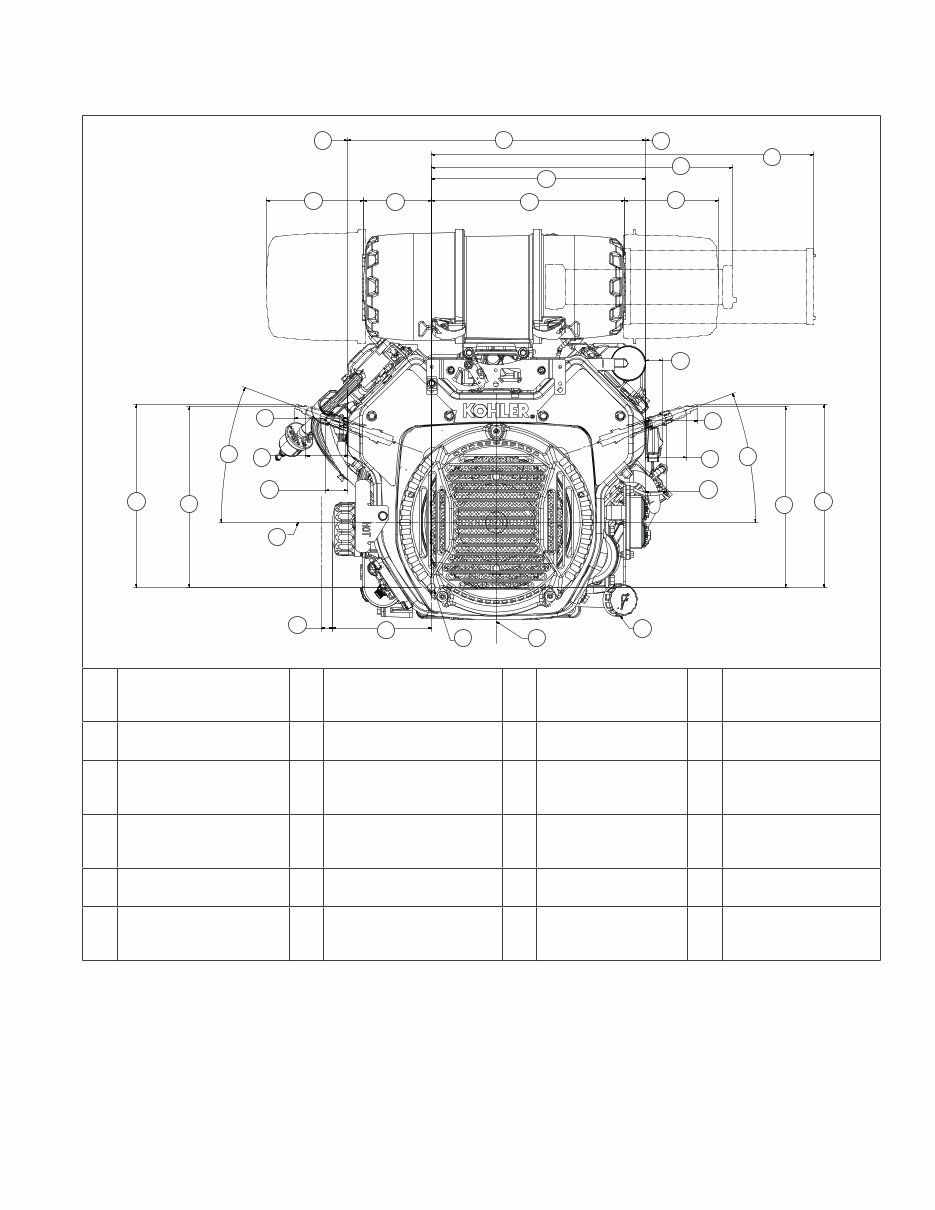

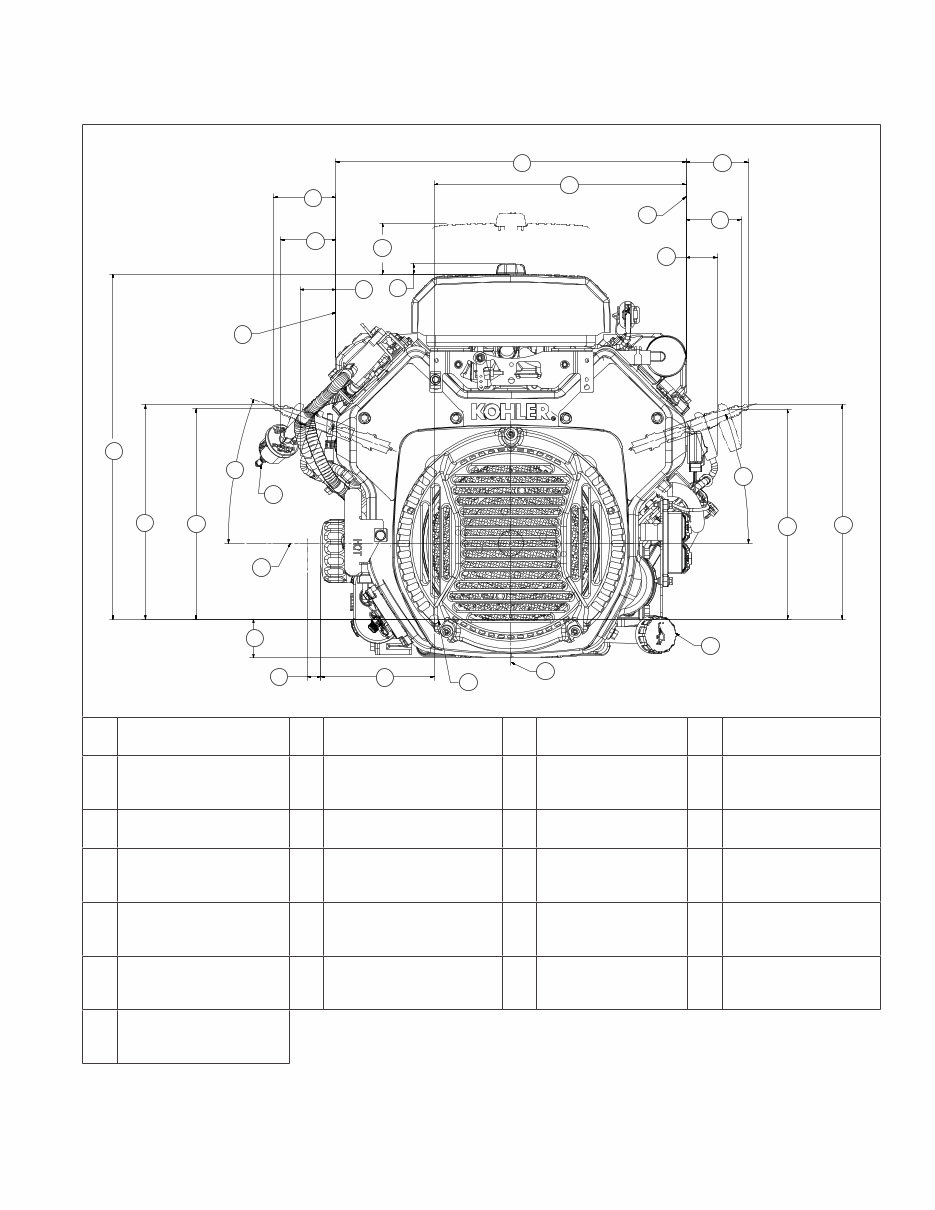

Engine Dimensions with Heavy-Duty Air Cleaner-Flywheel Side

F

E

G

H I

K

L

N

O

M

P

Q

R S

T

A B

D

C

J

U

V

X

W

A

K

L

M

R

A Valve Cover B 413.28 mm (16.271 in.) C

529.81 mm

(20.859 in.) Element

Removal

D

417.49 mm

(16.437 in.) Inner

Element Removal

E 130.0 mm (5.118 in.) F 268.16 mm (10.557 in.) G

296.44 mm

(11.671 in.)

H 94.34 mm (3.714 in.)

I 135.0 mm (5.315 in.) J

24.28 mm (0.955 in.)

Fuse Cover

K

253.53 mm

(9.981 in.) Spark Plug

Removal

L

250.23 mm

(9.852 in.) Spark

Plug Boot Removal

M 20° N

72.63 mm

(2.859 in.) Spark Plug

Removal

O

57.17 mm

(2.251 in.) Spark Plug

Boot Removal

P

29.69 mm

(1.169 in.) Spark

Plug Boot

Q

Oil Fill Tube and

Dipstick

R Engine Center Line S Mounting Hole "A" T

137.09 mm

(5.397 in.)

U

15.70 mm

(0.618 in.) Oil Filter

Removal

V

30.06 mm

(1.183 in.) Spark Plug

Boot

W

57.54 mm

(2.265 in.) Spark Plug

Boot Removal

X

73.0 mm

(2.874 in.) Spark

Plug Removal

Specifications

6 24 690 02 Rev. L KohlerEngines.com

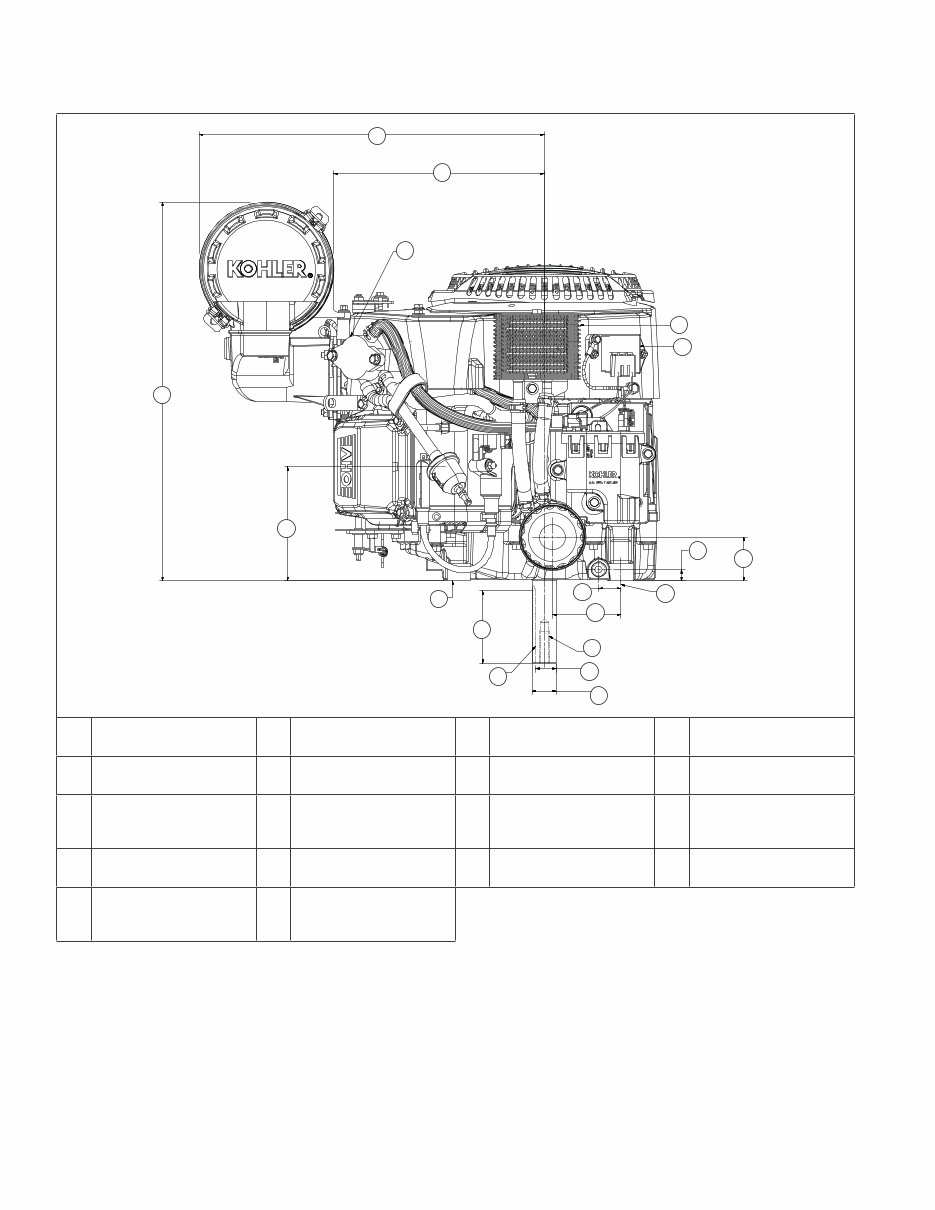

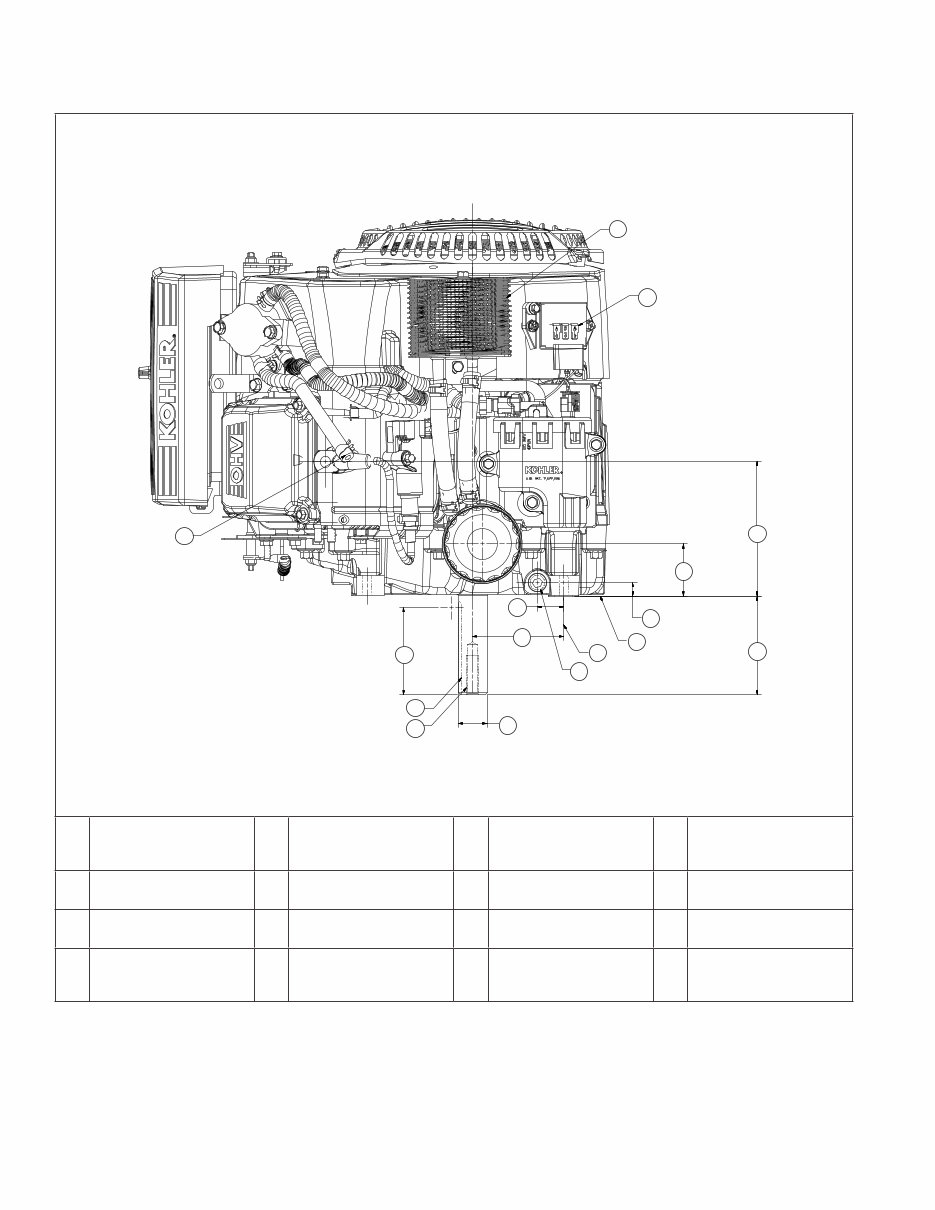

Engine Dimensions with Heavy-Duty Air Cleaner-Oil Filter Side

A

B

C

D

E

F

G

H I

J

K

L

M

N

O

P

R

Q

A

405.92 mm

(15.981 in.)

B 247.92 mm (9.761 in.) C Pulse Fuel Pump D Oil Cooler

E Rectifier-Regulator F

51.25 mm (2.018 in.)

Oil Filter

G 12.99 mm (0.511 in.) H

Center Line Mounting

Hole "A"

I 25.80 mm (1.016 in.) J

80.26 mm (3.160 in.)

Oil Filter

K

7/16-20 UNF 2B in.

38.10 mm (1.5 in.)

Deep

L

24.865 mm ±0.100

(0.980 in. ±0.004)

M

Ø 28.653 mm ±0.0125

(1.125 in. ±0.0005)

N 1/4 in. Square Keyway O 85.50 mm (3.366 in.) P

Engine Mounting

Surface

Q

134.04 mm (5.277 in.)

Spark Plug Center

Line

R

445.29 mm

(17.531 in.)

Specifications

7 24 690 02 Rev. L KohlerEngines.com

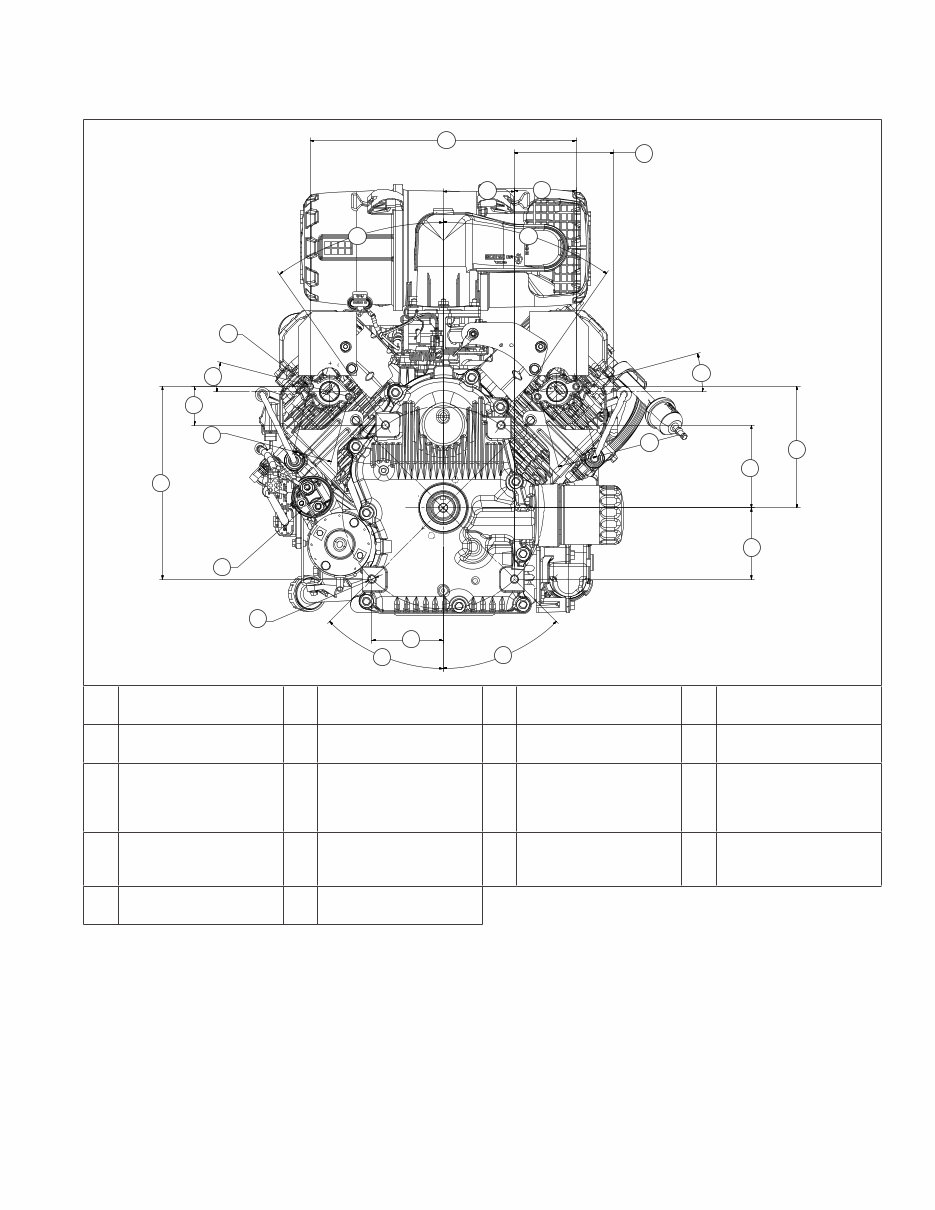

Engine Dimensions with Heavy-Duty Air Cleaner-PTO Side

B

A

C

E

F

D

G

H

I

J

L

K

M

N

P

O

C

H

P

A 334.7 mm (13.176 in.) B

125.09 mm (4.925 in.)

Evap Hose Fitting

C 15° D 152.48 mm (6.003in.)

E 104.03 mm (1.096 in.) F

50.00 mm (1.969 in.)

Exhaust Port #2

G 89.80 mm (3.536 in.) H 45°

I

2 X 89.80 mm

(3.536 in.)

J

4 X Ø 9.06 mm

(0.356 in.) Through Ø

254.0 mm

(10.0 in.) B.C.

K Solenoid Shift Starter L 242.29 mm (9.54 in.)

M

50.0 mm (1.97 in.)

Exhaust Port #1

Mounting Holes

N 48.45 mm (1.91 in.) O M8 X 1.25 mm (0.05 in.) P 35°

Q

2 X 89.80 mm

(3.54 in.)

R

2 X 77.53 mm

(3.05 in.)

Q R

Specifications

8 24 690 02 Rev. L KohlerEngines.com

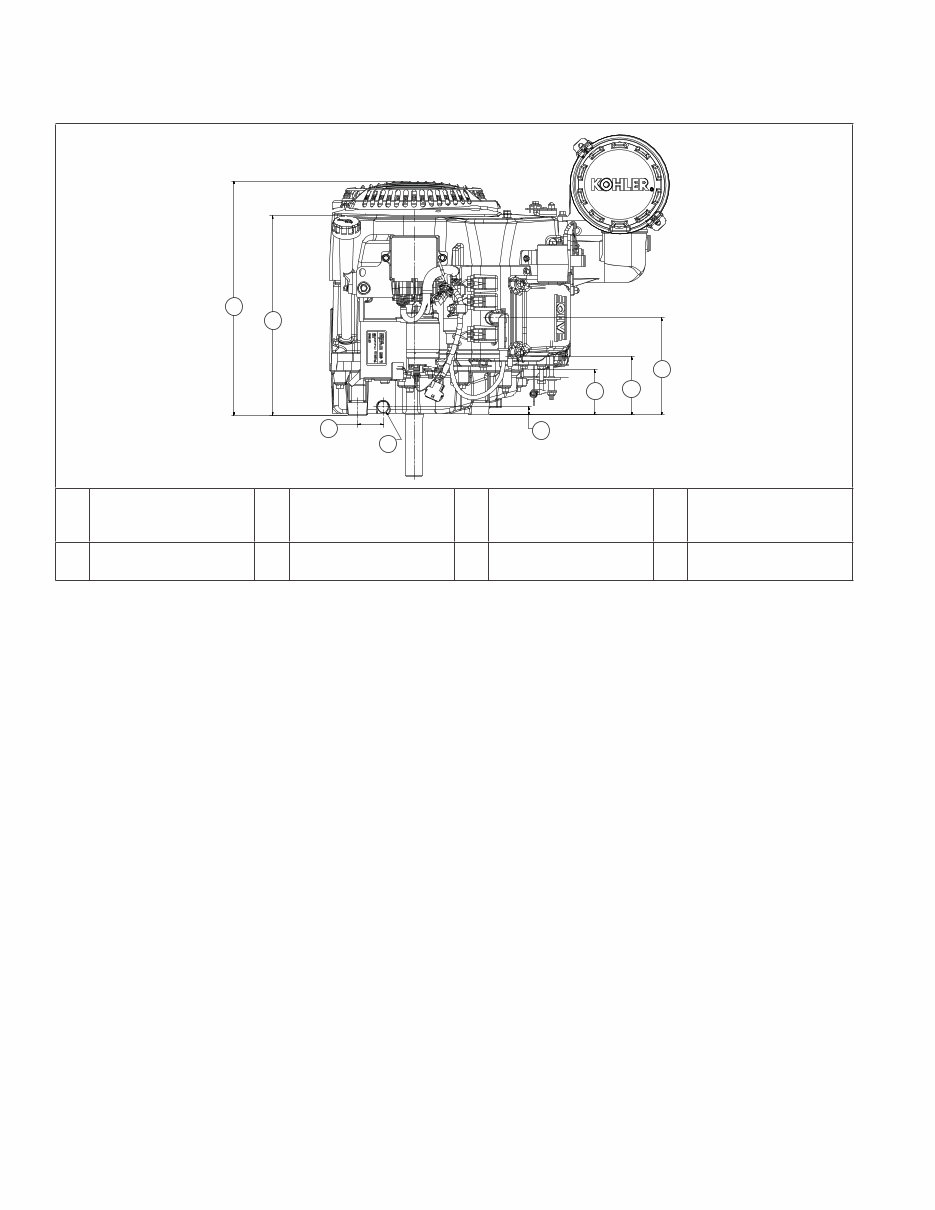

Engine Dimensions with Heavy-Duty Air Cleaner-Starter Side

A

B

C

D

E

G

F

H

A

154.04 mm (6.065 in.)

Center Line Spark

Plug

B

92.04 mm (3.624 in.)

Exhaust Port #1

C

72.04 mm (2.836 in.)

Exhaust Port #2

D 13.0 mm (0.512 in,)

E

Oil Drain Plug

3/8 N.P.T.

F 40.80 mm (1.606 in.) G 316.75 mm (12.47 in.) H

372.01 mm

(14.646 in.)

Specifications

9 24 690 02 Rev. L KohlerEngines.com

Engine Dimensions with Low-Profile Air Cleaner-Flywheel Side

F

E

G H

I

K

L

N

O

M

P

Q

R S

T

A

B

D

C

J

U V

X

W

Y

J

C

A 413.03 mm (16.261 in.) B 296.82 mm (11.769 in.) C Valve Cover D

79.45 mm (2.892 in.)

Spark Plug Removal

E

64.93 mm

(2.556 in.) Spark

Plug Boot Removal

F

37.02 mm

(1.458 in.) Spark

Plug Boot

G

248.11 mm

(9.768 in.) Spark

Plug Boot Removal

H

253.44 mm

(9.978 in.)

Spark Plug Removal

I

Oil Fill and

Dipstick Tube

J 20° K Engine Center Line L Mounting Hole "A"

M 134.09 mm (5.279 in.) N

15.70 mm (0.618 in.)

Oil Filter Removal

O 45.19 mm (1.779 in.) P

Crankshaft

Center Line

Q Fuel Filter R

248.41 mm (9.780 in.)

Spark Plug Boot

Removal

S

253.43 mm (9.977 in.)

Spark Plug Removal

T

407.35 mm (16.037

in.)

U

41.91 mm (1.650 in.)

Spark Plug Boot

V 12.14 mm (0.478 in.) W

60.08 mm (2.365 in.)

Air Cleaner

Cover Removal

X

65.04 mm

(2.561 in.) Spark

Plug Boot Removal

Y

73.38 mm (2.889 in.)

Spark Plug

Removal

Specifications

10 24 690 02 Rev. L KohlerEngines.com

Engine Dimensions with Low-Profile Air Cleaner-Oil Filter Side

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

A Oil Cooler B Regulator/Rectifier C

133.13 mm (5.241 in.)

Spark Plug

Center Line

D 96.93 mm (3.816 in.)

E

51.50 mm (2.028 in.)

Oil Filter

F 13.24 mm (0.521 in.) G

Engine Mounting

Surface

H

Mounting Hole "A"

Center Line

I

Oil Drain Plug

3/8 N.P.T.

J 89.80 mm (3.536 in.) K 25.80 mm (1.016 in.) L

Ø 28.56 mm

(1.125 in.)

M

7/16-20 UNF 2B in.

38.10 mm (1.5 in.)

Deep

N

6.33 X 3.31 mm

(0.25 X 0.13 in.)

Keyway

O

85.50 mm (3.366 in.)

Keyway

P

Fuel Filter

Removed for Clarity

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

Viewed 83 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

The KOHLER COMMAND PRO EFI MODEL ECV740 27HP ENGINE WORKSHOP MANUAL is a comprehensive resource for repairing, maintaining, rebuilding, refurbishing, or restoring your vehicle. It contains detailed diagnostic and repair procedures, making it valuable for both professional technicians and DIY enthusiasts.

- All repair procedures are covered from A-Z

- Includes high-quality photos, illustrations, and diagrams

Whether you are a professional or a DIY enthusiast, this manual allows you to save on service and repair costs. It provides easy access to complete repair procedures that can be viewed, printed, and utilized without requiring advanced computer skills. Say goodbye to messy and worn-out manuals.

Computer Requirements:

- Operates on Microsoft Windows 95, 98, 98SE, 2000, NT, ME, XP, Vista, and Windows 7

- Compatible with all Mac computers